Punch And Die Clearance Chart

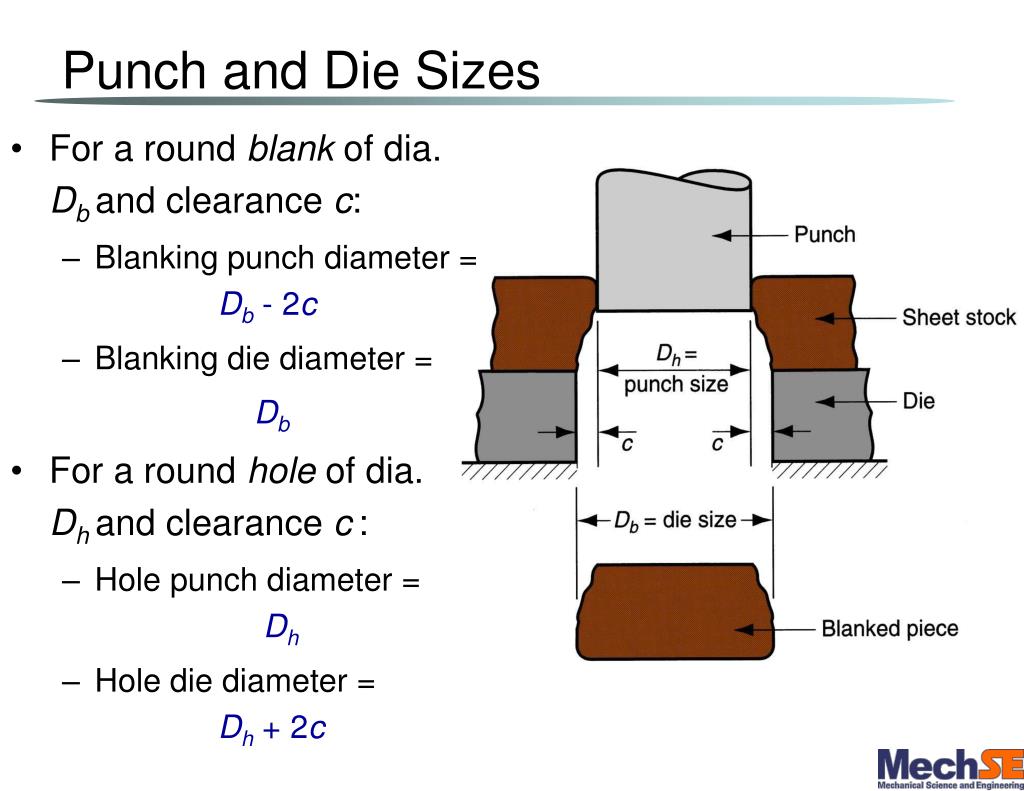

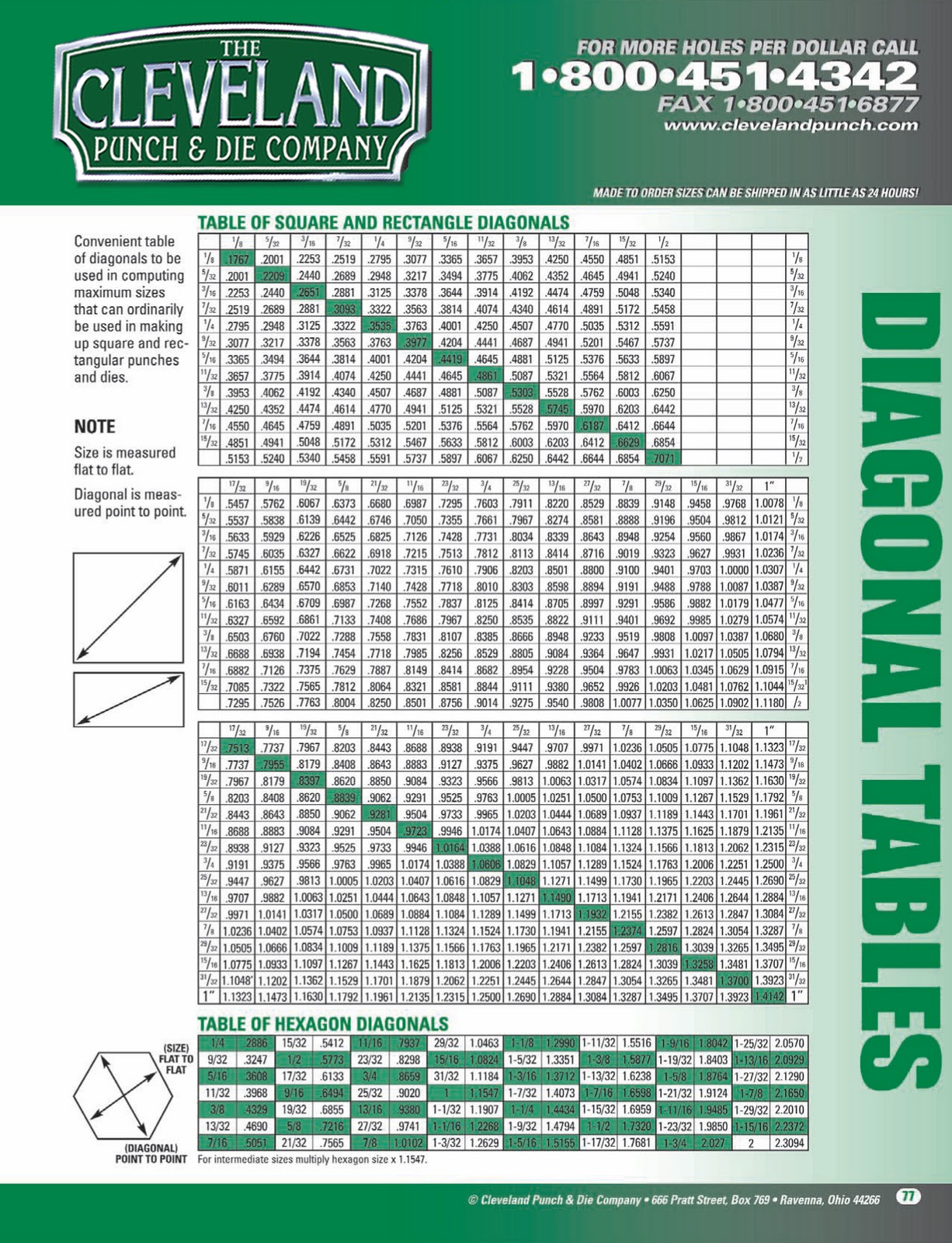

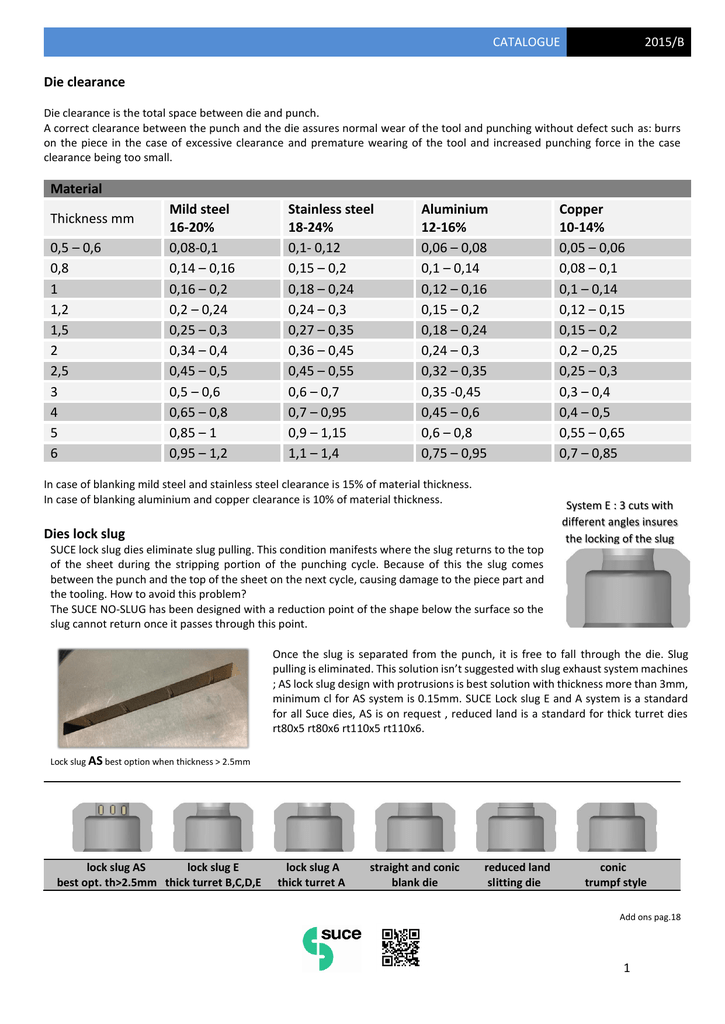

Punch And Die Clearance Chart - Enter the punch size and material thickness and get the clearance and die size instantly. Regardless of material thickness, the recommended penetration of the punch into a mate slugfree® die is 0.118(3.00) Web find out what size die you need for your punching application with this online tool. Web there is no clearance between the sizes you have selected and this will result in the punch and die colliding. Web the proper and safe clearance between the punch and the die will be different based on the size of hole you are punching, the material thickness, and the material hardness. Web the clearance in punching refers to the distance between the gap of the punch and die edges, denoted by the symbol c (see figure 1). Web factors that affect die clearance. Punch & workpiece material type; Web clearance guide for punching mild steel. That regular clearance was used on nearly all types of steel stock. This time, we summarized the selection criteria of the clearance. Using a clearance that is too large leads to large burrs and poor part quality. Web the clearance in punching refers to the distance between the gap of the punch and die edges, denoted by the symbol c (see figure 1). Use this tool to help determine the correct die. In the formula, “t max ” represents the maximum thickness of the material (mm); Web the proper and safe clearance between the punch and the die will be different based on the size of hole you are punching, the material thickness, and the material hardness. Web the dayton engineered clearance, considered by many as the “new” standard, offers a wider. Web clearance table for standard inch sizes 0.0065 0.0075 0.0086 0.0097 0.0108 0.0121 0.0134 0.0161 0.0188 0.0215 0.0225 0.0242 0.0269 0.0296 0.0323 0.0338 0.0350 0.0377 0.0404 0.0430 0.0450 0.0563 0.0675 0.0788 0.0900 o. Total die clearance = die clearance on both sides of punch total die clearance = die clearance 1 + die. Web there are two methods for determining. Web what is die clearance? Web the clearance in punching refers to the distance between the gap of the punch and die edges, denoted by the symbol c (see figure 1). 1350 o.1575 o.1800 max 0.0072 material thickness min 0.0043 o. ( ∆ = clearance per side.) the clearance itself depends on the stock thickness, the tensile strength, and the. 1350 o.1575 o.1800 max 0.0072 material thickness min 0.0043 o. Web die clearance is equal to the space between punch and die when the punch enters the die opening. Web find out what size die you need for your punching application with this online tool. Web clearance table for standard inch sizes 0.0065 0.0075 0.0086 0.0097 0.0108 0.0121 0.0134 0.0161. Web clearance guide for punching mild steel. Web learn how to estimate die clearance for punching steel and aluminum with simple formulas. Regardless of sheet thickness, the recommended penetration of the punch into a slug free ® die is 0.118(3.00). Punch & workpiece material thickness; For many years, 5% per side die clearance was used. Web find out what size die you need for your punching application with this online tool. That regular clearance was used on nearly all types of steel stock. 1350 o.1575 o.1800 max 0.0072 material thickness min 0.0043 o. Web the clearance in punching refers to the distance between the gap of the punch and die edges, denoted by the symbol. Web there is no clearance between the sizes you have selected and this will result in the punch and die colliding. Regardless of sheet thickness, the recommended penetration of the punch into a slug free ® die is 0.118(3.00). For many years, 5% per side die clearance was used. Optimizing the die clearance is the single most important contribution to. Selection of the die clearance also has a significant impact on the quality of the workpiece and the tool life. Punched hole size & geometry and tolerancing; For many years, 5% per side die clearance was used. Punch & workpiece material type; .079 (2mm).012 = (0.30mm) note: Punch & workpiece material type; Web there is no clearance between the sizes you have selected and this will result in the punch and die colliding. Web clearance table for standard inch sizes 0.0065 0.0075 0.0086 0.0097 0.0108 0.0121 0.0134 0.0161 0.0188 0.0215 0.0225 0.0242 0.0269 0.0296 0.0323 0.0338 0.0350 0.0377 0.0404 0.0430 0.0450 0.0563 0.0675 0.0788 0.0900 o. Use. For many years, 5% per side die clearance was used. Punch & workpiece material hardness; Web clearance is the gap between the punch and the die as shown in fig. Web learn how to estimate die clearance for punching steel and aluminum with simple formulas. Enter the punch size and material thickness and get the clearance and die size instantly. Web what is die clearance? Web die clearance is the distance between the punch cutting edge and the die button cutting edge. Web clearance table for standard inch sizes 0.0065 0.0075 0.0086 0.0097 0.0108 0.0121 0.0134 0.0161 0.0188 0.0215 0.0225 0.0242 0.0269 0.0296 0.0323 0.0338 0.0350 0.0377 0.0404 0.0430 0.0450 0.0563 0.0675 0.0788 0.0900 o. Web the clearance in punching refers to the distance between the gap of the punch and die edges, denoted by the symbol c (see figure 1). Web die clearance is equal to the space between punch and die when the punch enters the die opening. Web factors that affect die clearance. Wilson tool recommends the “best” % total clearance for optimum performance. Die clearance is equal to the space between punch and pie when the punch enters the die opening. Regardless of sheet thickness, the recommended penetration of the punch into a slug free® die is 0.118(3.00). Refer to the chart below to determine the correct clearance per material thickness. Regardless of material thickness, the recommended penetration of the punch into a mate slugfree® die is 0.118(3.00)

Punch Press Die Clearance Chart

PPT ME 350 Lecture 18 Chapter 20 PowerPoint Presentation, free

Contact Cleveland Punch & Die

Cleveland Punch and Die Company Blog Page Remember to Check Your

and Fig. 10 illustrate the relation between the punchdie clearance and

Die Clearance Chart and Metal Gages Card Crafts Building Materials

Punch And Die Clearance Chart

How does a punch and die actually work?

clearance table for metric metal punch sizes. Cleveland

Punch And Die Clearance

Also We Will Introduce One Pitch Thread Form As A Forming Tool.

Use The Online Calculator To Find The Die Clearance For Any Material Thickness.

Mild Steel With A Thickness Of 0.079 (2Mm) “Best” Die Clearance = 15% Of.079 (2Mm) =.012 (0.30Mm) % Material Thickness.

Web Die Clearance Selection Chart.

Related Post: