Torque Wheel Nuts Chart

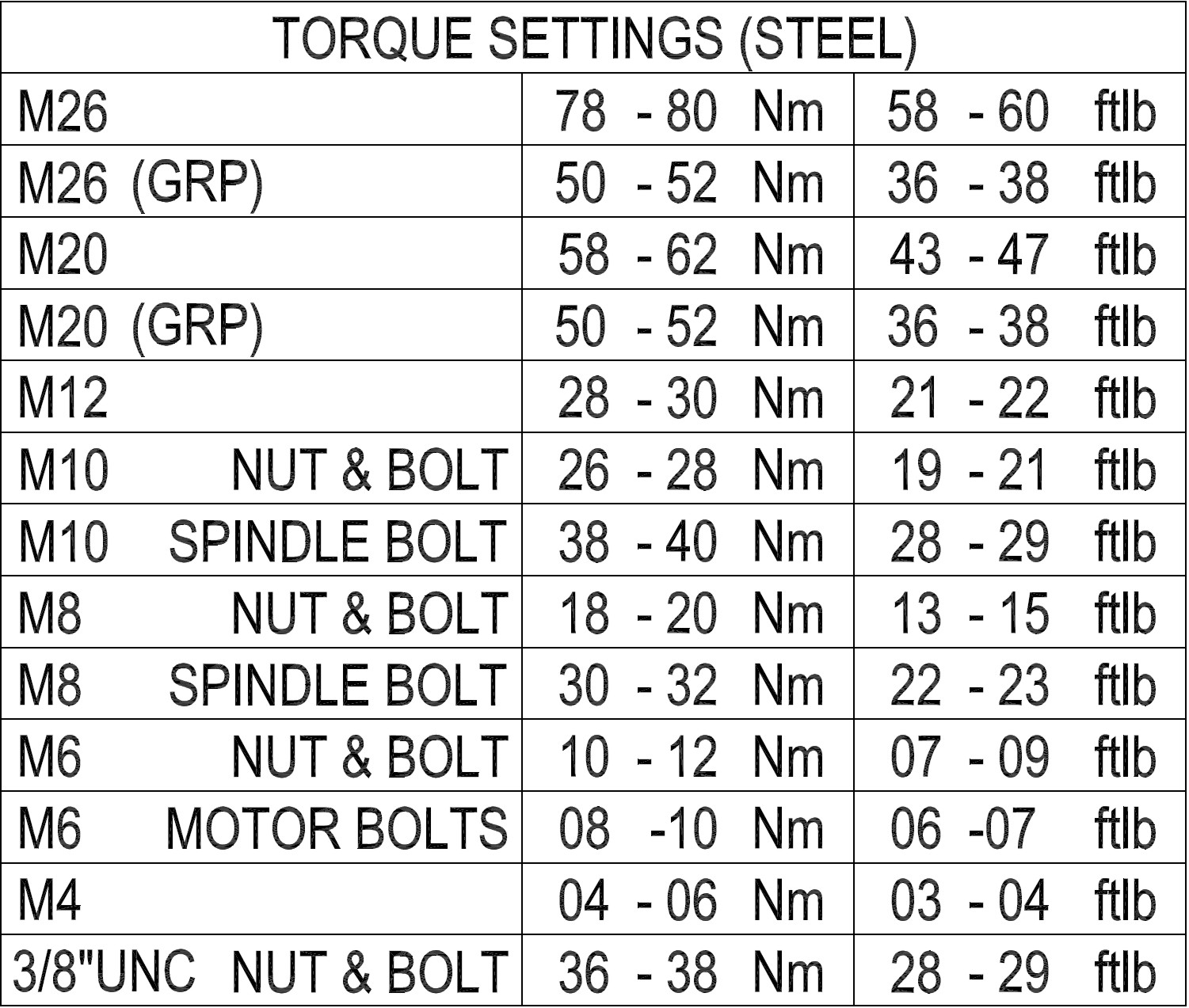

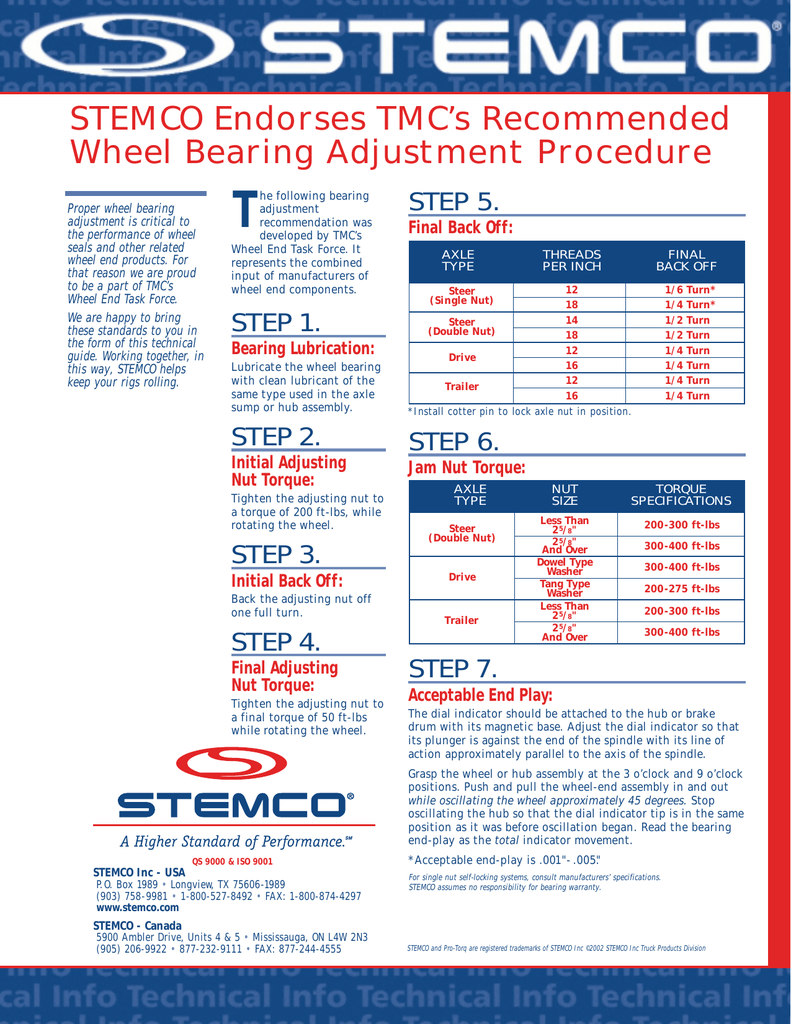

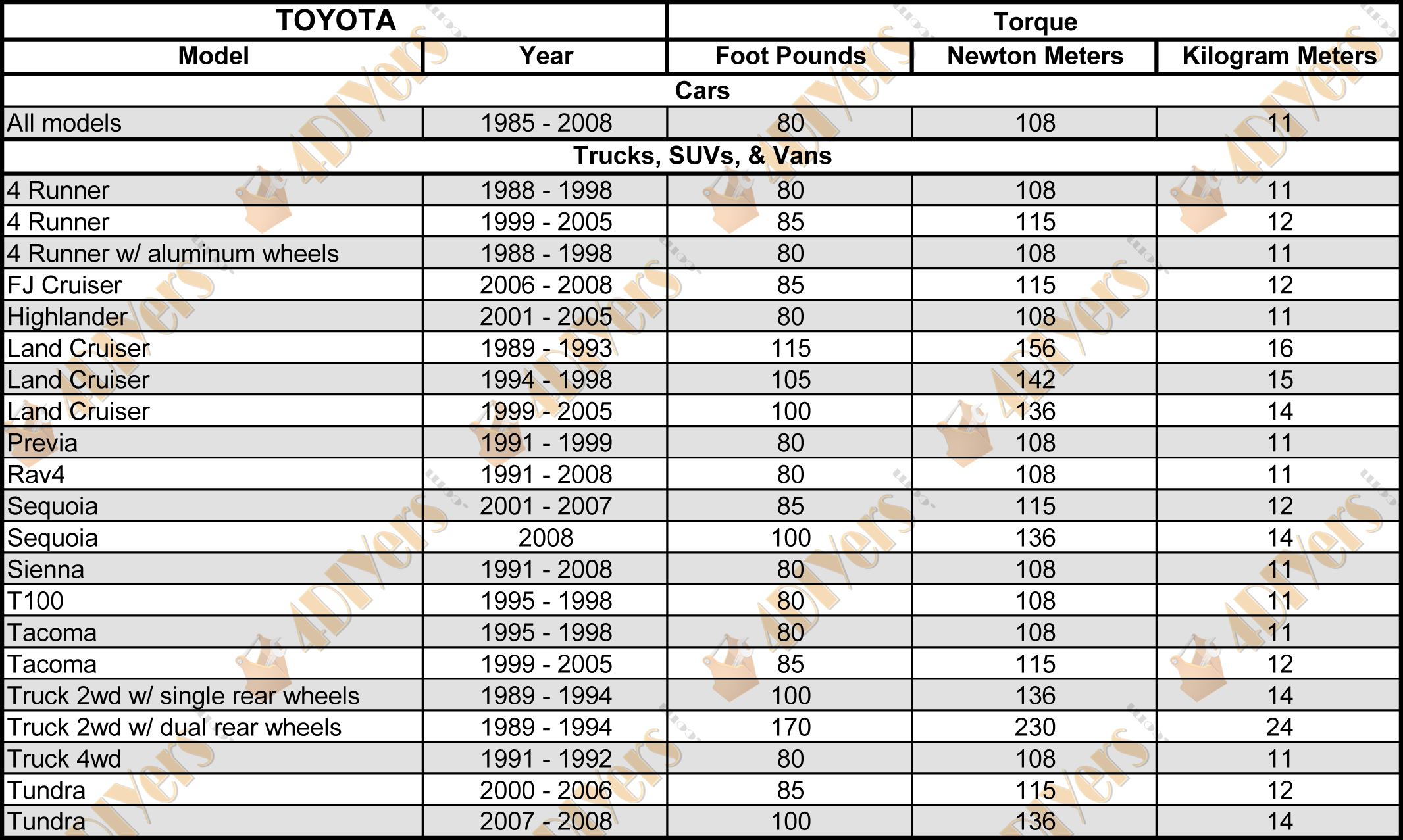

Torque Wheel Nuts Chart - Because the wheel size and the vehicle weight significantly influence the required torque. How tight do they need to be in order to hold the hub securely while avoiding damage? Now, why does size matter here? Web torque the lug nuts in two steps, starting at 40 ft/lbs of torque for your first step to get the wheel seated properly. Web a key issue when mounting the wheels is the torque of the wheel bolts. Web torquing lug nuts and bolts correctly is a vital part of making sure your tire and wheel assembly rides smoothly, wears evenly and performs as expected. Ensure you have the correct torque specifications for your specific toyota hilux model and year. How to properly torque the wheel nuts on a toyota hilux. Appointments find a store tips & guides. However, if these factory settings are not maintained during ownership, wheel nuts can become either too loose or too tight. Web find out more about your car's wheel fasteners — correct lug nut size, torque, and thread pitch You can learn all about it in this article. Because the wheel size and the vehicle weight significantly influence the required torque. Web torquing lug nuts and bolts correctly is a vital part of making sure your tire and wheel assembly rides. To achieve proper torque, you need to use a calibrated torque wrench at the proper torque level. Web torquing lug nuts and bolts correctly is a vital part of making sure your tire and wheel assembly rides smoothly, wears evenly and performs as expected. Web it is also important to tighten lug nuts or bolts incrementally to the final torque. To ensure the correct torque is applied to your vauxhall mokka’s wheel nuts, follow these steps: A star pattern, or crisscross sequence, is crucial to ensure an even distribution of torque across the wheel. Web a lug nut torque spec chart provides the proper torque specifications for your car’s wheels. What can we help you find? Web find out more. To achieve proper torque, you need to use a calibrated torque wrench at the proper torque level. Improper torque can lead to wheel hub movement and allow potential damage to the wheel hub and surrounding components. The tire lug nuts should also be properly torqued to secure the wheel to the wheel hub. Web torque the lug nuts in two. Web find out more about your car's wheel fasteners — correct lug nut size, torque, and thread pitch Web torquing lug nuts and bolts correctly is a vital part of making sure your tire and wheel assembly rides smoothly, wears evenly and performs as expected. Join club5 at tire supply network and save 5% on every order! Refer to the. To ensure the correct torque is applied to your vauxhall mokka’s wheel nuts, follow these steps: Finding the proper torque for lug nuts and lug bolts is the first step and can usually be found in the vehicles owner's manual. Web a lug nut torque spec chart provides the proper torque specifications for your car’s wheels. Be sure knuckle is. Web proper seating of the wheel hub to knuckle attachment. Starting at the top (12 o’clock), then the bottom (6 o’clock), then crisscross pattern until complete. The graphic below shows the three common bolt patterns and tightening sequences,. Tighten in a star pattern to evenly distribute the load and prevent warping. Simply download the pdf and print it out to. Read on to learn more about the lug nut torque, its specs, and how to read its spec chart. You can learn all about it in this article. To achieve proper torque, you need to use a calibrated torque wrench at the proper torque level. The lug nut should move at least a quarter turn before you arrive at final. How to properly torque the wheel nuts on a toyota hilux. Using a torque wrench, attach the appropriate socket size to the wrench. Because the wheel size and the vehicle weight significantly influence the required torque. Web table of torque values per model. Now, why does size matter here? Find the wheel torque specs for your vehicle. Web to make sure you’ve got the right torque for your lug nuts, we’ve created a free and printable lug nut torque chart pdf. Refer to the chart above. Then for the final torque refer to our chart below for torque recommendations based on your lug nut thread size. The tire lug. Because the wheel size and the vehicle weight significantly influence the required torque. However, if these factory settings are not maintained during ownership, wheel nuts can become either too loose or too tight. Simply download the pdf and print it out to keep in your car. It serves as a guide to making sure you apply the right amount of force when installing the lug nuts. The lug nut should move at least a quarter turn before you arrive at final torque. Join club5 at tire supply network and save 5% on every order! Tighten in a star pattern to evenly distribute the load and prevent warping. This involves using a torque wrench to apply the specified amount of force to each lug nut in a star or crisscross pattern. Then for the final torque refer to our chart below for torque recommendations based on your lug nut thread size. A star pattern, or crisscross sequence, is crucial to ensure an even distribution of torque across the wheel. The tire lug nuts should also be properly torqued to secure the wheel to the wheel hub. Web it is also important to tighten lug nuts or bolts incrementally to the final torque specification and doing so in the proper sequence. To achieve proper torque, you need to use a calibrated torque wrench at the proper torque level. Web proper seating of the wheel hub to knuckle attachment. Read on to learn more about the lug nut torque, its specs, and how to read its spec chart. Web torquing lug nuts and bolts correctly is a vital part of making sure your tire and wheel assembly rides smoothly, wears evenly and performs as expected.

Support Hepworth WWT

Axle Nut Torque Specs Chart Best Picture Of Chart

Axle Nut Torque Specs Chart

Bmw Lug Nut Torque Chart

KTool International KTI30103A K Tool Wheel Nut Torque Charts Summit

Truck Wheel Nut Torque Chart

2020 Gmc Terrain Lug Nut Torque

Wheel Nut Torque Specifications Chart

K Tool International KTI30103A Ktool 2019 Torque Chart, Wheel Nut Torq

Torque Charts Industrial Bolting and Torque Tools

Web Bump The Lug Nuts On.

Web Find Out More About Your Car's Wheel Fasteners — Correct Lug Nut Size, Torque, And Thread Pitch

Web Lug Nut Torque Chart (202*Lntc) 5 Reviews.

Proper Wheel Nut Torquing Procedure.

Related Post: