Thread Strength Chart

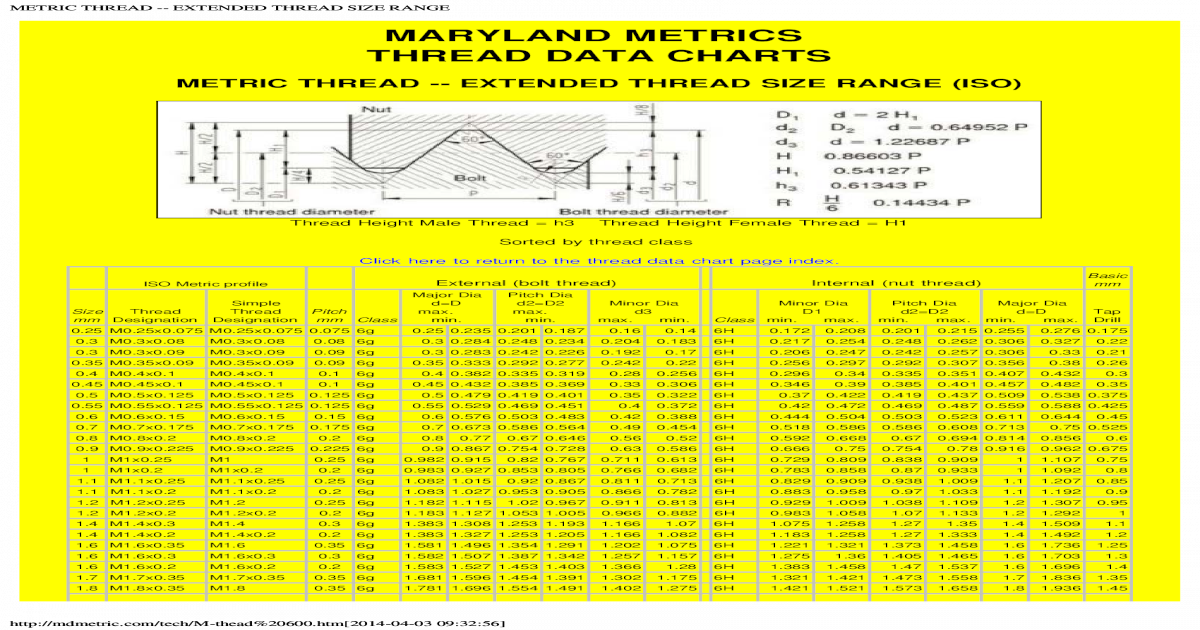

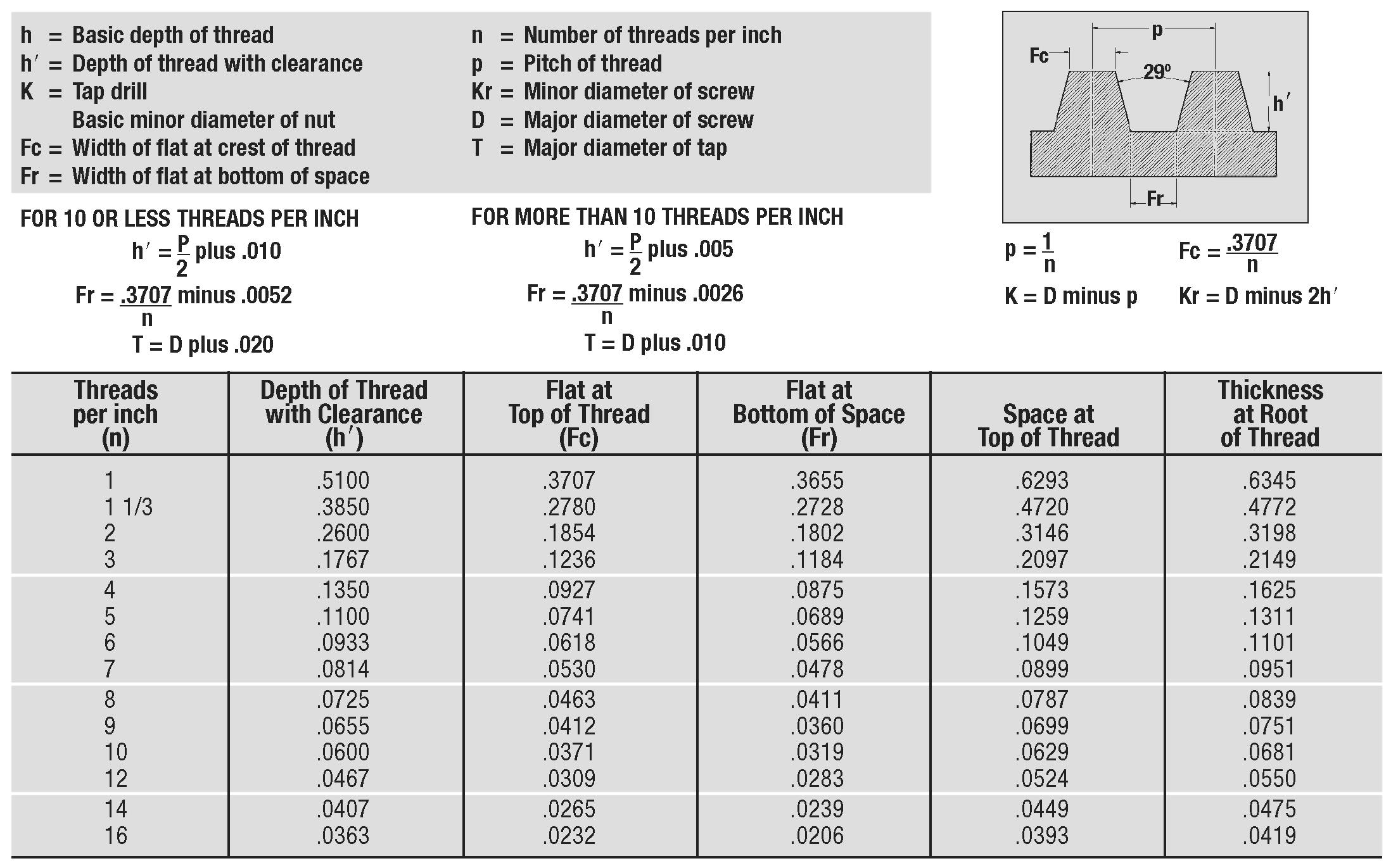

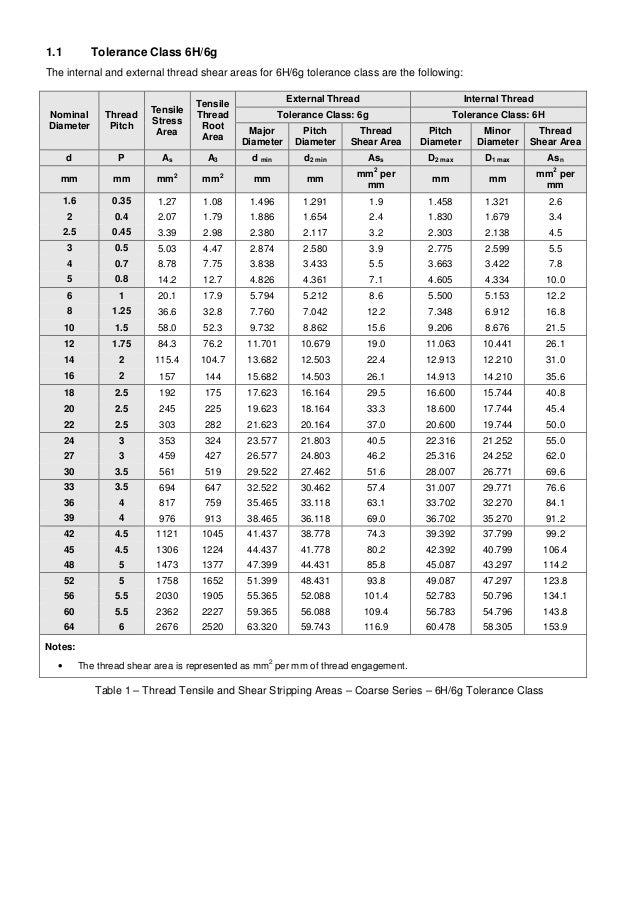

Thread Strength Chart - All areas are given in square inches. A thread engagement chart can guide the recommended thread engagement for different fasteners and materials. Web thread calculator and chart for metric thread, npt thread, bsp thread, unf thread, unc thread, acme thread, bspp thread, un thread, bspt thread, pipe thread, stub acme thread and buttress thread. More than a third of republicans said. Un thread chart and calculator = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75% of the proof loads specified by the standard. For aluminium , zinc or plastices the thread engagement should be at least 2 x nominal dia's of the thread. The diameter can range between 1/4″ to 5″. The reasoning behind this is if there is a product assembly error resulting in. The following are metric external thread size table chart for sizes m20 to m55 per. Web the following table chart defines standard metric external thread size m1.6 to m18 per. Web the height of the fundamental triangle is the distance, radially measured, between sharp crest and sharp root diameters. Un thread chart and calculator All areas are given in square inches. Web 1 mm = 0.039 inches. Forges bolts are called black and machined bolts are called bright. All units are in inches. And 1a, 2a, and 3a for external threads. Web roughly 10% of republicans say they are less likely to vote for mr trump, according to a reuters/ipsos survey conducted after the jury announced its verdict. The higher the class number, the tighter the fit. You also find the designation for different thread forms according to international standards. Most bolts are made of medium or low carbon steel. It is common to designate metric fine threads with the capital m plus an indication to their nominal outer diameter and their pitch: All units are in inches. Rolled threads have increased resistance to stripping because such. All areas are given in square inches. Web thread series pitch or in / rev minor dia min (2b / 3b) minor dia max (2b) minor dia max (3b) pitch dia min (2b / 3b) pitch dia max (2b) pitch dia Web improved tensile strength, shear & fatigue resistance. The following are metric external thread size table chart for sizes. Web ansi/ asme external screw thread size chart. It is common to designate metric fine threads with the capital m plus an indication to their nominal outer diameter and their pitch: You also find the designation for different thread forms according to international standards. Web this calculator calculates the tensile stress area of a screw thread fastener. All units are. Un thread chart and calculator Web the height of the fundamental triangle is the distance, radially measured, between sharp crest and sharp root diameters. Use this calculator for materials less than 100,000 psi ultimate tensile strength. Do not use these values for standard metric internal thread design. Web ansi/ asme external screw thread size chart. Other materials used are high tensile steel (ht bolts), stainless steel, alloy steel, brass and other materials. Web ansi screw and nut threads size chart. The distance measured parallel to the thread axis, between corresponding points on adjacent threads, is the thread pitch. Web for unified inch screw threads there are six standard classes of fit: I am basing both. Web threading formulas and definitions. Web the height of the fundamental triangle is the distance, radially measured, between sharp crest and sharp root diameters. These thread sizes and classes represent bolts and screws, as well, as other standard external threads. Web this calculator calculates the tensile stress area of a screw thread fastener. Web understanding how to calculate and choose. 1b, 2b, and 3b for internal threads; Download and print metric coarce threads clearance and tap drill chart. The reasoning behind this is if there is a product assembly error resulting in. Other materials used are high tensile steel (ht bolts), stainless steel, alloy steel, brass and other materials. And 1a, 2a, and 3a for external threads. Web threading formulas and definitions. Forges bolts are called black and machined bolts are called bright. For aluminium , zinc or plastices the thread engagement should be at least 2 x nominal dia's of the thread. All are considered clearance fits. Web 1 mm = 0.039 inches. Forges bolts are called black and machined bolts are called bright. The following are metric external thread size table chart for sizes m20 to m55 per. And 1a, 2a, and 3a for external threads. The diameter can range between 1/4″ to 5″. Web this calculator calculates the tensile stress area of a screw thread fastener. All units are in inches. Web ansi/ asme internal screw thread size chart. Use this calculator for materials less than 100,000 psi ultimate tensile strength. All are considered clearance fits. Most bolts are made of medium or low carbon steel. The thread grain structure is not severed; Web for cast iron or brass or bronze the thread engagement should be at least 1,5 x nominal dia's of the thread. It is common to designate metric fine threads with the capital m plus an indication to their nominal outer diameter and their pitch: Web the following table chart defines standard metric external thread size m1.6 to m18 per. Web improved tensile strength, shear & fatigue resistance. For aluminium , zinc or plastices the thread engagement should be at least 2 x nominal dia's of the thread.Unc Unf Metric Thread Chart Northwest Fastener PDF Screw Metalworking

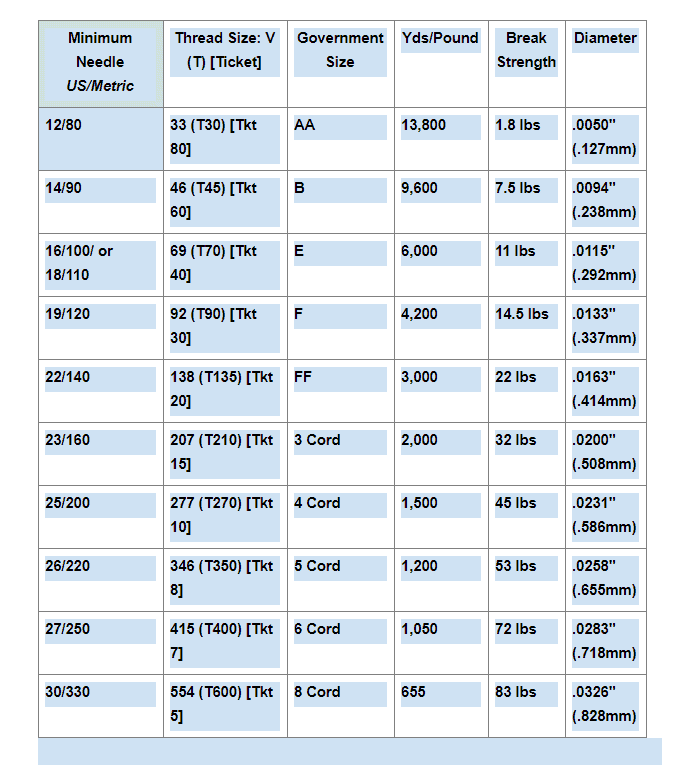

Sewing thread sizes how to choose the right size for a sewing project

Calculating Thread Strength Screw Strength Of Materials

Standard Fine Thread Chart

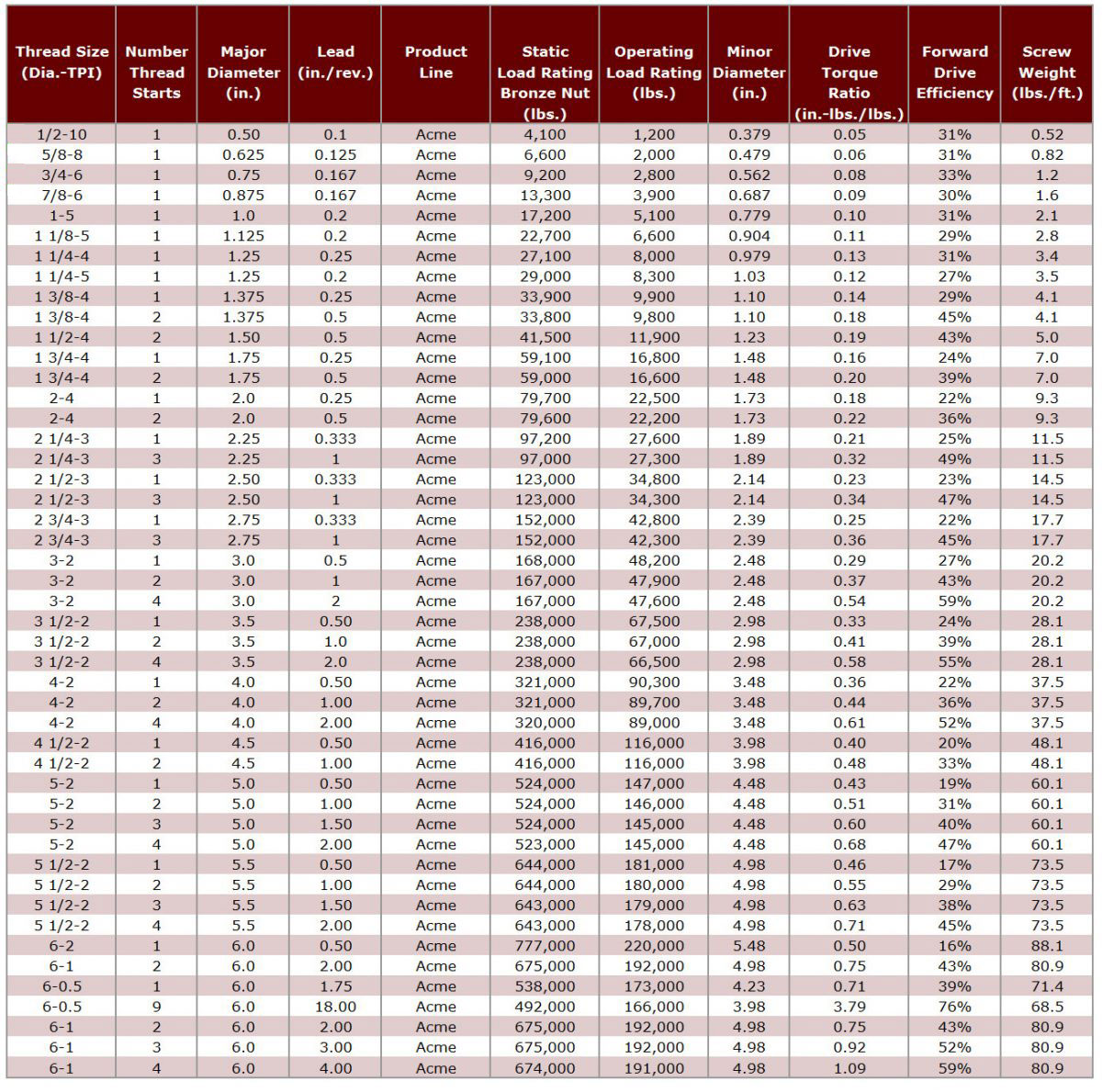

acme standard thread chart Focus

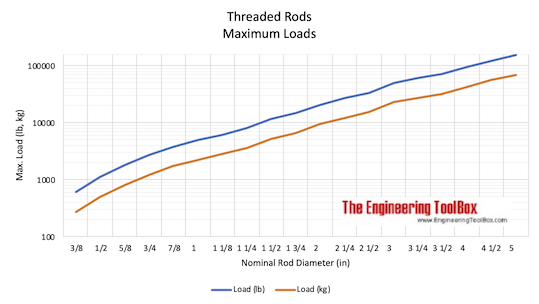

Threaded Rod Strength Chart Best Picture Of Chart

Thread Mastery A Guide to Understanding Thread Sewing Parts Online

Minimum Bolt Thread Engagement with Respect to Various Material Stren…

Acme Thread Chart Pdf

Threaded Rod Strength Chart Best Picture Of Chart

Nominal Diameter In Inch Fraction.

I Am Basing Both On A 80% Thread.

You Also Find The Designation For Different Thread Forms According To International Standards.

Web Understanding How To Calculate And Choose The Appropriate Thread Engagement Can Help Ensure The Strength And Effectiveness Of The Fastener In Any Given Application.

Related Post: