Welding Positions Chart

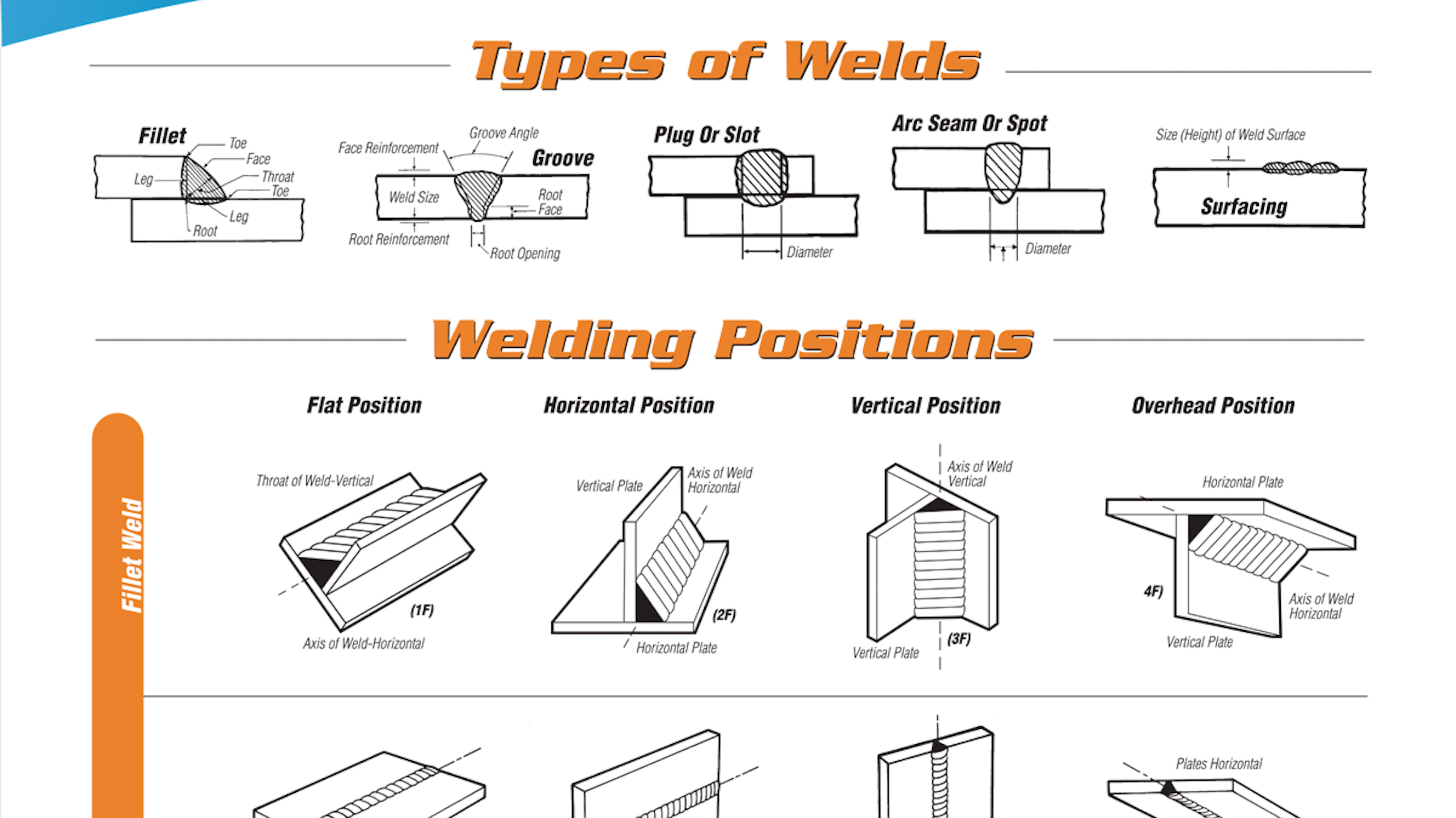

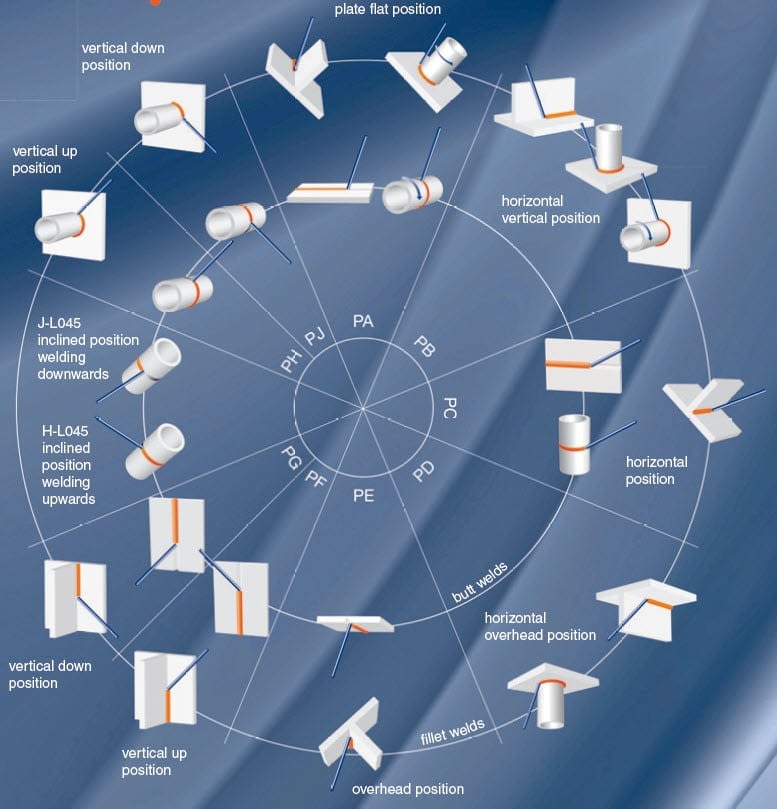

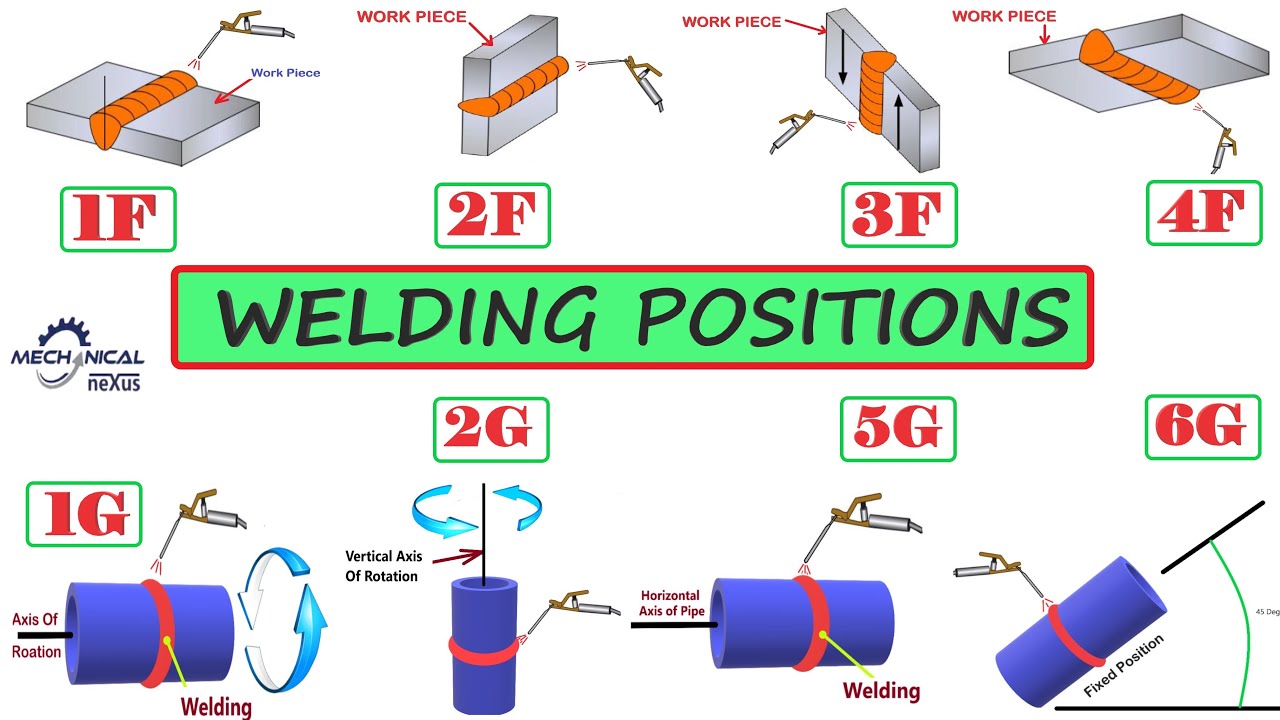

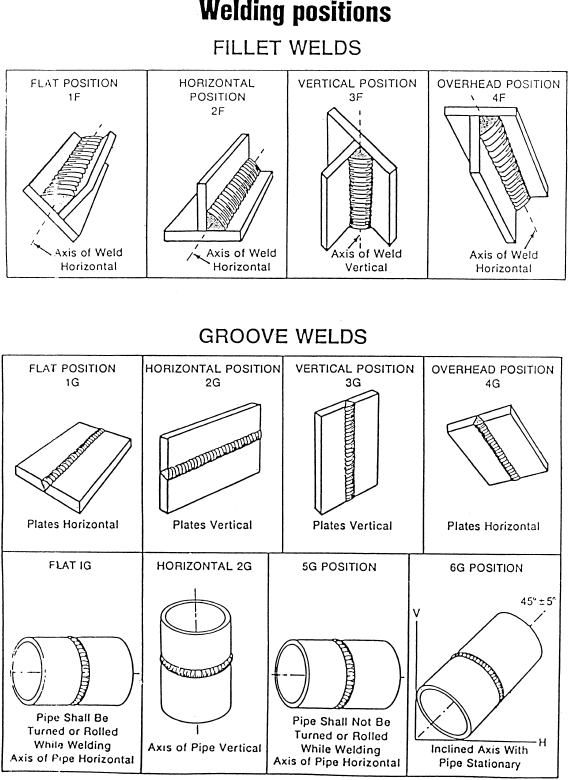

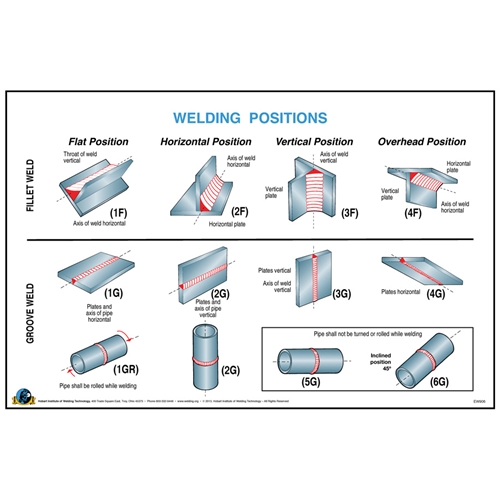

Welding Positions Chart - Web to help welder understand the type of weld joint (fillet or groove) and the weld position, each weld is given a number and a letter — 1g, 2g, 3g, 4g or 1f, 2f, 3f, 4f — to indicate the position and the type of weld required. The most common type of weld you will do is a fillet weld and a groove weld, and you can accomplish these welds in all four positions. Web a welding position chart is a comprehensive guide outlining the positions in which a welder can operate. Web we offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post for your welding team. To do this correctly, you need to weld from the top joint area. The chart also helps welders choose the best position for a particular weld. Welding is a versatile skill that allows for the joining of metal components through the application of heat and pressure. The position chart is especially helpful when welding in difficult positions. The welding position at the groove joint and the welding position at the fillet joint. Web learn pipe welding positions using welding positions chart; Web welders can use the welding position chart to learn new techniques. Web learn pipe welding positions using welding positions chart; Web to help welder understand the type of weld joint (fillet or groove) and the weld position, each weld is given a number and a letter — 1g, 2g, 3g, 4g or 1f, 2f, 3f, 4f — to indicate. Web to help welder understand the type of weld joint (fillet or groove) and the weld position, each weld is given a number and a letter — 1g, 2g, 3g, 4g or 1f, 2f, 3f, 4f — to indicate the position and the type of weld required. Flat, horizontal, vertical, and overhead. These welding positions are designated by a number. Web a welding position chart is a comprehensive guide outlining the positions in which a welder can operate. Web chart showing welding positions in accordance with bs en iso 6947:2011. It is very important to understand the below figure in order to find out actual welding position. En iso 6947 and asme use the same welding positions, but with different. Generally, the pipe welding position is divided into two types: The position chart is especially helpful when welding in difficult positions. The chart also helps welders choose the best position for a particular weld. To become a master welder, one must not only possess a strong understanding of the welding process but also be proficient in various welding positions. To. Web understanding the four basic welding positions can help you choose the right filler metal and welding process for your job. Web a welding position chart is a comprehensive guide outlining the positions in which a welder can operate. It reveals four welding positions and joint types such as 1g, 2g, 3g, 4g, 5g and 6g/6gr. But you also do. Web pick up your free welding symbols hand chart that we made! Knowing this alphanumeric system will help you make the right weld every time. Welding is a versatile skill that allows for the joining of metal components through the application of heat and pressure. These include the flat (1g/1f/pa), horizontal (2g/2f/pc/pb), vertical (3g/5g), and overhead (4g/4f) positions. It reveals. Web all welding can be classified according to the position of the workpiece or the position of the welded joint on the plates or sections being welded. Gravity keeps the molten weld metal in. It is very important to understand the below figure in order to find out actual welding position. Web gain insights into welding positions and joint types,. A conversion table is provided below. To do this correctly, you need to weld from the top joint area. It reveals four welding positions and joint types such as 1g, 2g, 3g, 4g, 5g and 6g/6gr. Gravity keeps the molten weld metal in. Unique letters designate fillet and groove welds (image credit: In the 1g welding position or horizontal rolled position, the pipe will be in the horizontal position, and it can be rotated along the horizontal (x) axis. The american welding society has defined the four basic welding positions as shown below. Web lok sabha election results 2024: The chart helps welders understand the correct techniques, tools, and types of welds. These welding positions are designated by a number and followed by a letter. Each welding position may require different techniques, parameters and preparation to achieve the best results. Web understanding the four basic welding positions can help you choose the right filler metal and welding process for your job. Web as described above, the 5 major welding positions widely used. Unique letters designate fillet and groove welds (image credit: These welding positions are designated by a number and followed by a letter. But you also do surface welds in all four positions as well, thought you will not do this type of weld very often. Web all welding can be classified according to the position of the workpiece or the position of the welded joint on the plates or sections being welded. Web angle of inclination and rotation of face: Web pick up your free welding symbols hand chart that we made! Web chart showing welding positions in accordance with bs en iso 6947:2011. The position chart is especially helpful when welding in difficult positions. Web typically, welders use five welding positions: Web to achieve more excellent welding quality, professional organizations (asme, aws, iso, jwes) make rules and classifications of welding positions. It reveals four welding positions and joint types such as 1g, 2g, 3g, 4g, 5g and 6g/6gr. Web as described above, the 5 major welding positions widely used in the welding industry are flat weld, horizontal weld, overhead weld, vertical weld, and piping weld. The most common type of weld you will do is a fillet weld and a groove weld, and you can accomplish these welds in all four positions. Knowing this alphanumeric system will help you make the right weld every time. These include the flat (1g/1f/pa), horizontal (2g/2f/pc/pb), vertical (3g/5g), and overhead (4g/4f) positions. Just type your email below!

Welding Types and Positions poster Fleet Maintenance

ASME Section IX Weld Positions

Weld Position Diagram Australian Welding Solutions

welding terminology material positions welding terminology ir g

Information Download Welding Procedures

WELDING POSITIONS FLAT POSITION HORIZONTAL POSITION VERTICAL

Weld Positions

Welding position in accordance with EN ISO 6947 — Capilla

Welding Positions Wall Poster Hobart Institute of Welding Technology

Welding Positions Chart Jasic Welding Inverters

The Chart Helps Welders Understand The Correct Techniques, Tools, And Types Of Welds For Each Position.

To Become A Master Welder, One Must Not Only Possess A Strong Understanding Of The Welding Process But Also Be Proficient In Various Welding Positions.

En Iso 6947 And Asme Use The Same Welding Positions, But With Different Labels.

Horizontal, Flat, Vertical, Overhead, And Inclined.

Related Post: