Wire Rope Breaking Strength Chart

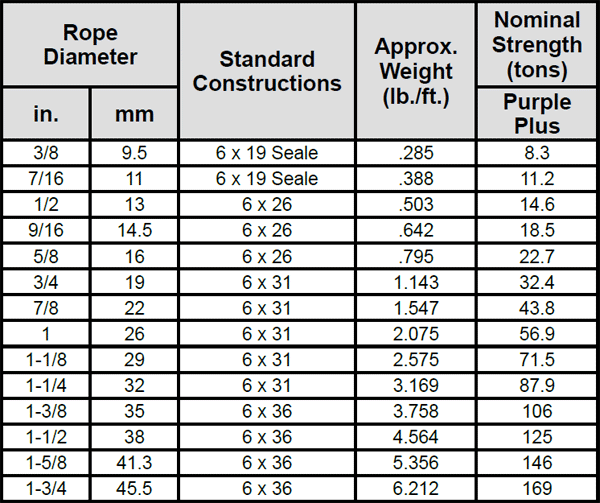

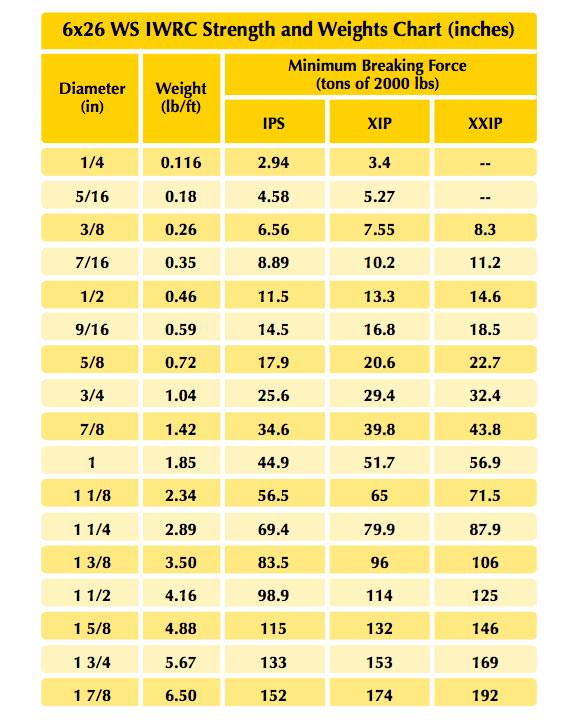

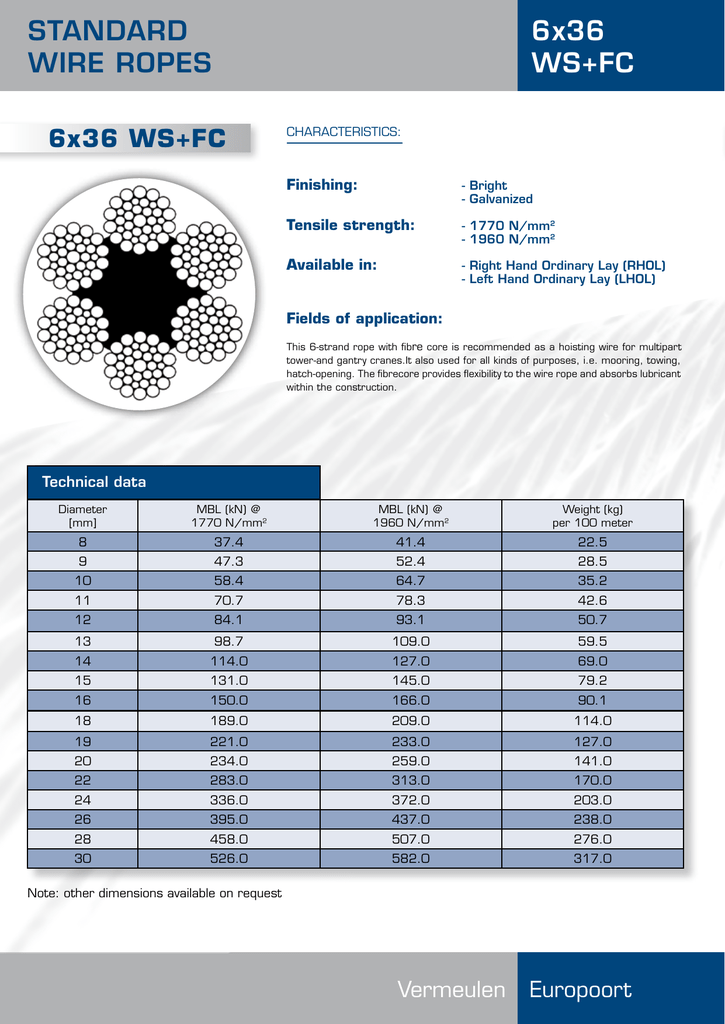

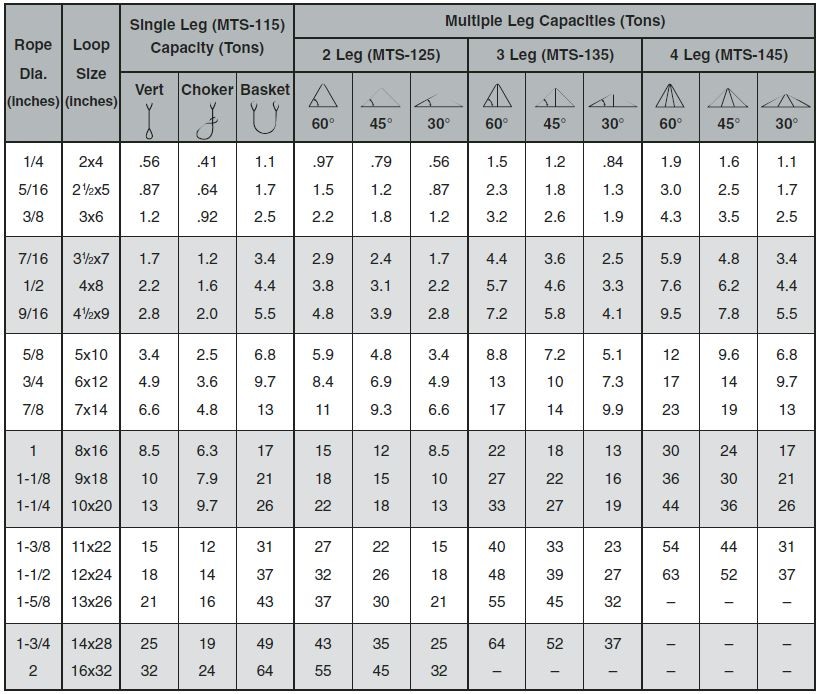

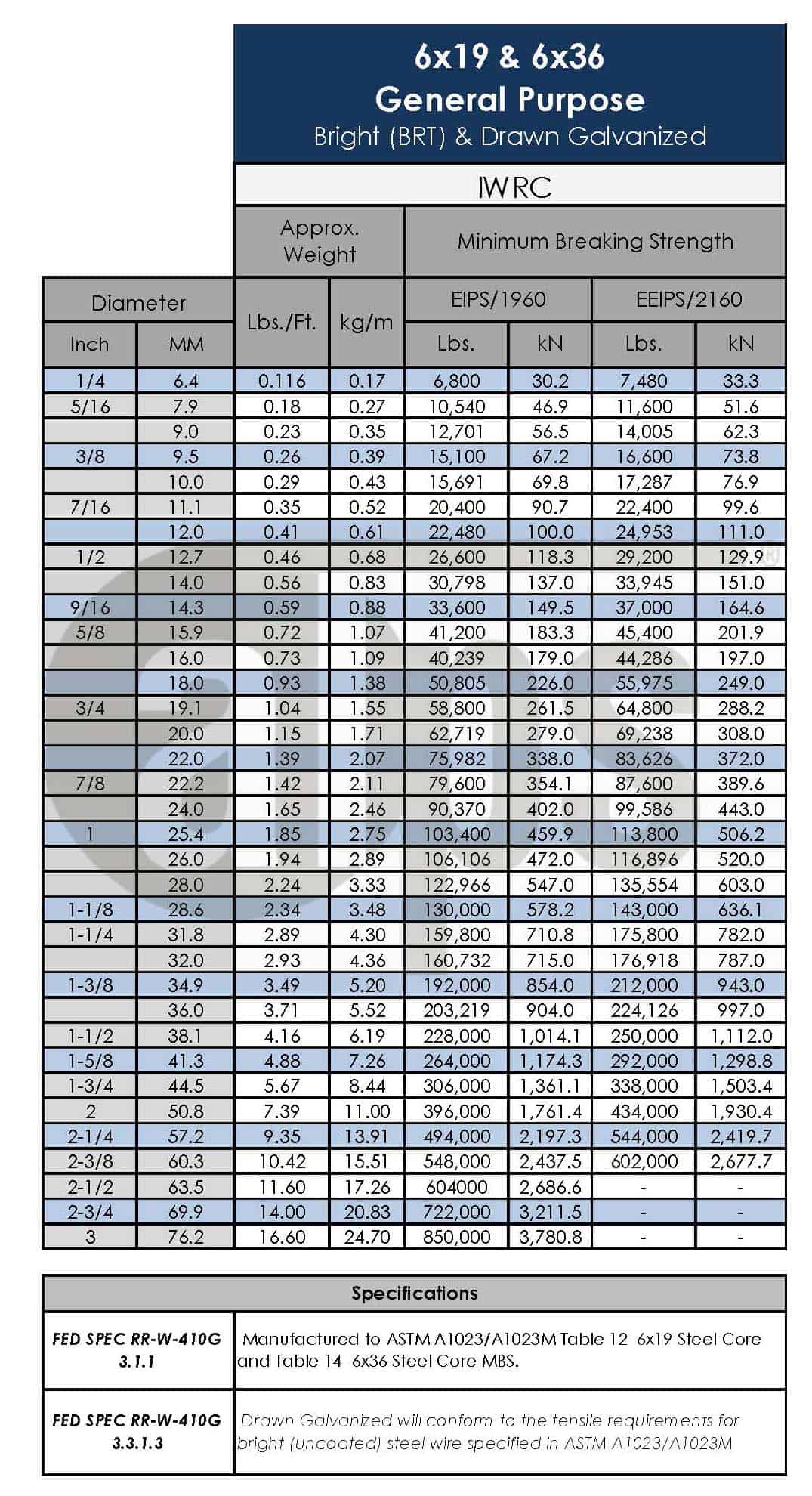

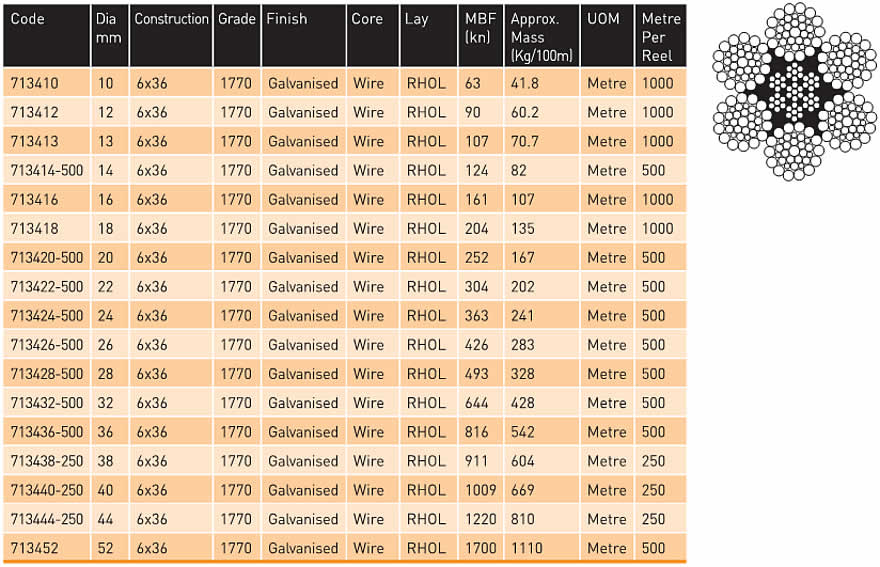

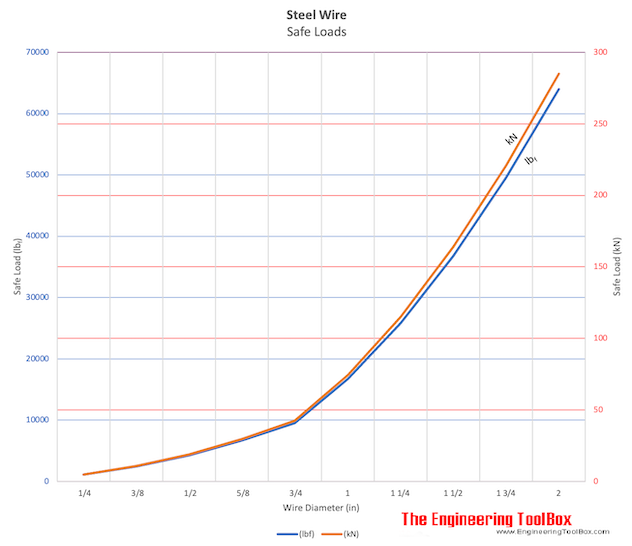

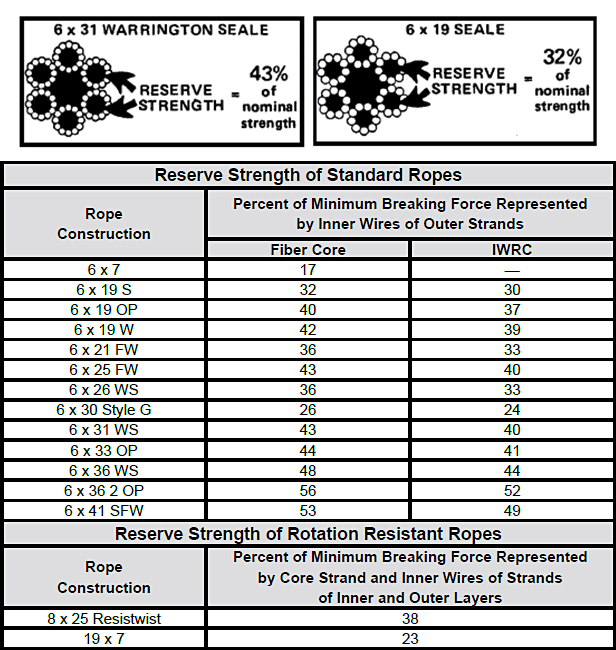

Wire Rope Breaking Strength Chart - This is a calculated strength that has been accepted by the wire rope industry. It is designated by the value according to the lower limit of tensile strength and is used when specifying wire and when determining the calculated minimum aggregate breaking force a rope, expressed in n/mm2. All ropes of the same size, grade and core offer somewhat similar minimum breaking force characteristics and weight per foot, though they do differ depending on the construction type and materials used. This fatigue resistance is made possible by the greater number of small wires per strand. Download and print wire rope safe load chart. Web stainless steel wire rope iwrc type 304 breaking strength (lbs) 16,300 22,800 28,500 35,000 49,600 58,000. But, as with all equipment, it does have a maximum lifting strength. A similar rope to 6x7 but the fibre core is replaced by a wire strand, resulting in a greater resistance to crushing and added strength, lacks flexibility on larger diameter ropes. Although their operating properties vary, all have the same weight per foot and the same minimum breaking force, size for size. The published values apply to new, unused rope. Web for an explanation on the voluntary nature of standards, the meaning of iso specific terms and expressions related to conformity assessment, as well as information about iso's adherence to the world trade organization (wto) principles in the technical barriers to trade (tbt) see the following url: Natural breaking strength of manila line is the standard against which other lines. The same minimum breaking force, size for size. Factor × maximum load = breaking strength. Web stainless steel wire rope iwrc type 304 breaking strength (lbs) 16,300 22,800 28,500 35,000 49,600 58,000. M = (10.9 103 n) / (9.81 m/s2) = 1111 kg. Our wire rope sling tables should be used for guidance only. It lists the strength of improved plow steel (ips) wire rope that is uncoated and has a fibre core. Rope breaking force can be seen as. Whether you're working with 1x7, 1x19, 7x7, or other configurations in 302/304 stainless steel or galvanized steel, our guide provides the essential 'g' factor for each type. This tolerance is used to offset variables. It lists the strength of improved plow steel (ips) wire rope that is uncoated and has a fibre core. Web the 6x36 classification of wire ropes includes standard 6 strand, round strand ropes with 27 through 49 wires per strand. Web stainless steel wire rope iwrc type 304 breaking strength (lbs) 16,300 22,800 28,500 35,000 49,600 58,000. Sling calculation using. Web the wire rope strength is shown as minimum breaking force (mbf). This is a calculated strength that has been accepted by the wire rope industry. M = (10.9 103 n) / (9.81 m/s2) = 1111 kg. Sling calculation using the breaking force of wire rope. A similar rope to 6x7 but the fibre core is replaced by a wire. Web nominal strengths of wire ropes provided by industrial rope. A fundamental requirement for wire ropes is the achievement of the minimum breaking force that complies with the crane or winch safe working load. 5 × 1000 = 5000. Factor × maximum load = breaking strength. Web the 6 x 36 classification of wire ropes includes standard 6 strand, round. Steel wire rope sling load (safety) chart. To avoid your equipment breaking, we have provided a breaking strain guide below. But, as with all equipment, it does have a maximum lifting strength. Minimum breaking strength* (tons of 2,000lbs.) *listed breaking strength is for bright wire rope, available galvanized at 10% lower strengths, or in equivalent strengths on special request. Each. This fatigue resistance is made possible by the greater number of small wires per strand. Web wire rope is designed to be an incredibly strong and sturdy piece of equipment that you can safely rely upon for your heavy lifting tasks. Web a level of requirement of tensile strength of a wire and its corresponding range. All ropes of the. Minimum breaking strength* (tons of 2,000lbs.) *listed breaking strength is for bright wire rope, available galvanized at 10% lower strengths, or in equivalent strengths on special request. What makes wire rope strong? Web to help demonstrate the breaking limit of wire rope, the engineering toolbox have put together this handy table. While the 6 x 19 ropes give primary important. For example, if you are using a gantry crane, which has a factor of 5, and your maximum load is 1000 lbs., you’ll need a wire rope with a minimum 5000 lbs. This tolerance is used to offset variables that occur during sample preparation and. In this reference document (an excerpt from the wire rope users handbook), you will learn. This fatigue resistance is made possible by the greater number of small wires per strand. All ropes of the same size, grade and core offer somewhat similar minimum breaking force characteristics and weight per foot, though they do differ depending on the construction type and materials used. Web 6 × 19 & 6 × 37 class wire rope, bright & galvanized. Web the wire rope strength is shown as minimum breaking force (mbf). Minimum breaking strength* (tons of 2,000lbs.) *listed breaking strength is for bright wire rope, available galvanized at 10% lower strengths, or in equivalent strengths on special request. A fundamental requirement for wire ropes is the achievement of the minimum breaking force that complies with the crane or winch safe working load. But, as with all equipment, it does have a maximum lifting strength. Web a simple wire rope strength chart can help you keep a close eye on wire rope strengths if find this to be an issue: Web to help demonstrate the breaking limit of wire rope, the engineering toolbox have put together this handy table. Web they lay around a “center” in a specified pattern in one or more layers to form a strand. Whether you're working with 1x7, 1x19, 7x7, or other configurations in 302/304 stainless steel or galvanized steel, our guide provides the essential 'g' factor for each type. Each type of line, natural fiber, synthetic and wire rope, have different breaking strengths and safe working loads. Web for an explanation on the voluntary nature of standards, the meaning of iso specific terms and expressions related to conformity assessment, as well as information about iso's adherence to the world trade organization (wto) principles in the technical barriers to trade (tbt) see the following url: Natural breaking strength of manila line is the standard against which other lines are compared. Although their operating properties vary, all have the same weight per foot and the same minimum breaking force, size for size. What makes wire rope strong?

Wire Rope Breaking Strength Chart

Wire Rope Breaking Strength Chart A Visual Reference of Charts Chart

Wire Rope Strength Chart

Rope Breaking Strength Chart

Wire Rope Chart A Visual Reference of Charts Chart Master

Wire Rope Breaking Strength Chart

General Purpose Arizona Wire Rope

Wire Ropes Strengths

What Are the Seven Primary Characteristics of Wire Rope?

Ultrahigh Strength Steel Wire Ropes — DrillSafe

Web Stainless Steel Wire Rope Iwrc Type 304 Breaking Strength (Lbs) 16,300 22,800 28,500 35,000 49,600 58,000.

Web A Level Of Requirement Of Tensile Strength Of A Wire And Its Corresponding Range.

Our Galvanized Strand Products Meet Or Exceed Astm Specifications A475 And Astm A363.

Sling Calculation Using The Breaking Force Of Wire Rope.

Related Post: