Insulsafe Sp Coverage Chart

Insulsafe Sp Coverage Chart - Insulsafe sp fiberglass blowing wool insulation offers durable versatility in residential and commercial construction, boasting excellent thermal and noise absorption qualities. Web coverage chart when properly installed with pneumatic equipment in attic horizontal open blow, the following thermal performance is achieved at the thicknesses, weights and coverages specified: Insulsafe sp is a fiberglass blowing insulation used in residential and commercial construction as a thermal and sound absorbing insulation. Web accordance with the chart to the right. It delivers optimum coverage that won't settle, and is a thermally efficient option that also delivers impeccable sound control. Net area maximum net coverage minimum weight initial installed thickness minimum. Web coverage chart— closed cavity (walls, floors, ceilings) retrofit applications the following thermal performance values are achieved at the thicknesses, weights and coverages specified when insulation is installed with pneumatic equipment in closed wall, floor and. Of installed insulation shall not be less than: Contents of bag shall not cover more than: Web net coverage minimum weight initial installed thickness minimum settled thickness to obtain a thermal resistance (r) of: Insulsafe sp has great potential in the retrofit market cert. Less waste & easy to transport to insulate a 1,000 sq. Web coverage chart— closed cavity (walls, floors, ceilings) retrofit applications the following thermal performance values are achieved at the thicknesses, weights and coverages specified when insulation is installed with pneumatic equipment in closed wall, floor and. Number of bags. Insulsafe® sp fiber glass blowing insulation. Of bags content of bag should not cover more than: Refer to insulsafe sp installation manual. It is designed for pheumatic installation in open attic areas and for retrofitting enclosed sidewall and floor/ceiling construction assemblies. Insulsafe sp is noncombustible, noncorrosive and odor free. Web coverage chart when properly installed with pneumatic equipment in attic horizontal open blow, the following thermal performance is achieved at the thicknesses, weights and coverages specified: Insulsafe® sp fiber glass blowing insulation. Minimum bags per 1000 sq. Web bags per 1,000 sq.ft. Minimum installed thickness minimum settled. It is designed for pneumatic installation in open (attic) and closed (sidewalls/floor) construction cavities. It delivers optimum coverage that won't settle, and is a thermally efficient option that also delivers impeccable sound control. Astm e90 and e413 the same stc ratings obtained with fiber glass blanket insulation can be estimated to be achieved by insulsafe sp. Web accordance with the. Complies with astm c764 as type 1 pnuematic application. Bags for 100m2 density minimum weight maximum coverage per bag in. Net area to obtain a thermal resistance (r) of: Web • in accordance with the above chart, you must install the minimum number of bags per 1,000 sq. The following thermal performances are achieved at the thicknesses, weights and coverages. Mm r rsi # # lbs./ft3 kg/m3 lbs./ft3 kg/m3 ft2 m2 Less waste & easy to transport to insulate a 1,000 sq. Web • in accordance with the chart above, you must install the minimum number of bags per 1,000 sq. It can take up to 3 packages of cellulose to cover 65.1 sq. Installation installation procedures and techniques must. The following thermal performances are achieved at the thicknesses, weights and coverages specified when insulation is installed with pneumatic equipment in a horizontal open blow application. Ft.) should not be less than: Minimum installed thickness minimum settled. Insulsafe sp is noncombustible, noncorrosive and odor free. Less waste & easy to transport to insulate a 1,000 sq. Per bag coverage minimum weight lbs. This product is made from premium quality fiberglass, offering superior thermal insulation and. Number of bags per 1000 sq. Fact sheet certainteed corporation p.o. Net area maximum net coverage minimum weight initial installed thickness minimum. The following thermal performances are achieved at the thicknesses, weights and coverages specified when insulation is installed with pneumatic equipment in a horizontal open blow application. Web accordance with the chart to the right. Ft.) should not be less than: Web coverage minimum weight minimum installed thickness* minimum settled thickness to obtain a thermal resistance (r) of: Per bag coverage. It can take up to 3 packages of cellulose to cover 65.1 sq. Web accordance with the chart to the right. This product is made from premium quality fiberglass, offering superior thermal insulation and. Web coverage minimum weight minimum installed thickness* minimum settled thickness to obtain a thermal resistance (r) of: It is designed for pheumatic installation in open attic. Installation installation procedures and techniques must be followed as recommended by certainteed corporation, using blowing machines approved for fibre glass insulation. Insulsafe® sp fiber glass blowing insulation Mm r rsi # # lbs./ft3 kg/m3 lbs./ft3 kg/m3 ft2 m2 In addition, insulsafe sp won’t settle,. Web • in accordance with the above chart, you must install the minimum number of bags per 1,000 sq. Insulsafe sp has great potential in the retrofit market cert. Web • in accordance with the chart above, you must install the minimum number of bags per 1,000 sq. (sq.ft.) 31.9 39.7 44.6 52.5 67.1 77.9 92.9 107.4 161.7 190.5 minimum weight weight per sq. Minimum installed thickness minimum settled. Ft.) should not be less than: It is designed for pheumatic installation in open attic areas and for retrofitting enclosed sidewall and floor/ceiling construction assemblies. Fact sheet certainteed corporation p.o. Web accordance with the chart to the right. Complies with astm c764 as type 1 pnuematic application. Bags for 1000 ft2 min. Box 860 valley forge, pa 19482 professional:

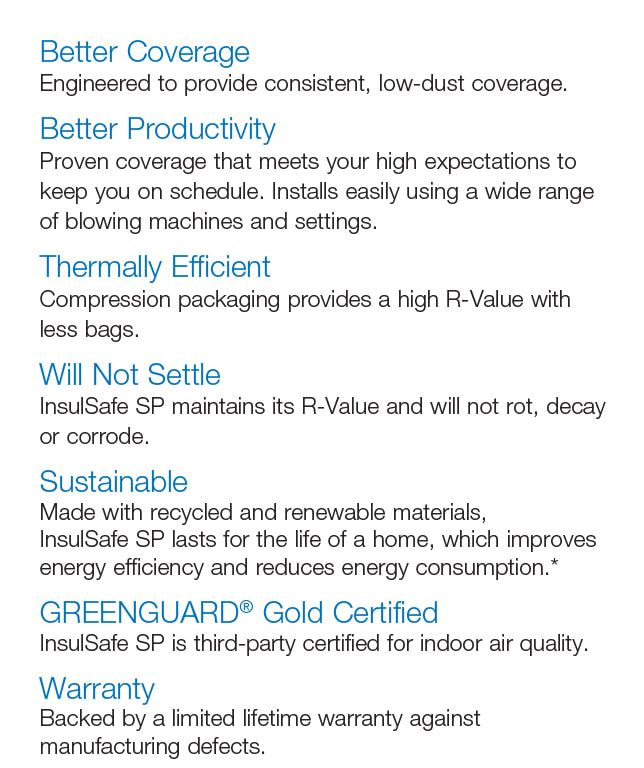

InsulSafe® SP Fiber Glass Blowing Insulation

(PDF) InsulSafe SP Fiber Glass Blowing Insulation Summary Brochure

Insulation Streamline Energy Solutions

CertainTeed INSULSAFE® SP Fiberglass Blowing Insulation IDI Insulation

Solutions CertainTeed InsulSafe SP +8 Fiberglass Blowing Insulation

products Florida Insulation of Tampa Bay LLC. (727) 2543028

InsulSafe® SP Premium Blowing Wool Building Insulation CertainTeed

CertainTeed InsulSafe SP Fiber Glass Blowing Insulation at J & B Materials

Energy Conservation How To Flawed Measurement Of RValue With A

Calaméo Isover InsulSafe

Per Bag Coverage Minimum Weight Lbs.

Web Coverage Chart— Closed Cavity (Walls, Floors, Ceilings) Retrofit Applications The Following Thermal Performance Values Are Achieved At The Thicknesses, Weights And Coverages Specified When Insulation Is Installed With Pneumatic Equipment In Closed Wall, Floor And.

Astm E90 And E413 The Same Stc Ratings Obtained With Fiber Glass Blanket Insulation Can Be Estimated To Be Achieved By Insulsafe Sp.

Of Bags Content Of Bag Should Not Cover More Than:

Related Post: