Tig Filler Rod Chart

Tig Filler Rod Chart - Web filler rod is what you use when you are tig welding and working along a joint, melting your two base metals together (you also use filler rod with oxygen acetylene welding, and for that i often do use coat hangers!). Web for sheet metal thicknesses ( 1/8 (3.2mm) and under) rod size should not be thicker than the metal being welded. Generally speaking, use a filler rod that has a diameter that is less than the thickness of the metal. 4047 aluminum filler rod contains 12% silicon. It could be due to your choice of tig filler rods. And do yourself a favor and get some 4047 aluminum filler rod for castings where porosity rares its ugly head. Browse suggested weld parameter settings for tig welding. 0.035”, 0.045”, 1/16”, 3/32” and 1/8”; The information in this manual represents the best judgement of ck worldwide, inc. Web choosing a tig filler rod depends on a number of variables. Web there is a really good chart for selecting aluminum filler rods here. And do yourself a favor and get some 4047 aluminum filler rod for castings where porosity rares its ugly head. 0.035”, 0.045”, 1/16”, 3/32” and 1/8”; The base metal composition, joint type, stock thickness, cleanliness of the stock, and thermal properties of the metal can all play. You don’t want to put in an 1/8″ tungsten and try to run it at 20 amps. However, only bare uncoated rods should be used. Web tig filler rods for hard facing play a crucial role in extending the life of metal parts exposed to harsh wear conditions. And do yourself a favor and get some 4047 aluminum filler rod. What metal are you welding? Web for sheet metal thicknesses ( 1/8 (3.2mm) and under) rod size should not be thicker than the metal being welded. However, only bare uncoated rods should be used. Web there is a really good chart for selecting aluminum filler rods here. This handy selection guide to help identify the best weldclass brazing rod, or. The chart contains detailed descriptions of the different types of rods available for use in tig welding processes, as well as their respective characteristics and. Generally speaking, using filler metal slightly thinner that what is being welded works best. Plus, with endless options on the market, they can be difficult to choose. Web the chart usually includes the current range,. Web for sheet metal thicknesses ( 1/8 (3.2mm) and under) rod size should not be thicker than the metal being welded. Web this article will teach you the basics of tig filler rods and help you establish your filler rod collection because 99% of the jobs are done with the rods we will discuss soon. He has the 1/8″, the. By using the chart, welders can determine the optimal settings for their welding machine based on the material they are welding and the desired weld size. Browse suggested weld parameter settings for tig welding. Web blowing holes and making a mess with your welds? Generally speaking, using filler metal slightly thinner that what is being welded works best. Web for. Web tig filler rods for hard facing play a crucial role in extending the life of metal parts exposed to harsh wear conditions. How to read the chart. However, only bare uncoated rods should be used. Understanding the properties of these rods, and how to properly use them, can significantly enhance the performance and longevity of the finished piece. This. And do yourself a favor and get some 4047 aluminum filler rod for castings where porosity rares its ugly head. You should wear a dust mask when grinding, and make sure to keep skin covered and. This handy selection guide to help identify the best weldclass brazing rod, or filler rod for your project. However, only bare uncoated rods should. Web welding electrode selection chart for carbon steel to stainless steel, all stainless steel. Plus, with endless options on the market, they can be difficult to choose. Additionally, we will give you tig filler rod charts for all standard and less often used rods, including titanium. And do yourself a favor and get some 4047 aluminum filler rod for castings. And do yourself a favor and get some 4047 aluminum filler rod for castings where porosity rares its ugly head. The chart contains detailed descriptions of the different types of rods available for use in tig welding processes, as well as their respective characteristics and. Typical manual tig welding parameters. Light gauge metals less than 1/16 (1.6mm) thick should always. Web selection chart for oxy brazing rods & tig filler wires. The below chart gives very detailed guidelines for stick welding (smaw) or equivalent tig/mig filler wires for different types of stainless steel welding. Web we offer a variety of helpful welding charts plus guides that you can reference online, or buy as a pdf to print, disperse, or post for to welding team. Additionally, we will give you tig filler rod charts for all standard and less often used rods, including titanium. And do yourself a favor and get some 4047 aluminum filler rod for castings where porosity rares its ugly head. How to read the chart. However, only bare uncoated rods should be used. It’s the most common type of filler rod found in an automotive shop and is great for sheet metal, chassis, and suspension components. Typical manual tig welding parameters. Generally speaking, using filler metal slightly thinner that what is being welded works best. Web tig filler rods for hard facing play a crucial role in extending the life of metal parts exposed to harsh wear conditions. Web there is a really good chart for selecting aluminum filler rods here. Next he shows a helpful chart from the american welding society that shows how e3 tungsten size relates to amperage. You should wear a dust mask when grinding, and make sure to keep skin covered and. Web filler rod is what you use when you are tig welding and working along a joint, melting your two base metals together (you also use filler rod with oxygen acetylene welding, and for that i often do use coat hangers!). The chart contains detailed descriptions of the different types of rods available for use in tig welding processes, as well as their respective characteristics and.

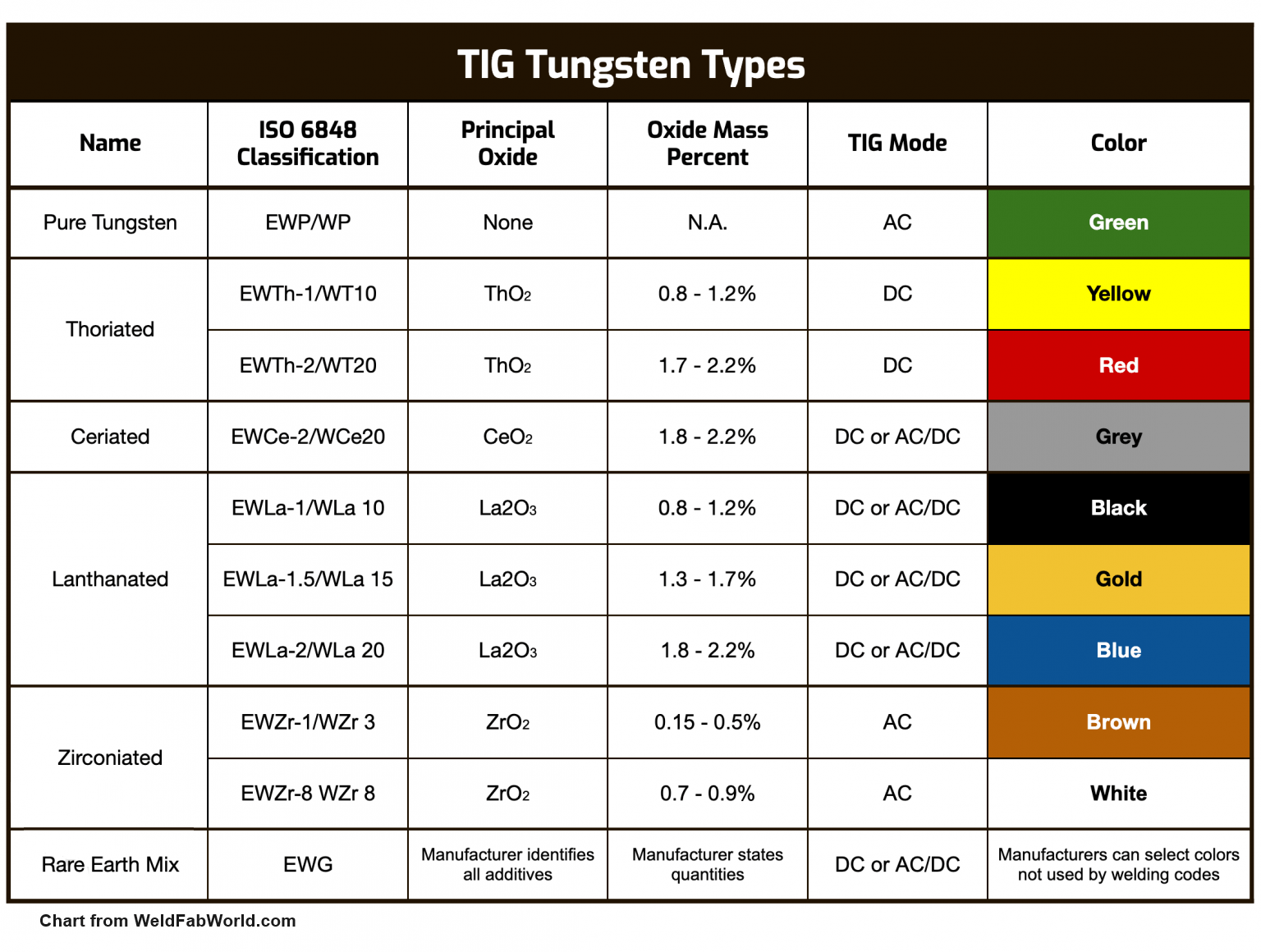

Tungsten Electrodes For TIG (with Color Chart) Welding Fabrication World

Tig Aluminum Filler Rod Chart

Download Tig Welding Aluminum Amperage Chart Pics All About Welder

Tig Welding Rods Chart

Tig Welding Filler Rod Selection Chart Reviews Of Chart

Image result for tig welding rods chart Welding info Pinterest Chart

Tig Welding Rod Chart

Aluminum Filler Alloy Selection Chart PDF Welding Construction

How Do I Calculate How Much Welding Rod I Need

Welding rod chart, Welding rods, Stainless steel welding

Troubleshooting Guide For Tig Welding.

0.035”, 0.045”, 1/16”, 3/32” And 1/8”;

Light Gauge Metals Less Than 1/16 (1.6Mm) Thick Should Always Be Welded With Dcsp Using Argon Gas.

You Don’t Want To Put In An 1/8″ Tungsten And Try To Run It At 20 Amps.

Related Post: