Torque Chart For Flanges

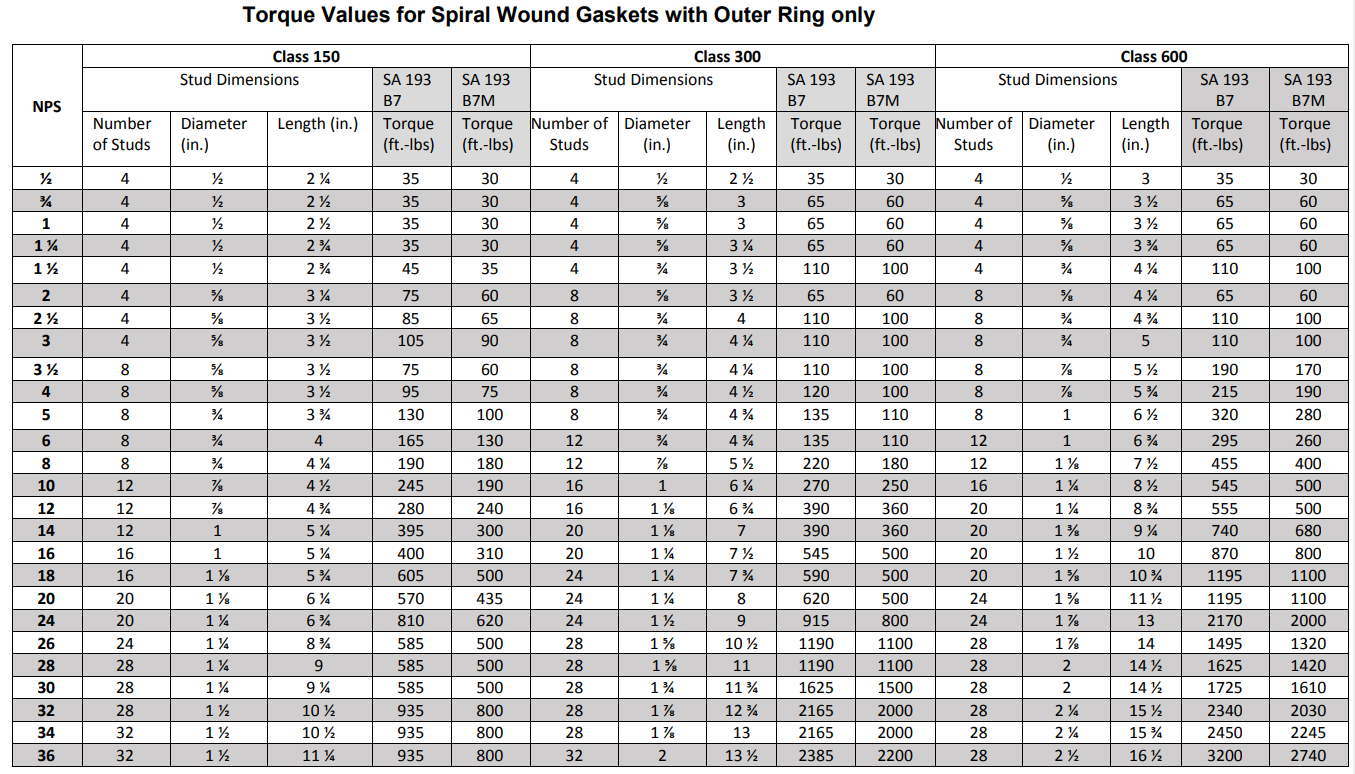

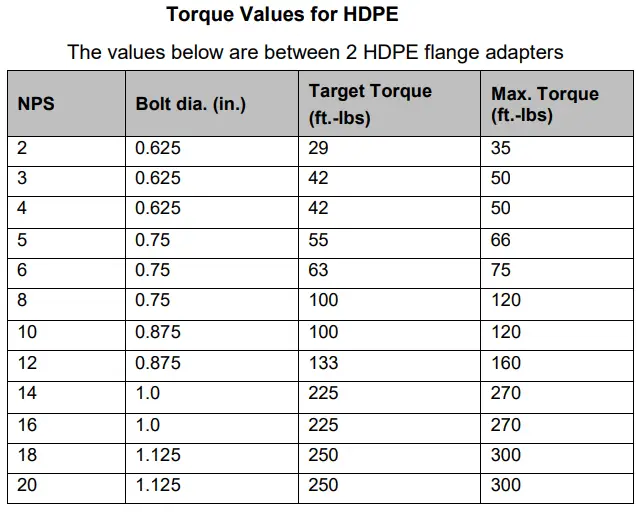

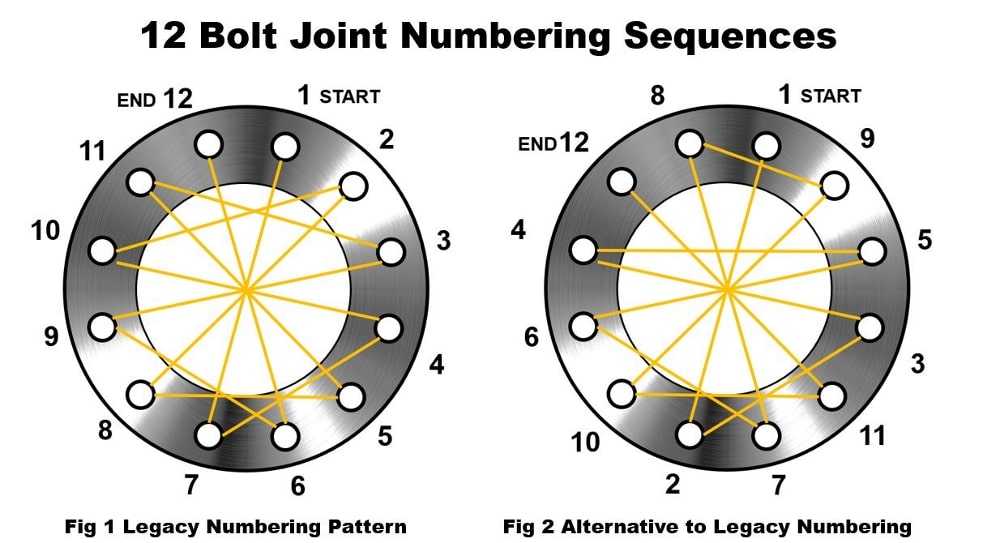

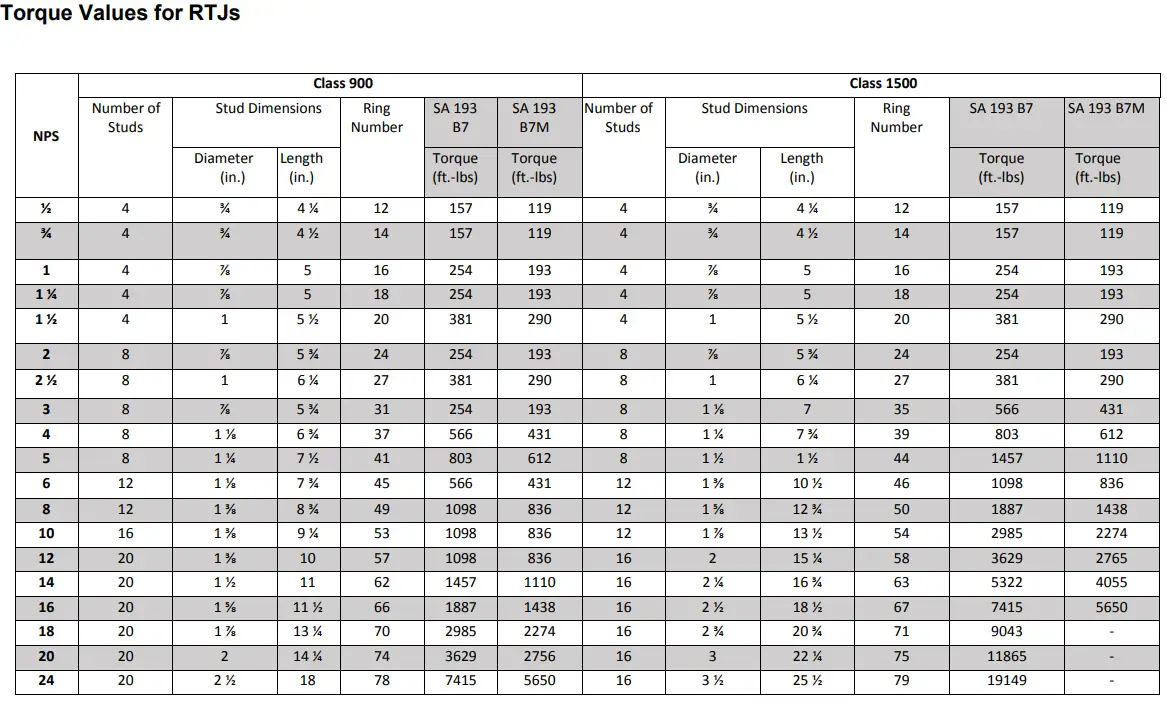

Torque Chart For Flanges - Web welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges under normal assembly conditions. Web bolt yield should be at least 80,000 psi. Flange rating:ansi b16.5, class 600. The torque values are applicable for the type of gasket specified and bolts, nuts and washers should be free from damage, rust etc. The final torque value accounts for 10% bolt relaxation. Just enter the flange size, class, and type and the app instantly populates the correct values from the flange bolt size chart and the flange torque sequence chart, along with wrench size. Based on using weldneck flanges & lubricated stud bolts with a 0.15 friction factor.***. Web however, there is no direct method of measuring this load on the gasket, but the applied torque on the flanged bolts can be measured and controlled. Web a complete torque tightening sequence with charts for class 150 to 2500 flanges. Web flange bolt size chart and torque patterns. In this article, we will learn the basics of flange bolt torque calculation and. Nut factor calculation of target torque. Before using a given torque table, these assumptions should be verified to insure they are appropriate for the specific application. The torque tables are built on specific assumptions regarding bolt and nut factor. Web maximum torque per bolt at 60,000. Based on using weldneck flanges & lubricated stud bolts with a 0.15 friction factor.***. The application of the recommended torque is only valid for the listed teadit products. Web a complete torque tightening sequence with charts for class 150 to 2500 flanges. For a307 grade a, 75% of 36,000 psi is utilized. Web bolt torque values for asme b16.5 series. Of the flange by 1/4:” to 3/8”, stop tightening. Web flange torque charts listed by nps and by flange class. In this article, we will learn the basics of flange bolt torque calculation and. For a307 grade a, 75% of 36,000 psi is utilized. The torque tables are built on specific assumptions regarding bolt and nut factor. Web length of stud bolts [note (1)] nps outside diameter of flange diameter of bolt circle diameter of bolt holes number of bolts diameter of bolts raised To achieve a reliable seal, adequate gasket stress must be applied Web instant flange bolt sizes and torque patterns: Actual torque values to be determined by user. Web the torque values are approved. Lookup bolt lengths, wrench sizes, and torque patters using the flange bolt app. The following charts indicate the approximate bolt torque required to seal flanged joints against internal pressure. Web flange bolting torque table. In this article, you will learn about the torque sequence of pipe flanges. This table does not take flange strength into consideration. Flange rating:ansi b16.5, class 600. Web however, there is no direct method of measuring this load on the gasket, but the applied torque on the flanged bolts can be measured and controlled. Based on using weldneck flanges & lubricated stud bolts with a 0.15 friction factor.***. Of the flange by 1/4:” to 3/8”, stop tightening. For full face homogenous elastomeric. Bolting materials:astm a193 grades b7 and b7m, astm a320 grades l7, l7m and l43. To achieve a reliable seal, adequate gasket stress must be applied Gasket contact area (square inches) as defined by previous columns (1) Web the torque values are approved for spiral wound graphite and ptfe filled gaskets, graphite sheet gaskets ghe and ghr types, ring joint, double. See load on stud bolts under torque table in the engineered gasketing products catalog. Web class 600 flange torque charts listed by nominal pipe size. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75% of the proof loads specified by the standard. The. Flange materials:astm a105, astm a182 grades f50 and f51, astm a350 grades lf2 and lf3, astm a694 grades f52 and f60. This table does not take flange strength into consideration. Web flange bolting torque table. Web the torque values are approved for spiral wound graphite and ptfe filled gaskets, graphite sheet gaskets ghe and ghr types, ring joint, double jacketed. Web welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges under normal assembly conditions. Web class 1500 flange torque charts listed by nominal pipe size. Web bolt yield should be at least 80,000 psi. Web these bolt torque. The final torque value accounts for 10% bolt relaxation. Lookup bolt lengths, wrench sizes, and torque patters using the flange bolt app. Just enter the flange size, class, and type and the app instantly populates the correct values from the flange bolt size chart and the flange torque sequence chart, along with wrench size. To achieve a reliable seal, adequate gasket stress must be applied Web torque tables for the installation of flat gaskets with standard asme flanges. Of the flange by 1/4:” to 3/8”, stop tightening. The torque tables are built on specific assumptions regarding bolt and nut factor. Web length of stud bolts [note (1)] nps outside diameter of flange diameter of bolt circle diameter of bolt holes number of bolts diameter of bolts raised Web flange bolt size chart and torque patterns. The torque values are applicable for the type of gasket specified and bolts, nuts and washers should be free from damage, rust etc. Before using a given torque table, these assumptions should be verified to insure they are appropriate for the specific application. Web bolt torque values for asme b16.5 series a class 150# flat flanges with a193 grade b7 bolts. Bolting materials:astm a193 grades b7 and b7m, astm a320 grades l7, l7m and l43. In this article, you will learn about the torque sequence of pipe flanges. This torque table applies for 1/16” and 1/8” thick homogenous elastomeric gaskets. Web these bolt torque values are intended for use as guidelines only and are based on ideal conditions, perfect flanges, flange alignment & new well lubricated bolts/nuts according to the national boiler code, installed in accordance with the central plastics company flange installations guidelines.

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Flange Bolt Torque Calculation and Pipe Flange Bolt Torque Chart (With

Asme Flange Bolt Torque Chart

Flange Bolt Torque Calculation and Pipe Flange Bolt Torque Chart What

Pipe Flange Torque Chart

FlangeBoltingPatterns Industrial Bolting and Torque Tools

Torque Charts Industrial Bolting and Torque Tools

StandardFlangeSpecifications Industrial Bolting and Torque Tools

Bolt Tightening Flange Torque Sequence Chart

Flange Bolt Torque Calculation and Pipe Flange Bolt Torque Chart (With

Actual Torque Values To Be Determined By User.

Minus 101 Thru’ Plus 400Oc (Per Piping Class).

The Torques Given Are Based On Using A 3Mm Thick 70 Irhd Rubber Gasket.

= Clamp Load For J429 Grade 5 And 8, Fnl Grade 9, A574, Class 4.6, 8.8, 10.9 And 12.9, The Clamp Loads Are Listed At 75% Of The Proof Loads Specified By The Standard.

Related Post: