Ti Anodizing Chart

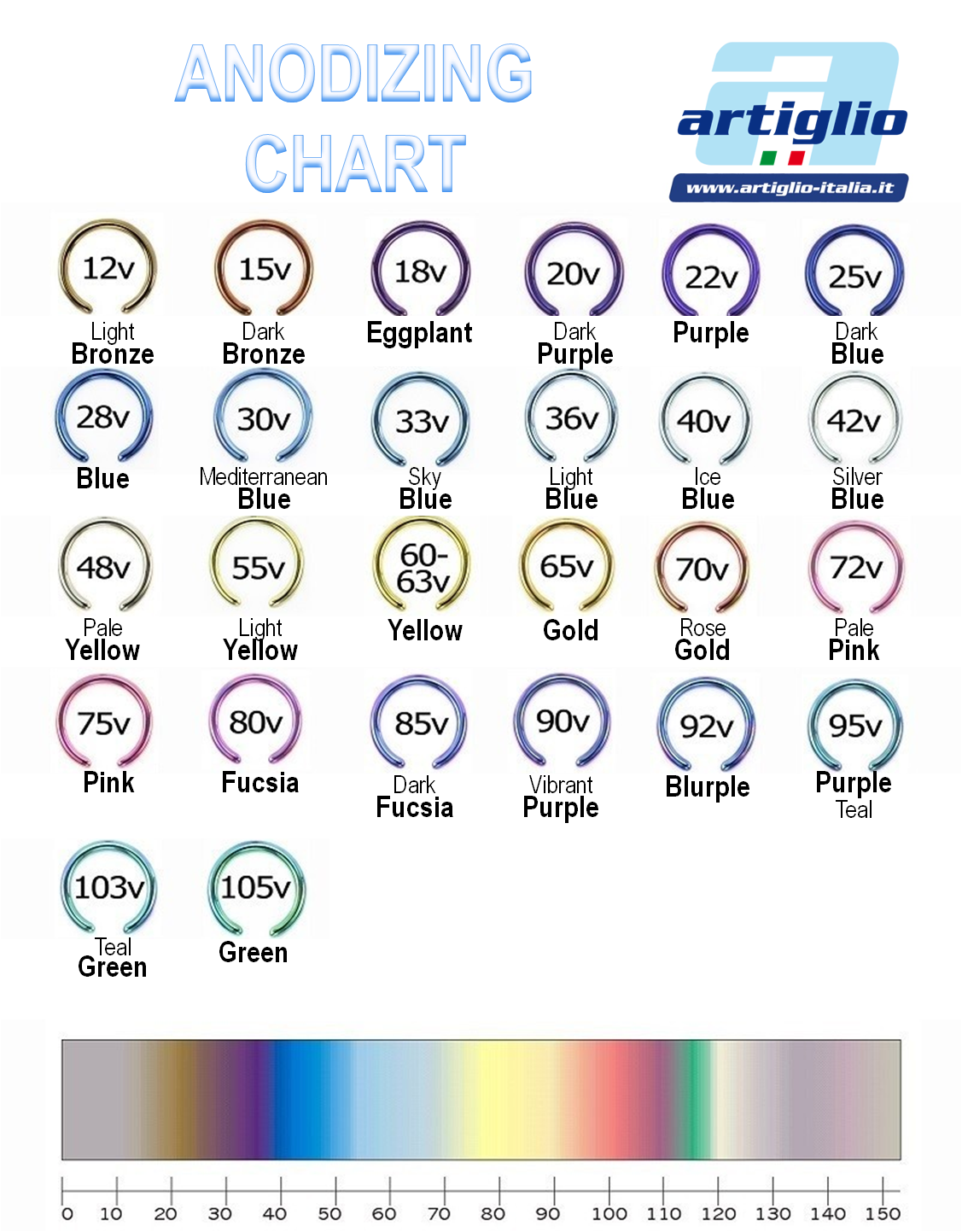

Ti Anodizing Chart - It’s best for applications where a decorative finish is desired. Wonder what colors titanium can be anodized? Web 6 prepare the titanium surface. Dip two or three times to work any air bubbles out of the parts, then place in the titanium anodize tank. Much easier to control consistency, solid color and precise colors and fades. Web january 18, 2023 | 12:15 pm. Type 1 anodizing typically results in a thin, semiconducting oxide layer. The color of the anodized titanium depends on the thickness of the oxidized layer created on the surface of the titanium. Web titanium color anodizing 2450 deelyn dr. Web technical bulletin5metalast international, inc. Web how does it work? Www.danco.net interference colors the colors produced by these metals are known as interference colors. Any titanium fasteners we sell can be custom anodized for our customers. Teal magenta green seafoam gray gold no. Start the rectifier and let it ramp up to target voltage or amperage. 253k views 6 years ago #anodizing. This comprehensive guide will cover everything you need to know about the process, including the steps involved, its advantages, challenges to overcome, and various applications. Fades from one voltage to another are acceptable. Anodizing titanium involves the electrochemical process of building up an oxide film on the surface of the metal. Wonder what colors. Type 1 anodizing typically results in a thin, semiconducting oxide layer. Much easier to control consistency, solid color and precise colors and fades. Web below is a anodized titanium color chart along with voltage used to produce the color. 1.3k views 10 months ago. Titanium anodizing september 14, 2000. This is just one chart that i took pictures of at different angles. Web the available colors for anodized titanium are: Full resolution version (4k uhd) of colors available here: Web technical bulletin5metalast international, inc. They are generated by a transparent oxide film grown on the metal surface. In contrast to type 2, type 3 titanium color anodizing lacks an overarching industry specification. Anodizing titanium is a fascinating and straightforward electrochemical process. Much easier to control consistency, solid color and precise colors and fades. This article will further discuss titanium anodizing, its purpose, uses, how it works, limitations, benefits, and important properties. The color of the anodized titanium. Anodizing titanium is a fascinating and straightforward electrochemical process. I did reach 91 volts. The range here is from 0 volts to 100 volts. Web titanium anodizing is the oxidation of titanium to alter the surface properties of produced parts, including improved wear properties and enhanced cosmetic appearance. Anodized titanium is used in a number of industries such as the. The color of the anodized titanium depends on the thickness of the oxidized layer created on the surface of the titanium. This makes color matching of parts from one batch to another a real challenge. The process of anodizing gives titanium all the advantages of hardening and coloring without changing the metals mechanical properties. Use the voltage chart (pictured) to. Start the rectifier and let it ramp up to target voltage or amperage. This comprehensive guide will cover everything you need to know about the process, including the steps involved, its advantages, challenges to overcome, and various applications. Web titanium anodizing is the oxidation of titanium to alter the surface properties of produced parts, including improved wear properties and enhanced. 1.3k views 10 months ago. There are no pigments or dyes involved. But it took a while. Web titanium anodizing is a process used in metal finishing to apply a layer to finished products. One of the remarkable features of titanium anodizing is the range of colors that can be achieved without dyes. 253k views 6 years ago #anodizing. Web ti + 2h2o → tio2 + 4h+ + 4e−. Type 1 anodizing typically results in a thin, semiconducting oxide layer. Much easier to control consistency, solid color and precise colors and fades. The color of the anodized titanium depends on the thickness of the oxidized layer created on the surface of the titanium. 253k views 6 years ago #anodizing. Type 1 anodizing typically results in a thin, semiconducting oxide layer. The range here is from 0 volts to 100 volts. Teal magenta green seafoam gray gold no. Web visit our titanium anodize color selector chart to explore tfc’s specific color designations. This makes color matching of parts from one batch to another a real challenge. The color isn’t a result of pigmentation but rather an optical phenomenon known as interference. Dip two or three times to work any air bubbles out of the parts, then place in the titanium anodize tank. Web titanium anodizing is a process used in metal finishing to apply a layer to finished products. Fades from one voltage to another are acceptable. They are generated by a transparent oxide film grown on the metal surface. Web how does it work? Use the voltage chart (pictured) to specify the voltage for your preferred color choice (s). Web the available colors for anodized titanium are: Anodizing involves submerging the titanium in an acid electrolyte solution and passing an electric current through it, which creates a layer of oxidation on the metal that gives it a unique colour. Web ti + 2h2o → tio2 + 4h+ + 4e−.

Titanium Anodizing Chart — 11 X 17 Poster ubicaciondepersonas.cdmx.gob.mx

Titanium Anodizing ChemTalk

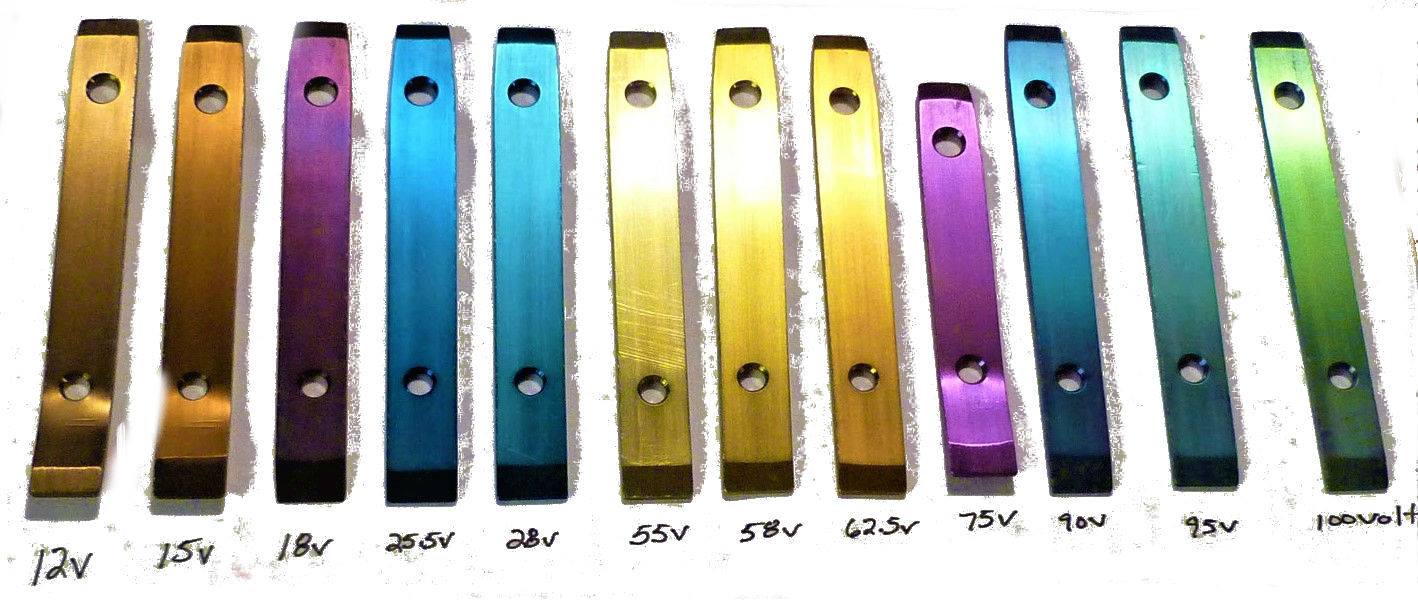

Anodized titanium color chart 9 thru 90 volts Oakley Forum

Anodized titanium color chart 9 thru 90 volts Oakley Forum

Toronto Cycles Titanium Anodizing at set Voltages

Titanium anodizer Milling machines/Parallelometers/Dental attachments

Anodized titanium color chart 9 thru 90 volts Oakley Forum

Anodized titanium color chart 9 thru 90 volts Oakley Forum

Titanium Anodizing Voltage Color Chart

Titanium Anodization (See Color Chart) EDC Specialties Every Day

This Comprehensive Guide Will Cover Everything You Need To Know About The Process, Including The Steps Involved, Its Advantages, Challenges To Overcome, And Various Applications.

Bronze, Blue, Yellow, Magenta (Pink/Purple), Cyan (Teal), And Green.

In Contrast To Type 2, Type 3 Titanium Color Anodizing Lacks An Overarching Industry Specification.

Much Easier To Control Consistency, Solid Color And Precise Colors And Fades.

Related Post: