Weld Size Chart

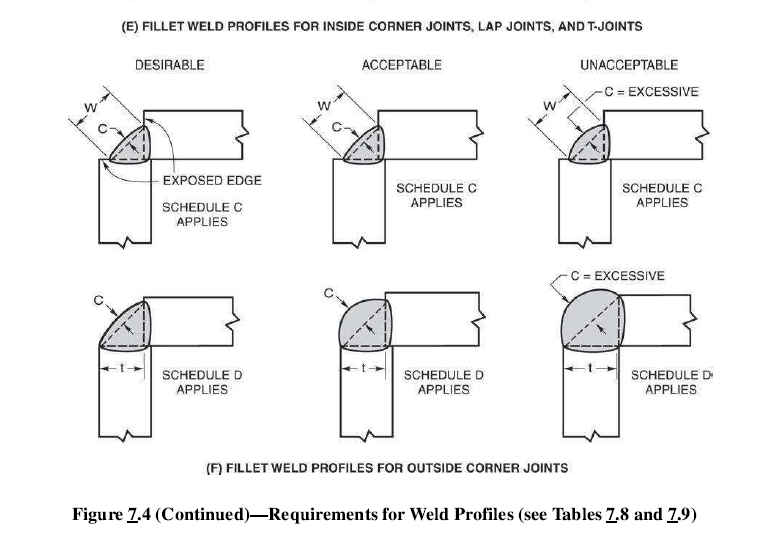

Weld Size Chart - Web if the plate thickness is unknown, you can always fall back to the default 6mm fillet weld size, with the minimum and maximum possible values being 3mm and 0.7t respectively. The american institute of steel construction specifies minimum fillet weld sizes based on the thickness of the material being welded. In this article, you’ll learn if you should calculate and note your weld sizes, instead of mostly leaving them to the designer. Ensure your welding meets specs with our comprehensive guide. Web built with convertkit. Fillet welds are employed in lap, t, and corner joint configurations, formed using various welding methods such as shielded metal arc welding (smaw) or gas metal arc welding (gmaw). Welding rods, under the fitting. Welding symbol chart (desk size) Maximum size of fillet weld. Web welding symbols are the integral part and the basic requirements for fabrication as they provide vital information for the welding joint location, weld size (throat or leg length, depth of penetration) & length, weld type & quality requirements for the fabrication or construction drawing. The fillet weld size will be the optimum weld size using this calculation and. Web the aws d 1.1 (structural welding code ― steel) code, table 7.7 (given below) specifies the minimum fillet weld size for each base material thickness. Welding rods, under the fitting. In this article, you’ll learn if you should calculate and note your weld sizes, instead. Web the size of a fillet weld should be calculated by the designer of the welded structure, based on the nature and magnitude of applied loads, on the material and on the design basis. Web welding symbols are the integral part and the basic requirements for fabrication as they provide vital information for the welding joint location, weld size (throat. Web click here for pdf version. Welding is a fundamental process in various industries, from construction to manufacturing, where the integrity and strength of the welded joints are paramount. Web discover effective techniques for how to measure a fillet weld size with precision. Central to ensuring the quality and durability of welded. (2) the size of an unequal leg fillet. There might be affiliate links in this post. Contents [ show] how to choose the right welding rod size. Web built with convertkit. The fillet weld size will be the optimum weld size using this calculation and. Web (1) the size of an equal leg fillet is the leg length of the largest inscribed right isosceles triangle. The fillet weld size will be the optimum weld size using this calculation and. Theoretical throat = 0.7 × size of weld. Web if the plate thickness is unknown, you can always fall back to the default 6mm fillet weld size, with the minimum and maximum possible values being 3mm and 0.7t respectively. Leg length of a fillet weld, (2). The minimum fillet size requirement. The fillet weld size will be the optimum weld size using this calculation and. Welding rods, under the fitting. (2) the size of an unequal leg fillet weld is the shorter leg length of the largest right triangle that can be inscribed within the fillet weld cross section. Meaning welding anything bigger would be total. The welding rod should be thinner than the base metal, but not thinner than half of the base metal. In this article, you’ll learn if you should calculate and note your weld sizes, instead of mostly leaving them to the designer. Buying through them can earn us a small commission at no cost to you. Theoretical throat = 0.7 ×. Leg length of a fillet weld, Maximum size of fillet weld. The primary factor when choosing the size of a welding rod is the thickness of the base metal that’s going to be welded. These legs form a triangle, and the effective throat determines the effective area of the weld after multiplying this distance by the effective length (see figure).. The welding rod should be thinner than the base metal, but not thinner than half of the base metal. Web 2.2.3 weld size and length. The minimum fillet size requirement. This provides a uniform welding gap between the curvature of the run and base of fitting. Web (1) the size of an equal leg fillet is the leg length of. Theoretical throat = 0.7 × size of weld. Web welding symbols are the integral part and the basic requirements for fabrication as they provide vital information for the welding joint location, weld size (throat or leg length, depth of penetration) & length, weld type & quality requirements for the fabrication or construction drawing. Leg length of a fillet weld, The. Web welding symbols are the integral part and the basic requirements for fabrication as they provide vital information for the welding joint location, weld size (throat or leg length, depth of penetration) & length, weld type & quality requirements for the fabrication or construction drawing. The primary factor when choosing the size of a welding rod is the thickness of the base metal that’s going to be welded. Web built with convertkit. Meaning welding anything bigger would be total waste with no added benefits. Fillet welds are employed in lap, t, and corner joint configurations, formed using various welding methods such as shielded metal arc welding (smaw) or gas metal arc welding (gmaw). This covers our wages and keeps our resources free to use. This provides a uniform welding gap between the curvature of the run and base of fitting. Theoretical throat = 0.7 × size of weld. Web if the plate thickness is unknown, you can always fall back to the default 6mm fillet weld size, with the minimum and maximum possible values being 3mm and 0.7t respectively. Buying through them can earn us a small commission at no cost to you. Top row in inches / bottom row in millimeters. Web this post gives simple calculations for determining the minimum and maximum fillet weld sizes to withstand the maximum stresses at the weld. Maximum size of fillet weld. Ensure your welding meets specs with our comprehensive guide. The minimum fillet size requirement. The welding rod should be thinner than the base metal, but not thinner than half of the base metal.

Welding Rod Sizes Here's The Complete Guide

Welding Rod Sizes And Uses Pdf

Fillet Weld Size Chart

MIG welder settings explained Amperage & Wire Speed

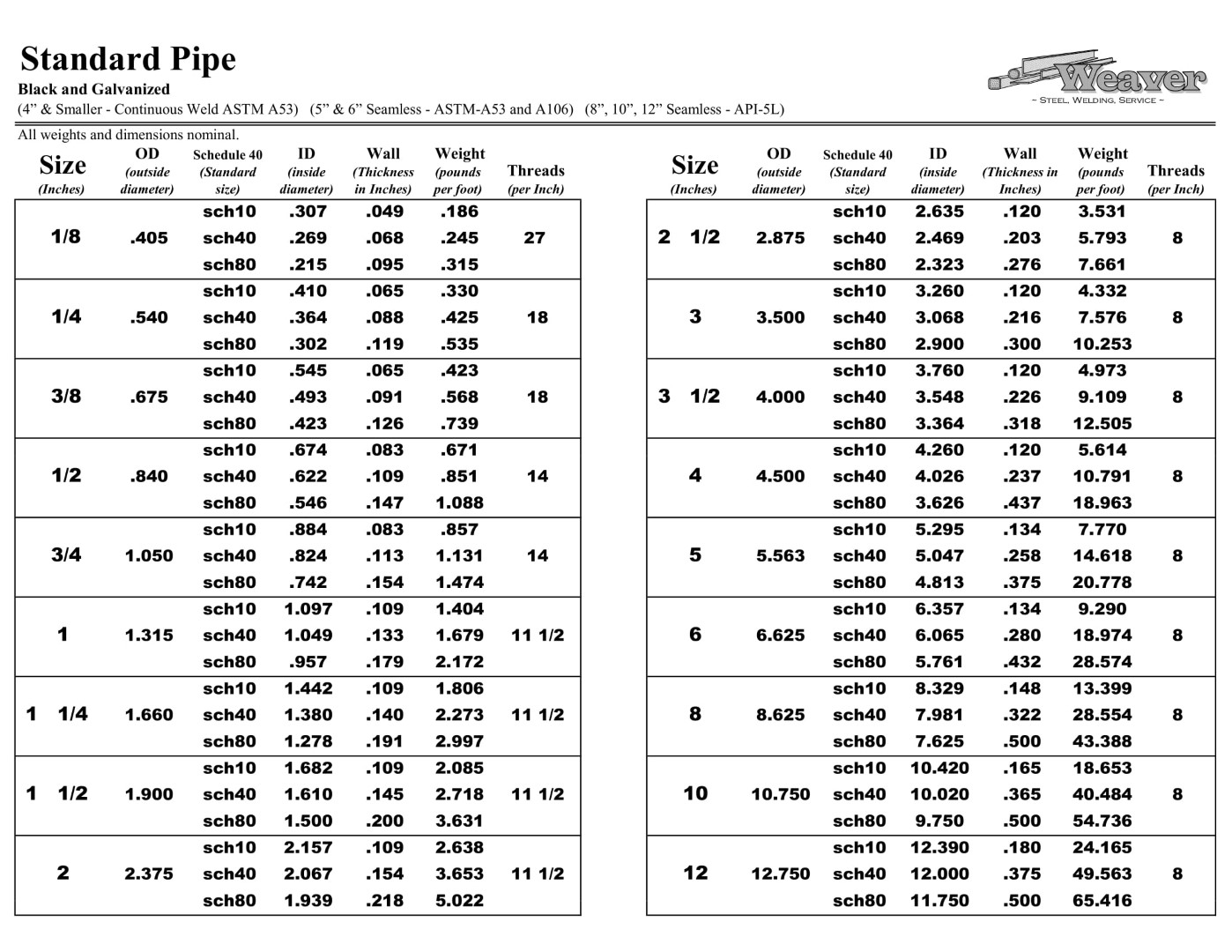

Pipe Size Chart Weaver Steel Welding

Mig welding how to set up your welder from a to z Artofit

Fillet Weld Size Chart

Fillet Weld Sizing Guidelines OnestopNDT

Weld Length for Ismc Metalworking Chemistry

Weldolet Chart

Welding Is A Fundamental Process In Various Industries, From Construction To Manufacturing, Where The Integrity And Strength Of The Welded Joints Are Paramount.

Web Discover Effective Techniques For How To Measure A Fillet Weld Size With Precision.

Methods For The Calculation Of Fillet Weld Sizes Are Explained Here.

These Legs Form A Triangle, And The Effective Throat Determines The Effective Area Of The Weld After Multiplying This Distance By The Effective Length (See Figure).

Related Post: