Plasma Cutter Settings Chart

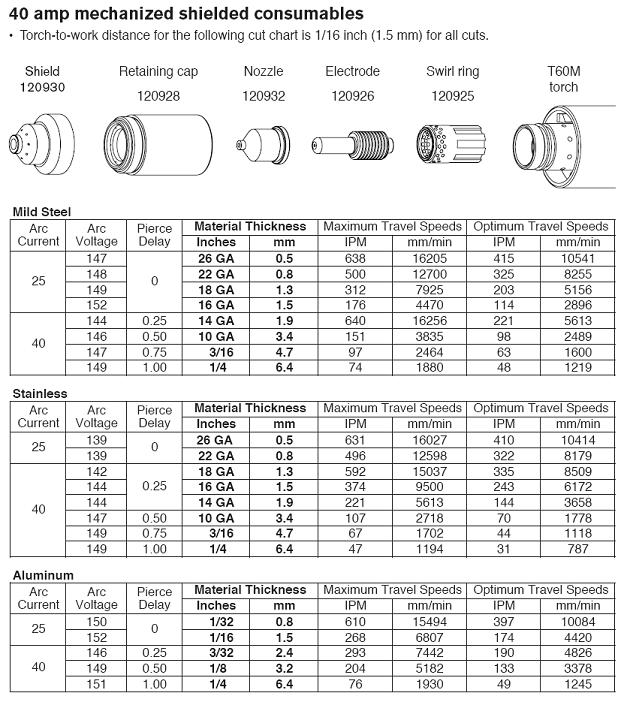

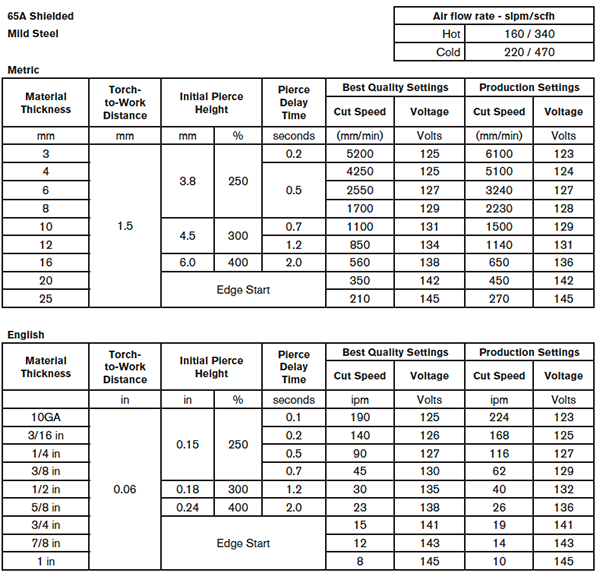

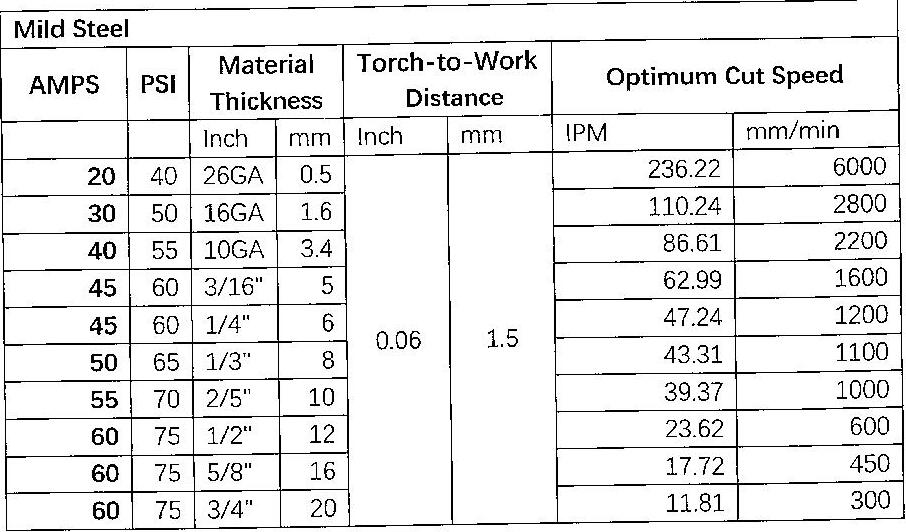

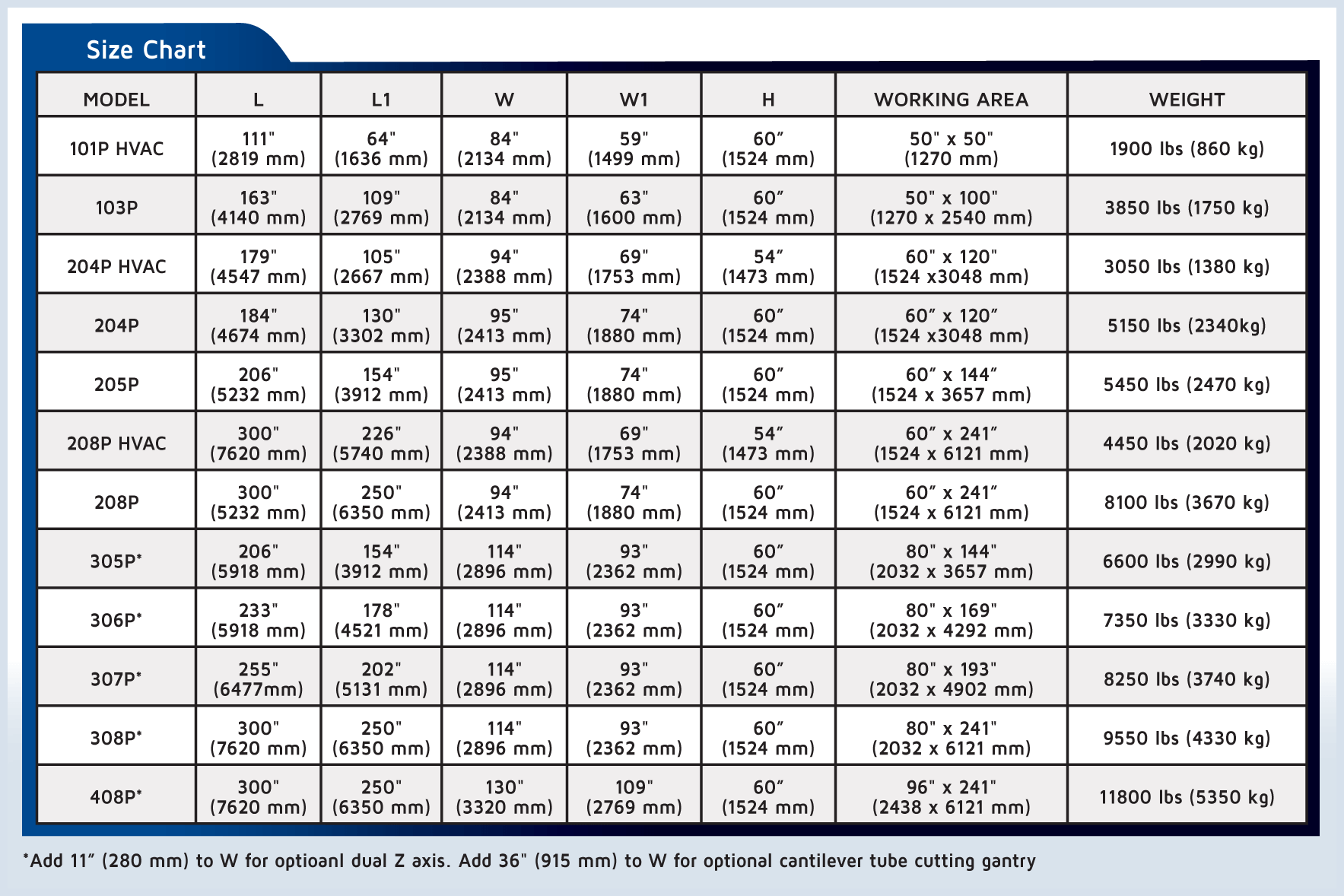

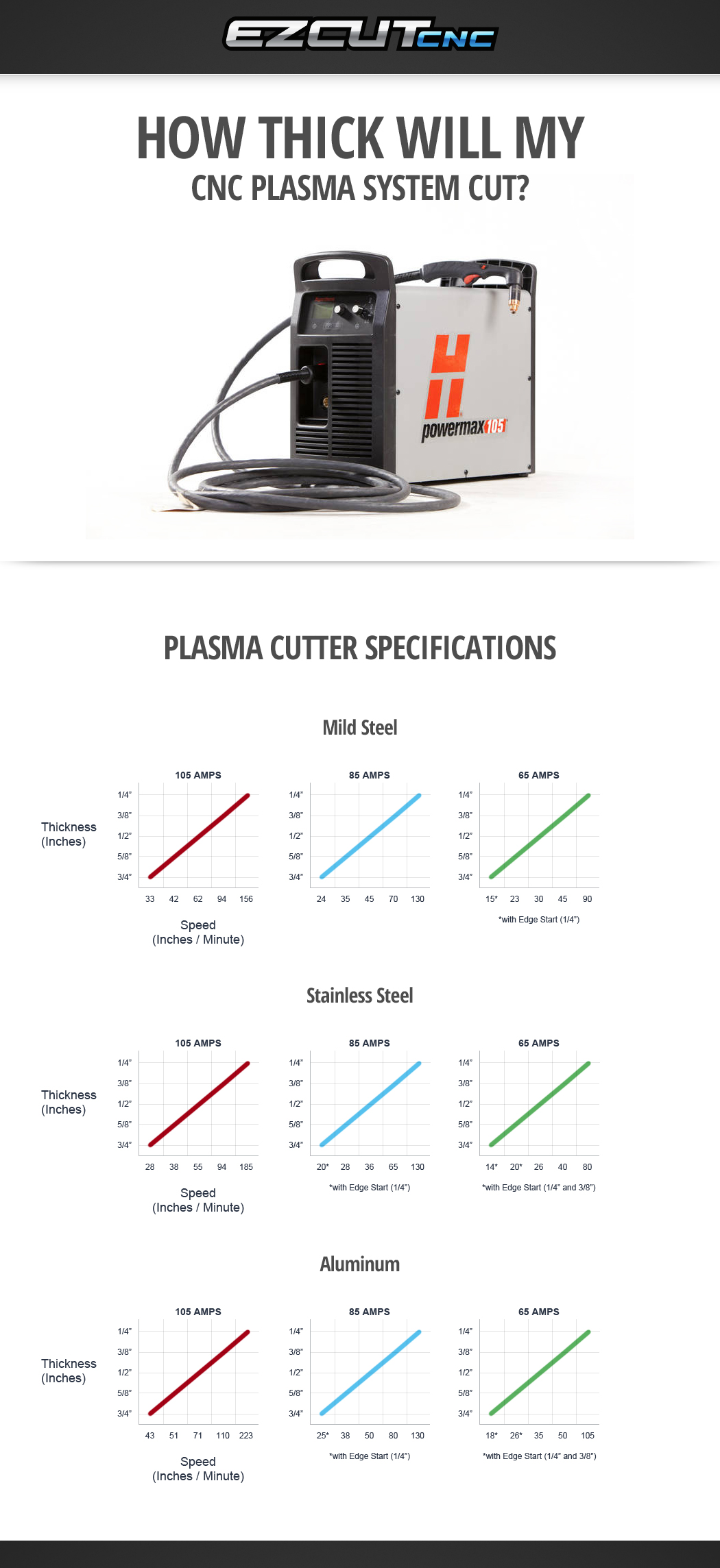

Plasma Cutter Settings Chart - Web since this was the first thread in the search box when i tried “primeweld cut60 cut chart”, i’ll add my updated chart here. Settings vary and will provide different results; The user manual should contain a chart or table specifying the suggested amperage and air settings for various metal thicknesses. Select the appropriate plasma cutting setting process for: Web to determine the optimal amperage and air setting for your plasma cutter, consider the following steps: Choose the right plasma cutter. Explain which consumable set to use and at what amperage; We’ll also include handy charts to help you adjust settings based on material type and thickness. Web this is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Web the charts cover all the material thicknesses that can be cut with that system; Web how to set the correct air pressure and amperage for your plasma cutter. Ceb december 23, 2021, 8:43pm 3. Web be sure to follow the plasma cutter settings and specifications in the cut charts. Cut charts are included for: It is critical that these plasma cutter settings are correct: Cutting mild steel, stainless steel, and aluminum at. Web the charts cover all the material thicknesses that can be cut with that system; Cutting stainless steel at 45 a with f5 using shielded consumables. Web the pierce height knob at first should be at a ‘noon’ position. Select the appropriate plasma cutting setting process for: After turning on your cabinet, plasma power supply, air compressor and other components, you are ready to define the work to be performed by your cnc plasma cutter. It does not cover mechanized cutting. Web the charts cover all the material thicknesses that can be cut with that system; Low amperage cuts will require less air pressure for more stable. Web start by using settings from a chart like what’s shown above as a starting point and begin testing from there. It is critical that these plasma cutter settings are correct: Web be sure to follow the plasma cutter settings and specifications in the cut charts. Web this is what i have found to work with most plasma cutter nozzles/tips. Web the following cut charts show the consumable parts, cutting speeds and the gas and torch settings required for each process. *your setup may differ if you are running multiple tools and have multiple output lines. Ceb december 23, 2021, 8:43pm 3. It is important to know the best practices and use conditions for your particular plasma cutter. 35k views. Cutting mild steel, stainless steel, and aluminum at 45 a with air using shielded consumables. Web cut charts are provided for each set of mechanized cutting and marking consumables. The following recommended settings are for mechanized cutting at 50 amps. *your setup may differ if you are running multiple tools and have multiple output lines. Cutting mild steel and stainless. Think about the jobs you will. Web the pierce height knob at first should be at a ‘noon’ position. Settings vary and will provide different results; 35k views 4 years ago. Cutting stainless steel at 45 a with f5 using shielded consumables. Cut50 welding system pdf manual download. Some of the key factors to keep in mind when selecting a plasma cutter are output power, cutting speed, input power, duty cycle, and weight and size. Settings vary and will provide different results; A consumable diagram with part numbers precedes each cut chart. Web the following cut charts show the consumable parts, cutting. Web to determine the optimal amperage and air setting for your plasma cutter, consider the following steps: Web this is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. We’ll also include handy charts to help you adjust settings based on material type and thickness. Web the pierce height. It does not cover mechanized cutting. I bought some 22 gauge yesterday and noticed it was not on the chart. Think about the jobs you will. Refer to the plasma cutter's user manual: After turning on your cabinet, plasma power supply, air compressor and other components, you are ready to define the work to be performed by your cnc plasma. Some of the key factors to keep in mind when selecting a plasma cutter are output power, cutting speed, input power, duty cycle, and weight and size. Web the plasma cutter settings chart is a reference guide that provides recommendations for amperage, gas pressure, cutting speed, and standoff distance based on different material thicknesses and desired cut qualities. 35k views 4 years ago. Refer to the plasma cutter's user manual: Settings vary and will provide different results; They provide information on the best settings to use when cutting a particular material, such as the recommended cutting. Web bad plasma cutting setup ruins productivity and cut quality. Web view and download s7 cut50 owner's manual online. By matching the correct air pressure settings with the correct amperage settings for. I bought some 22 gauge yesterday and noticed it was not on the chart. Cut50 welding system pdf manual download. It is important to know the best practices and use conditions for your particular plasma cutter. The user manual should contain a chart or table specifying the suggested amperage and air settings for various metal thicknesses. Web cut charts are included for: Low amperage cuts will require less air pressure for more stable operation, sometimes down to 45 psi or so, or the arc will be blown out. *your setup may differ if you are running multiple tools and have multiple output lines.

Plasma Cutter Settings Chart Best Guides From Expert

CNC Plasma

UltraCut HighPrecision plasma cutting systems. 130 amp 800 amp

Improve cut quality with these CNC steel and metal cutting tips

A check list for a plasma cutting table retrofit The Fabricator

Cut charts for everlast plasma 9 by hunterthehobbyist Plasma

Plasma Cutting Machine 3000 Series MultiCam East, Shrewsbury PA

Plasma Cutting Thickness Chart

A Guide to Plasma Cutting

Cut 50 Plasma Cutter Settings Chart Best Guides Ever

I Have Only Cut.125 So Far But It Seems To Do Well At 45Amps And 65Ipm.

Think About The Jobs You Will.

Web The Following Cut Charts Show The Consumable Parts, Cutting Speeds And The Gas And Torch Settings Required For Each Process.

Cutting Mild Steel, Stainless Steel, And Aluminum At.

Related Post: