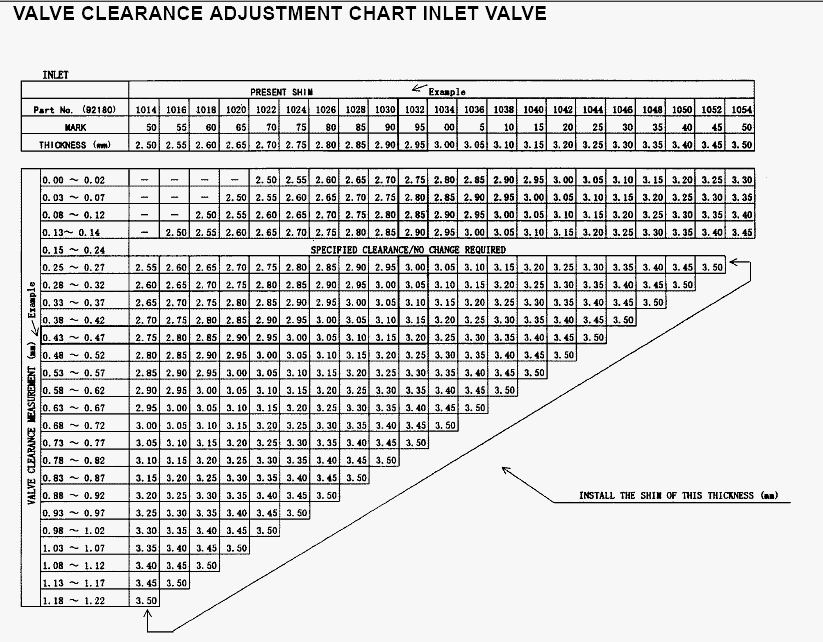

Valve Clearance Chart

Valve Clearance Chart - Therefore, use the dial gauge and check the amount of valve lift. Valve clearances should always be adjusted on a cold engine. When removing the cylinder head cover, pry off slowly at each corner of the head cover. Experts also suggest adding.030 to each valve if the engine is equipped with aluminum rods as they tend to stretch more than steel. Web tappet clearance, also known as valve clearance, is the small gap between the rocker arm and the top of the valve stem (yoke). Intake and exhaust clearances for briggs & stratton engines used on a variety of outdoor power equipment applications. How to adjust the valve clearance on a briggs and stratton single cylinder overhead valve engine. Web find the correct valve clearances for inlet and exhaust valves, and whether they should be adjusted with the engine hot or cold. 1 cylinder just as if we were degreeing. Web measure the valve clearance (see step (a)). Then shade in the arrows to indicate which valve can be adjusted when the engine is at the #1 tdc position and when the engine is in the #4 tdc position. Turn the ignition switch to the lock (off) position. (1) turn the camshaft so that the cam lobe for the valve to be adjusted faces up. Engineers can observe. In the squares above the valve rocker arm diagram, indicate the valve clearance each rocker arm should be adjusted to. Check the valve clearance by placing a feeler gauge between the valve head and the rocker arm. What do i need to watch out for when replacing and repairing valves? Check the valve clearance by placing a feeler gauge between. Consequential damage to valves can often be caused by old and worn valve guides. Then shade in the arrows to indicate which valve can be adjusted when the engine is at the #1 tdc position and when the engine is in the #4 tdc position. Valve clearances should always be adjusted on a cold engine. 82k views 3 years ago. They will be used later to determine the required replacement adjusting shim. Web valve adjustment is the process of adjusting the clearance between the valve stem and the rocker arm or camshaft. Intake and exhaust clearances for briggs & stratton engines used on a variety of outdoor power equipment applications. Web the oil clearance between the arm and the shaft. Web feeler gauge/ leaf gauge you will ned to check valve clearance: Web valve adjustment is the process of adjusting the clearance between the valve stem and the rocker arm or camshaft. In the squares above the valve rocker arm diagram, indicate the valve clearance each rocker arm should be adjusted to. Remove the four 6 x 12 mm flange. (.find tdc, get our your feeler gauges, and write down the clearances) Web find the correct valve clearances for inlet and exhaust valves, and whether they should be adjusted with the engine hot or cold. Check the valve clearance by placing a feeler gauge between the valve head and the rocker arm. Turn the ignition switch to the lock (off). (3) using sst (a), press down the valve lifter and place Check the valve clearance by placing a feeler gauge between the valve head and the rocker arm. Therefore, use the dial gauge and check the amount of valve lift. (.find tdc, get our your feeler gauges, and write down the clearances) Remove the four 6 x 12 mm flange. Web find small engine specifications using your model number for maintenance & replacement parts on your briggs & stratton engine! Check the valve clearance by placing a feeler gauge between the valve head and the rocker arm. Remove the rocker cover assembly. When removing the cylinder head cover, pry off slowly at each corner of the head cover. Also learn. This clearance is essential for proper engine operation. Web the exhaust valves are the most likely to be out, but there is some tolerance; Chances are though, at least one of the gaps will need adjusting. Web valve adjustment is the process of adjusting the clearance between the valve stem and the rocker arm or camshaft. They will be used. Check the valve clearance by placing a feeler gauge between the valve head and the rocker arm. Check the valve clearance by placing a feeler gauge between the valve head and the rocker arm. The first thing we'll need to do is establish top dead center (tdc) on the no. Adjust the clearances as required by turning the rocker screw.. Chances are though, at least one of the gaps will need adjusting. Web briggs and stratton valve clearances. 82k views 3 years ago 12 union st. Place the engine upright with the cylinder head cover facing up. (1) turn the camshaft so that the cam lobe for the valve to be adjusted faces up. Intake and exhaust clearances for briggs & stratton engines used on a variety of outdoor power equipment applications. Let the engine be in cold state. In the squares above the valve rocker arm diagram, indicate the valve clearance each rocker arm should be adjusted to. Check the valve clearance by placing a feeler gauge between the valve head and the rocker arm. Then shade in the arrows to indicate which valve can be adjusted when the engine is at the #1 tdc position and when the engine is in the #4 tdc position. (.find tdc, get our your feeler gauges, and write down the clearances) How to remove briggs and stratton engine from lawn. Adjust valve clearance (a) remove the adjusting shim. Engineers can observe and adjust tappet clearance only when the valves are in a closed position and. Checking and adjusting valve clearances for optimal engine performance!in this comprehensive tutorial, we dive deep into the critical process. Valve clearances should always be adjusted on a cold engine.

Valve Clearance Check and Adjustment

Small Engine Valve Clearance Chart

VALVE CLEARANCE ADJUSTMENT CHART EXHAUST VALVE

Honda Valve Clearance Chart

Ohv Briggs And Stratton Valve Clearance Chart

Ohv Briggs And Stratton Valve Clearance Chart

Valve Clearance Check and Adjustment

2004 GMC Truck Sierra 2500HD 4WD 6.0L FI OHV 8cyl Repair Guides

Repair Guides Engine Mechanical Components Valve Lash (clearance

Versys Ventures, and more Kawasaki 1000 Valve Clearances

Experts Also Suggest Adding.030 To Each Valve If The Engine Is Equipped With Aluminum Rods As They Tend To Stretch More Than Steel.

Web Find The Correct Valve Clearances For Inlet And Exhaust Valves, And Whether They Should Be Adjusted With The Engine Hot Or Cold.

If The Clearance Is Too Small, The Valve May Not Fully Close, Causing A Loss Of Power And Increased Engine Wear.

Check Only The Valves Indicated.

Related Post: