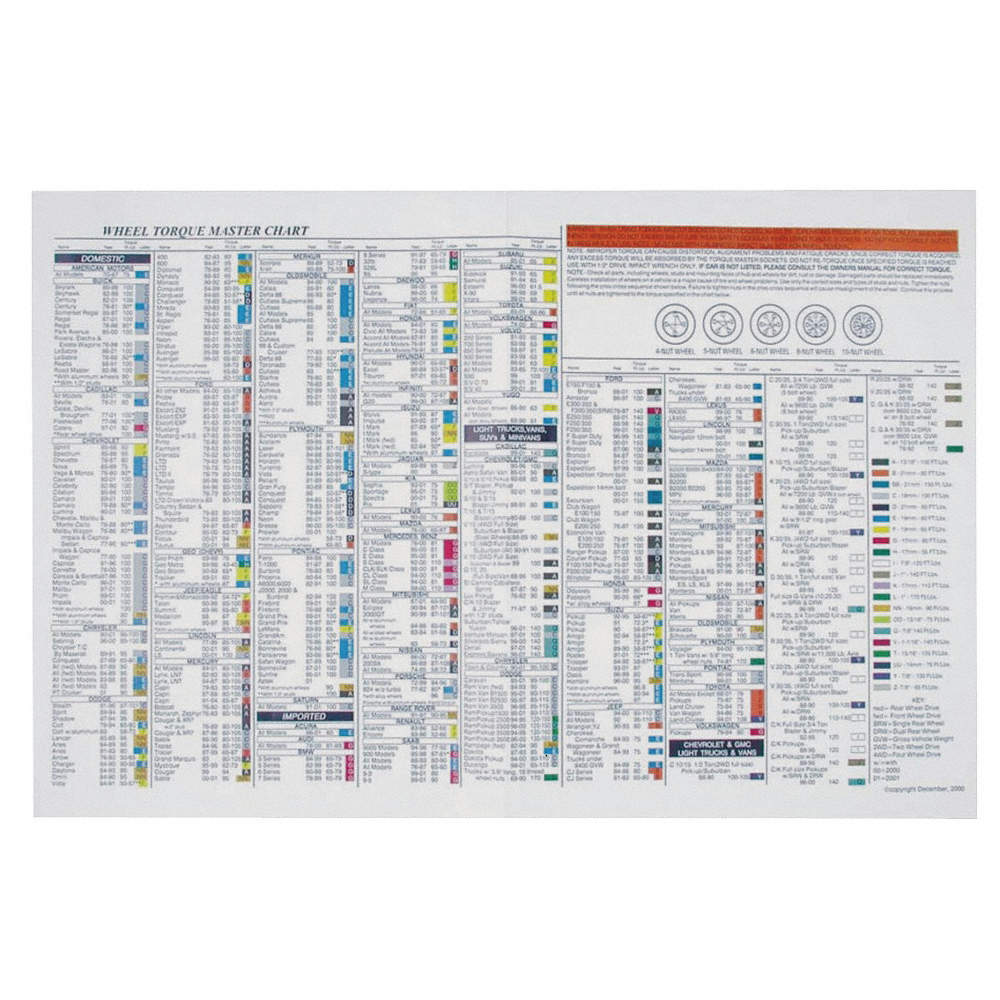

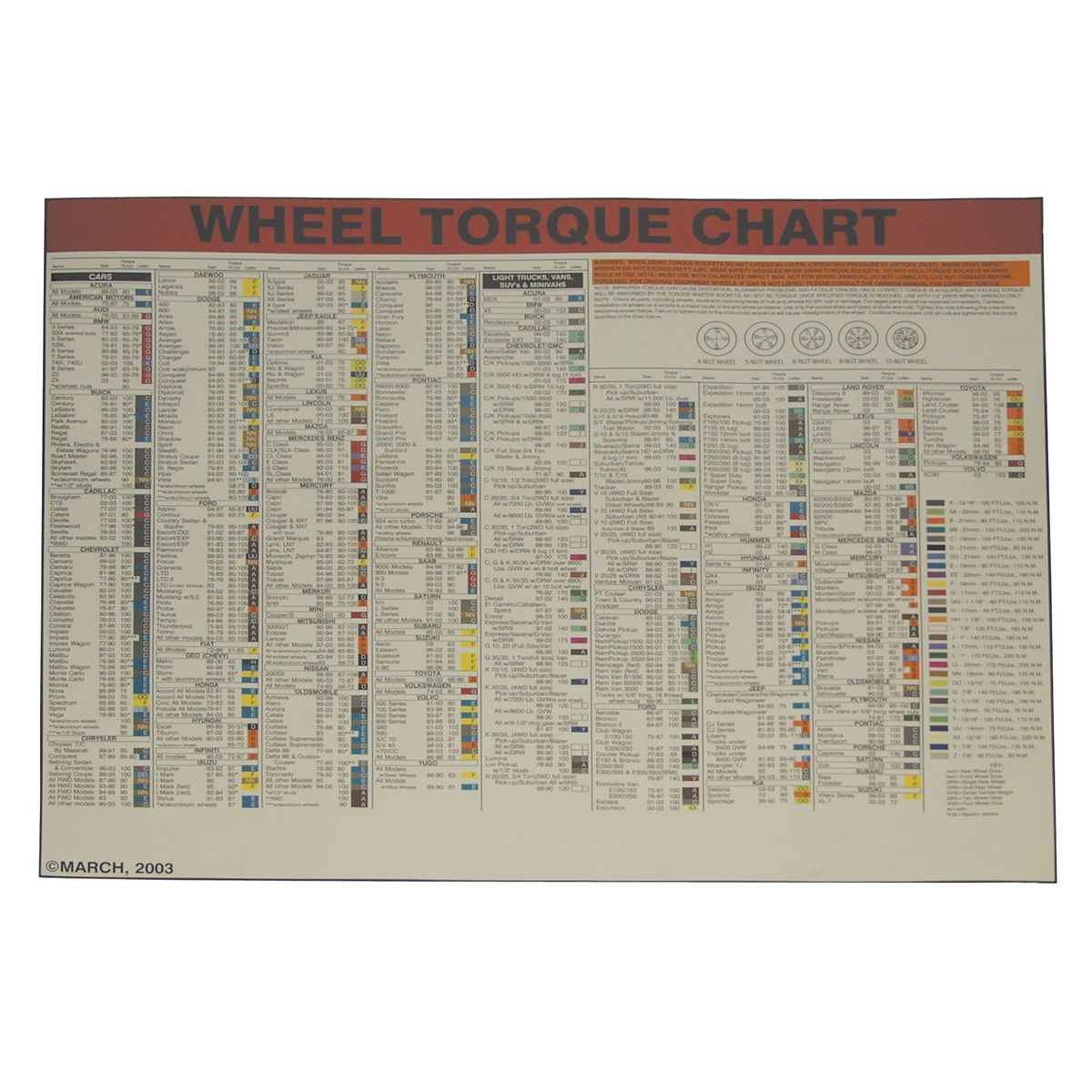

Torque Wheel Chart

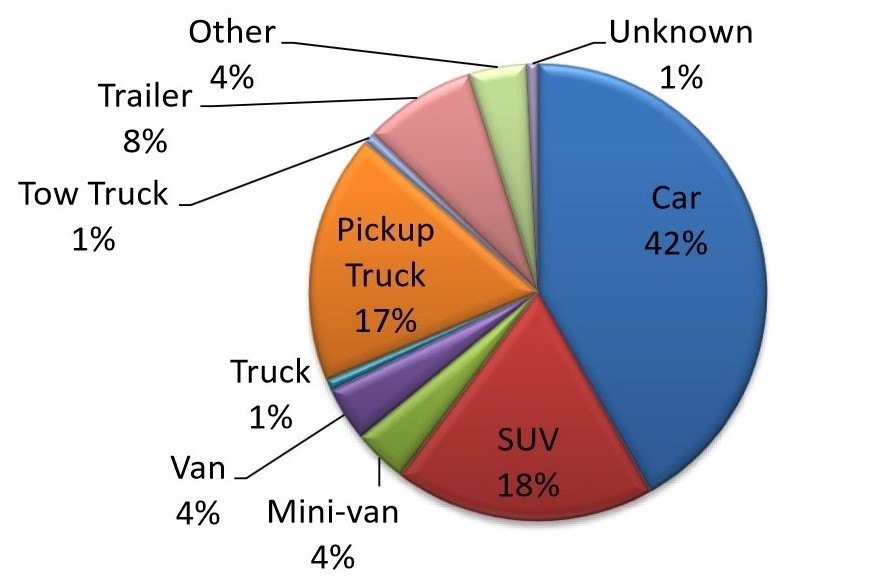

Torque Wheel Chart - Web torque the lug nuts in two steps, starting at 40 ft/lbs of torque for your first step to get the wheel seated properly. This info is often in the owner’s manual or a certified chart from the manufacturer. How tight do they need to be in order to hold the hub securely while avoiding damage? Proper wheel torque sequence is critical for installation and to ensure safety on the road. How to torque wheel lug nuts and free torque info. 1.2 proper installation and torque specifications. Web wheel nut torque specifications (shown in ft. The contents are the most current available. It is prudent to recheck the torque specifications after a test drive of the vehicle, especially with alloy or. Web 1.1 types and sizes of lug nuts. Web torque for mechanics is simply a twisting or turning motion around the axis of the thread. Generally, the higher the rotational resistance, the greater tension in the threaded fastener. This info is often in the owner’s manual or a certified chart from the manufacturer. Rotating tires and installing new wheels are jobs that many of us can handle ourselves.. Torque wrench considerations and calibrations; What are wheel torque specs? (2) inspect the bolts with washers to ensure that the washer is not damaged and is correctly. A key issue when mounting the wheels is the torque of the wheel bolts. Always consult the parts catalog for correct hub bolts. 2 applying the correct torque. Rotating tires and installing new wheels are jobs that many of us can handle ourselves. It serves as a guide to making sure you apply the right amount of force when installing the lug nuts. Can i fasten my wheel nuts too much? Simply download the pdf and print it out to keep in your. The contents are the most current available. Fitting wheels to a car is not difficult, but this does not mean that caution is not required. Web before you start, check the car wheel nut torque settings specific to your vehicle and apply them to the torque wrench. A key issue when mounting the wheels is the torque of the wheel. Web torque for mechanics is simply a twisting or turning motion around the axis of the thread. Web the tire lug nuts should also be properly torqued to secure the wheel to the wheel hub. The contents are the most current available. Web the graphic below shows the three common bolt patterns and tightening sequences, appropriate for most automotive applications.. Rotating tires and installing new wheels are jobs that many of us can handle ourselves. Finding the proper torque for lug nuts and lug bolts is the first step and can usually be found in the vehicles owner's manual. It serves as a guide to making sure you apply the right amount of force when installing the lug nuts. Web. Web torquing lug nuts and bolts correctly is a vital part of making sure your tire and wheel assembly rides smoothly, wears evenly and performs as expected. Within minutes, you can complete the task and get back on the road. How to torque wheel lug nuts and free torque info. Web before you start, check the car wheel nut torque. For a307 grade a, 75% of 36,000 psi is utilized. What can we help you find? Potential loss of wheel or broken wheel studs can occur if torque speciication is not correct. How to torque wheel lug nuts and free torque info. Fitting wheels to a car is not difficult, but this does not mean that caution is not required. Web the graphic below shows the three common bolt patterns and tightening sequences, appropriate for most automotive applications. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75% of the proof loads specified by the standard. But doing the job right requires more than. Simply download the pdf and print it out to keep in your car. Finding the proper torque for lug nuts and lug bolts is the first step and can usually be found in the vehicles owner's manual. How do i know how much torque my wheels need? Proper wheel torque sequence is critical for installation and to ensure safety on. Appointments find a store tips & guides. Web the tire lug nuts should also be properly torqued to secure the wheel to the wheel hub. The contents are the most current available. Is it important to follow a specific pattern when tightening lug nuts? (2) inspect the bolts with washers to ensure that the washer is not damaged and is correctly. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75% of the proof loads specified by the standard. How do i know how much torque my wheels need? 2.2 adhering to torque patterns and specifications. Always consult the parts catalog for correct hub bolts. How do i get the right torque for my wheels? Torque wrench considerations and calibrations; Fitting wheels to a car is not difficult, but this does not mean that caution is not required. Web a specialized tool known as a torque wrench is used to set a fastener’s torque. How tight do they need to be in order to hold the hub securely while avoiding damage? Do it once and do it right. Generally, the higher the rotational resistance, the greater tension in the threaded fastener.

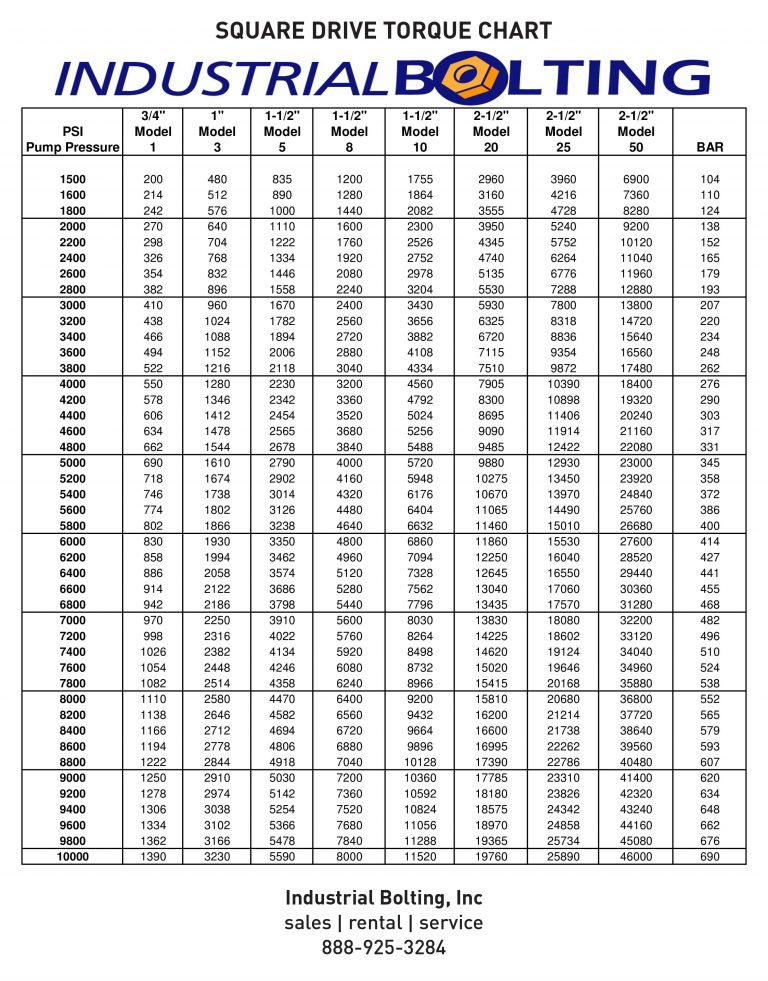

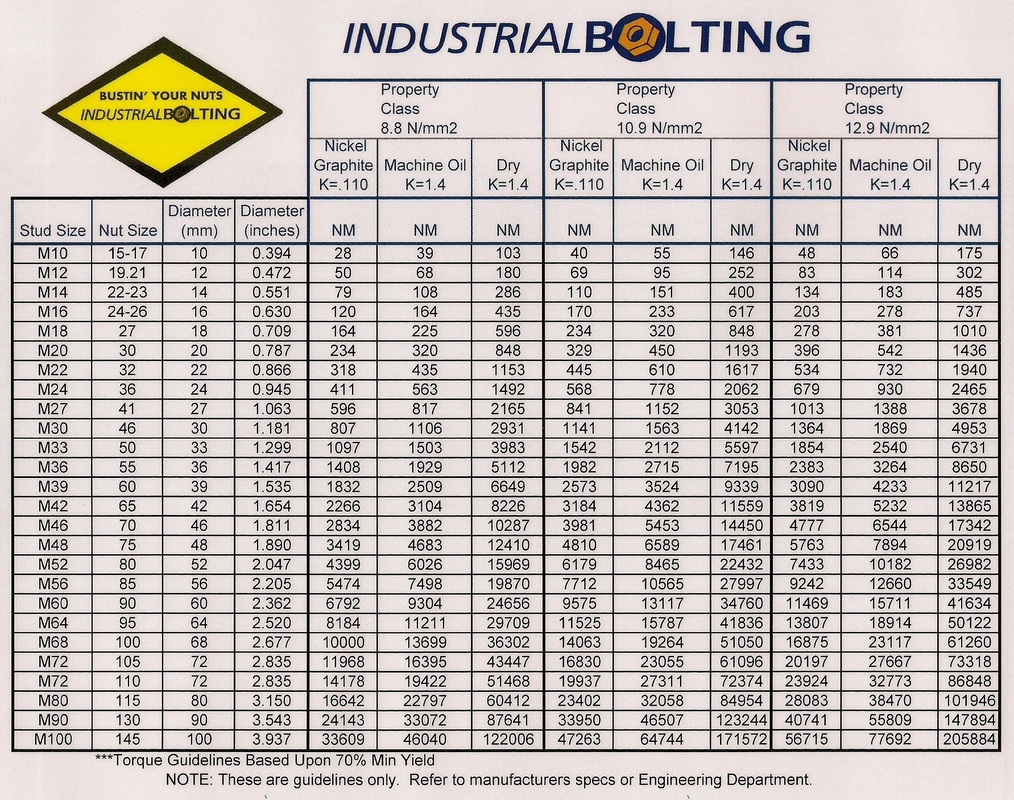

Torque Charts Industrial Torque Tools

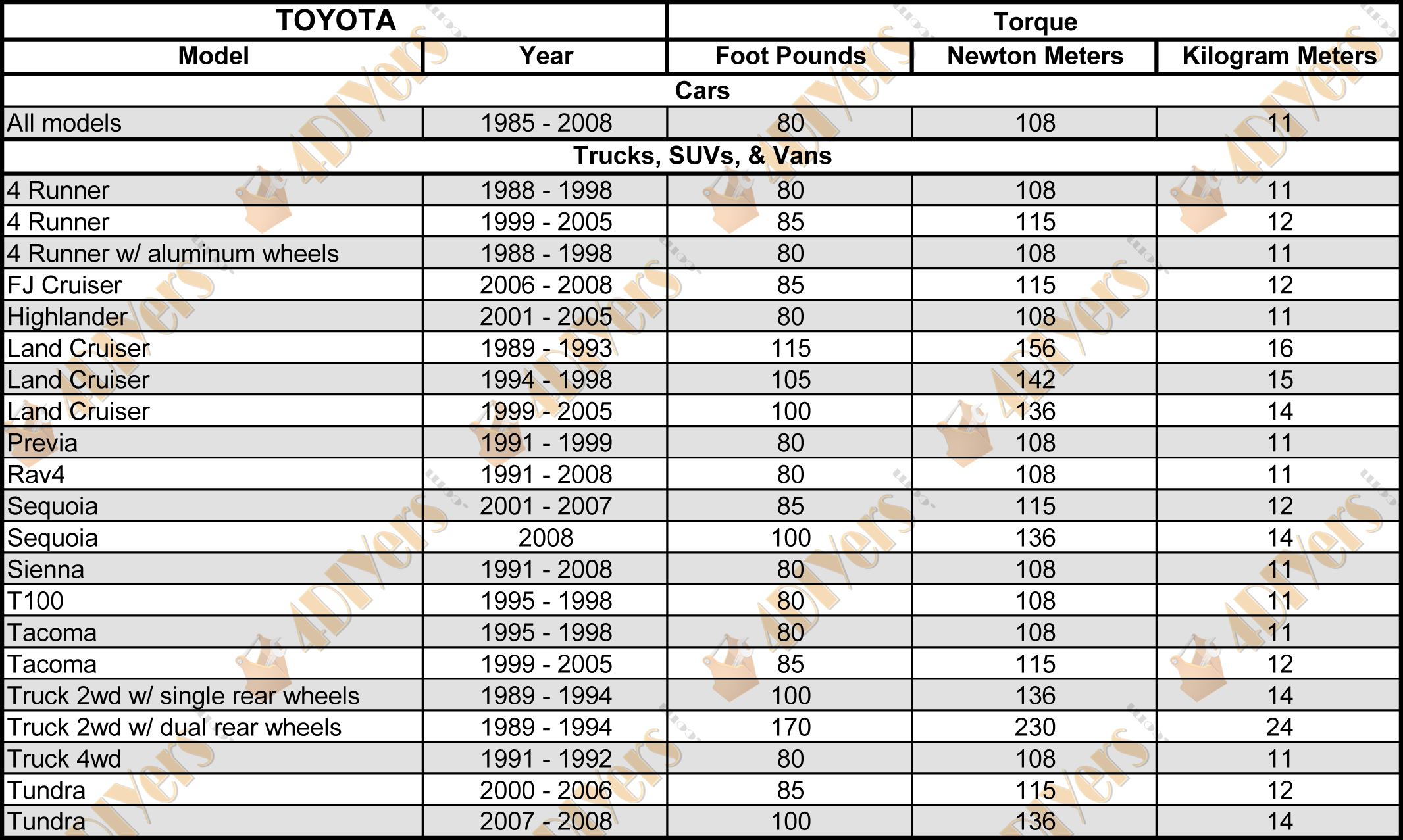

Wheel Torque Specs Chart

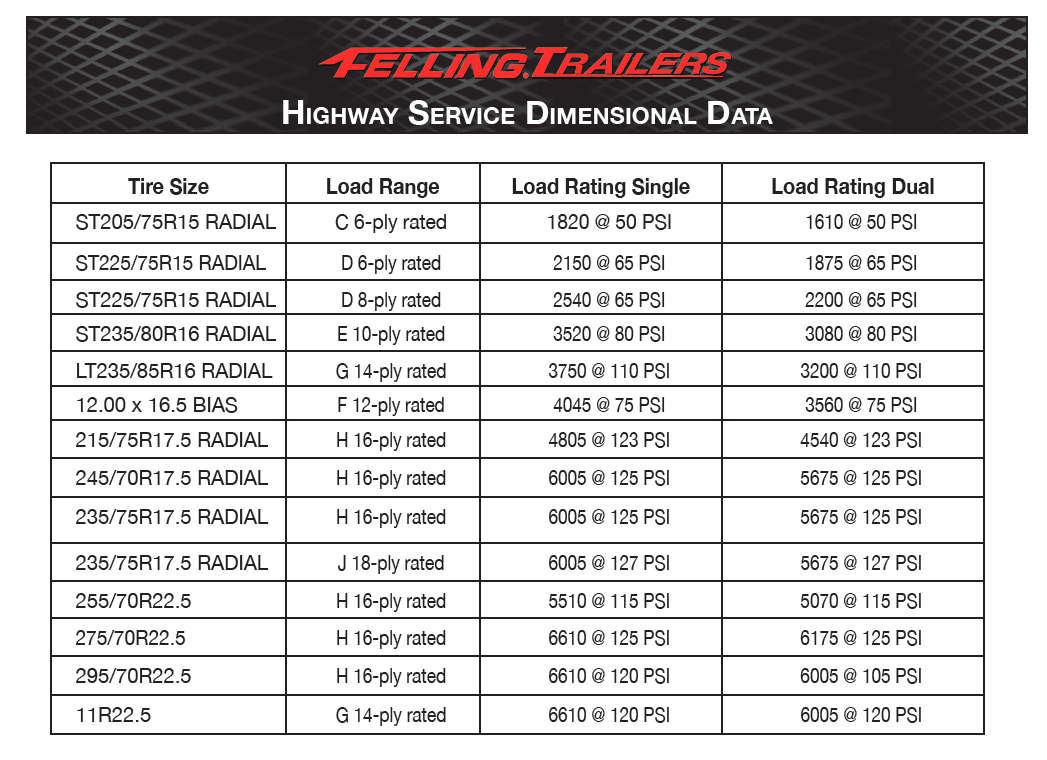

Commercial Truck Wheel Torque Chart

KTool International KTI30103A K Tool Wheel Nut Torque Charts Summit

Wheel Torque Specs Chart

Torque Wall Chart Lock Technology LT1500LWC

Wheel Torque Spec Chart

Printable Automotive Wheel Torque Chart Printable World Holiday

Wheel Torque Specs Chart

Torque Charts Industrial Torque Tools

It Is Prudent To Recheck The Torque Specifications After A Test Drive Of The Vehicle, Especially With Alloy Or.

Download The Lug Nut Torque Chart Pdf.

Using The Proper Torque Helps Ensure That The Wheel Assembly Is Securely Installed.

2.1 The Importance Of Torque Wrenches.

Related Post: