Tool Steel Hardness Chart

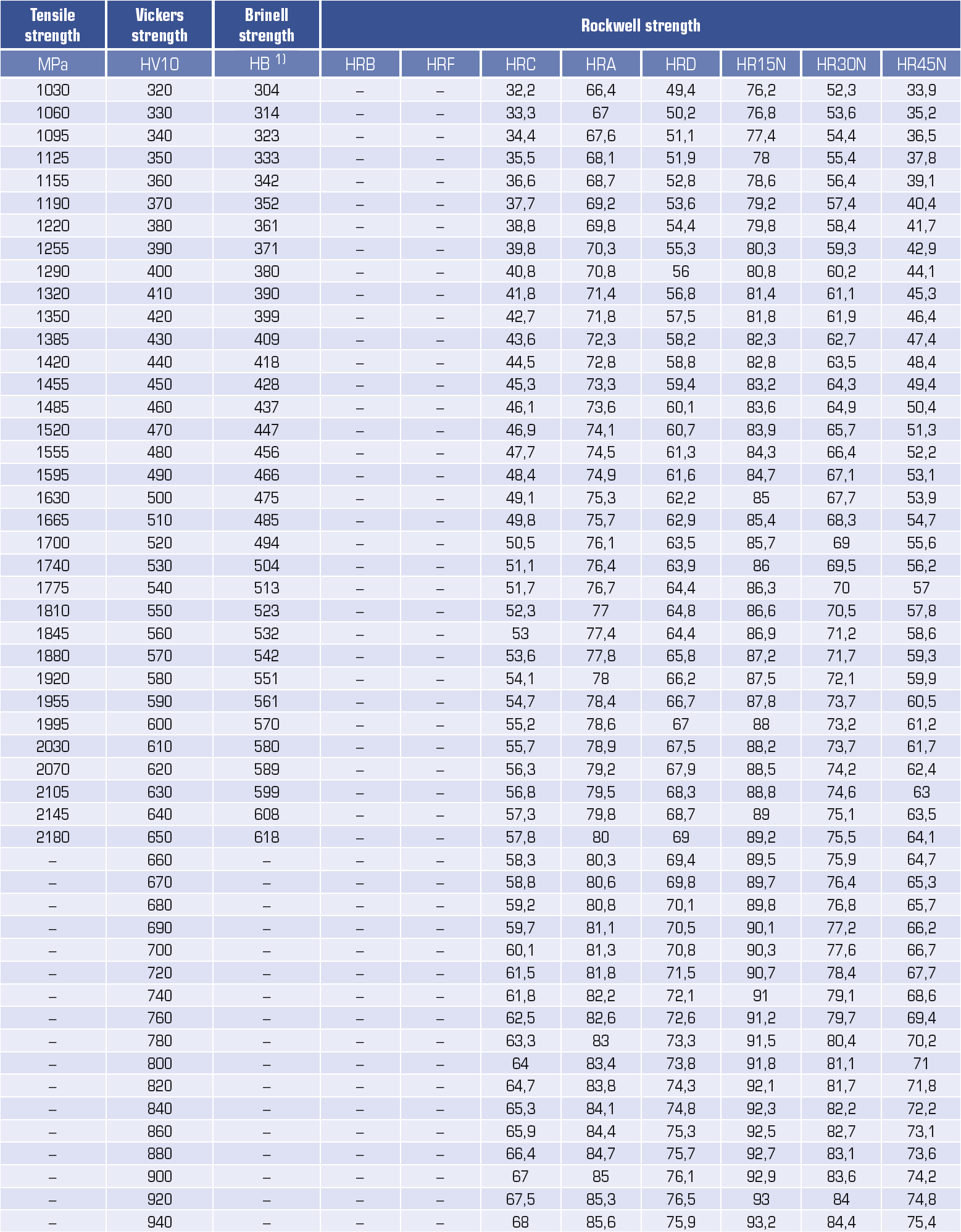

Tool Steel Hardness Chart - These conversion charts are provided for guidance only as each scales uses different methods of measuring hardness. These products can potentially expose you to chemicals including nickel, chromium, lead, cobalt, mercury and beryllium, which are known to the state of california to cause cancer and/or birth defects or other reproductive harm. Molybdenum provides excellent toughness and high hardenability; Air quench part to below 65°c. Web powder high speed steel for cutting tools with excellent wear resistance, toughness and good hot hardness. A2 tool steel’s composition provides excellent wear resistance, making it suitable for cutting and forming applications. Hardness is a measure of a steel’s resistance to deformation. Hardened cold work tool steels are generally about 58/64 hrc (hardness rockwell c), depending on the grade. It also has a high grindability rating. Web properties of tool steels — hardness. Hardness in tool steels is most commonly measured using the rockwell c test. Compare grades using mechanical properties including abrasion resistance, toughness, size stability, machinability and grindability. Web d2 tool steel annealing temperature: Web untempered martensitic steel is very hard, but too brittle for most applications. Web this table shows approximate hardness of steel using brinell, rockwell b and c. Vanadium results in a higher degree of dispersion of the hard vanadium carbides, resulting in higher wear resistance. Compare grades using mechanical properties including abrasion resistance, toughness, size stability, machinability and grindability. Web powder high speed steel for cutting tools with excellent wear resistance, toughness and good hot hardness. Rockwell hardness test is one of the most common indentation hardness. Hardness is a measure of a steel’s resistance to deformation. Its high carbon content allows it to be used often without heat treatment for maintenance applications. Web d2 tool steel annealing temperature: Web aisi s7 steel equivalent material is listed in the table below, including european en, iso, german din, chinese gb and japanese jis standard, etc. These conversion charts. Web o1 provides good wear resistance and toughness sufficient for standard tool and die applications making it a suitable choice for tooling with good tool life and econimcal production. Web powder high speed steel for cutting tools with excellent wear resistance, toughness and good hot hardness. Molybdenum provides excellent toughness and high hardenability; Hardness in tool steels is most commonly. Use high side of hardening range for thicker sections. Web o1 provides good wear resistance and toughness sufficient for standard tool and die applications making it a suitable choice for tooling with good tool life and econimcal production. Web compare popular tool steel grades a2, m2, d2, s7, o1 using the chart below. Air quench part to below 65°c. It. Web this table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. The annealed hardness is 202 to 248 brinell. Web the table below list mechanical properties of a2 tool steel including tensile strength, yield strength, elongation, reduction of area, etc. Air quench part to below 65°c. Web properties of tool steels — hardness. Web the table below list mechanical properties of a2 tool steel including tensile strength, yield strength, elongation, reduction of area, etc. D2 tool steel ofers excellent wear resistance and is widely used in cold work applications that require sharp edges, abrasion resistance, and compressive strength. Web d2 tool steel annealing temperature: Web compare popular tool steel grades a2, m2, d2,. Vanadium results in a higher degree of dispersion of the hard vanadium carbides, resulting in higher wear resistance. To minimize surface decarburization, use salt bath, controlled atmosphere furnace or pack harden. Web d2 tool steel annealing temperature: Web untempered martensitic steel is very hard, but too brittle for most applications. D2 tool steel ofers excellent wear resistance and is widely. Web this table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. For more information, visit www.p65warnings.ca.gov. Web the table below list mechanical properties of a2 tool steel including tensile strength, yield strength, elongation, reduction of area, etc. Web o1 provides good wear resistance and toughness sufficient for standard tool and die applications making it. The upper limit of the range applies to large sections and the lower limit to smaller sections. Compare grades using mechanical properties including abrasion resistance, toughness, size stability, machinability and grindability. Web untempered martensitic steel is very hard, but too brittle for most applications. In situations that require greater size stability during. Web powder high speed steel for cutting tools. The right hand column show an approximate equivalent tensile strength. Web alloys & tool steel. The upper limit of the range applies to large sections and the lower limit to smaller sections. Web untempered martensitic steel is very hard, but too brittle for most applications. The annealed hardness is 202 to 248 brinell. H13 tool steel is a secondary hardening. Vanadium results in a higher degree of dispersion of the hard vanadium carbides, resulting in higher wear resistance. Web this table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. Web tool steels come in seven main types: To minimize surface decarburization, use salt bath, controlled atmosphere furnace or pack harden. Its high carbon content allows it to be used often without heat treatment for maintenance applications. In situations that require greater size stability during. Web o1 provides good wear resistance and toughness sufficient for standard tool and die applications making it a suitable choice for tooling with good tool life and econimcal production. Hardened cold work tool steels are generally about 58/64 hrc (hardness rockwell c), depending on the grade. Use high side of hardening range for thicker sections.

Hardness Scale Metals

Alloy Selection Guide

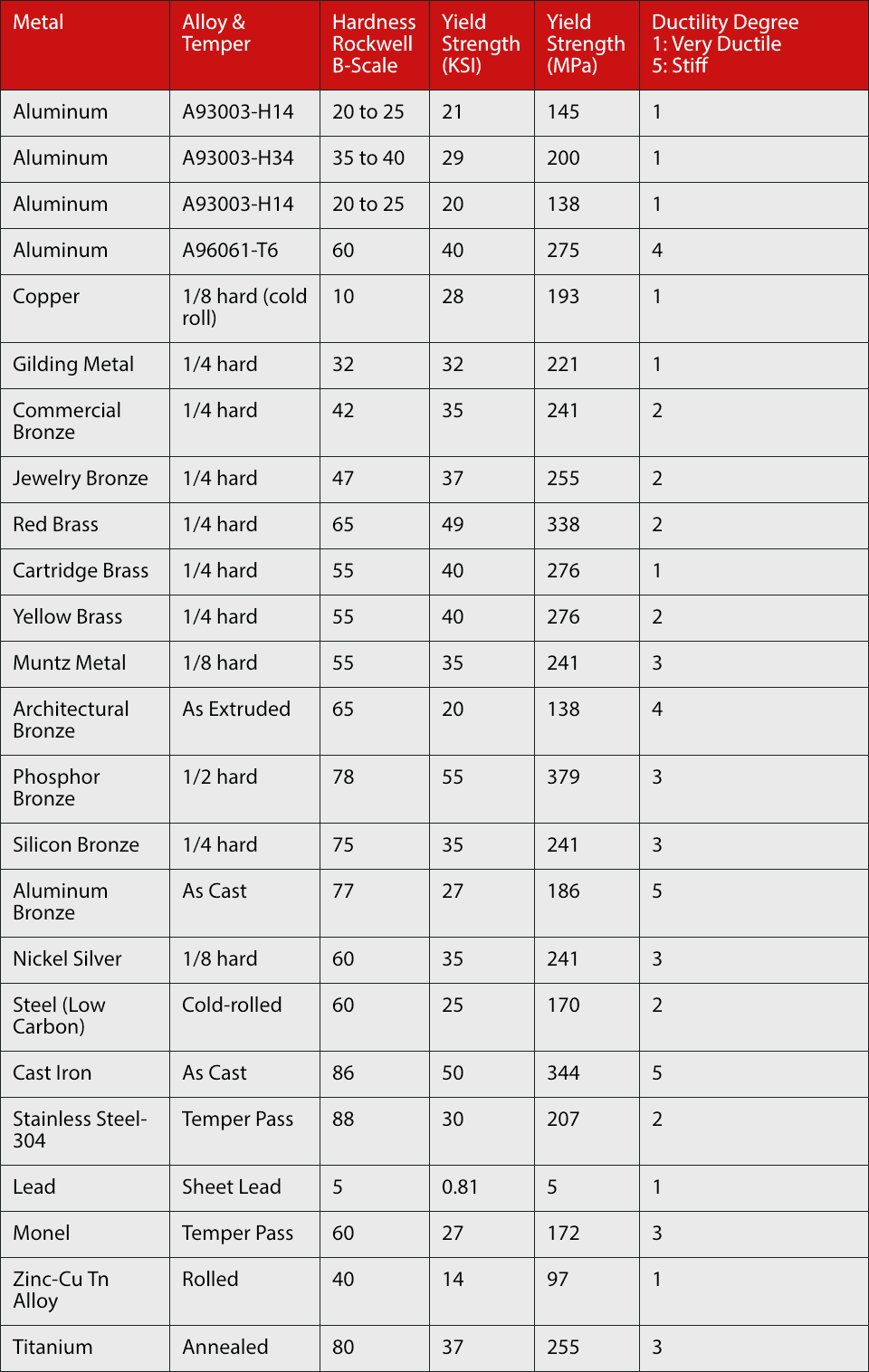

Metal Hardness Zahner — Innovation and Collaboration to Achieve the

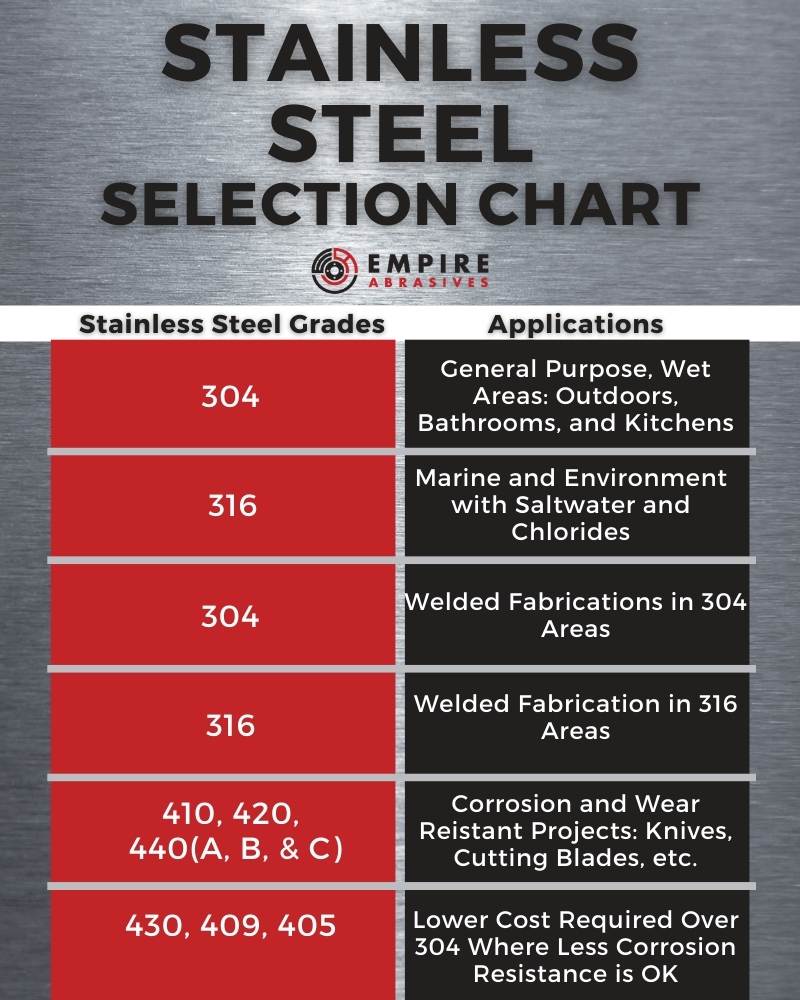

Stainless Steel Hardness Scale Steel Choices

Steel Hardness Conversion Table Les tests Ingénierie de produits

Inox Liên Minh CHẾ TẠO THÉP KHÔNG GỈ NHƯ THẾ NÀO?

Metal Hardness Scale Chart

Pin by Kevin Gannon on tensile strenght hair Metal lathe tools, Metal

Tool Steel Comparison Chart

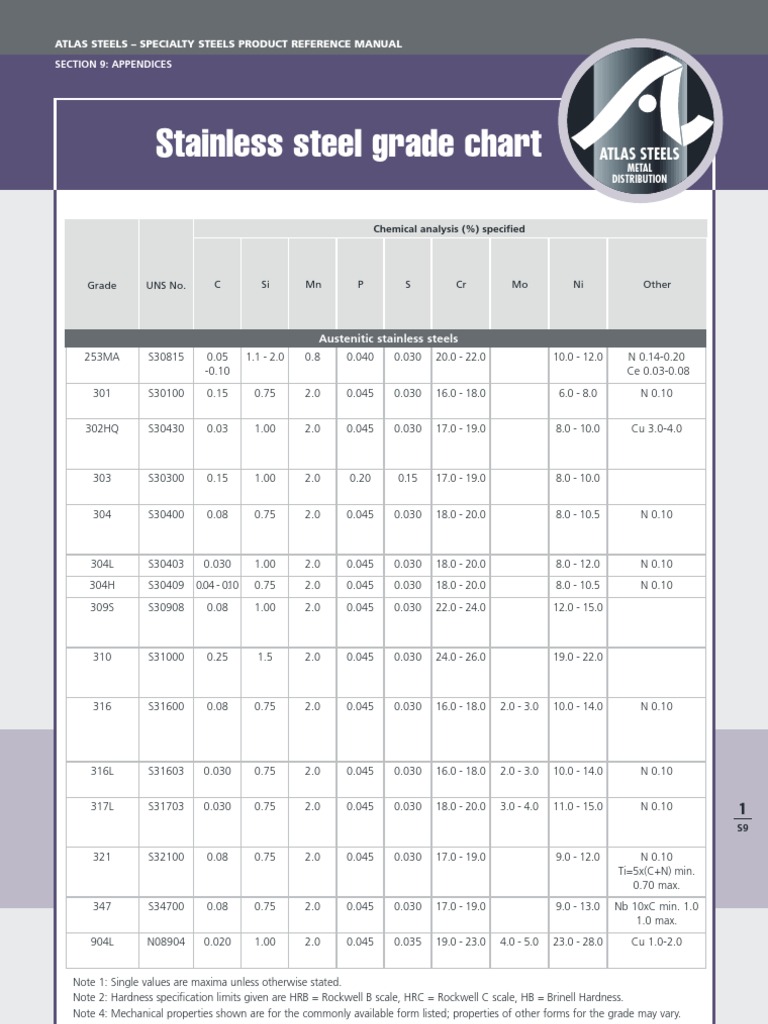

Stainless Steel Grade Chart PDF Stainless Steel Steel

Air Quench Part To Below 65°C.

Compare Grades Using Mechanical Properties Including Abrasion Resistance, Toughness, Size Stability, Machinability And Grindability.

Heat A2 Tool Steel Part In A Standard (Non Vacuum) Furnace To 970°C (1780°F).

For More Information, Visit Www.p65Warnings.ca.gov.

Related Post: