X Bar R Control Chart

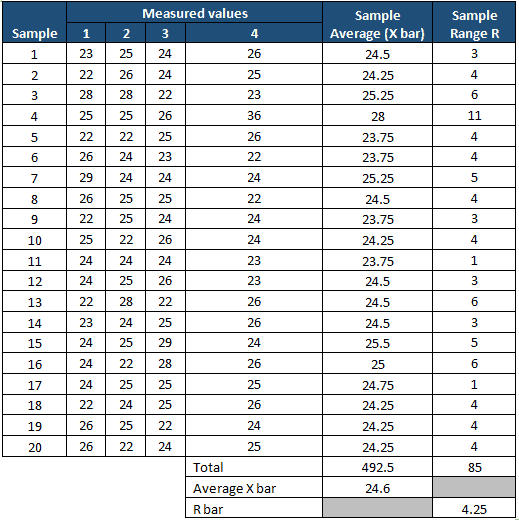

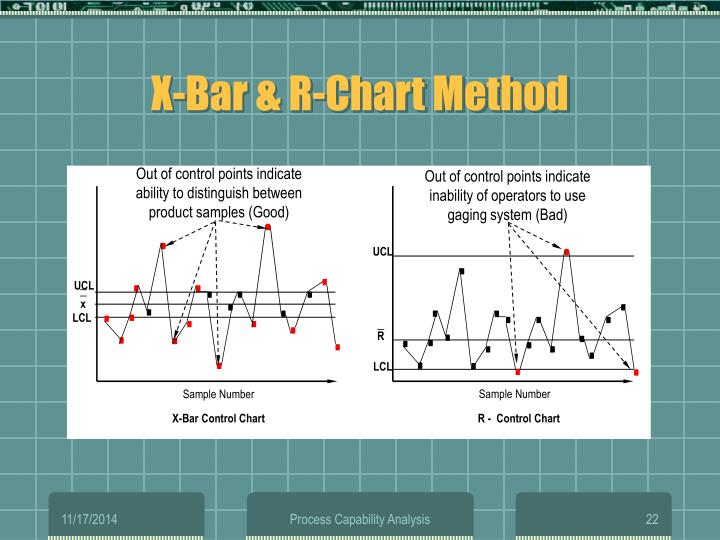

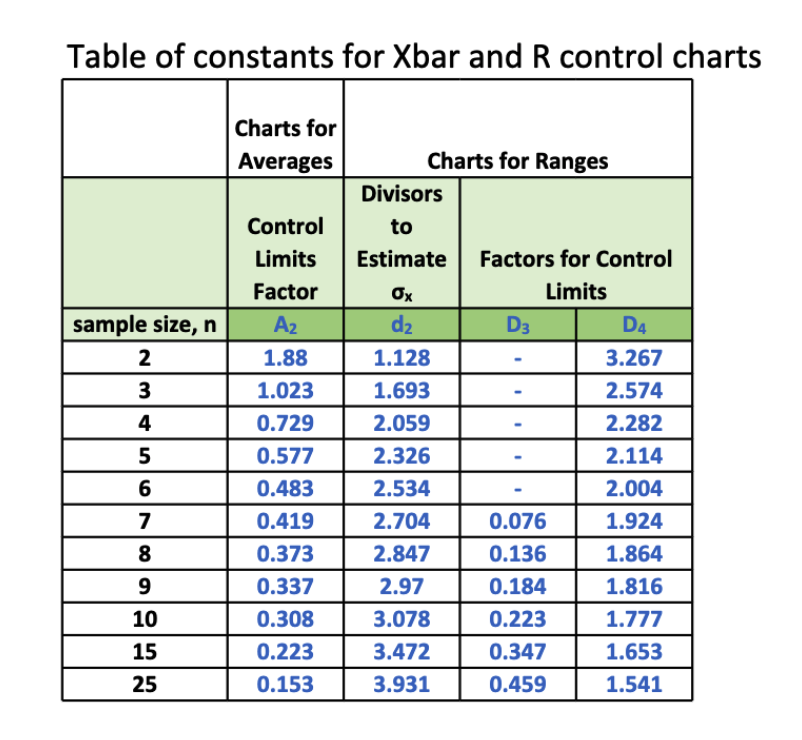

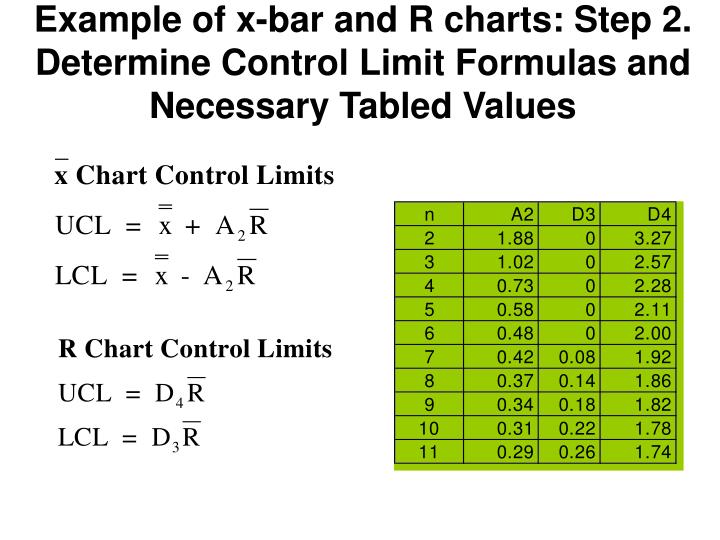

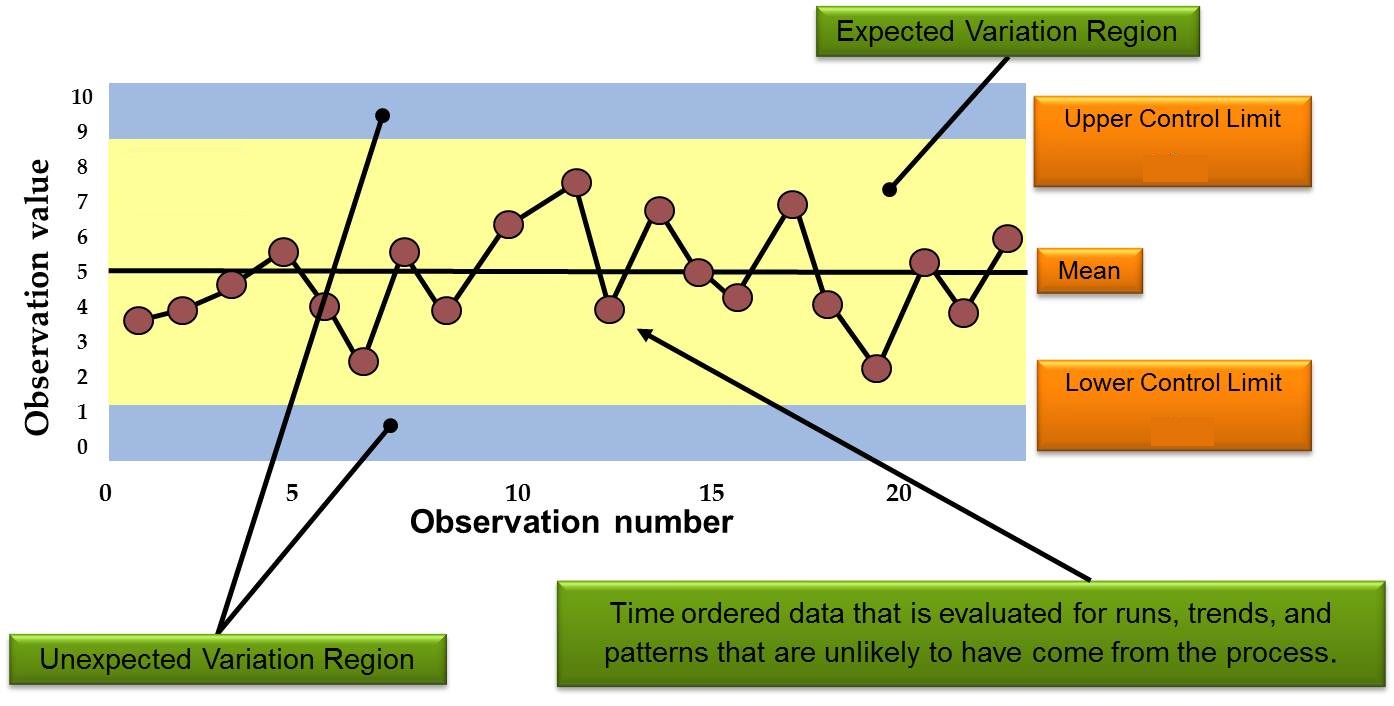

X Bar R Control Chart - Web x ¯ control charts. So, if we use x ¯ ¯ (or a given target) as an estimator of μ and r ¯ / d 2 as an estimator of σ , then the parameters of the x ¯ chart are u c l = x ¯ ¯ + 3 d 2 n r ¯ center line = x ¯ ¯ l c l = x ¯ ¯ − 3 d 2 n r ¯. We can estimate σ from m subgroups taken from a process. The engineer looks at the r chart first because, if the r chart shows that the process variation is not in control, then the control limits on the xbar chart are inaccurate. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Web the x bar & r chart is used for variable data that results in a measured value along a continuous scale (e.g. First the r chart is constructed. Web the control chart basics, including the 2 types of variation and how we distinguish between common and special cause variation, along with how to create a ra. The range (r) chart shows the variation within each variable (called subgroups). Web the range chart. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. The control limits on both chats are used to monitor the mean and variation of the process going forward. Quality engineers at a manufacturing plant monitor part lengths. Web the x bar & r chart is used for variable data that results. The engineer looks at the r chart first because, if the r chart shows that the process variation is not in control, then the control limits on the xbar chart are inaccurate. If the r chart validates that the process variation is in statistical control, the xbar chart is constructed. First the r chart is constructed. Web xbar r charts. We can estimate σ from m subgroups taken from a process. So, if we use x ¯ ¯ (or a given target) as an estimator of μ and r ¯ / d 2 as an estimator of σ , then the parameters of the x ¯ chart are u c l = x ¯ ¯ + 3 d 2 n. Quality engineers at a manufacturing plant monitor part lengths. Web the range chart. Web x ¯ control charts. The range (r) chart shows the variation within each variable (called subgroups). First the r chart is constructed. First the r chart is constructed. Quality engineers at a manufacturing plant monitor part lengths. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process. The control limits on both chats are used to monitor the mean and variation of the process going forward. Web in statistical process control. First the r chart is constructed. The control limits on both chats are used to monitor the mean and variation of the process going forward. To build control limits for a range chart we need to estimate the standard deviation, σ. Web xbar r charts are often used collectively to plot the process mean (xbar) and process range (r) over. Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a part in a production process, etc). Web the control chart basics, including the 2 types of variation and how we distinguish between common and. Please let me know if you find it helpful! Web xbar r charts are often used collectively to plot the process mean (xbar) and process range (r) over time for continuous data. If the r chart validates that the process variation is in statistical control, the xbar chart is constructed. They provide continuous data to determine how well a process. Each subgroup is a collection of n samples made under like conditions. Web in statistical process control (spc), the ¯ and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously, when samples are collected at regular intervals from a business or industrial process. Please. To build control limits for a range chart we need to estimate the standard deviation, σ. Web xbar r charts are often used collectively to plot the process mean (xbar) and process range (r) over time for continuous data. The control limits on both chats are used to monitor the mean and variation of the process going forward. The engineer. The range (r) chart shows the variation within each variable (called subgroups). Quality engineers at a manufacturing plant monitor part lengths. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Web the range chart. The control limits on both chats are used to monitor the mean and variation of the process going forward. Web in statistical process control (spc), the ¯ and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously, when samples are collected at regular intervals from a business or industrial process. Web x ¯ control charts. Each subgroup is a collection of n samples made under like conditions. The engineer looks at the r chart first because, if the r chart shows that the process variation is not in control, then the control limits on the xbar chart are inaccurate. To build control limits for a range chart we need to estimate the standard deviation, σ. Process that is in statistical control is predictable, and characterized by points that fall between the lower and upper control limits. Web the control chart basics, including the 2 types of variation and how we distinguish between common and special cause variation, along with how to create a ra. We can estimate σ from m subgroups taken from a process. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process. Web the x bar & r chart is used for variable data that results in a measured value along a continuous scale (e.g. Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a part in a production process, etc).

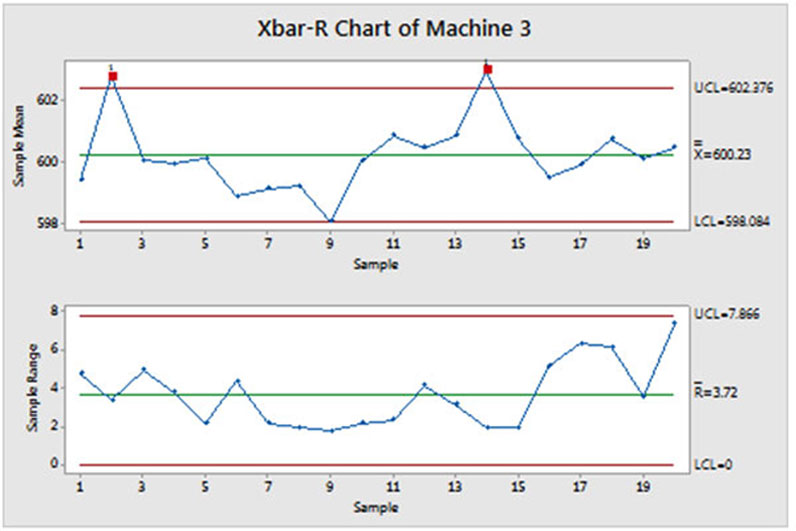

Control Limits for xbar r chart show out of control conditions

How To Plot Xbar And RBar Chart In Excel acetored

Control Chart Excel Template New X Bar R Chart Mean Range Free Control

Xbar and R Chart Formula and Constants The Definitive Guide

X Bar R Control Charts

X Bar And R Chart

Solved Table of constants for Xbar and R control charts

PPT X AND R CHART EXAMPLE INCLASS EXERCISE PowerPoint Presentation

How To Analyze Xbar And R Charts Chart Walls

After discussing the several aspects and uses ofXbar and R Charts, we

If The R Chart Validates That The Process Variation Is In Statistical Control, The Xbar Chart Is Constructed.

Web Xbar R Charts Are Often Used Collectively To Plot The Process Mean (Xbar) And Process Range (R) Over Time For Continuous Data.

So, If We Use X ¯ ¯ (Or A Given Target) As An Estimator Of Μ And R ¯ / D 2 As An Estimator Of Σ , Then The Parameters Of The X ¯ Chart Are U C L = X ¯ ¯ + 3 D 2 N R ¯ Center Line = X ¯ ¯ L C L = X ¯ ¯ − 3 D 2 N R ¯.

Please Let Me Know If You Find It Helpful!

Related Post: