Welding Polarity Chart

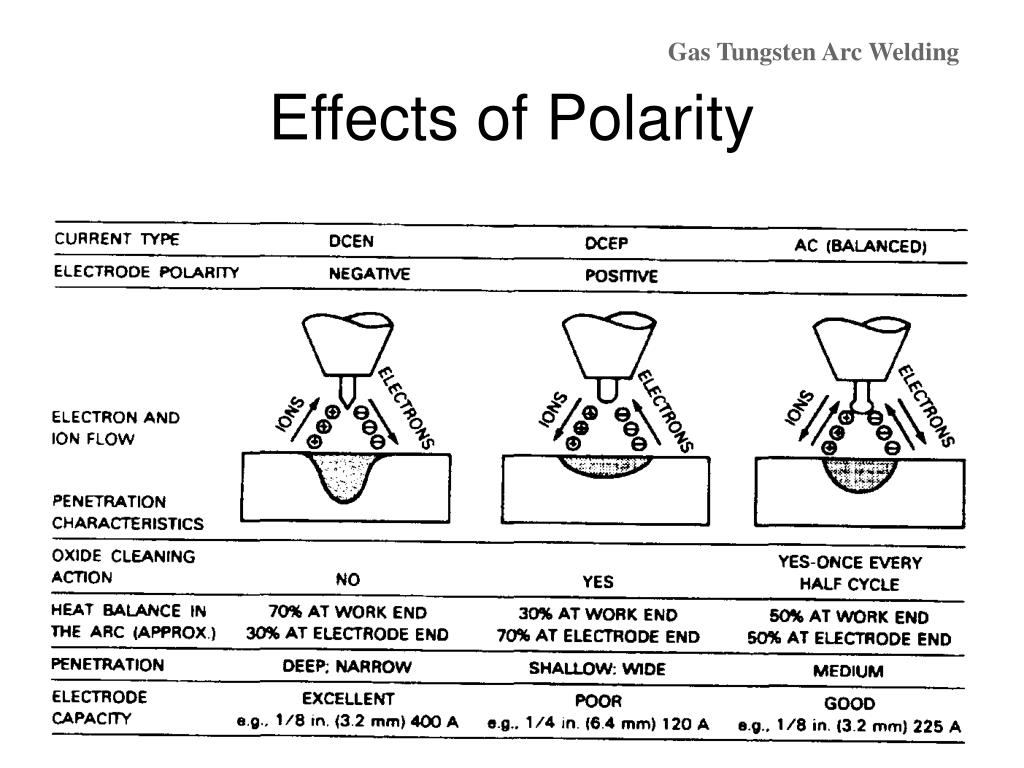

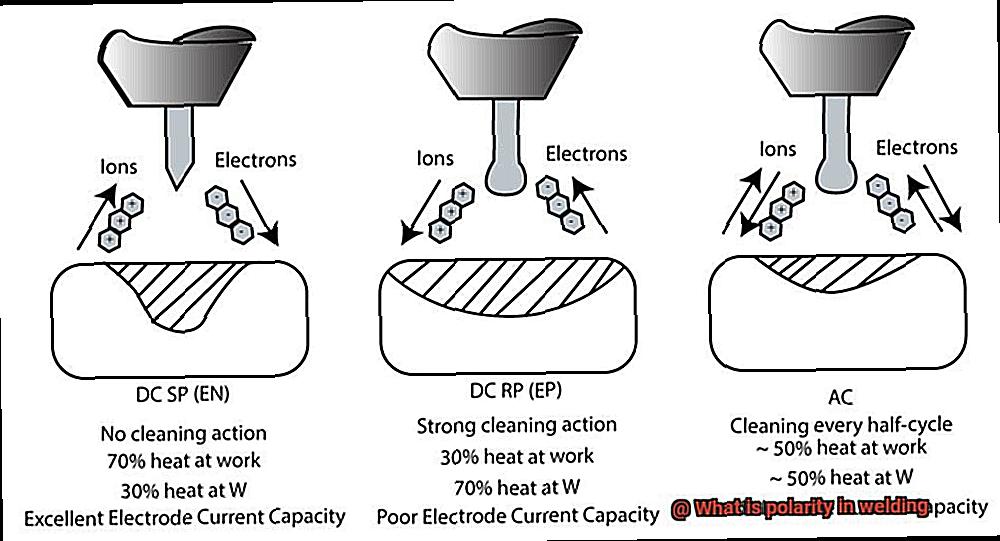

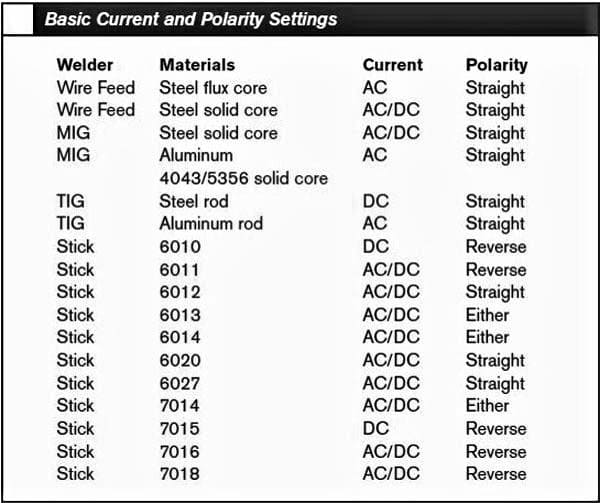

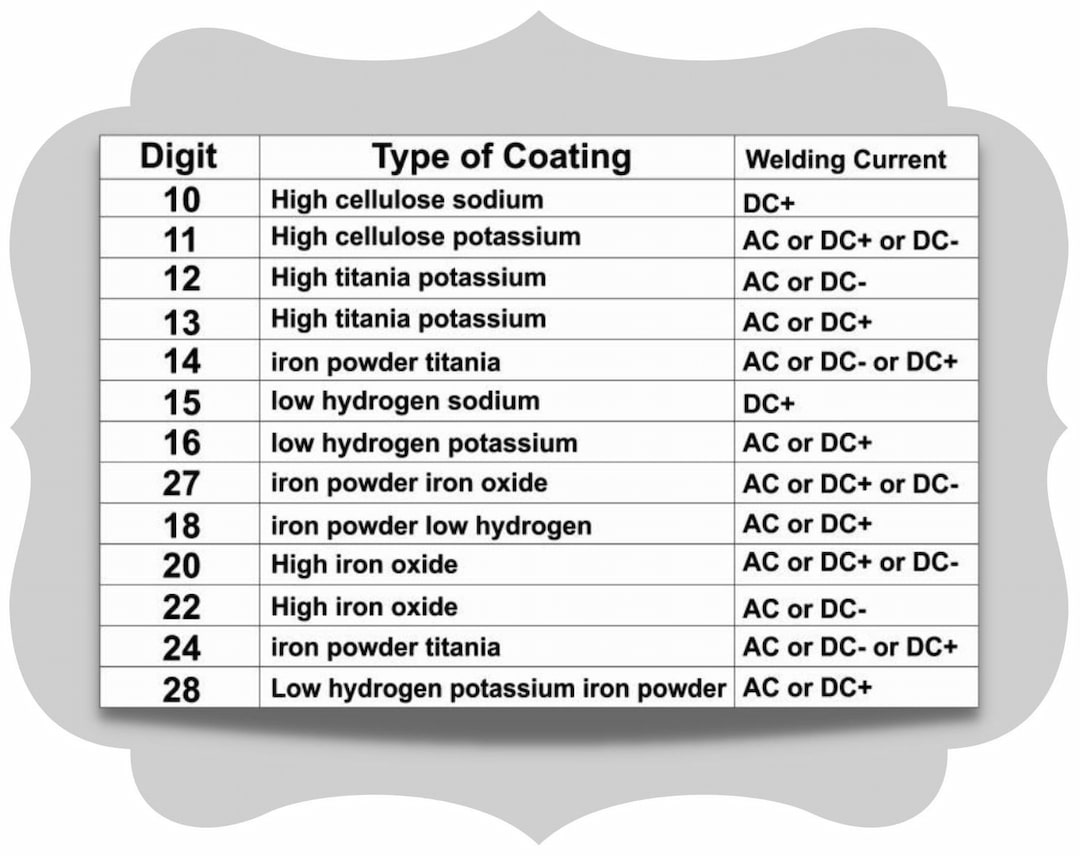

Welding Polarity Chart - Processes like stick welding require a different polarity type, which we’ll get into below. Direct current electrode positive (dcep) A low carbon content means it is similar to iron, soft, and easily formed. The right polarity choice can mean the difference between a strong, clean weld and a weak, contaminated one. Stick welding electrodes come in a range of classifications and sizes for every kind of weld. Web find the best electrode for your welding project with the stick welding rod charts and calculator. Web below we’ve created an expanded stick welding polarity chart that is designed to serve as a quick reference guide, helping you choose the right electrode for your welding project based on its optimal polarity and characteristics. Tig electrode is kept as negative. The polarity can be reversed by changing the leads on the welding machine, which changes the direction of the current flow. Web there are two options when it comes to polarity; Web the three primary types of polarity in welding are direct current straight polarity, direct current reverse polarity, and alternating current polarity. Tig electrode is kept as negative. Web what is the right polarity for stick welding? Web find the best electrode for your welding project with the stick welding rod charts and calculator. It's quite simple and beginner friendly. Positive polarity (dcep) #1 choice. A low carbon content means it is similar to iron, soft, and easily formed. Tig electrode is kept as negative. Web 10 rows an electrode polarity chart based on ac or dc current and type of stick welding electrode. Welders should be aware of the different types of polarity and how they can affect the. Keep reading to learn all about polarity in welding — what it is, how it works, the different types and more. No two projects are exactly alike, and polarity must be adjusted for each material depending on the desired outcome. Tig electrode is kept as negative. Web the following are the main polarity for tig welding: The polarity of a. Stick welding electrodes come in a range of classifications and sizes for every kind of weld. Web learn the correct polarity for tig welding so you can get off to the right start with any project. The right polarity choice can mean the difference between a strong, clean weld and a weak, contaminated one. Web 10 rows an electrode polarity. Web polarity is what determines the strength and quality of the weld. Web 10 rows an electrode polarity chart based on ac or dc current and type of stick welding electrode. Web the three primary types of polarity in welding are direct current straight polarity, direct current reverse polarity, and alternating current polarity. Tig electrode is kept as negative. Web. Web the two types of polarity in welding are direct current electrode positive (dcep), where the majority of the heat is concentrated at the electrode, and direct current electrode negative (dcen), where the majority of the heat is concentrated at the workpiece. Tig welding success hinges on one critical setting: Web learn the correct polarity for tig welding so you. Web find the best electrode for your welding project with the stick welding rod charts and calculator. Is the tig electrode positive or negative? No two projects are exactly alike, and polarity must be adjusted for each material depending on the desired outcome. Web what is polarity in welding? Web the two types of polarity in welding are direct current. Web as a general guideline, a 2.5mm diameter electrode suits metal with a thickness of 3mm to 6mm, a 3.2mm electrode is suitable for 6mm to 12mm, and a 4mm electrode works for metal between 12mm and 25mm. Stick welding electrodes come in a range of classifications and sizes for every kind of weld. Web polarity is what determines the. Web the welding electrode polarity chart for stick welding electrodes e6010, e6012, e6013, e7014, e7015, e7018, and e7024 is shown in the below picture. Web as a general guideline, a 2.5mm diameter electrode suits metal with a thickness of 3mm to 6mm, a 3.2mm electrode is suitable for 6mm to 12mm, and a 4mm electrode works for metal between 12mm. Polarity matters greatly in welding because choosing the right polarity affects the strength and quality of the weld. Welders should be aware of the different types of polarity and how they can affect the quality of their welds. Positive polarity (dcep) #1 choice. Web the three primary types of polarity in welding are direct current straight polarity, direct current reverse. Direct current straight polarity occurs when the plates are positive and the electrode is negative, causing the electrons to go from the electrode tip to the base plates. Direct current electrode negative (dcen) and direct current electrode positive (dcep). Picking the right polarity between these two choices will greatly impact whether you have a sound weld that would pass industry standards or a weld that. In a weld, the electrode is the positive terminal, and the workpiece is the negative terminal. Stick welding electrodes come in a range of classifications and sizes for every kind of weld. No two projects are exactly alike, and polarity must be adjusted for each material depending on the desired outcome. Is the tig electrode positive or negative? Web polarity is what determines the strength and quality of the weld. Web what is the right polarity for stick welding? Web the following are the main polarity for tig welding: Web find the best electrode for your welding project with the stick welding rod charts and calculator. The right polarity choice can mean the difference between a strong, clean weld and a weak, contaminated one. Tig electrode is kept as negative. Web as a general guideline, a 2.5mm diameter electrode suits metal with a thickness of 3mm to 6mm, a 3.2mm electrode is suitable for 6mm to 12mm, and a 4mm electrode works for metal between 12mm and 25mm. The polarity can be reversed by changing the leads on the welding machine, which changes the direction of the current flow. Web learn the correct polarity for tig welding so you can get off to the right start with any project.

Tig Welding Polarity Chart

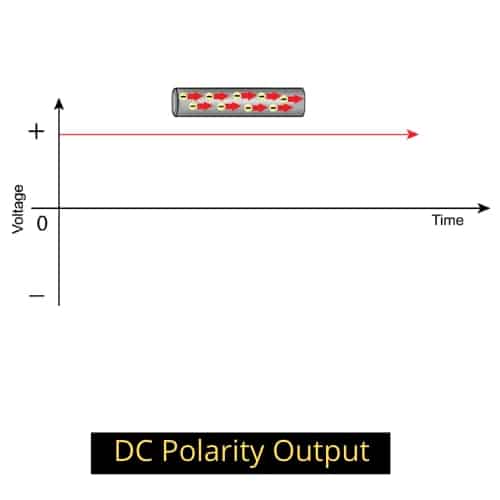

What is polarity in welding? The Welding Guru

Tig Welding Polarity Chart

What is Polarity in Welding? A Complete Guide MIG, TIG & Stick Weld

Mig Welding Polarity Chart

Tig Welding Polarity Chart

Mig Welding Polarity Chart

how to check polarity on mig welder Wiring Work

Polarity in ARC welding, straight polarity and reverse polarity, what

Mig Welding Polarity Chart A Visual Reference of Charts Chart Master

It's Quite Simple And Beginner Friendly.

This Will Help You Choose The Right Stick For The Welding Job.

Keep Reading To Learn All About Polarity In Welding — What It Is, How It Works, The Different Types And More.

Web The Two Types Of Polarity In Welding Are Direct Current Electrode Positive (Dcep), Where The Majority Of The Heat Is Concentrated At The Electrode, And Direct Current Electrode Negative (Dcen), Where The Majority Of The Heat Is Concentrated At The Workpiece.

Related Post: