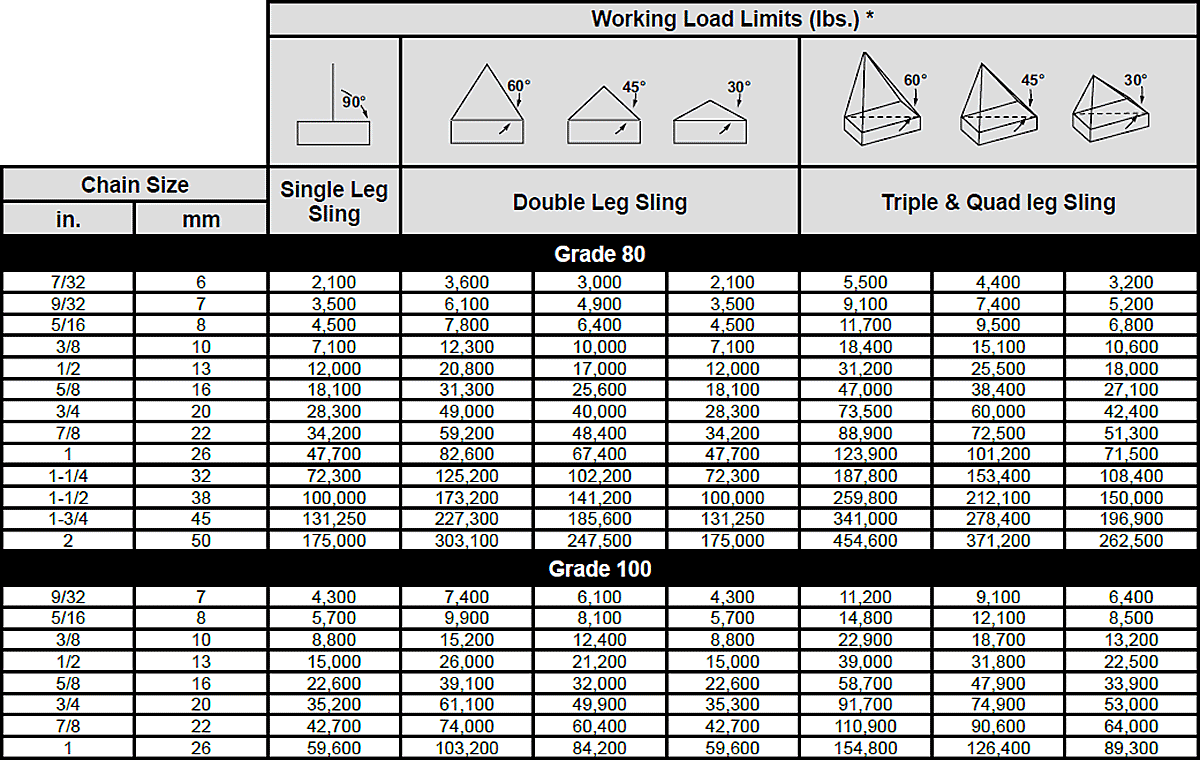

Working Load Limit Chart

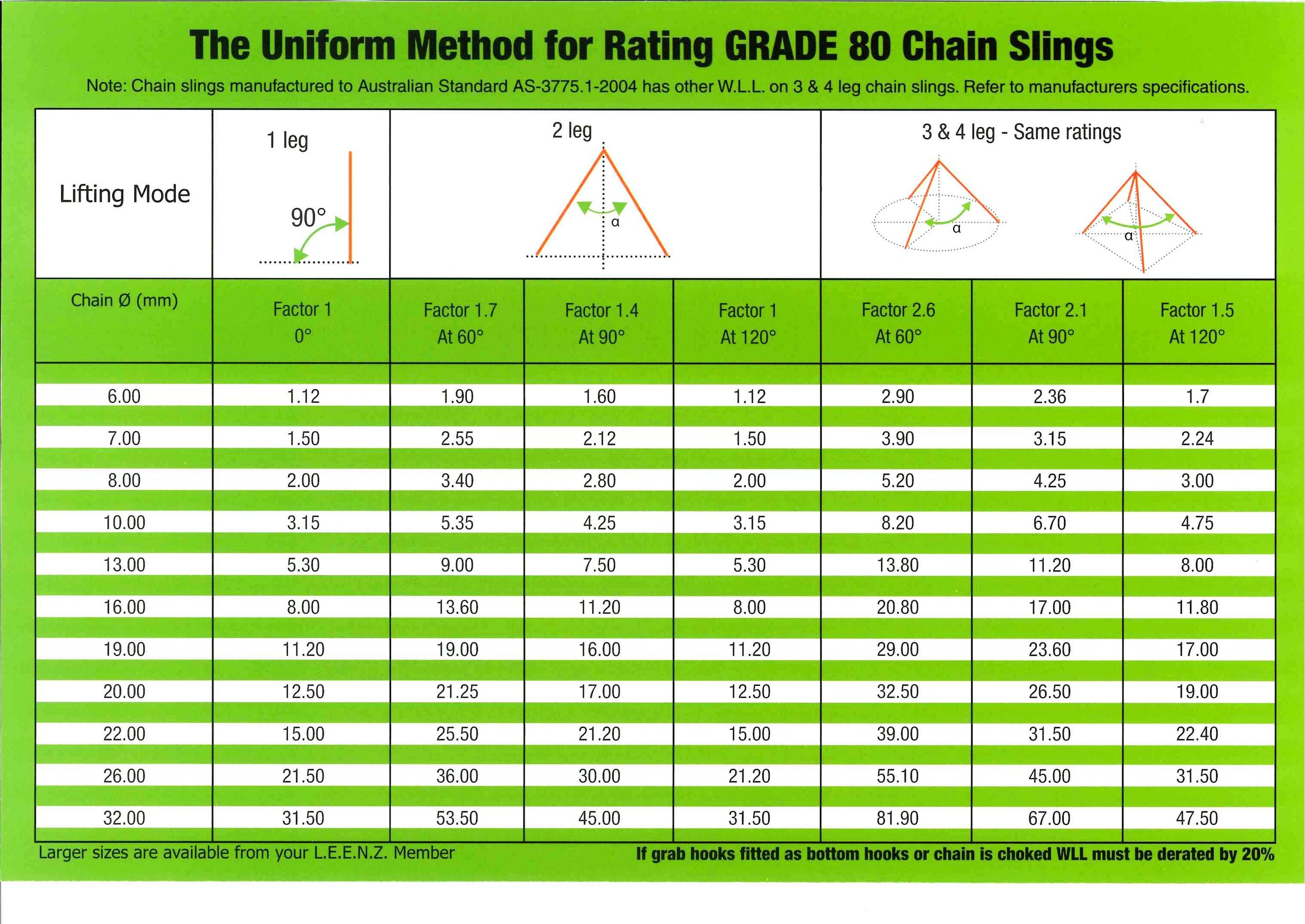

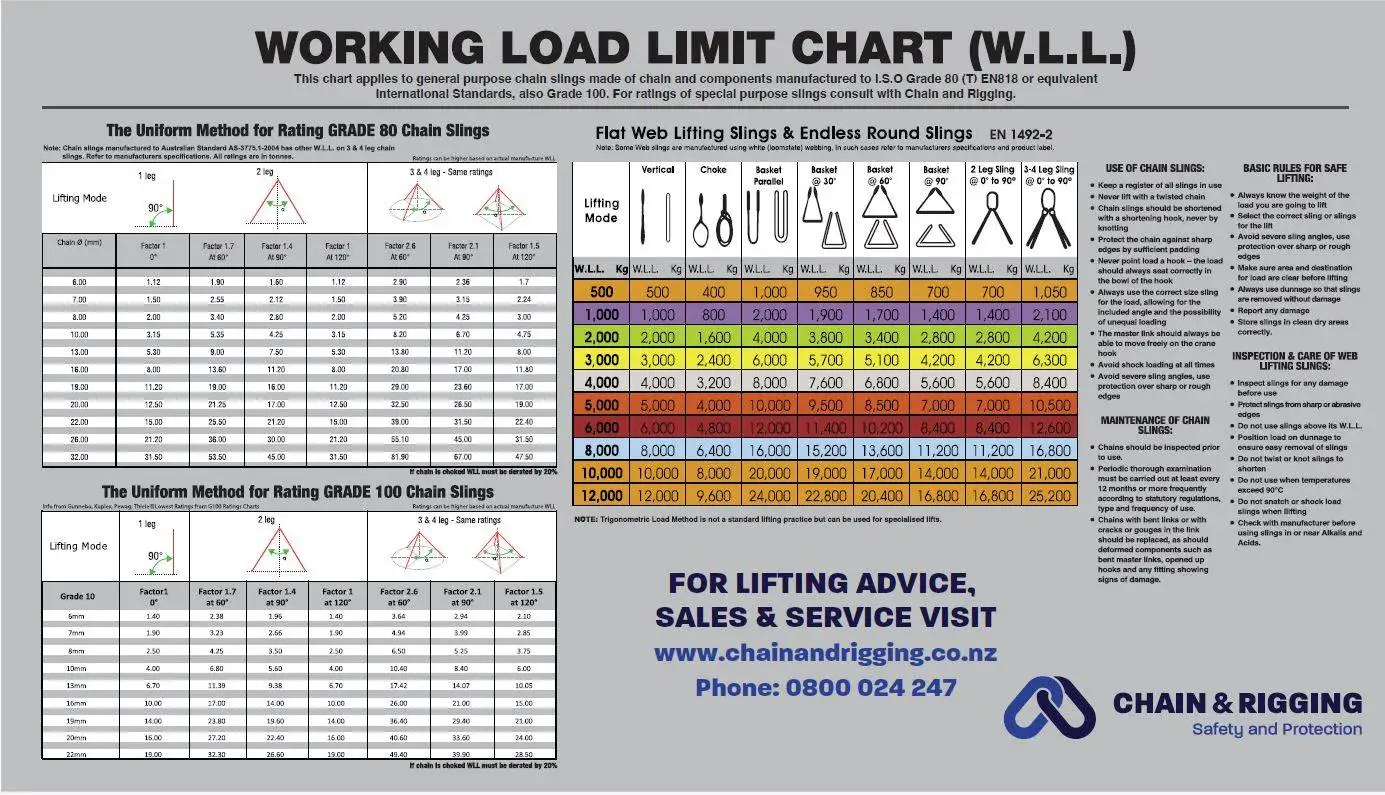

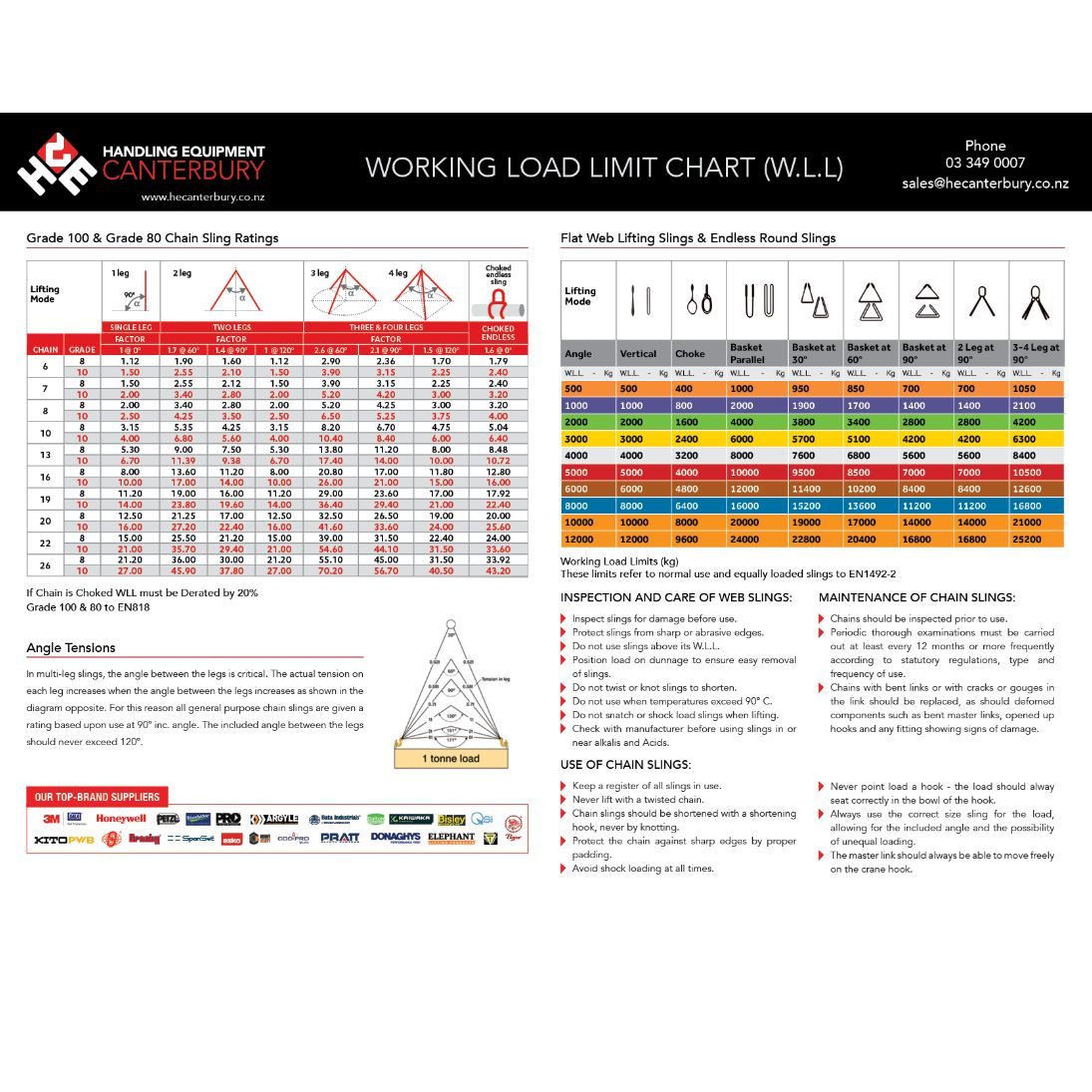

Working Load Limit Chart - Chain is embossed with both the grade and size so you can determine its wll using this chart. Web working load limit (wll) is the maximum working load designed by the manufacturer. About working load limit calculator (formula) the working load limit calculator is a tool used to determine the maximum load or weight that a lifting device or equipment can safely handle. Web when placing two (2) sling legs in hook, make sure the angle from vertical to the leg nearest the hook tip is not greater than 45 degrees, and the included angle between the legs does not exceed 90 degrees* (see figure 5). Look for the wll rating, often marked as wll or working load limit. Web m = (10.9 103 n) / (9.81 m/s2) = 1111 kg. Web a working load limit tag is a tag on the side of the tie down strap that provides you with information of what your straps are rated for. Grade 80 & grade 100 alloy chain. The chain grade and diameter determines the working load limit of the chain. The engineering toolbox privacy policy. Web the working load limit (wll) is a term used to define the maximum weight that a particular piece of equipment can safely handle. These ratings are based on ideal conditions, however in practice, working conditions may vary widely. It is an important specification provided by manufacturers to ensure the safe and proper usage of lifting gear. This is not. Handling tolerance for slings or parts of slings indicated as vertical = 6 degrees. Web the good news is, finding the working load limit for your equipment is usually quite straightforward. Diameter of curvature (d/d) angle of loading. Web in this website, the maximum working load limit for each size of chain is shown. Web a working load limit tag. Look for the wll rating, often marked as wll or working load limit. Web m = (10.9 103 n) / (9.81 m/s2) = 1111 kg. It is an important specification provided by manufacturers to ensure the safe and proper usage of lifting gear. Web 2.1 these specifications cover properties and grades of welded steel chain for industrial and commercial uses. Web the working load limit is calculated by dividing the minimum breaking strength of the chain by the assigned safety factor rating. Web the working load limits of tiedowns used for cargo securement on commercial motor vehicles may be determined by using either the tiedown manufacturer’s markings or by using the tables shown below. Web working load limit (wll) is. Web discover the meaning, calculation, and key differences between safe working load (swl) and working load limit (wll) in the context of lifting equipment safety. Web the working load limit (wll) is a term used to define the maximum weight that a particular piece of equipment can safely handle. M = mode factor for symmetrical loading. The wll is calculated. Web 2.1 these specifications cover properties and grades of welded steel chain for industrial and commercial uses produced to accepted commercial tolerances. The grade and diameter of the chain are also used to determine the working load limit. Web m = (10.9 103 n) / (9.81 m/s2) = 1111 kg. This is not to be confused with the breaking strength. M = mode factor for symmetrical loading. Web m = (10.9 103 n) / (9.81 m/s2) = 1111 kg. Web discover the meaning, calculation, and key differences between safe working load (swl) and working load limit (wll) in the context of lifting equipment safety. Web working load limit (wll) is the maximum working load designed by the manufacturer. Most lifting. Web the good news is, finding the working load limit for your equipment is usually quite straightforward. Popular internal searches in the engineering toolbox. Sling working load limits are determined by the following: It helps ensure proper load capacity and safety in lifting operations. M = mode factor for symmetrical loading. It is an important specification provided by manufacturers to ensure the safe and proper usage of lifting gear. Web m = (10.9 103 n) / (9.81 m/s2) = 1111 kg. Web the working load limits (wll) listed in the tables below are the maximum weights which slings are designed to sustain in general lifting service, according to the standard uniform. M = mode factor for symmetrical loading. It is an important specification provided by manufacturers to ensure the safe and proper usage of lifting gear. It is determined by various factors such as material strength, design factors, and safety factors. Special products such as sprocket chain, pocket wheel chain, etc., are not covered by this specification. It helps ensure proper. Web the working load limit is calculated by dividing the minimum breaking strength of the chain by the assigned safety factor rating. Handling tolerance for slings or parts of slings indicated as vertical = 6 degrees. The chain grade and diameter determines the working load limit of the chain. These ratings are based on ideal conditions, however in practice, working conditions may vary widely. Web the working load limit (wll) is a term used to define the maximum weight that a particular piece of equipment can safely handle. Failure to read, understand and follow the cautions listed here may cause serious physical injury and property damage. Web the working load limit indicates the maximum load that should be applied to the sling and should never be exceeded during use to ensure operator safety. Look for the wll rating, often marked as wll or working load limit. It is determined by various factors such as material strength, design factors, and safety factors. The wll is calculated by dividing mbl by a safety factor (sf). It is an important specification provided by manufacturers to ensure the safe and proper usage of lifting gear. Usage, wear, twists, overloading, corrosion, alteration and misuse all affect the chain load rating of any chain. The following table lists the minimum number of chain assemblies required to secure a. Web when placing two (2) sling legs in hook, make sure the angle from vertical to the leg nearest the hook tip is not greater than 45 degrees, and the included angle between the legs does not exceed 90 degrees* (see figure 5). It helps ensure proper load capacity and safety in lifting operations. This load represents a force that is much less than that required to make the lifting equipment fail or yield.

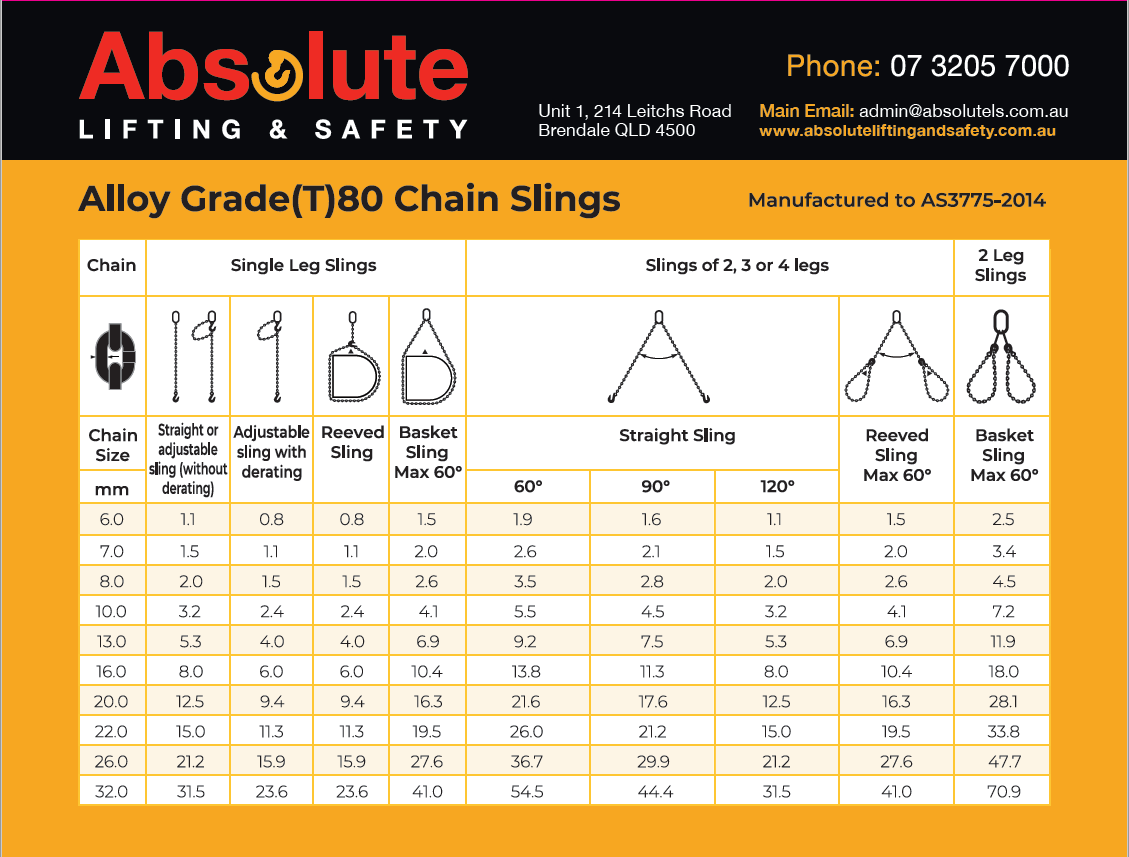

Chain Sling Working Load Limits Absolute Lifting and Safety Blog

Chain Working Load Limit Chart

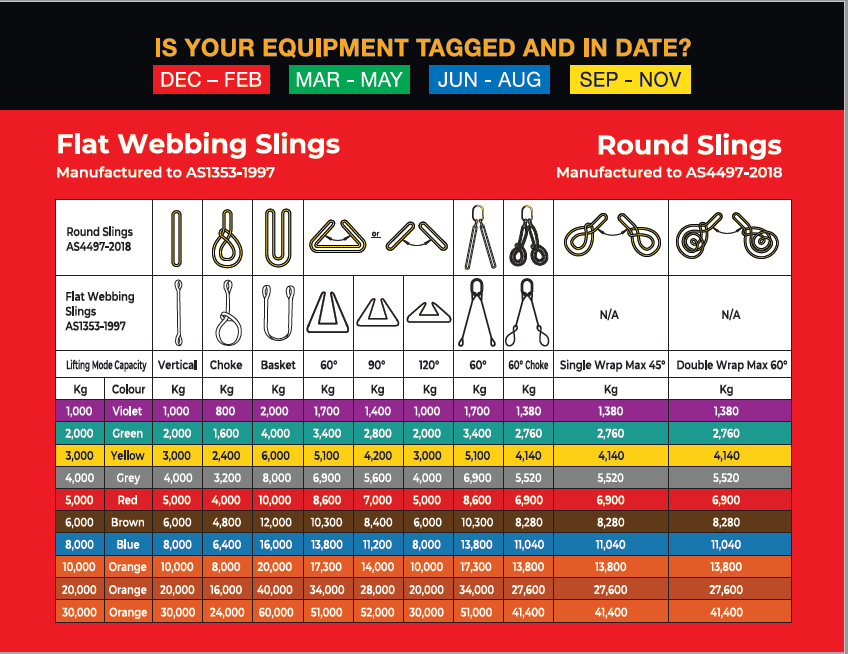

Synthetic Sling Working Load Limit Guide Lifting & Rigging Geelong

Working Load Limits Handling Equipment Canterbury

Select the Sling You Need With Our Working Load Limit Chart Chain

Lifting Chain Sets Handling Equipment Canterbury

Chain Grades Chart Cargo Chain Strength and Grades Guide for Flatbedder’s

Chain Working Load Limit Chart

Flat Slings 4 Ply Lifting Slings Absolute Lifting and Safety

Chain Working Load Limit Chart

Web The Working Load Limits Of Tiedowns Used For Cargo Securement On Commercial Motor Vehicles May Be Determined By Using Either The Tiedown Manufacturer’s Markings Or By Using The Tables Shown Below.

About Working Load Limit Calculator (Formula) The Working Load Limit Calculator Is A Tool Used To Determine The Maximum Load Or Weight That A Lifting Device Or Equipment Can Safely Handle.

Web Working Load Limit (Wll) Is The Maximum Working Load Designed By The Manufacturer.

Special Products Such As Sprocket Chain, Pocket Wheel Chain, Etc., Are Not Covered By This Specification.

Related Post: