Tig Settings Chart

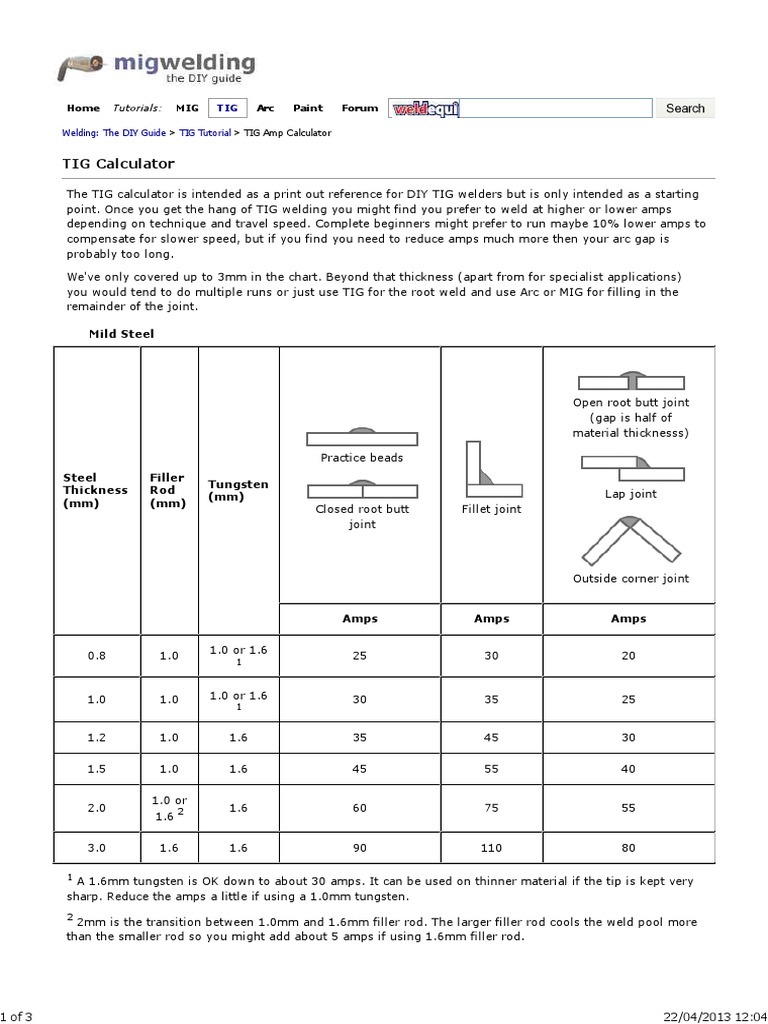

Tig Settings Chart - For mild steel, it recommends running 10% lower amps for complete beginners. The guide is split into specific areas of welding and cutting and designed to give an understanding of these areas. The diagrams below show arc characteristics of. Web a tig welding chart visually represents the welding parameters needed to achieve a specific weld. Web the document provides a tig welding amp calculator chart for mild steel and stainless steel in thicknesses ranging from 0.8mm to 3mm. Use ac (alternating current) when welding aluminum and magnesium. Read and understand the safety data sheets (sdss) and the manufacturer’s instructions for adhesives, coatings, cleaners, consumables, coolants, degreasers, fluxes, and metals. Let’s dive into how travel speed and temperature control work in harmony to elevate your tig welding prowess. Amperage and gas flow rate. Whether you’re new to pulsed tig welding or trying to get the stacked dimes look, selecting the right settings is the key to success. Web what metal are you welding? For mild steel, it recommends running 10% lower amps for complete beginners. The guide is split into specific areas of welding and cutting and designed to give an understanding of these areas. Tungsten inert gas (tig) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to. Web see the chart below for recommended flow rates. And even two dissimilar metals. By using the chart, welders can determine the optimal settings for their welding machine based on the material they are. Web 8 rows printable charts shiowing the amps and tungstons you might select for various. Web the document provides a tig welding amp calculator chart for. Filler metal can be either wire or rod and should be compatible with the base alloy. The chart usually includes the current range, polarity, filler metal type, shielding gas type, and tungsten electrode size. By using the chart, welders can determine the optimal settings for their welding machine based on the material they are. Gas flow rates for tig welding.. The guide is split into specific areas of welding and cutting and designed to give an understanding of these areas. Filler metal can be either wire or rod and should be compatible with the base alloy. Web basic tig welder settings. The type of current used will have a great effect on the penetration pattern as well as the bead. Filler metal can be either wire or rod and should be compatible with the base alloy. Use ac (alternating current) when welding aluminum and magnesium. Web a tig welding chart visually represents the welding parameters needed to achieve a specific weld. Web what metal are you welding? Filler metal must be dry, free of oxides, grease, or other foreign matter. The guide is split into specific areas of welding and cutting and designed to give an understanding of these areas. Web follow requirements in osha 1910.252 (a) (2) (iv) and nfpa 51b for hot work and have a fire watcher and extinguisher nearby. Tig welding can be used to weld aluminium, copper, titanium etc. Tungsten inert gas (tig) welding is. Web a tig welding chart visually represents the welding parameters needed to achieve a specific weld. Web see the chart below for recommended flow rates. Tungsten inert gas (tig) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join the metals together. It outlines the optimal settings based on material thickness. However, a good starting point is to maintain a stable arc, adequate heat input, and proper gas coverage throughout the welding process. Use ac (alternating current) when welding aluminum and magnesium. Filler metal must be dry, free of oxides, grease, or other foreign matter. The diagrams below show arc characteristics of. For mild steel, it recommends running 10% lower amps. Web a tig welding chart visually represents the welding parameters needed to achieve a specific weld. Web from setup to troubleshooting, learn more about the basics of tig welding and get tips for tig welding success. The chart usually includes the current range, polarity, filler metal type, shielding gas type, and tungsten electrode size. Filler metal can be either wire. Filler metal must be dry, free of oxides, grease, or other foreign matter. Filler metal can be either wire or rod and should be compatible with the base alloy. Web basic tig welder settings. Read and understand the safety data sheets (sdss) and the manufacturer’s instructions for adhesives, coatings, cleaners, consumables, coolants, degreasers, fluxes, and metals. Use ac (alternating current). Web understanding tig pulse settings with ron covell. It outlines the optimal settings based on material thickness and joint type. This guide is designed to provide helpful information relating to the electric arc welding and cutting process. The chart usually includes the current range, polarity, filler metal type, shielding gas type, and tungsten electrode size. Use ac (alternating current) when welding aluminum and magnesium. Amperage and gas flow rate. The type of current used will have a great effect on the penetration pattern as well as the bead configuration. Web a tig welding settings chart is an indispensable tool for welders, offering a roadmap to the ideal settings for various materials and thicknesses. Let’s dive into how travel speed and temperature control work in harmony to elevate your tig welding prowess. The older transformer machines, but even some cheap newer ones, served as a traditional power source that only has only two basic tig welder settings: Web follow requirements in osha 1910.252 (a) (2) (iv) and nfpa 51b for hot work and have a fire watcher and extinguisher nearby. Read and understand the safety data sheets (sdss) and the manufacturer’s instructions for adhesives, coatings, cleaners, consumables, coolants, degreasers, fluxes, and metals. Tig welding can be used to weld aluminium, copper, titanium etc. By using the chart, welders can determine the optimal settings for their welding machine based on the material they are. It notes that the chart provides starting point amps that may need adjusting based on technique and travel speed. Web the balanced setting for tig welding depends on factors such as material thickness, joint configuration, welding position, and desired weld characteristics.

Aluminum Tig Welding Settings Chart

Tig Welding Rods Chart

Tig parameters chart MIG Welding Forum

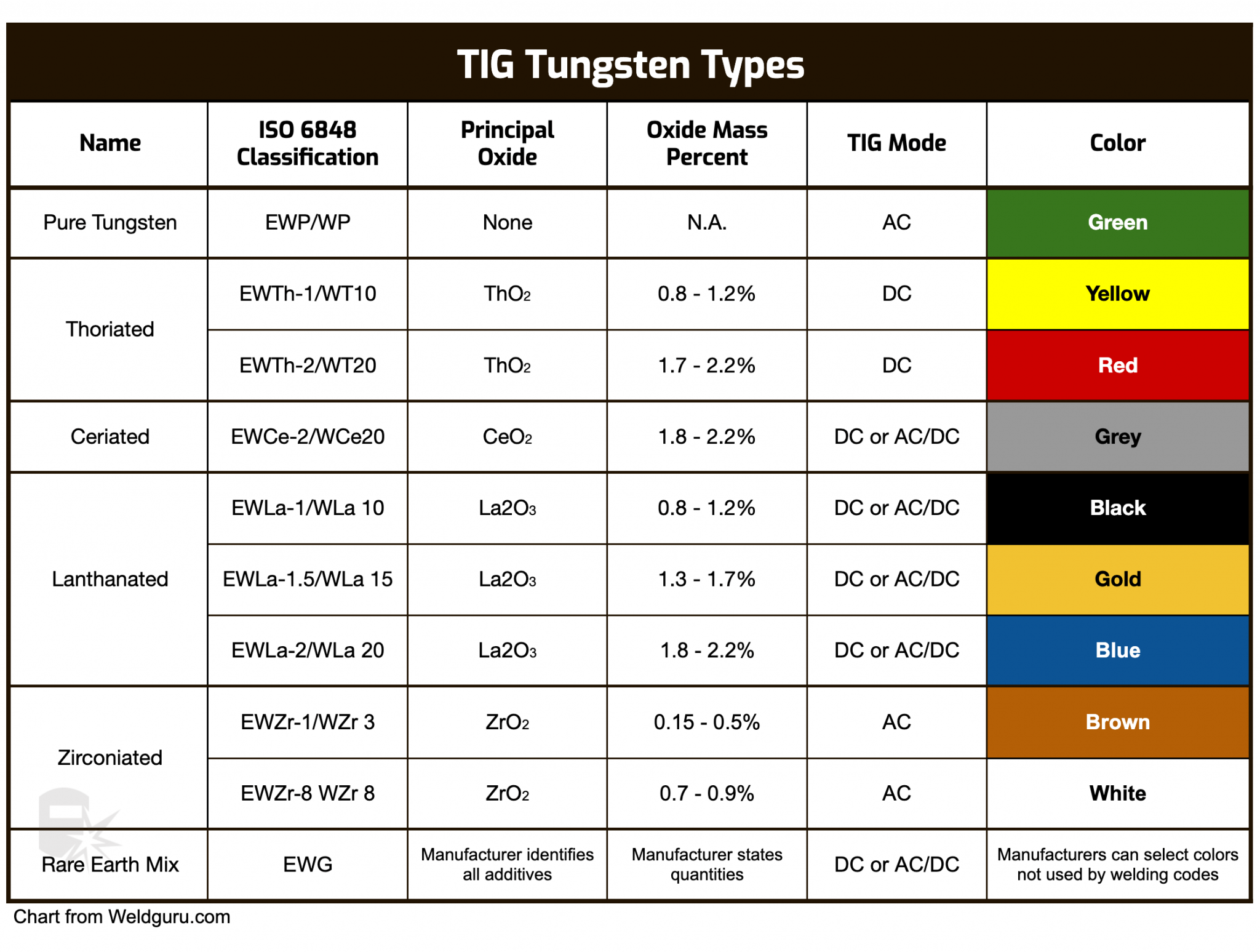

TIG Tungsten Electrodes Explained (with Color Chart)

Aluminum Tig Welding Settings Chart

Tig Welding Settings Chart Pdf

TIG Welding Amp Charts Welding Building Materials

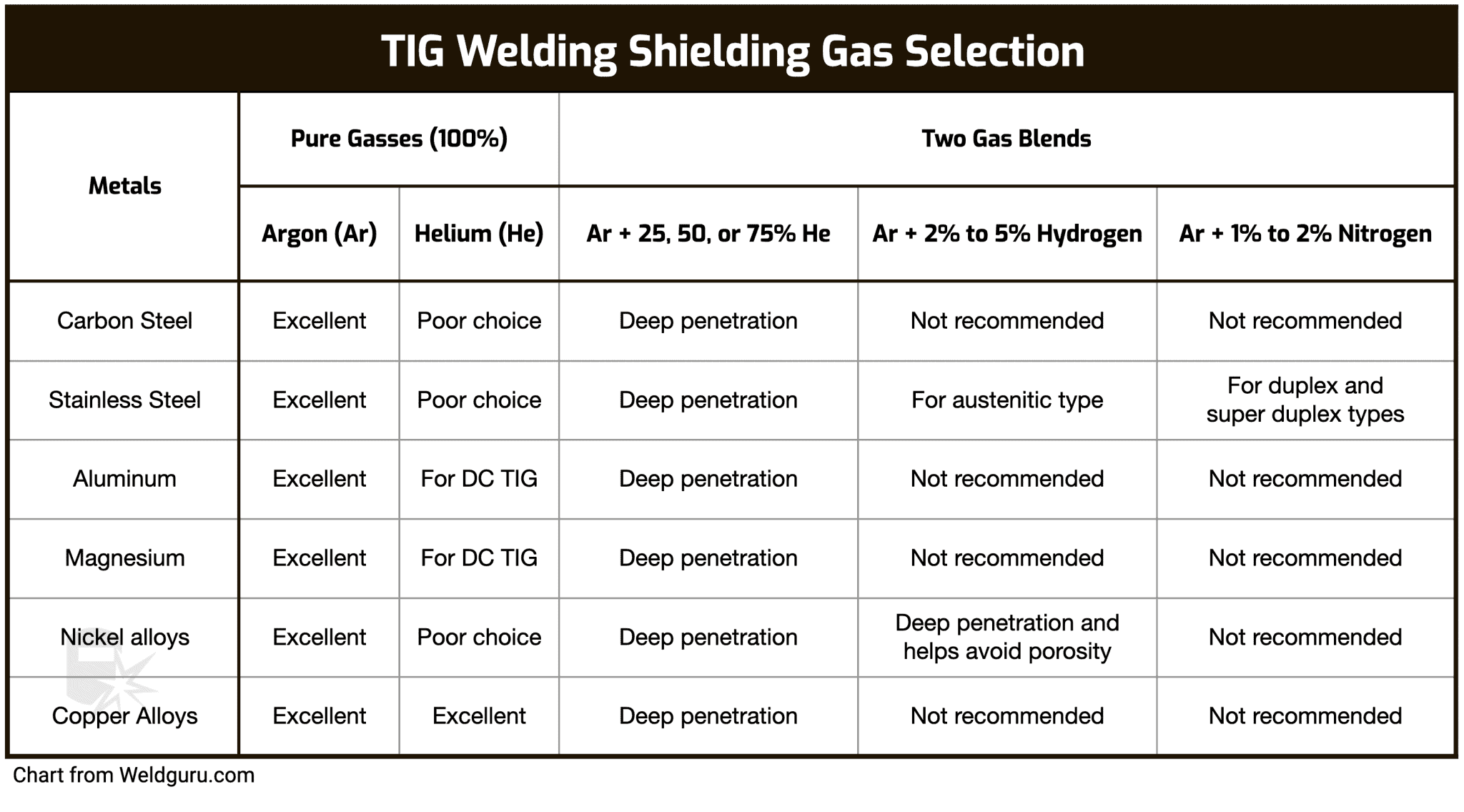

What Gas Should You Use for TIG Welding? (with Chart)

TIG Tungsten Electrodes Explained (with Color Chart)

TIG Welding Charts ILMO Products Company

Filler Metal Can Be Either Wire Or Rod And Should Be Compatible With The Base Alloy.

Web A Look At Each Type And Its Uses Will Help The Operator Select The Best Current Type For The Job.

The Diagrams Below Show Arc Characteristics Of.

Gas Flow Rates For Tig Welding.

Related Post: