X Bar Chart

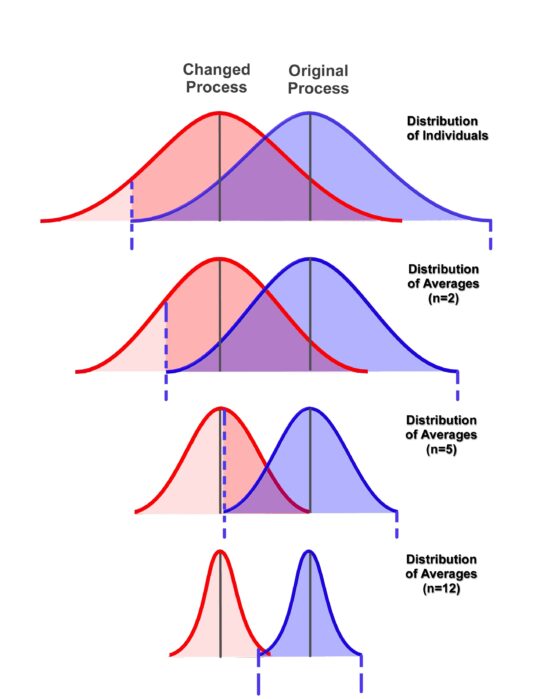

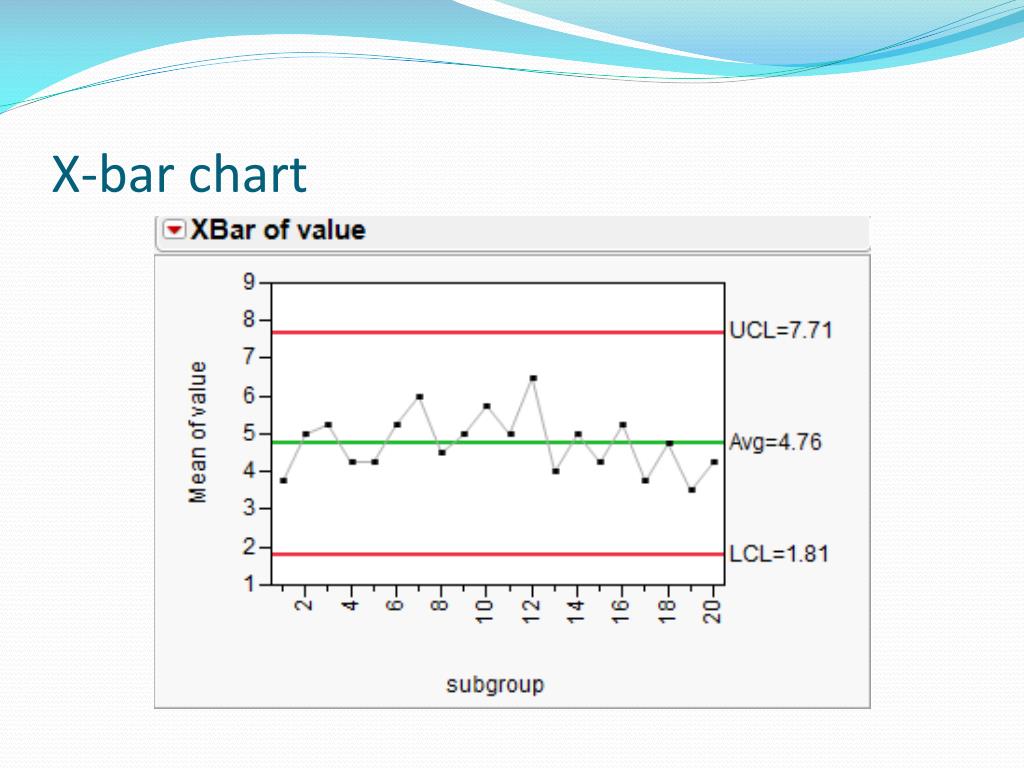

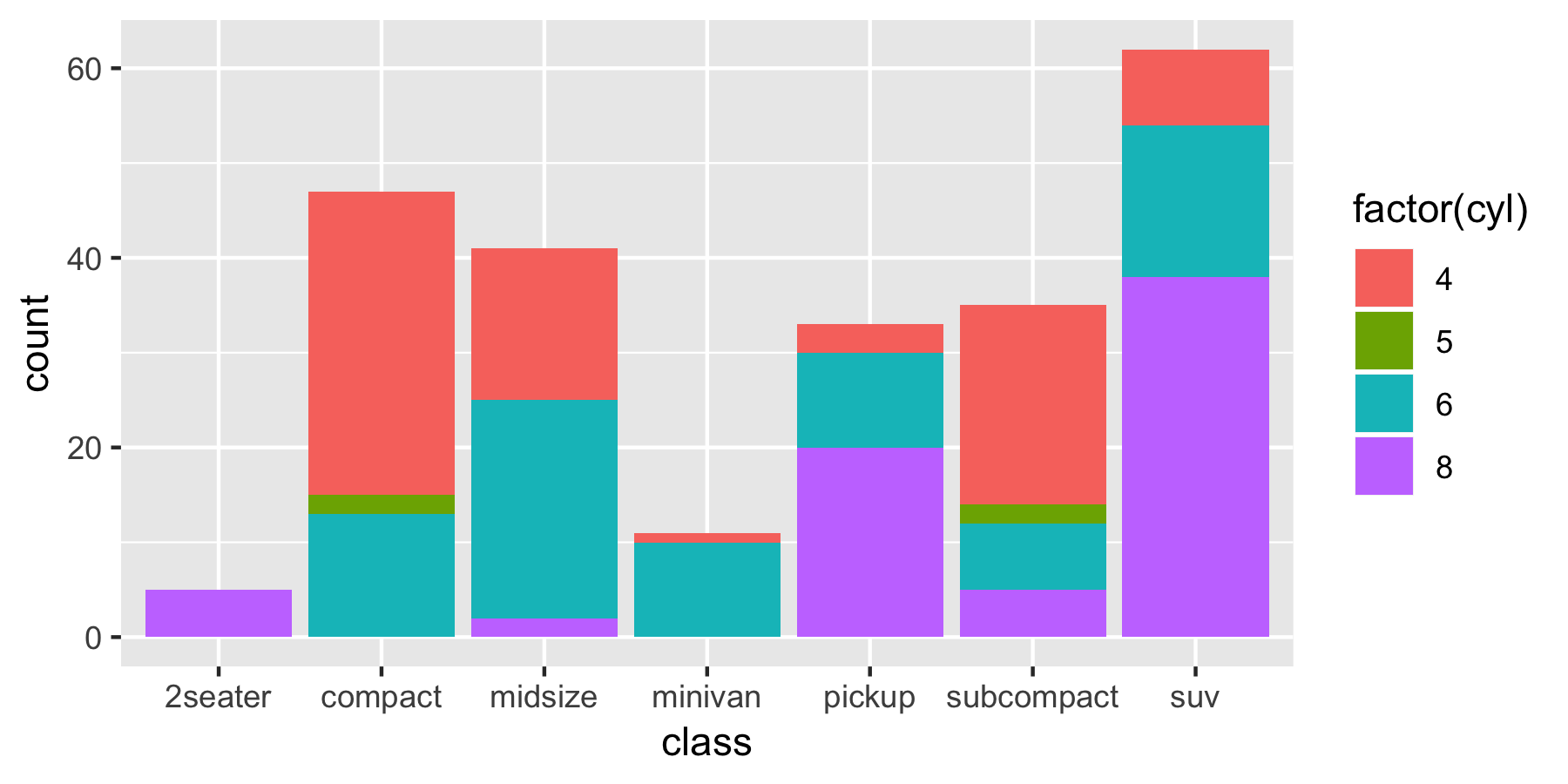

X Bar Chart - The mean or average change in the process over time from subgroup values. For example, a plastics manufacturer wants to determine whether the production process for a new product is in control. Data points representing process outcomes. Web x bar s control chart definitions. Future experimental subsets are plotted compared to these values. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process. From histograms and heatmaps to word clouds and network diagrams, here's how to take full advantage of this powerful capability. Control charts typically contain the following elements: Web an x bar chart, also known as an average chart, is a visualization tool used to display the average values of a dataset. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Web the xbar chart plots the average of the measurements within each subgroup. Control charts typically contain the following elements: 5.4k views 2 years ago quality management. The xbar & r chart is the most commonly used. Select the method or formula of your choice. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. The mean or average change in the process over time from subgroup values. In statistical process control (spc), the and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally. The control limits on the xbar chart, which are set at a distance of 3 standard deviations above and below the center line, show the amount of variation that is expected in the subgroup averages. Control limits depict the range of normal process variability. This type of control chart is used for characteristics that can be measured on a continuous. The control limits on both chats are used to monitor the mean and variation of the process going forward. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process. Here is some further information about the charts. Select the method or formula of your choice. Analyzing the pattern of. Web x̅ and r chart. Future experimental subsets are plotted compared to these values. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. The control limits on both chats are used to monitor the mean and variation of the process going forward. Analyzing the pattern of variance depicted by a quality. In statistical process control (spc), the and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously, when samples are collected at regular intervals from a business or industrial process. The mean or average change in the process over time from subgroup values. The standard. It is used for continuous data, when individual measurements are collected in subgroups at regular intervals. 5.4k views 2 years ago quality management. The control limits on both chats are used to monitor the mean and variation of the process going forward. Select the method or formula of your choice. It is often used in statistical process control to monitor. Future experimental subsets are plotted compared to these values. The xbar & r chart is the most commonly used. The control limits on both chats are used to monitor the mean. Web create xbar r or xbar s control charts to monitor the performance of a continuous variable with subgrouping over time. Select the method or formula of your choice. Web x̅ and r chart. Here is some further information about the charts. For example, a plastics manufacturer wants to determine whether the production process for a new product is in control. Future experimental subsets are plotted compared to these values. The xbar & r chart is the most commonly used. The mean or average change in the process over time from subgroup values. In statistical process control (spc), the and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously, when samples are collected at regular intervals from a business or industrial process. The center. The control limits on the xbar chart, which are set at a distance of 3 standard deviations above and below the center line, show the amount of variation that is expected in the subgroup averages. The control limits on both chats are used to monitor the mean. It is used for continuous data, when individual measurements are collected in subgroups at regular intervals. It is often used in statistical process control to monitor the stability and consistency of a process over time. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process. The center line is the average of all subgroup averages. Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a part in a production process, etc). The xbar & r chart is the most commonly used. Control limits depict the range of normal process variability. 5.4k views 2 years ago quality management. Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or systematically. Control charts typically contain the following elements: Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process. Future experimental subsets are plotted compared to these values. The standard deviation of the. The mean or average change in the process over time from subgroup values.

What is a good way to select subgroup size for an Xbar Chart

Quality Control Charts xbar chart, schart and Process Capability

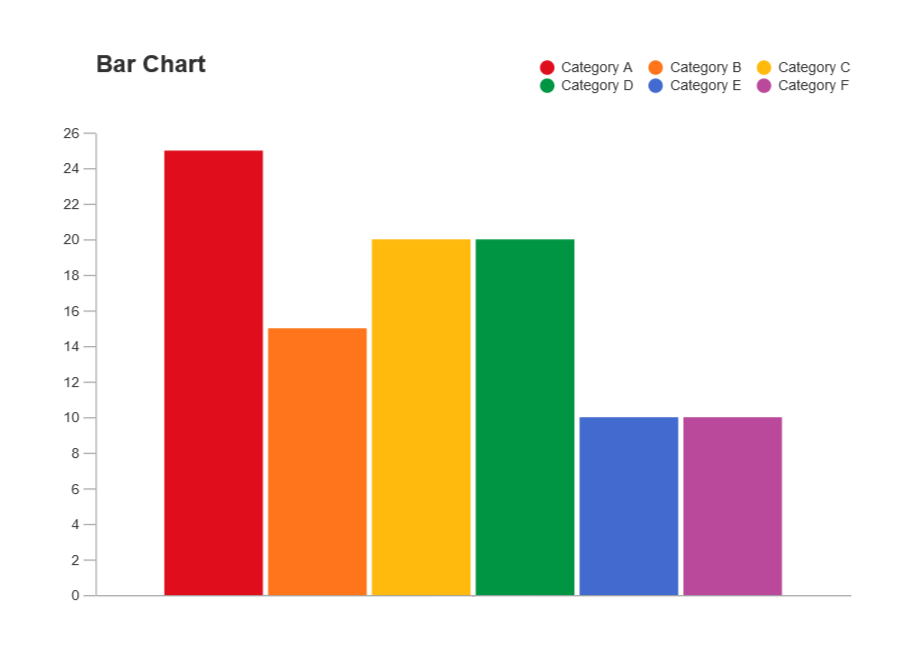

Bar Graph Learn About Bar Charts And Bar Diagrams Riset

PPT Xbar and R charts PowerPoint Presentation, free download ID

Detailed Guide To The Bar Chart In R With Ggplot 12672 Hot Sex Picture

![[10000ダウンロード済み√] 2^n chart 250973N2 organization chart Saesipapictpe4](https://media.cheggcdn.com/media/ea3/ea3fd77a-5d31-452f-8a99-aa69806155c2/php6pgTch.png)

[10000ダウンロード済み√] 2^n chart 250973N2 organization chart Saesipapictpe4

Spc X Bar Chart Example Free Table Bar Chart ZOHAL

A2 Chart For X Bar

Horizontal Bar Diagram

Types of Control Charts Statistical Process Control.PresentationEZE

They Provide Continuous Data To Determine How Well A Process Functions And Stays Within Acceptable Levels Of Variation.

In Statistical Process Control (Spc), The And R Chart Is A Type Of Scheme, Popularly Known As Control Chart, Used To Monitor The Mean And Range Of A Normally Distributed Variables Simultaneously, When Samples Are Collected At Regular Intervals From A Business Or Industrial Process.

For Example, A Plastics Manufacturer Wants To Determine Whether The Production Process For A New Product Is In Control.

The Control Limits On Both Chats Are Used To Monitor The Mean And Variation Of The Process Going Forward.

Related Post: