Tig Welder Tig Welding Settings Chart

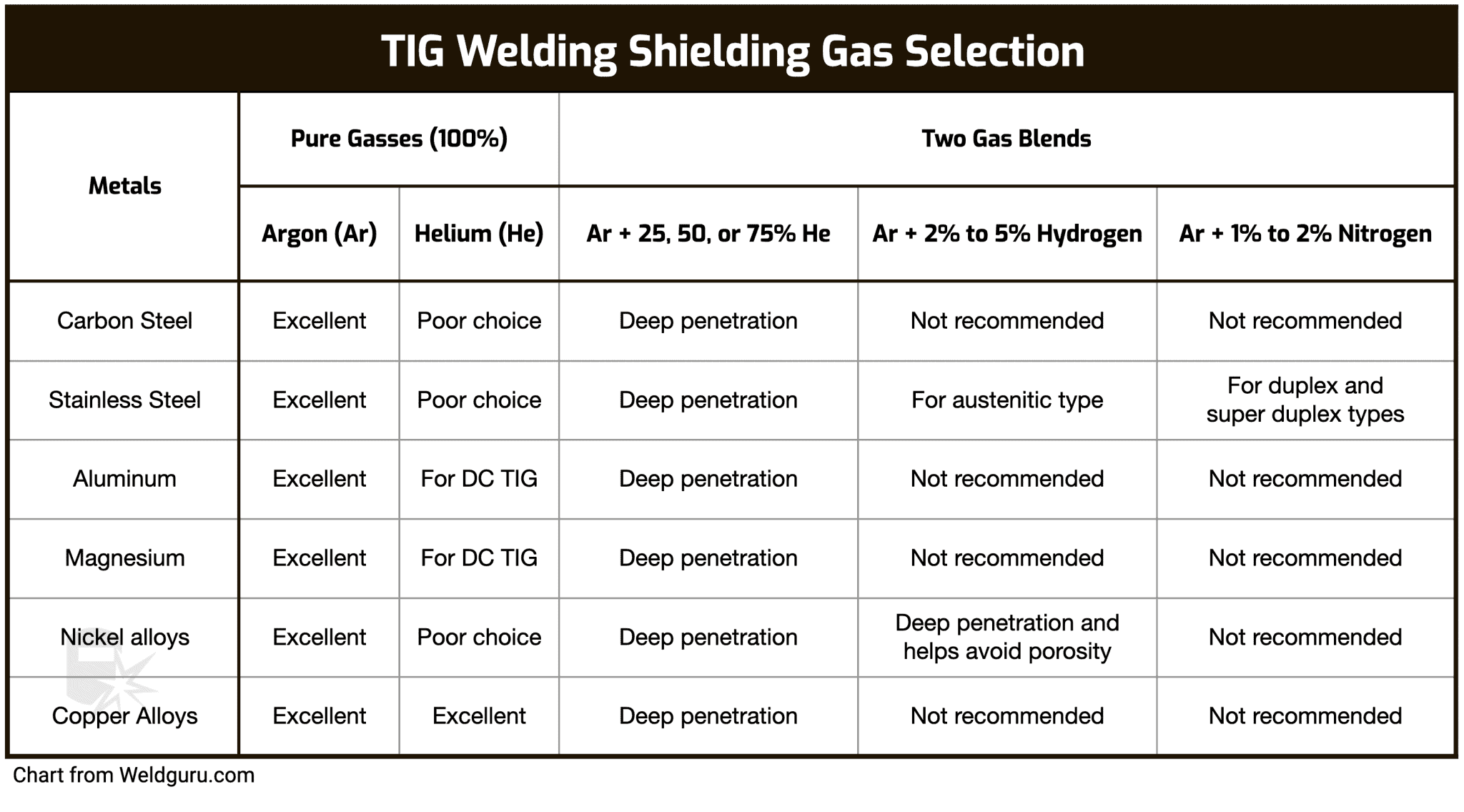

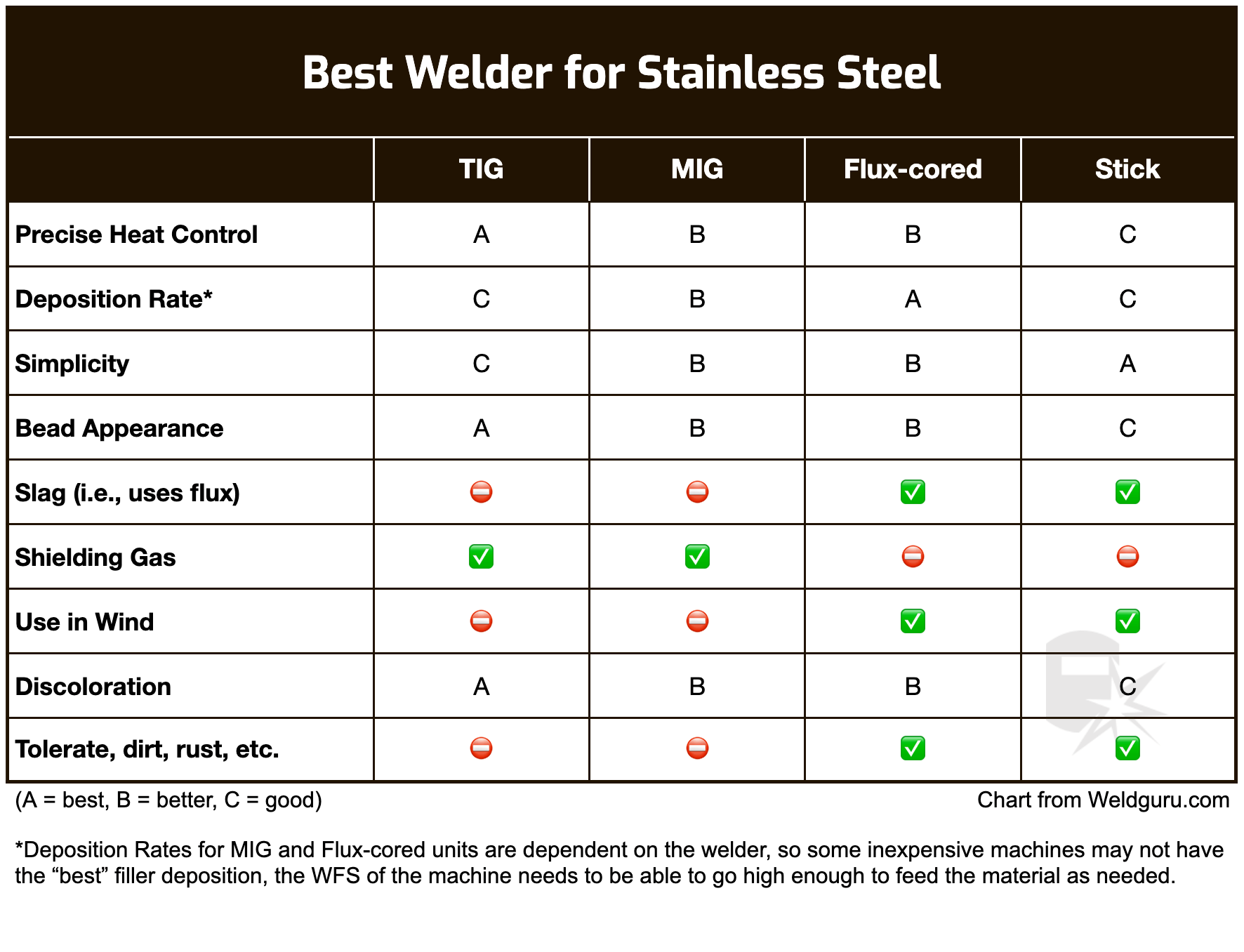

Tig Welder Tig Welding Settings Chart - So i extrapolated for the rest. Filler metal can be either wire or rod and should be compatible with the base alloy. Web a tig welding chart visually represents the welding parameters needed to achieve a specific weld. Whether you’re working on steel, aluminum, or stainless steel, this tool provides you with tailored recommendations for electrode size, type, and amperage, ensuring that your welds meet the highest standards. And even two dissimilar metals. Web typical manual tig welding parameters. Install the collet holder onto the front end of your torch, but don’t use any random collet holder; Empower your tig welding projects with our free online tig welding calculator. Troubleshooting guide for tig welding. Web for beginners it’s recommended to stick with a 3/32” diameter tungsten. So i extrapolated for the rest. Tungsten inert gas (tig) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join the metals together. Web understanding what amperage is and the best settings for each situation will help provide a beautiful outcome every time. Web new owner of a kemppi minarctig evo. Stainless is less thermally conductive than mild steel, so heat does not flow away from the weld quite so quickly. What metal are you welding? By using the chart, welders can determine the optimal settings for their welding machine based on the material they are. Web i have three charts here, all from the same source (ck worldwide technical specifications. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Let’s dive into how travel speed and temperature control work in harmony to elevate your tig welding prowess. By using the chart, welders can determine the optimal settings for their welding machine based on the material they are. According to these charts, mild steel requires. What metal are you welding? Web in this article, we’ll explain the various tig welder settings and waveform controls, including amperage, gas flow rate, and more advanced like pulse, ac features, and dc controls. Tungsten inert gas (tig) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join the metals together.. Web let’s explain how to do these step by step in detail. Browse suggested weld parameter settings for tig welding. Filler metal can be either wire or rod and should be compatible with the base alloy. Web by doug bates, handgun repair shop. Web in this article, we’ll explain the various tig welder settings and waveform controls, including amperage, gas. Let’s dive into how travel speed and temperature control work in harmony to elevate your tig welding prowess. According to these charts, mild steel requires the most amperage (not aluminum), and also the fastest travel speed. Empower your tig welding projects with our free online tig welding calculator. Filler metal must be dry, free of oxides, grease, or other foreign. Troubleshooting guide for tig welding. Web a tig welding settings chart is an indispensable tool for welders, offering a roadmap to the ideal settings for various materials and thicknesses. Web understanding what amperage is and the best settings for each situation will help provide a beautiful outcome every time. Web in this article, we’ll explain the various tig welder settings. The information in this manual represents the best judgement of ck worldwide, inc. Never operate any equipment without carefully reading, understanding, and following all of the related safety rules and. Empower your tig welding projects with our free online tig welding calculator. Web but some brands of tig welders have their ac balance knob where the higher number setting indicaties. Web a tig welding chart visually represents the welding parameters needed to achieve a specific weld. Tungsten inert gas (tig) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join the metals together. Whether you’re working on steel, aluminum, or stainless steel, this tool provides you with tailored recommendations for electrode. Empower your tig welding projects with our free online tig welding calculator. Filler metal must be dry, free of oxides, grease, or other foreign matter. The tig process can be used to weld everything from bike frames to door handles to automotive parts. We need a lot less flow in tig welding. The information in this manual represents the best. Tig welding can be used to weld aluminium, copper, titanium etc. Whether you’re working on steel, aluminum, or stainless steel, this tool provides you with tailored recommendations for electrode size, type, and amperage, ensuring that your welds meet the highest standards. Let’s dive into how travel speed and temperature control work in harmony to elevate your tig welding prowess. The amps required to weld stainless are about 10% lower than the amps used for mild steel. Web understanding what amperage is and the best settings for each situation will help provide a beautiful outcome every time. A tig torch is composed of a torch body, short or long back cap, collet, collet body, ceramic cup, and a tungsten electrode. See the chart below for current ranges of all sizes. We need a lot less flow in tig welding. Web tig welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze and even gold. You can replace the collet body with the gas lens kit for improved shielding gas flow, but it’s not necessary for most jobs. So i extrapolated for the rest. The information in this manual represents the best judgement of ck worldwide, inc. Web a tig welding settings chart is an indispensable tool for welders, offering a roadmap to the ideal settings for various materials and thicknesses. And is intended for use by experienced personnel. Tungsten diameter and cup size. Web the use of tig welding for aluminum has many advantages for both manual and automatic processes.Tig parameters chart MIG Welding Forum

Tig Welding Settings Chart Pdf

TIG Tungsten Electrodes Explained (with Color Chart)

TIG Welding Charts ILMO Products Company

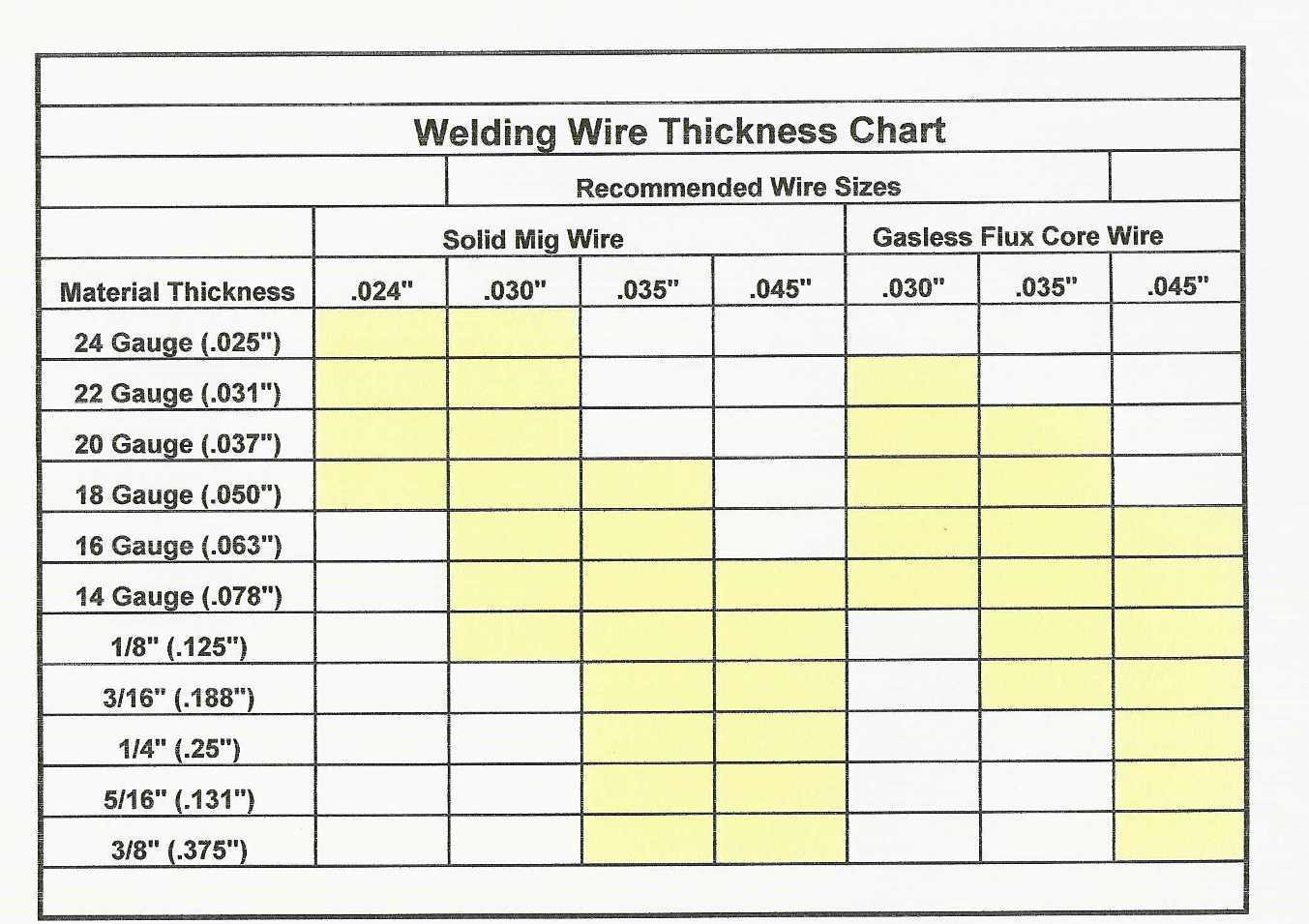

instructions on welding in auto floor pan Grumpys Performance Garage

Tig Welder Settings Chart

Tig Welding Settings Chart

Aluminum Tig Welding Settings Chart

How to Weld Stainless Steel A Complete Guide

Tig Welding Settings Chart

Never Operate Any Equipment Without Carefully Reading, Understanding, And Following All Of The Related Safety Rules And.

Filler Metal Can Be Either Wire Or Rod And Should Be Compatible With The Base Alloy.

And Even Two Dissimilar Metals.

I Did Come Across The Diy Guide Here On This Site, But It Only Goes Up To 3Mm.

Related Post: