Welding Temperature Chart

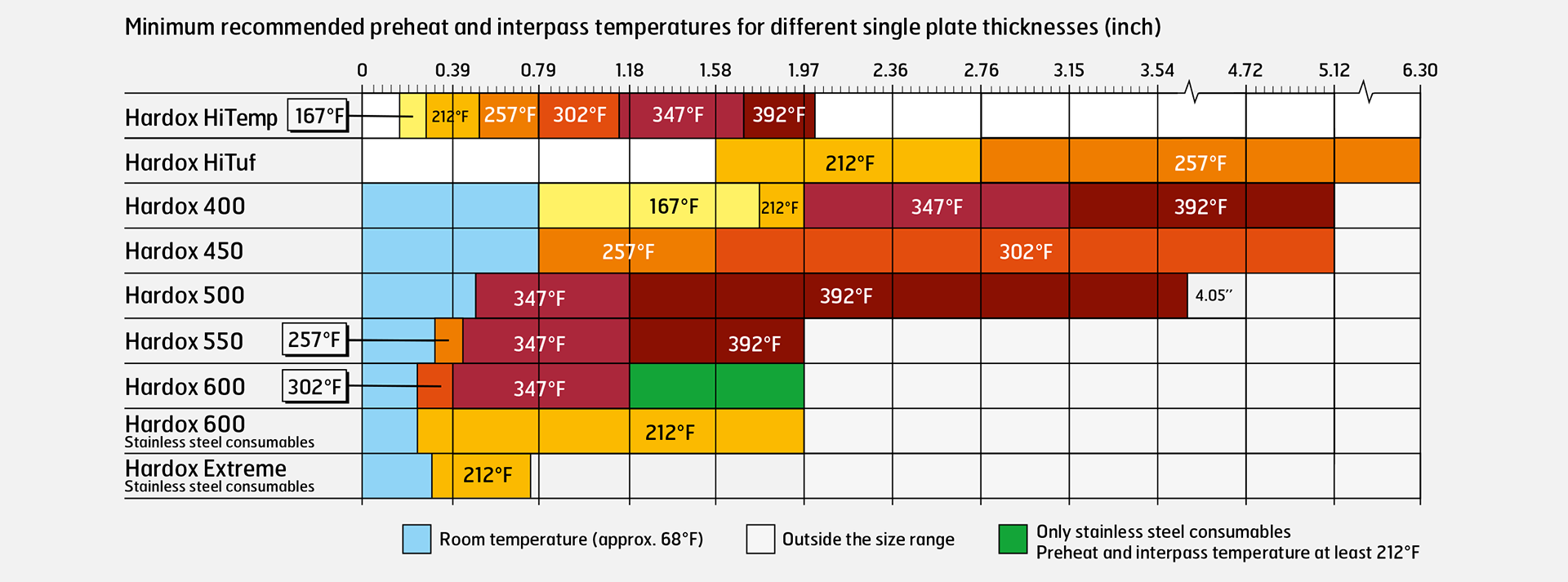

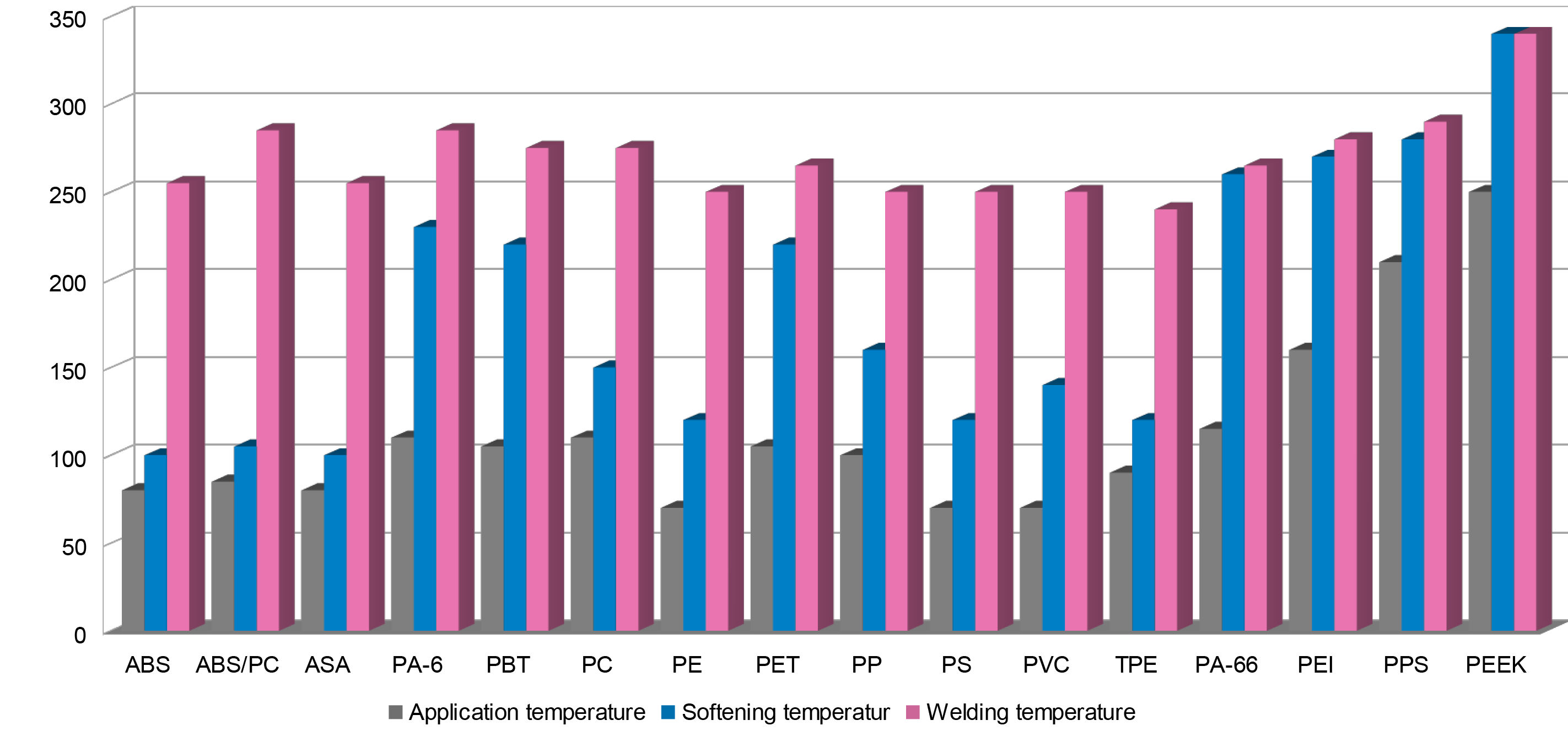

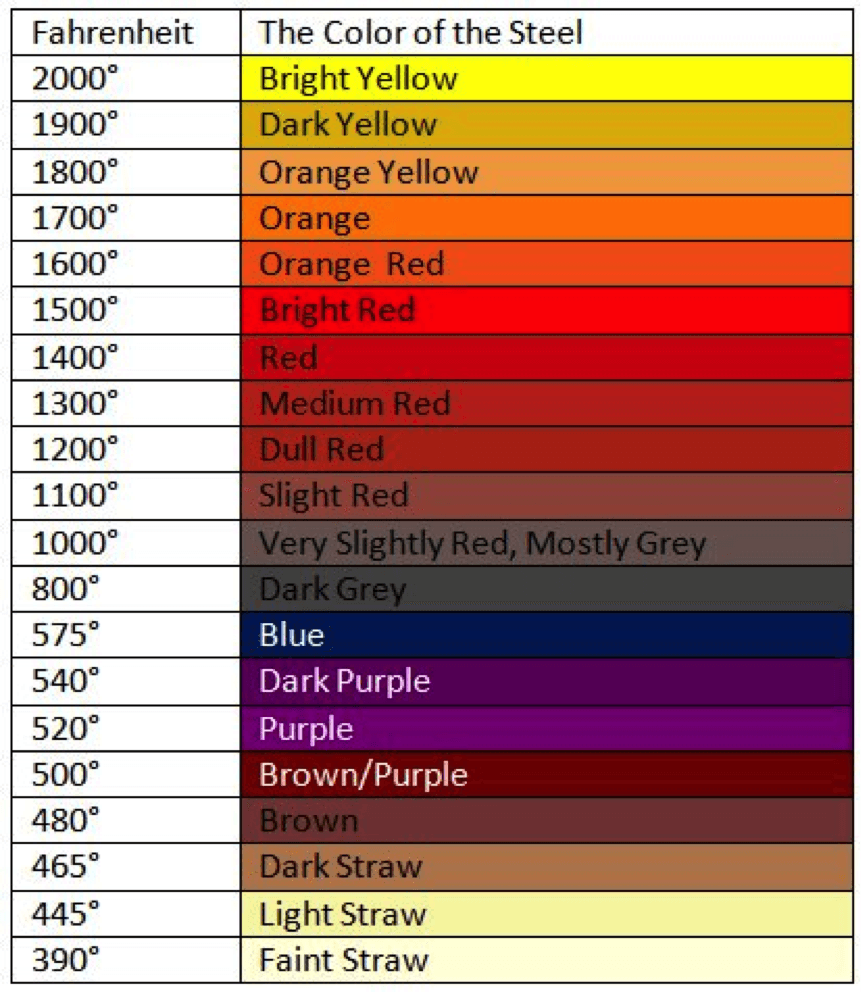

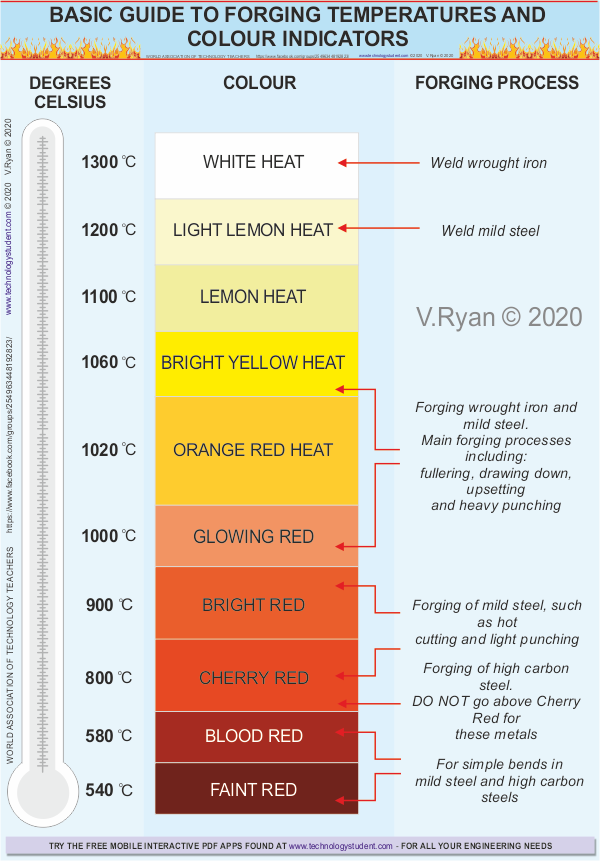

Welding Temperature Chart - The information contained in this article is for general information purposes only. Web what metal are you welding? The preheat should be uniform thought out and around the joint. Heat can be applied directly around the area of the weld joint, or the entire part can be heated. 35 users found this article useful. Controlling welding temperatures is vital for the success of welding operations. Set the welding temperature on the rotary control according to the rod material to be used in the test. Select proper wire size according to amperage. Web thermoplastic welding products guide. There are many mig setting charts available from manufacturers that all vary. Web thermoplastic welding products guide. Welding temperatures according to material and tool. This temperature shall be maintained while welding, unless a minimum interpass temperature is stated. The preheat should be uniform thought out and around the joint. Use the seelye welders for these and other thermoplastic applications. Web as a guideline, each.001 inch of material thickness requires 1 amp of output: The interpass temperature can be specified as a minimum, a maximum, or both, depending on. Web methods of preheating. .125 inch = 125 amps. Web melting and welding temperatures. Select proper wire size according to amperage. Recommendation for temperatures during plastic welding. Welding temperatures according to material and tool. Measure and adjust the interpass temperature; Heat can be applied directly around the area of the weld joint, or the entire part can be heated. The preheat should be uniform thought out and around the joint. .125 inch = 125 amps. Set the welding temperature on the rotary control according to the rod material to be used in the test. Induction creates a magnetic field that generates eddy currents within the base metal, heating it internally from within. 35 users found this article useful. Induction creates a magnetic field that generates eddy currents within the base metal, heating it internally from within. Seelye's standard welding temperature chart for pp, pe, abs & pvc. Web when the base metal temperature is below 32°f [0°c], the base metal shall be preheated to a minimum of 70°f [20°c] and the minimum interpass temperature shall be maintained during. Measure and adjust the interpass temperature; Web when the base metal temperature is below 32°f [0°c], the base metal shall be preheated to a minimum of 70°f [20°c] and the minimum interpass temperature shall be maintained during welding. Web to measure and adjust the temperature effectively, the engineer must: Welding alloys offers a preheat temperature calculator for unalloyed and low. Calculate heat input (the energy transferred during the process of welding); Web when the base metal temperature is below 32°f [0°c], the base metal shall be preheated to a minimum of 70°f [20°c] and the minimum interpass temperature shall be maintained during welding. .125 inch = 125 amps. Heat can be applied directly around the area of the weld joint,. Welding alloys offers a preheat temperature calculator for unalloyed and low alloy steels based on the chemical analysis of the base metal. Welding preheat temperature chart for carbon steel, alloy steel, martensitic stainless steels, nickel alloys and other material is given below for reference taken from asme b31.3. Web what metal are you welding? And decide whether—and how—postweld heat treatment. The ultimate sign of correct welding temperature is a strong weld There are four common welding preheat methods: Web a preheat of 250f may be recommended when 150f would do. Use the seelye welders for these and other thermoplastic applications. Web melting and welding temperatures. The preheat should be uniform thought out and around the joint. There are also indicators that can help guide you to the correct temperature. Determine whether or not to apply preheat; And decide whether—and how—postweld heat treatment (pwht) should be applied. Web a preheat of 250f may be recommended when 150f would do. The preheat should be uniform thought out and around the joint. Welding temperatures according to material and tool. Recommendation for temperatures during plastic welding. The information contained in this article is for general information purposes only. The ultimate sign of correct welding temperature is a strong weld Welding alloys offers a preheat temperature calculator for unalloyed and low alloy steels based on the chemical analysis of the base metal. Induction creates a magnetic field that generates eddy currents within the base metal, heating it internally from within. Web what metal are you welding? Web to measure and adjust the temperature effectively, the engineer must: Controlling welding temperatures is vital for the success of welding operations. 35 users found this article useful. Preheat means the minimum preheat temperature before welding. Web thermoplastic welding products guide. Welding preheat temperature chart for carbon steel, alloy steel, martensitic stainless steels, nickel alloys and other material is given below for reference taken from asme b31.3. The interpass temperature can be specified as a minimum, a maximum, or both, depending on. Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode.

Welding Temperature Chart My XXX Hot Girl

Welding temperatures OrbiTech

Tig Help Fabrication / Welding HybridZ

Temperature welding cycle for TIG welding with different preheating

Heat Tint Charts Huntingdon Fusion Techniques HFT Weld Purging

METALS FOR AND TEMPERATURES

Welding Chart

Welding temperatures (maximum temperatures measured during the welding

Preheat Temperature Table For Different Materials in Welding Steel

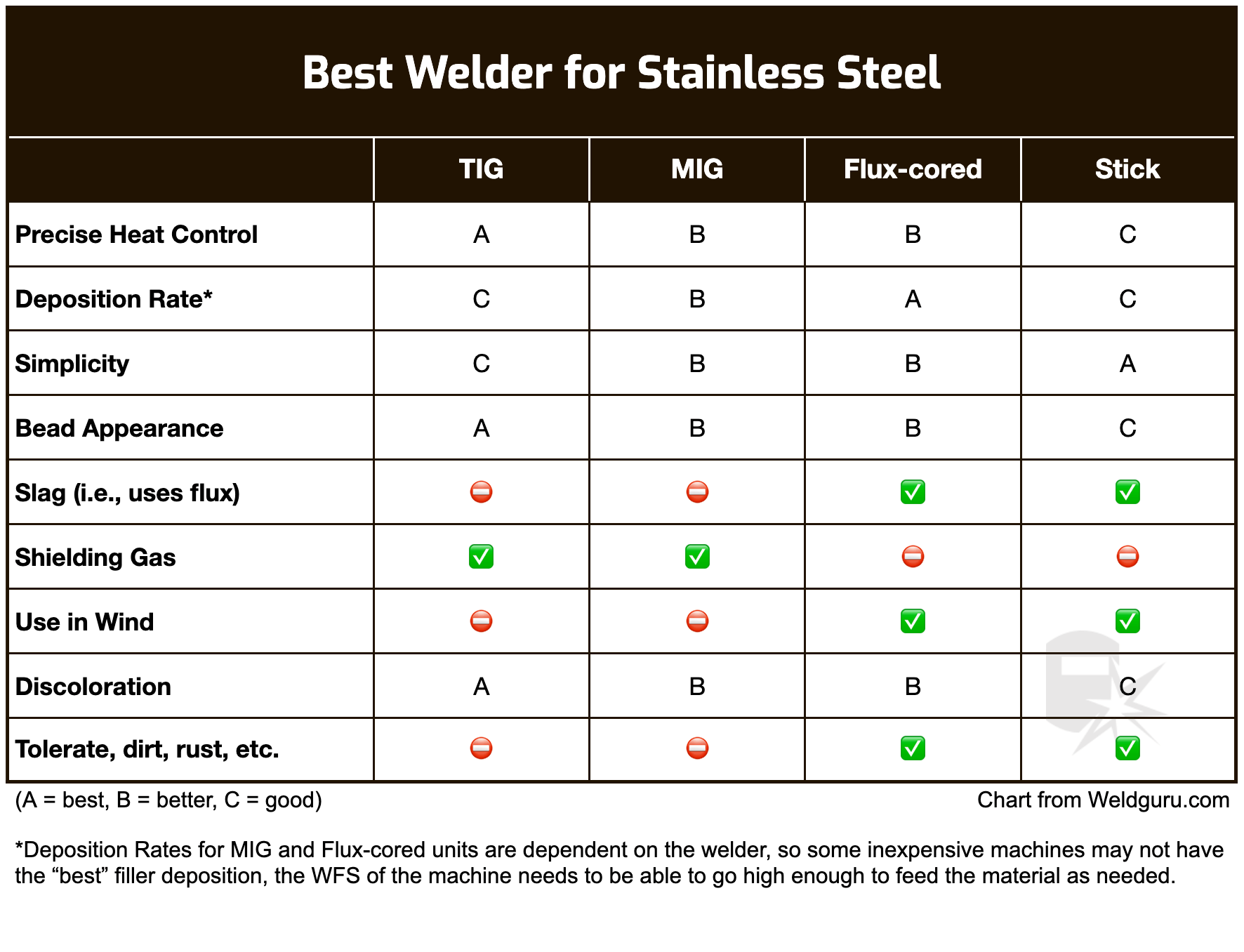

How to Weld Stainless Steel A Complete Guide

There Are Many Mig Setting Charts Available From Manufacturers That All Vary.

Web Methods Of Preheating.

This Temperature Shall Be Maintained While Welding, Unless A Minimum Interpass Temperature Is Stated.

Fit The Most Appropriate Welding Nozzle To The Techspan Plastic Welder.

Related Post: