Welding Position Chart

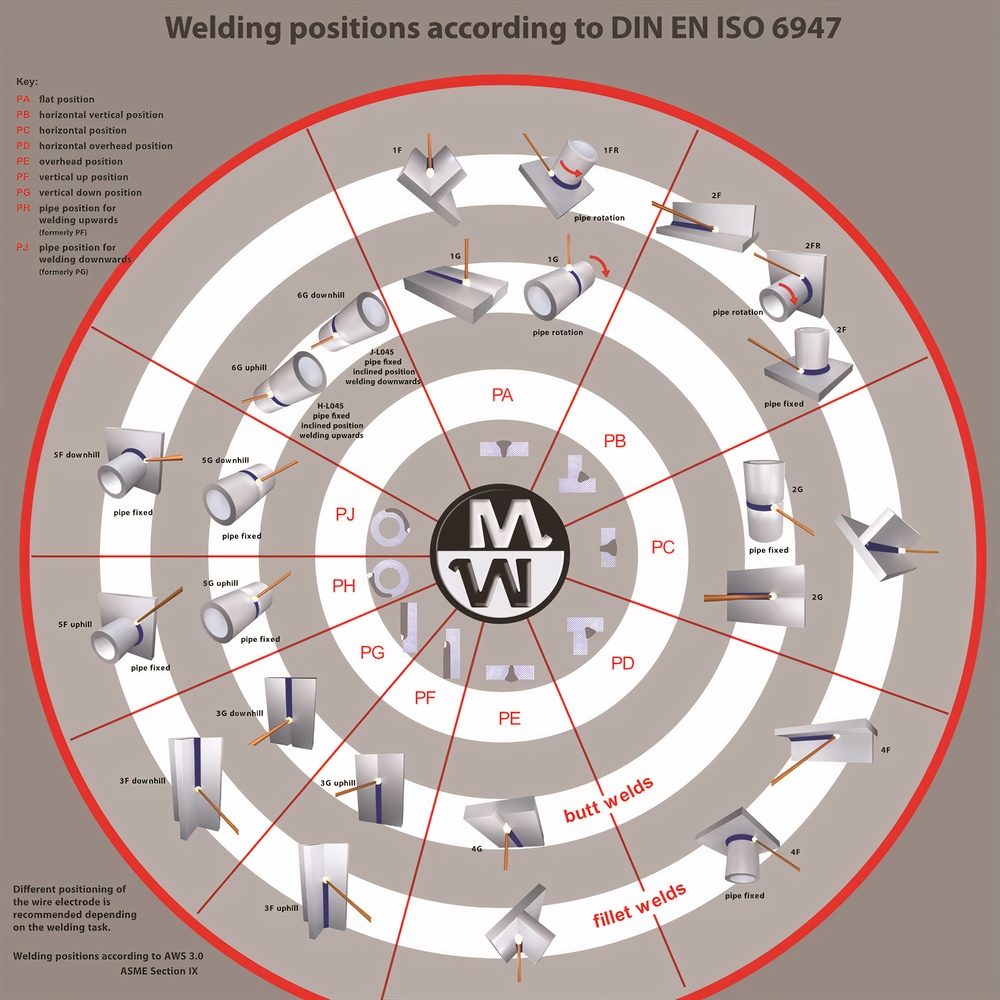

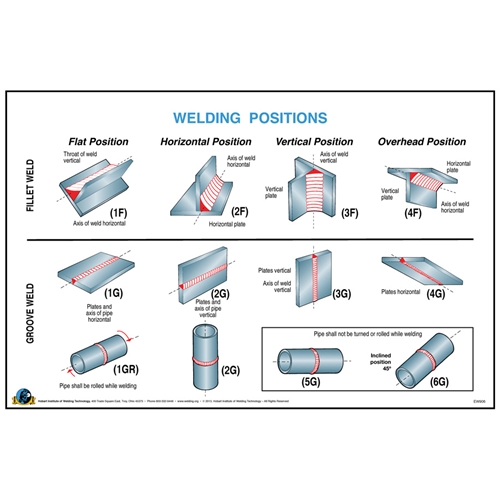

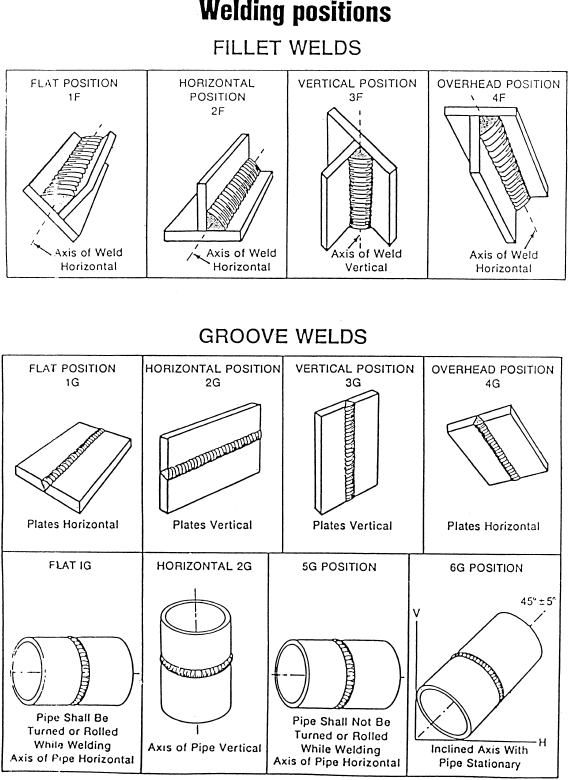

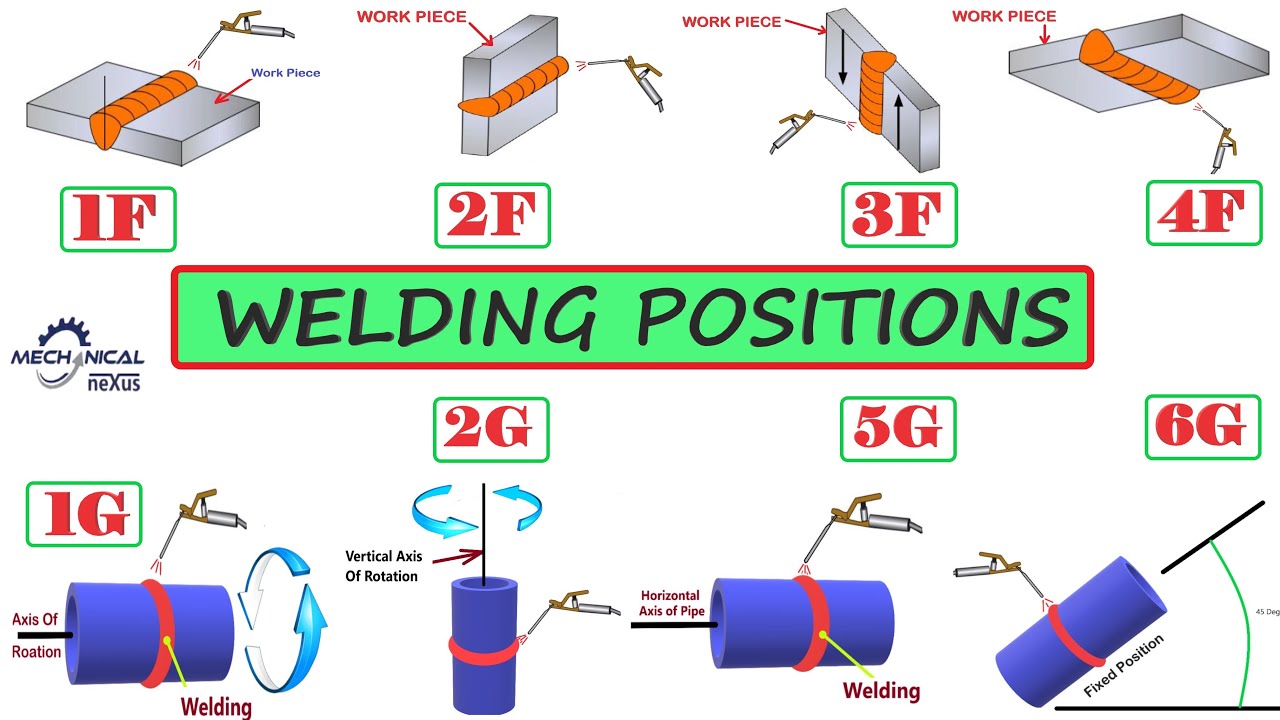

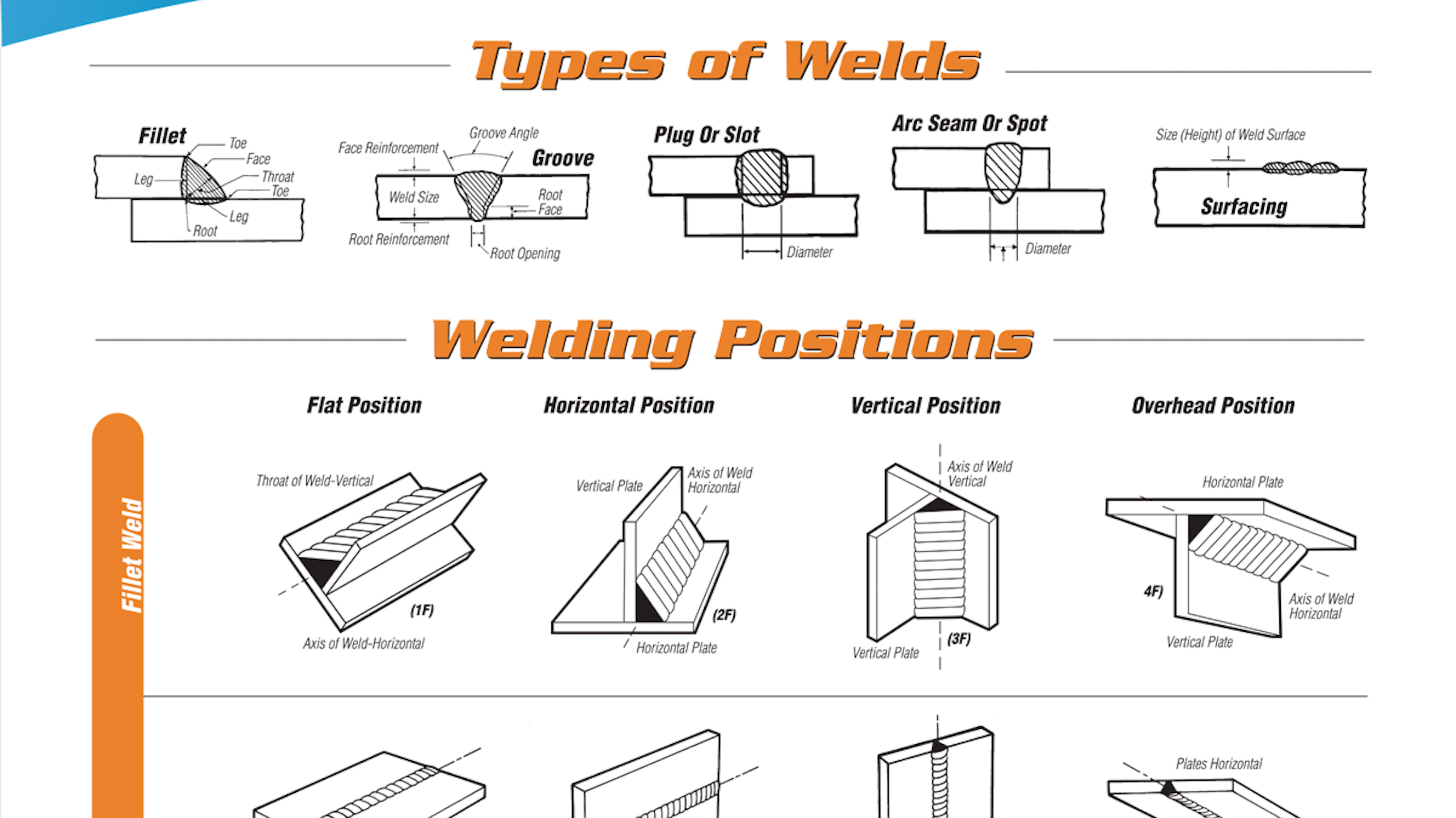

Welding Position Chart - Web hobart has the solution poster download. August 9, 2022 by sandeep kumar. When it is flat, gravity pulls the molten metal down into the joining. The most common type of weld you will do is a fillet weld and a groove weld, and you can accomplish these welds in all four positions. Each welding position may require different techniques, parameters and preparation to achieve the best results. The welding position relies upon the filler metal, the welding system as well as the transfer mode. Horizontal welding is pretty tricky. The flow of the molten metal will change depending on the position you adopt. Web to achieve more excellent welding quality, professional organizations (asme, aws, iso, jwes) make rules and classifications of welding positions. The position chart is especially helpful when welding in difficult positions. Web angle of inclination and rotation of face: Web learn pipe welding positions using welding positions chart. These include the flat (1g/1f/pa), horizontal (2g/2f/pc/pb), vertical (3g/5g), and overhead (4g/4f) positions. As of 03/2021 | © messer group. Web typically, welders use five welding positions: Web unfortunately, we still have some welding professionals who are not familiar with the welding symbol chart. Web gain insights into welding positions and joint types, including 1g to 6g, ensuring accurate and efficient practices for optimal, safe, and effective welding results. Web a welding position chart is a comprehensive guide outlining the positions in which a welder can operate.. Horizontal, flat, vertical, overhead, and inclined. Web in this article, we will learn about the 4 different types of pipe welding positions, basics consideration for welding, weld joints inspection, etc. Web in the 1g position, the weld bead moves in a horizontal direction, while in the 2g position, it moves vertically. These welding positions are designated by a number and. As of 03/2021 | © messer group. These welding positions are designated by a number and followed by a letter. The 4 main welding positions. Web to help welder understand the type of weld joint (fillet or groove) and the weld position, each weld is given a number and a letter — 1g, 2g, 3g, 4g or 1f, 2f, 3f,. Web learn pipe welding positions using welding positions chart. Each welding position may require different techniques, parameters and preparation to achieve the best results. Web unfortunately, we still have some welding professionals who are not familiar with the welding symbol chart. We offer a variety of helpful welding charts and guides that you can reference online, or download as a. This dynamic requires the welder to adjust heat and travel speed to keep excess molten weld metal from falling out of the weld joint. Web to help welder understand the type of weld joint (fillet or groove) and the weld position, each weld is given a number and a letter — 1g, 2g, 3g, 4g or 1f, 2f, 3f, 4f. Web there are five sorts of welding positions i.e., flat, horizontal, inclined, vertical, and overheard. Web in the 1g position, the weld bead moves in a horizontal direction, while in the 2g position, it moves vertically. Web gain insights into welding positions and joint types, including 1g to 6g, ensuring accurate and efficient practices for optimal, safe, and effective welding. The 2g welding position requires the welder to adjust their technique to account for gravity’s effect on the molten metal. Web typically, welders use five welding positions: (note, downloadable versions are below the table for printing.) (found this page useful? We offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf. A conversion table is provided below. Different positioning of the wire electrode is recommended depending on the welding task. Web the four basic welding positions are: What you need to know. When it is flat, gravity pulls the molten metal down into the joining. Web horizontal position (2g and 2f) in the horizontal position, the weld is performed on the side of the joint and the weld axis is horizontal. En iso 6947 and asme use the same welding positions, but with different labels. Different positioning of the wire electrode is recommended depending on the welding task. The welding position at the groove joint. Generally, the pipe welding position is divided into two types: Web unfortunately, we still have some welding professionals who are not familiar with the welding symbol chart. The chart helps welders understand the correct techniques, tools, and types of welds for each position. Web all welding can be classified according to the position of the workpiece or the position of the welded joint on the plates or sections being welded. As of 03/2021 | © messer group. Web gain insights into welding positions and joint types, including 1g to 6g, ensuring accurate and efficient practices for optimal, safe, and effective welding results. Pipe welding positions are essential to know in order to be a proficient welder. What you need to know. Web welders can use the welding position chart to learn new techniques. This results in a quicker, and much easier welding process. Web horizontal position (2g and 2f) in the horizontal position, the weld is performed on the side of the joint and the weld axis is horizontal. But you also do surface welds in all four positions as well, thought you will not do this type of weld very often. A conversion table is provided below. The most common type of weld you will do is a fillet weld and a groove weld, and you can accomplish these welds in all four positions. It might be for amateurs, but professional welders have to have exact knowledge about welding symbols. Each welding position may require different techniques, parameters and preparation to achieve the best results.

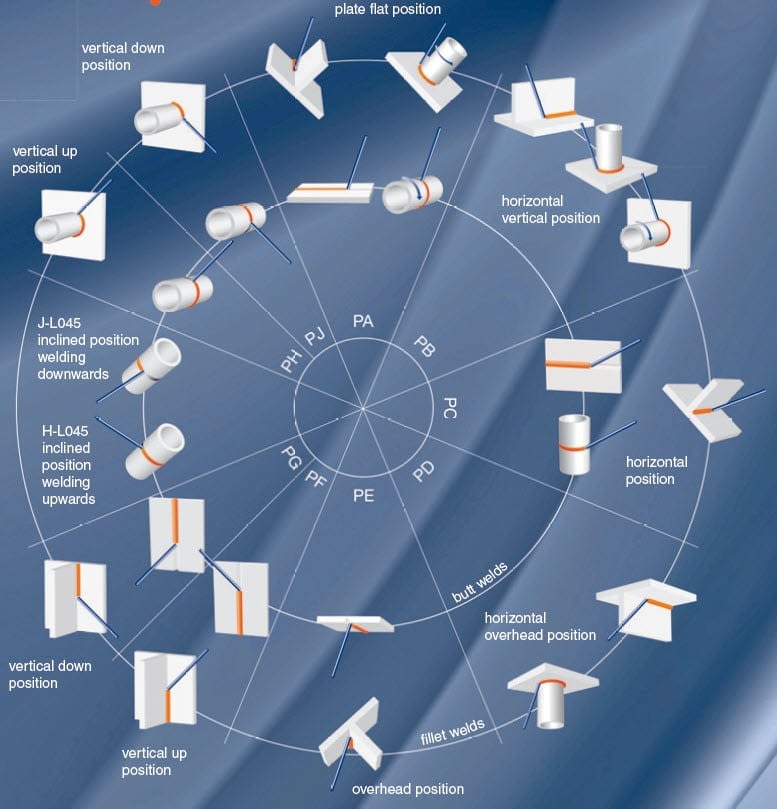

Welding Positions to DIN EN ISO 6947 MasterWeld

Welding Positions Wall Poster Hobart Institute of Welding Technology

Weld Positions

WELDING POSITIONS FLAT POSITION HORIZONTAL POSITION VERTICAL

Welding position in accordance with EN ISO 6947 — Capilla

Printable Welding Charts

Weld Position Diagram Australian Welding Solutions

Xa00152120 Welding Positions Eng New Iso June 2010

Welding Positions Chart Jasic Welding Inverters

Welding Types and Positions poster Fleet Maintenance

En Iso 6947 And Asme Use The Same Welding Positions, But With Different Labels.

Web The Four Basic Welding Positions Are:

The Position Chart Is Especially Helpful When Welding In Difficult Positions.

Flat, Horizontal, Vertical, And Overhead.

Related Post: