X Bar Range Chart

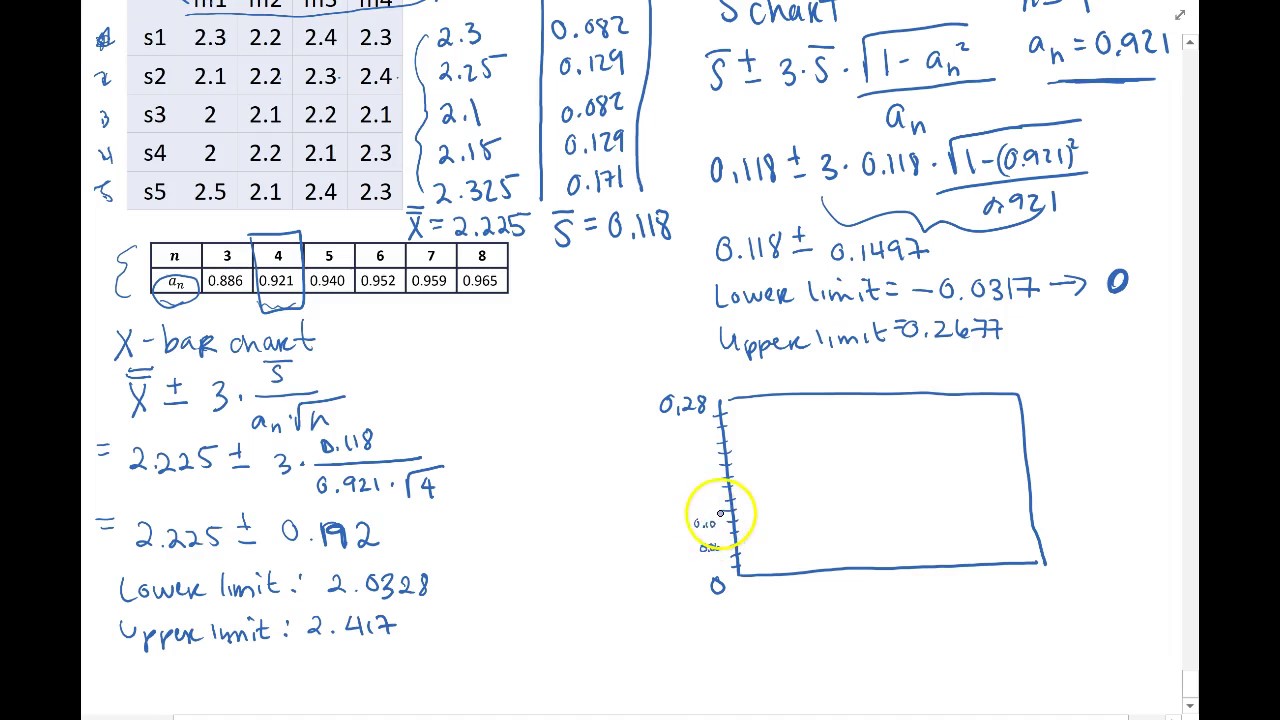

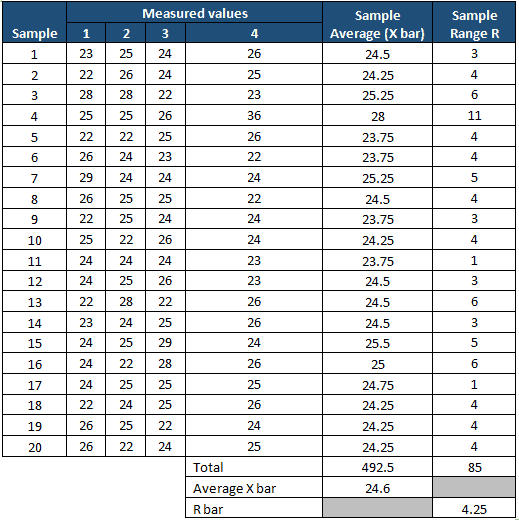

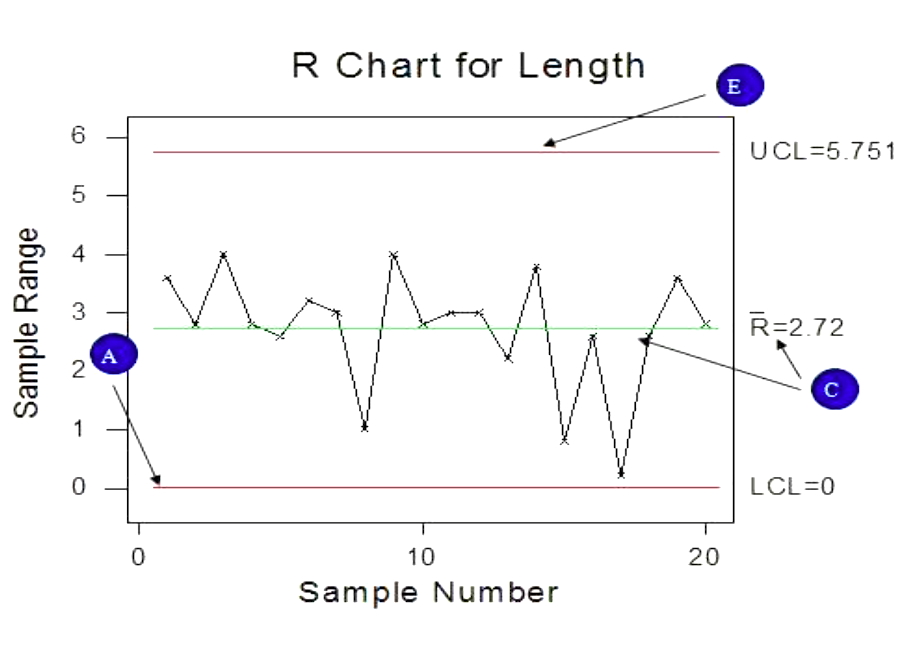

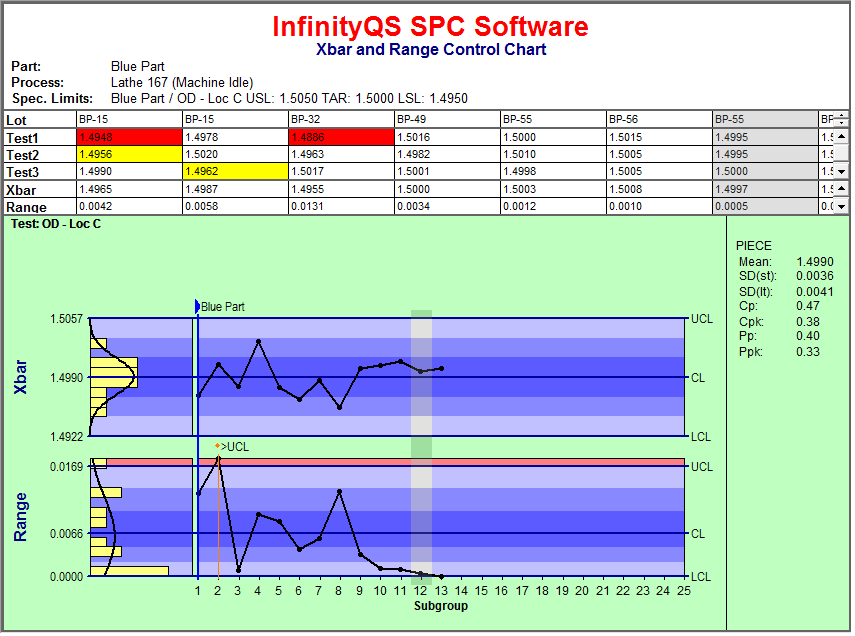

X Bar Range Chart - Process that is in statistical control is predictable, and characterized by points that fall between the lower and upper control limits. You can also use them to collect data from subgroups at set time periods. It is actually two plots to monitor the process mean and the process variation over time and is an example of statistical process control. Xbarr chart data usually looks like this: The range (r) chart shows the variation within each variable (called subgroups). Web click on qi macros menu > control charts (spc) > variable > xbarr. If you enter an historical value for sigma, then minitab uses the historical value. The xbar & r chart is the most commonly used control chart. Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or systematically. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process. A simulation was developed to help do this. You can also use them to collect data from subgroups at set time periods. Web click on qi macros menu > control charts (spc) > variable > xbarr. Web x bar. Web x bar r chart is used to monitor the process performance of continuous data. The range chart plots ranges in each subgroup used to evaluate the consistency of variation. The control limits on the xbar chart, which are set at a distance of 3 standard deviations above and below the center line, show the amount of variation that is. Process that is in statistical control is predictable, and characterized by points that fall between the lower and upper control limits. The range (r) chart shows the variation within each variable (called subgroups). The control limits on the xbar chart, which are set at a distance of 3 standard deviations above and below the center line, show the amount of. In statistical process control (spc), the and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously, when samples are collected at regular intervals from a business or industrial process. Web the xbar chart plots the average of the measurements within each subgroup. Data points. Web the xbar chart plots the average of the measurements within each subgroup. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process. Web click on qi macros menu > control charts (spc) > variable > xbarr. Web x̅ and r chart. For the purposes of this publication, the. Open the sample data, camshaftlength.mtw. You can also use them to collect data from subgroups at set time periods. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. Web x̅ and r chart. Example of an xbarr chart (average and range chart) created by qi macros. Web the xbar chart plots the average of the measurements within each subgroup. Control limits depict the range of normal process variability. The xbar & r chart is the most commonly used control chart. Open the sample data, camshaftlength.mtw. For example, a plastics manufacturer wants to determine whether the production process for a new product is in control. Web use xbar chart to monitor the mean of your process when you have continuous data in subgroups. If you enter an historical value for sigma, then minitab uses the historical value. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Control limits depict the range of normal process variability. The. The xbar & r chart is the most commonly used control chart. For the purposes of this publication, the chart to use is the one that gives you the best estimate of the process standard deviation. Qi macros will do the math and draw the graph for you. Xbarr chart data usually looks like this: Data points representing process outcomes. Web the xbar chart plots the average of the measurements within each subgroup. Here is some further information about the charts. Open the sample data, camshaftlength.mtw. Web x bar r chart is used to monitor the process performance of continuous data. The process standard deviation is also called sigma, or σ. For example, a plastics manufacturer wants to determine whether the production process for a new product is in control. Otherwise, minitab uses one of the following methods to estimate sigma from the data. Xbarr chart data usually looks like this: The control limits on the xbar chart, which are set at a distance of 3 standard deviations above and below the center line, show the amount of variation that is expected in the subgroup averages. Process that is in statistical control is predictable, and characterized by points that fall between the lower and upper control limits. Web x̅ and r chart. A simulation was developed to help do this. Web click on qi macros menu > control charts (spc) > variable > xbarr. Web x bar r chart is used to monitor the process performance of continuous data. Example of an xbarr chart (average and range chart) created by qi macros. The range (r) chart shows the variation within each variable (called subgroups). The xbar & r chart is the most commonly used control chart. Control charts typically contain the following elements: In statistical process control (spc), the and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously, when samples are collected at regular intervals from a business or industrial process. The center line is the average of all subgroup averages. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc.:max_bytes(150000):strip_icc()/dotdash_final_Range_Bar_Charts_A_Different_View_of_the_Markets_Dec_2020-03-cba4a4a095fc487c9ea82feafc7c07e7.jpg)

Range Bar Charts A Different View Of The Markets

Xbar Control Chart

Xbar (Mean) and R (Range) chart. John S. Oakland (2003). Download

X Bar R Control Charts

Xbar (Mean) chart and R (Range) chart. John S. Oakland (2003

Control Charts Enhancing Your Business Performance

Xbar and range chart (What is it? When is it used?) Data analysis

Control Chart Software, Statistical Quality Control Charts InfinityQS®

:max_bytes(150000):strip_icc()/dotdash_final_Range_Bar_Charts_A_Different_View_of_the_Markets_Dec_2020-01-98530a5c8f854a3ebc4440eed52054de.jpg)

Range Bar Charts A Different View Of The Markets

Types of Control Charts Statistical Process Control.PresentationEZE

They Provide Continuous Data To Determine How Well A Process Functions And Stays Within Acceptable Levels Of Variation.

Open The Sample Data, Camshaftlength.mtw.

Data Points Representing Process Outcomes.

Use This Control Chart To Monitor Process Stability Over Time So That You Can Identify And Correct Instabilities In A Process.

Related Post: