Xbar S Chart

Xbar S Chart - These charts are used when the subgroups have large sample sizes. X bar s charts often use control charts to examine the process mean and standard deviation over time. Web what are x bar s control charts? This means they can be used in place of x. Conversely, the s charts provide a better understanding of the spread of subgroup data than the range. Web in this video you’ll learn how to create an xbar‑r or s charts in minitab online. Web the center line for the xbar chart represents the average of the plotted points (also called the process mean). From histograms and heatmaps to word clouds and network diagrams, here's how to take full advantage of this powerful capability. It can be easily created in either microsoft excel or minitab. Web in statistical quality control, the ¯ and s chart is a type of control chart used to monitor variables data when samples are collected at regular intervals from a business or industrial process. If the s chart validates that the process variation is in statistical control, the xbar chart is constructed. Select this link for information on the spc for excel software.) Key output includes the xbar chart, the s chart, and test results. Select the method or formula of your choice. We should use the \(s\) chart first to determine if the. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. If the s chart validates that the process variation is in statistical control, the xbar chart is constructed. This is connected to traditional statistical quality control (sqc) and statistical process control (spc). Select “spc knowledge base” to. Each plotted point, , represents the mean of the observations for subgroup,. These charts are used when the subgroups have large sample sizes. This is connected to traditional statistical quality control (sqc) and statistical process control (spc). Web the center line for the xbar chart represents the average of the plotted points (also called the process mean). X bar s. The center line on the s chart is the average of all subgroup standard deviations. Select “spc knowledge base” to go to the spc knowledge base homepage. Web what are x bar s control charts? All constituencies at a glance > download voter helpline app to see results on mobile. Web create xbar r or xbar s control charts to. From histograms and heatmaps to word clouds and network diagrams, here's how to take full advantage of this powerful capability. Key output includes the xbar chart, the s chart, and test results. X bar s charts often use control charts to examine the process mean and standard deviation over time. Web create xbar r or xbar s control charts to. Use the center line to observe how the process performs compared to the average. This is connected to traditional statistical quality control (sqc) and statistical process control (spc). Web the center line for the xbar chart represents the average of the plotted points (also called the process mean). Conversely, the s charts provide a better understanding of the spread of. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a part. Let us consider the case where we have to estimate \(\sigma\) by analyzing past data. Web in this video you’ll learn how to create an xbar‑r or s charts in minitab online. Like all control charts, they will send a signal when a special cause of variation is present. Web we begin with \(\bar{x}\) and \(s\) charts. Web x bar. The control limits on both chats are used to monitor the mean and variation of the process going forward. The center line on the s chart is the average of all subgroup standard deviations. Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or systematically. Select “spc knowledge base” to. Select “spc knowledge base” to go to the spc knowledge base homepage. This means they can be used in place of x. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process. Web we begin with \(\bar{x}\) and \(s\) charts. Analyzing the pattern of variance depicted by a quality. Web we begin with \(\bar{x}\) and \(s\) charts. Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or systematically. Web in this video you’ll learn how to create an xbar‑r or s charts in minitab online. Web the center line for the xbar chart represents the average of the plotted points (also called the process mean). Web what are x bar s control charts? Each hour, the engineer collects a subgroup of 10 cans. This is connected to traditional statistical quality control (sqc) and statistical process control (spc). Like all control charts, they will send a signal when a special cause of variation is present. The center line on the s chart is the average of all subgroup standard deviations. Use the center line to observe how the process performs compared to the average. It can be easily created in either microsoft excel or minitab. The control limits on both chats are used to monitor the mean and variation of the process going forward. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. These charts are used when the subgroups have large sample sizes. From histograms and heatmaps to word clouds and network diagrams, here's how to take full advantage of this powerful capability. Web in statistical quality control, the ¯ and s chart is a type of control chart used to monitor variables data when samples are collected at regular intervals from a business or industrial process.

Xbar and R Chart Formula and Constants The Definitive Guide

xbar & s chartThe Tao of MedicineHospital Quality and Safety Consultant

When to use an Xbar R Chart versus Xbar S Chart

Xbar S Chart with SigmaXL Lean Sigma Corporation

XbarS chart of loose tube. Download Scientific Diagram

XbarS Chart

How To Run A XBar & S Chart In SigmaXL

Xbar S Chart with Minitab Lean Sigma Corporation

Two Way Charts

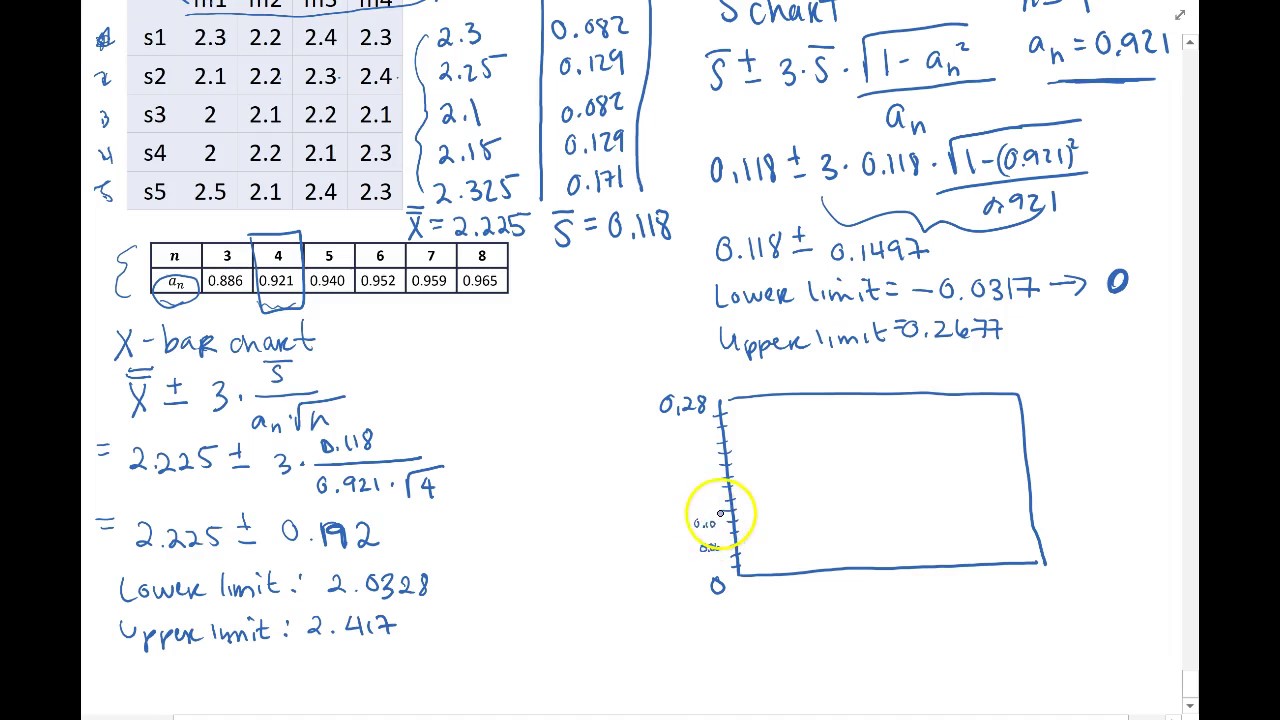

SPC xbar and s chart Example by Hand YouTube

First The S Chart Is Constructed.

X Bar S Charts Often Use Control Charts To Examine The Process Mean And Standard Deviation Over Time.

Select “Spc Knowledge Base” To Go To The Spc Knowledge Base Homepage.

Use This Control Chart To Monitor Process Stability Over Time So That You Can Identify And Correct Instabilities In A Process.

Related Post: