Welding Cable Sizes Chart

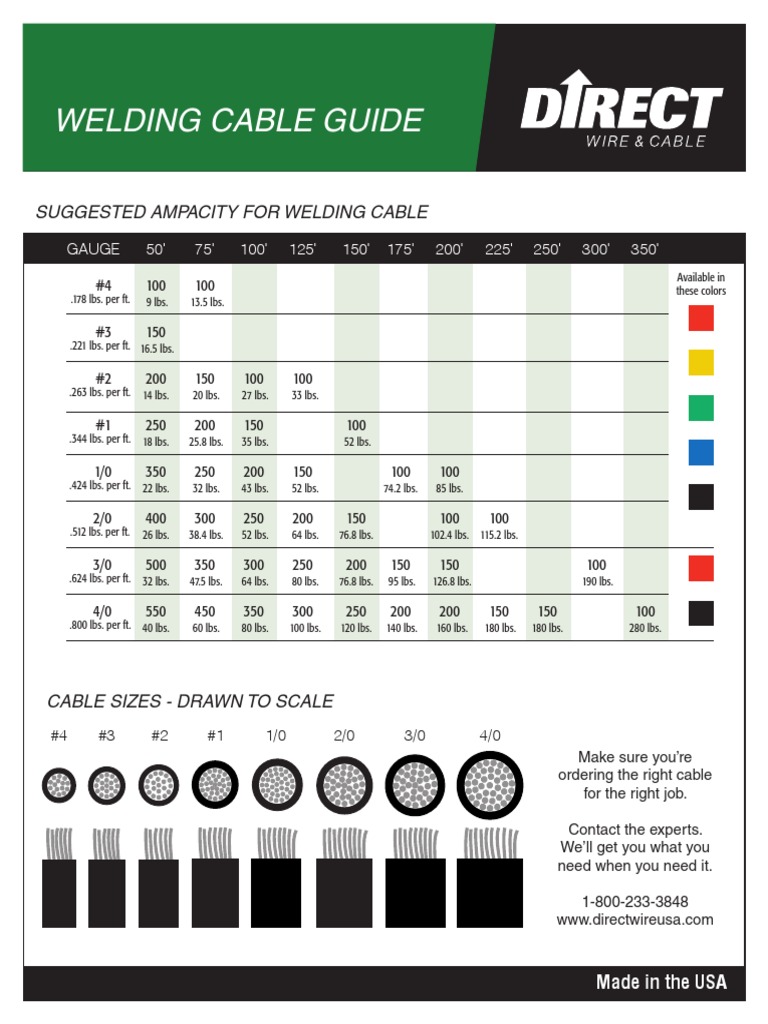

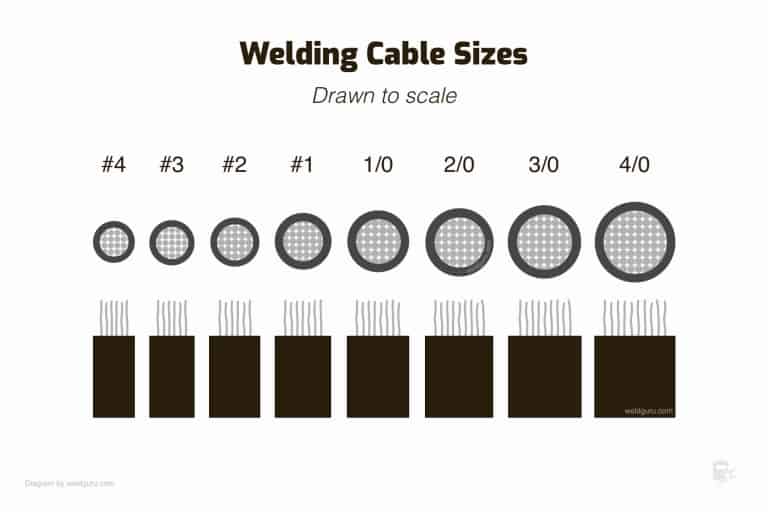

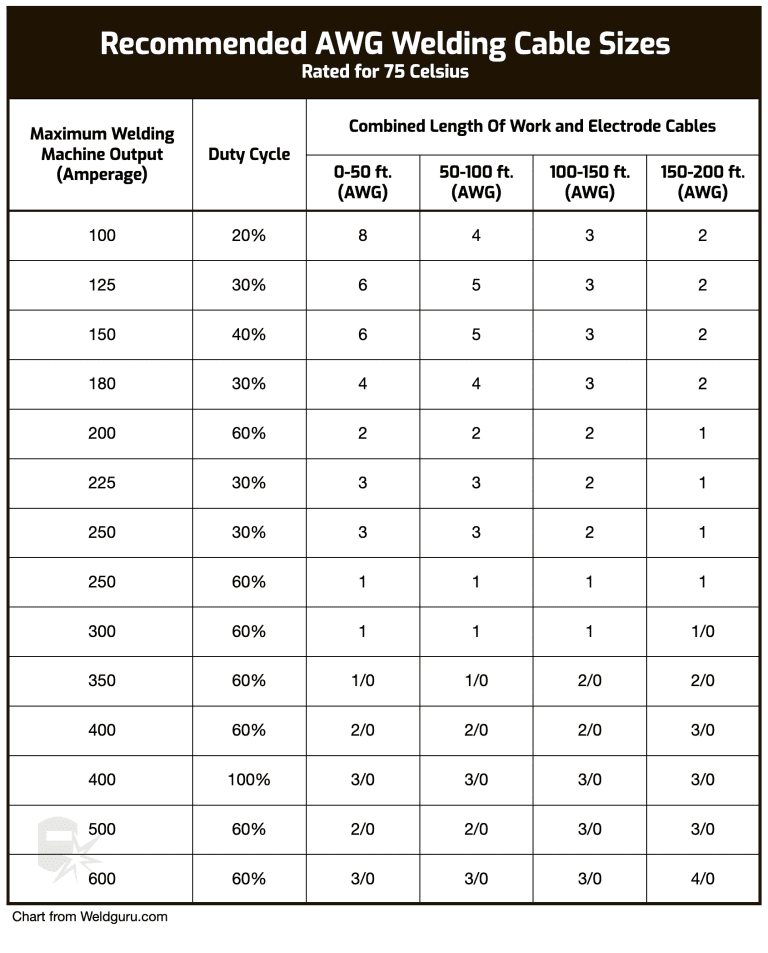

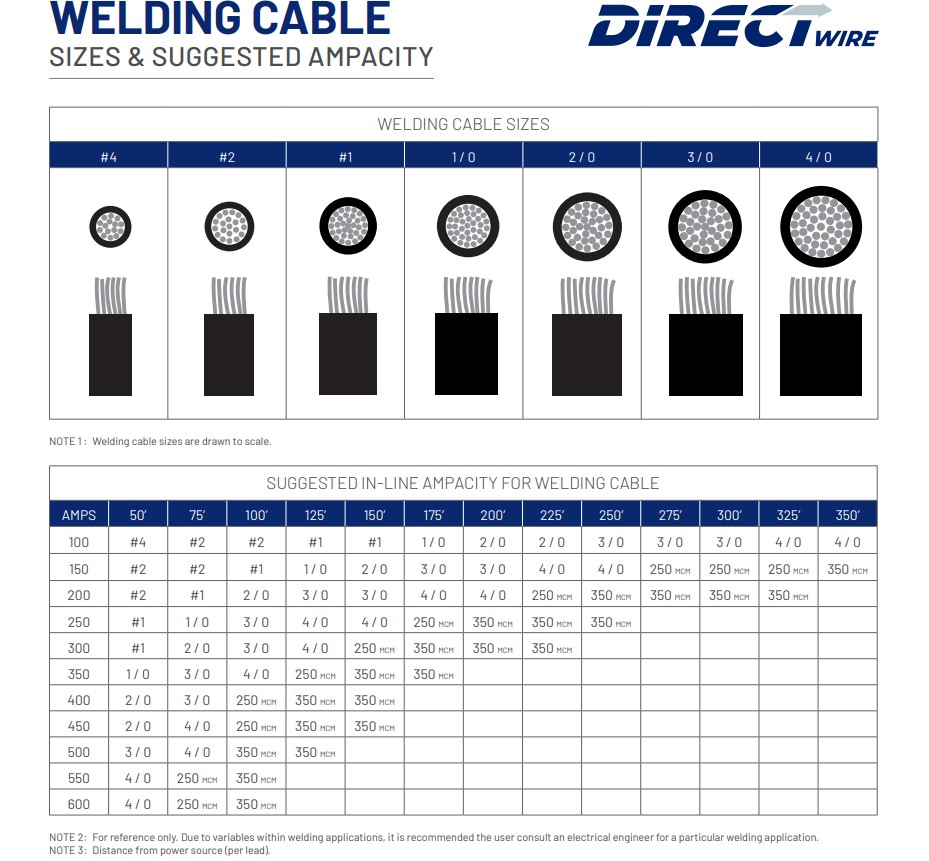

Welding Cable Sizes Chart - For higher current levels, two or more cables are often recommended and should be hooked up in parallel or together in order to share the current load. Awg sizes will have three numbers, for example, 2 awg 625/30. this means that the welding cable has a total cross sectional area of 2 awg and is made from 625 strands of 30 awg wire. This includes identifying specific criteria including minimum copper content, gauge sizing, electrical performance, and resistance for welding cable sizes. Web in this article, we’ll navigate the key points, from deciphering cable and lead size charts to pinpointing the exact cable size that fits your specific needs using guidance from aws f4.2:2020 handbook. This proactive approach minimizes voltage drop, ensures stable arc characteristics, and enhances overall welding quality. Cable sizes are dictated by many factors including the cable length, the amperage, the machine’s duty cycle, and the cable’s insulation rating. Web use the american wire gauge (awg) chart as a reference. Welding cable size is measured by the american wire gauge (awg) standard. For a hobby welder using less than 240 amps and less than 50 ft in combined cable length, a 1 gauge welding lead is. Figure 2 shows a comparison between welding cables in awg sizes and metric sizes. This includes identifying specific criteria including minimum copper content, gauge sizing, electrical performance, and resistance for welding cable sizes. Web for determining proper welding cable size, you need to add together the full lengths of the electrode cable and the work cable. Cable sizes are dictated by many factors including the cable length, the amperage, the machine’s duty cycle, and. Welding cable sizes are drawn to scale. Due to variables within welding applications, it is recommended the user consult an electrical engineer for a particular welding application. Understanding awg and metric cable sizes. Web use the american wire gauge (awg) chart as a reference. Welding cable size is measured by the american wire gauge (awg) standard. Awg sizes will have three numbers, for example, 2 awg 625/30. this means that the welding cable has a total cross sectional area of 2 awg and is made from 625 strands of 30 awg wire. How do we measure the welding cable sizes? Cable sizes are dictated by many factors including the cable length, the amperage, the machine’s duty. Due to variables within welding applications, it is recommended the user consult an electrical engineer for a particular welding application. Higher amperage and longer lead lengths require larger diameter cables (lower awg number) to minimize voltage drop, resistance, and cable overheating. Web this document provides guidance on the safe and proper selection of welding cables. Figure 2 shows a comparison. Web cable sizes between #4 and #4/0 are typically used for welding cable. The right welding cable size will help your work, while the wrong one will give you some problems. The total circuit length includes both welding and ground leads (based on 4. Welding cable sizes are drawn to scale. Utilize a cable size chart. The variation in sizes is essential for the normal performance of a welding machine. In this article, we will discuss how to choose the right welding cable sizes. Web use the american wire gauge (awg) chart as a reference. Higher amperage and longer lead lengths require larger diameter cables (lower awg number) to minimize voltage drop, resistance, and cable overheating.. Cable sizes are dictated by many factors including the cable length, the amperage, the machine’s duty cycle, and the cable’s insulation rating. Figure 2 shows a comparison between welding cables in awg sizes and metric sizes. Web cable sizes between #4 and #4/0 are typically used for welding cable. Cable sizes are increased for longer lengths primarily for the purpose. The electrode cable attaches to either an electrode holder, tig torch or wire feeder. The right welding cable size will help your work, while the wrong one will give you some problems. Web in this article, we’ll navigate the key points, from deciphering cable and lead size charts to pinpointing the exact cable size that fits your specific needs using. Web sizes & suggested ampacity. In this article, we will discuss how to choose the right welding cable sizes. Understand your power source output. Web consulting the welding cable size chart enables welders to match cable size with the anticipated welding current. To ensure your welding project works without a hitch, you should know your way around welding cables. Welding cable size is measured by the american wire gauge (awg) standard. Understand your power source output. To ensure your welding project works without a hitch, you should know your way around welding cables. The electrode cable attaches to either an electrode holder, tig torch or wire feeder. Welding cable sizes are drawn to scale. Web for determining proper welding cable size, you need to add together the full lengths of the electrode cable and the work cable. Therefore, you will have to match the amperage of the power to the proper cable size. The right welding cable size will help your work, while the wrong one will give you some problems. Web in order for a welding cable to be adequate for your specific setup, it must have an appropriate diameter. For a hobby welder using less than 240 amps and less than 50 ft in combined cable length, a 1 gauge welding lead is. Web use the american wire gauge (awg) chart as a reference. Web the welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness and type of welding. Welding cable size is measured by the american wire gauge (awg) standard. Awg sizes will have three numbers, for example, 2 awg 625/30. this means that the welding cable has a total cross sectional area of 2 awg and is made from 625 strands of 30 awg wire. For higher current levels, two or more cables are often recommended and should be hooked up in parallel or together in order to share the current load. Understand your power source output. Measure your welding circuit length. Cable sizes are dictated by many factors including the cable length, the amperage, the machine’s duty cycle, and the cable’s insulation rating. Welding cables have a significant role in welding industries for efficient working. The electrode cable attaches to either an electrode holder, tig torch or wire feeder. Utilize a cable size chart.Welding Cable Size Amperage Chart

![What Size Welding Leads Do I Need? [Welding Cable Chart] Beginner](https://beginnerweldingguide.com/wp-content/uploads/2023/01/awg-welding-cable-sizes.jpg)

What Size Welding Leads Do I Need? [Welding Cable Chart] Beginner

![Welding Cable [Price/Pricing/Cost, Sizes, Ampacity, Specs]](https://1xtechnologies.com/wp-content/uploads/2021/12/Welding-Cable-Specifications-Sizes-Amps-Ampacity-Weight-OD-Price-Cost-Buy-Manufacturers-2-1.png)

Welding Cable [Price/Pricing/Cost, Sizes, Ampacity, Specs]

Welding Cable Size Guide Charts & Tips for the Right Choice

Welding Cable Size What's Best? (with Chart)

Airgas

Selecting the Proper Size Welding Cables Fabricating and Metalworking

Welding Cable Size What’s Best? (with Chart)

![Welding Cable Sizes and Gauges explained Thoroughly [2024]](https://weldingpros.net/wp-content/uploads/2022/03/different-circular-mill.webp)

Welding Cable Sizes and Gauges explained Thoroughly [2024]

Welding Cable Size What's Best? (with Chart), 50 OFF

How Do We Measure The Welding Cable Sizes?

This Document Provides Guidance On The Safe And Proper Selection Of Welding Cables.

This Includes Identifying Specific Criteria Including Minimum Copper Content, Gauge Sizing, Electrical Performance, And Resistance For Welding Cable Sizes.

Figure 2 Shows A Comparison Between Welding Cables In Awg Sizes And Metric Sizes.

Related Post: