Welding Lens Shade Chart

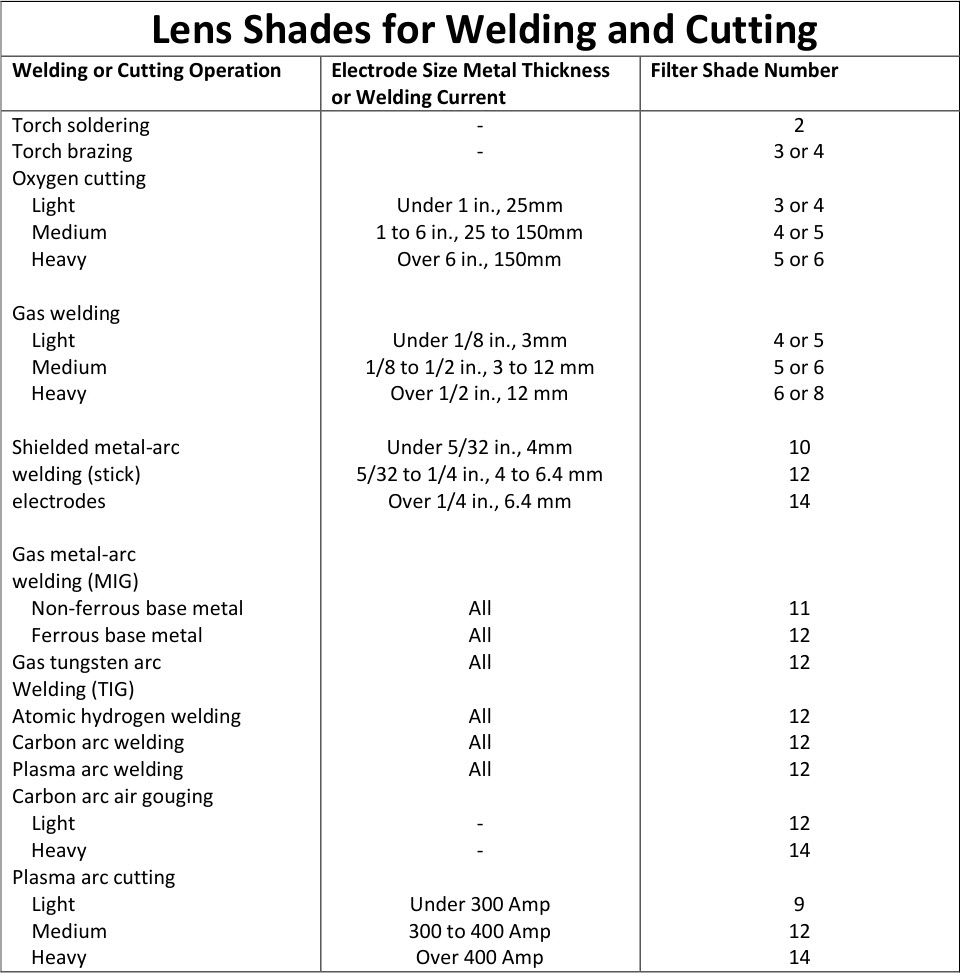

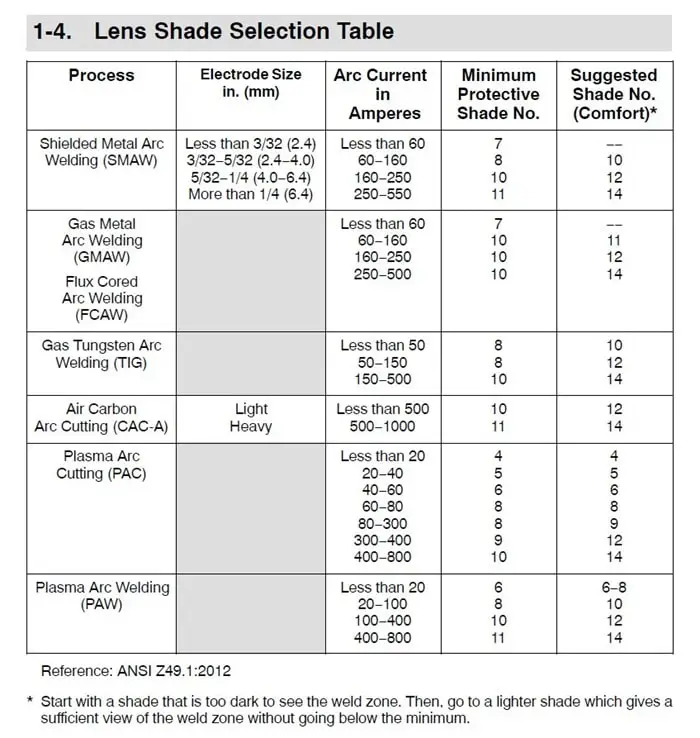

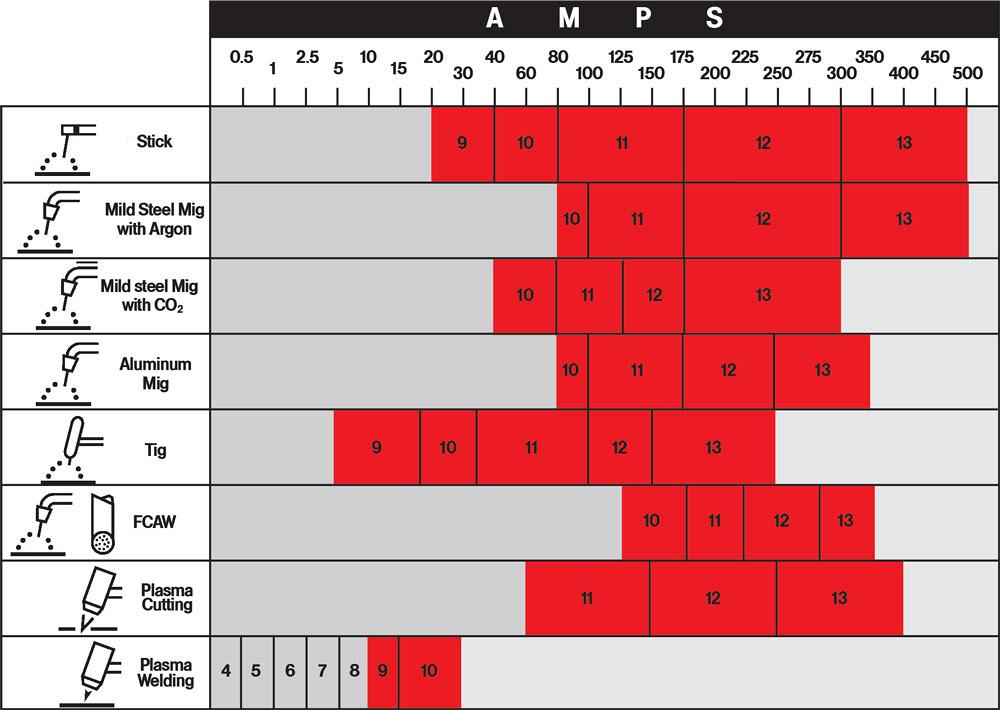

Welding Lens Shade Chart - Select the appropriate shade to protect your eyes from harmful radiation during welding. Web welding shade number luminous transmittance safety chart. The earlier numbers from 4 to 8 are useful in grinding and cutting processes. Operation electrode size arc current (amperes) osha minimum protective shade number. Web typical shade numbers range from 4 to 14. See the chart below to determine the correct shade number for. A welding helmet with a higher shade number is better for most welding applications. Web welding lens shade chart. It helps welders determine the appropriate level of darkness to protect their eyes from. While the shades from 9 to 13 are mainly used for different welding processes. Web based on the type of process and arc current, you can find the lens shade range of your welding mask from the calculator as well as the chart, according to osha, ansi z87.1, and aws guidelines. While the shades from 9 to 13 are mainly used for different welding processes. Web the shade of glass that you choose for. A welding helmet with a higher shade number is better for most welding applications. Web these charts are not intended to be the user's sole reference in the selection of eye and face protectors. Operation electrode size arc current (amperes) osha minimum protective shade number. The larger the shade number, the darker the filter lens. The light given off during. When choosing welding helmet lenses, understanding the different shades, filter strength and lens features is an important factor in obtaining optimal eye protection, preventing. Vs eyewear’s welding safety equipment includes torching and brazing safety glasses, glass window sheeting, and welding safety glasses that are suited for all welding applications. When a worker wears eyewear equipped with filter lenses under a. Recommended shade numbers for common welding and cutting operations are listed in below table (from ansi z 49.1, welding safety). Web the tables below list the minimum protective lens shade numbers for commonly used welding and cutting processes. The tables below show the recommended welding helmet lens shade number based on the type of welding and your amperage range. The. Web within this reference, you will find a detailed table featuring different welding currents and their corresponding recommended lens shade levels for mma, mig, tig, mag, plasma cutting, plasma welding, gouging arc/air, and more. Web a higher shade number indicates a darker lens and a lower shade number indicates a lighter lens. It helps welders determine the appropriate level of. Web within this reference, you will find a detailed table featuring different welding currents and their corresponding recommended lens shade levels for mma, mig, tig, mag, plasma cutting, plasma welding, gouging arc/air, and more. The higher shade number provides greater protection from harmful uv and infrared rays that are emitted during welding. Recommended shade numbers for common welding and cutting. Web the amperage guides most shade level charts and in combination with material welded and the welding process used, will give you a good indication of how much you should set your shade knob on your welding helmet. This article is a guide to help you determine what job needs what number shade. The earlier numbers from 4 to 8. Factors such as material thickness, welding position, and eye sensitivity also play vital roles in determining the perfect shade. How to determine the appropriate lens shade. The larger the shade number, the darker the filter lens. Select the appropriate shade to protect your eyes from harmful radiation during welding. To get a better idea of the shade you should be. The light given off during most welding processes is as bright as the sun, which makes retinal damage a real issue for welders, according to barker. Web typical shade numbers range from 4 to 14. Recommended shade numbers for common welding and cutting operations are listed in below table (from ansi z 49.1, welding safety). Web the tables below list. Determine how dark the welding filter gets when the welding arc is struck. Web welding lens shade chart. Web welding lens selection chart subject: While the shades from 9 to 13 are mainly used for different welding processes. The one thing that surprises most people is that the shade number of the lens doesn’t have anything to do with eye. It helps welders determine the appropriate level of darkness to protect their eyes from. Recommended shade numbers for common welding and cutting operations are listed in below table (from ansi z 49.1, welding safety). Web typical shade numbers range from 4 to 14. Web welding helmet shades numbers vary from 4 to 13. Factors such as material thickness, welding position, and eye sensitivity also play vital roles in determining the perfect shade. The larger the shade number, the darker the filter lens. The eyewear should have proper protection on the filter lens, which is indicated by the shade number. Web filter lenses for protection during other welding and cutting operations. The tables below show the recommended welding helmet lens shade number based on the type of welding and your amperage range. Web welding lens shade chart. Web welding lens shade chart. How to determine the appropriate lens shade. The one thing that surprises most people is that the shade number of the lens doesn’t have anything to do with eye protection. Web the shade of glass that you choose for your welding helmet is dependent on many things. The higher shade number provides greater protection from harmful uv and infrared rays that are emitted during welding. Chart showing what lens shade to use based on welding or cutting process and current (amps).

Welding Helmet Lens Shade Chart Ultimate Guide Helmets Lab

Welding Lens Selector Guide

Welding Shade Number Luminous Transmittance Safety Chart VS Eyewear

Metalwork Eye Protection Guide

Welding Lens Color Chart

What shade lens is used for welding & welding lens shade chart

Welding Safety Guide Jasic Blog

.jpg)

Parkson Safety Industrial Corp.

Welding Lens Shade Chart

What to look for in a welders helmet

Operation Electrode Size Arc Current (Amperes) Osha Minimum Protective Shade Number.

Web Lens Shade Number Guide.

See The Chart Below To Determine The Correct Shade Number For.

Web The Tables Below List The Minimum Protective Lens Shade Numbers For Commonly Used Welding And Cutting Processes.

Related Post: