Thickness Welding Rod Sizes Chart

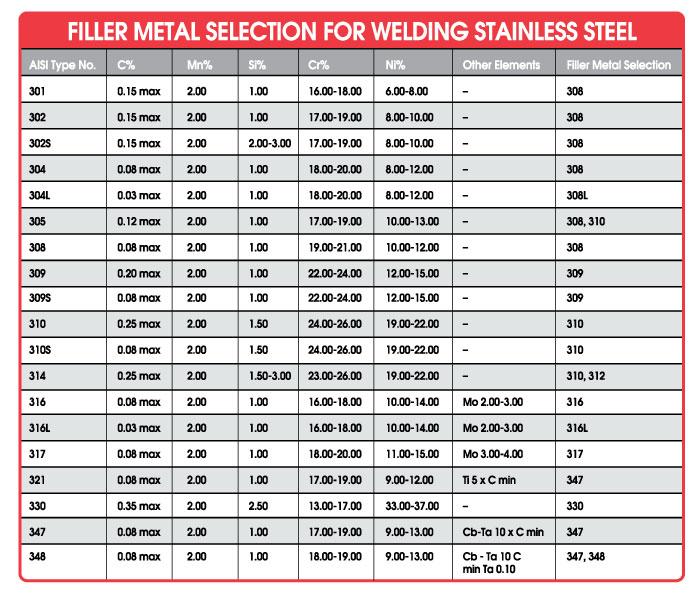

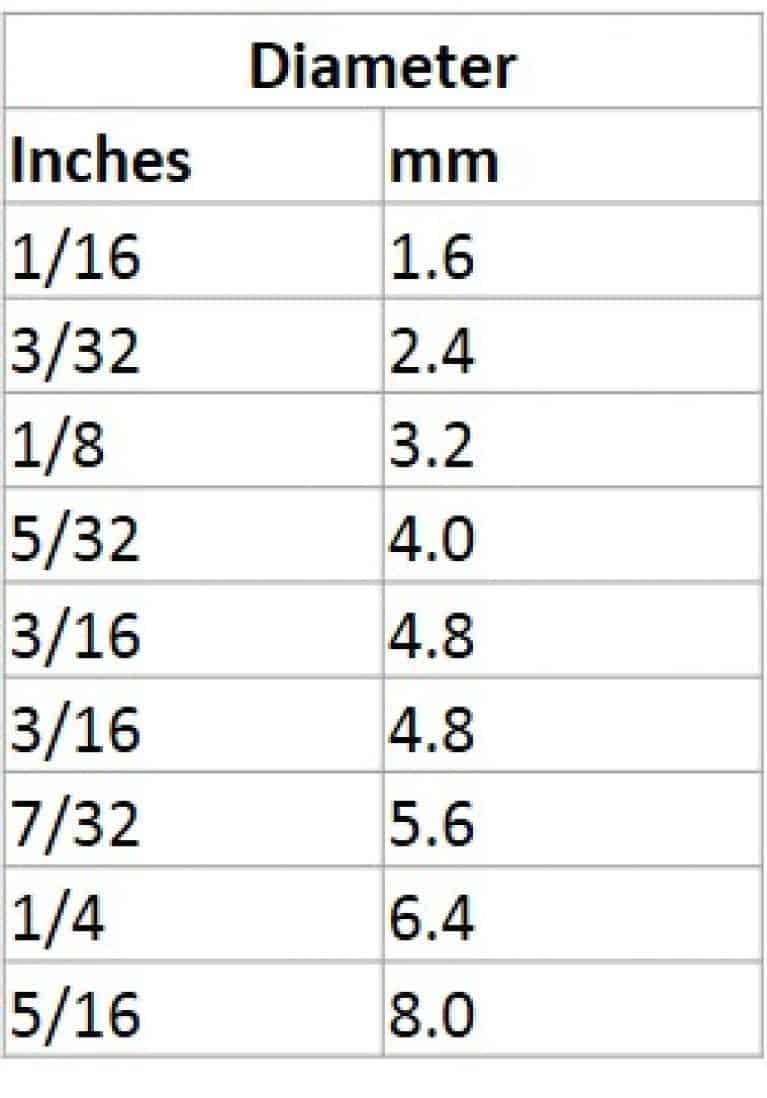

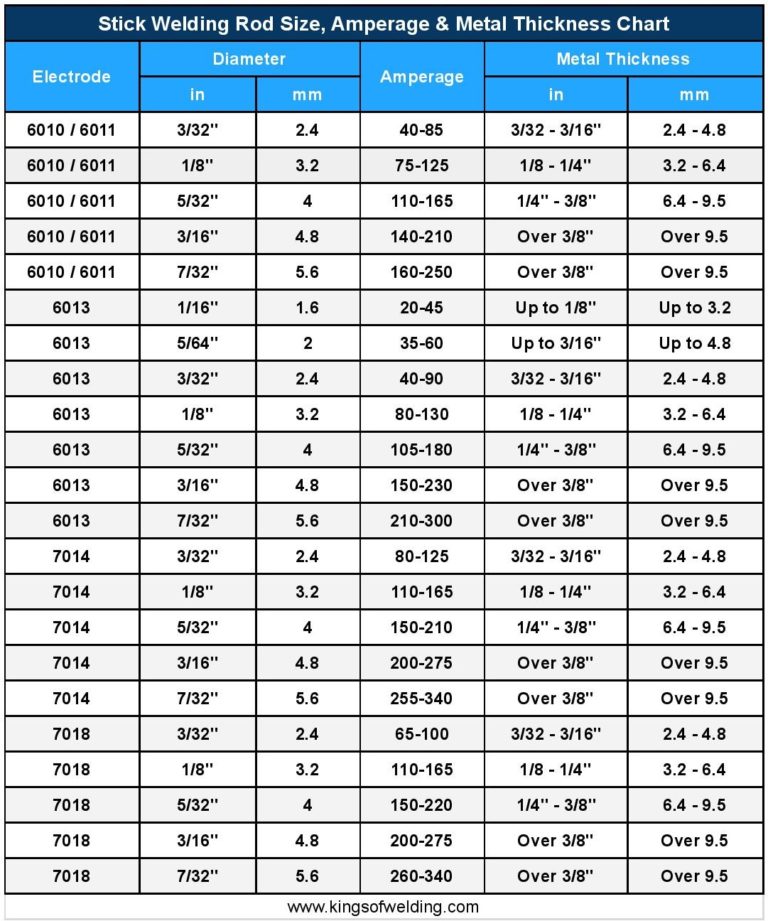

Thickness Welding Rod Sizes Chart - E6010 and e6011 size and amperage chart. The primary factor when choosing the size of a welding rod is the thickness of the base metal that’s going to be welded. The thickness of the metal being welded is a crucial factor in determining the appropriate rod size. So, choosing the appropriate welding rod size is crucial. Web these charts provide information on recommended rod sizes based on material thickness and welding amperage. What are the welding rods? Browse suggested weld parameter settings for stick welding. Below is a chart that will give you a starting point for choosing the correct welding rod size. There are some other sizes as well. Web how to choose the right welding rod size. The thicker the base metal, the larger the welding rod diameter and amperage. 6010 and 6011 are virtually the same rod. Web i'm still new to stick welding and have been looking around for a chart for quite a while that would recommend what size rod to use at what amps for a certain base metal thickness. They also determine. Web s ti ck w el d i n g r o d ch ar t w w w. The welding rod should be thinner than the base metal but not thinner than half of the base metal. The document provides guidelines for selecting the proper amperage and electrode size for stick welding based on the thickness of the metal. We cover everything related to rod types, sizes, and how to pick the right one for your needs. The general trend is that the thicker the base metal to weld, the larger the electrode size needed. Web how to choose the right welding rod size. 3.1 thickness of the metal and electrode size. You can’t use a rod that doesn’t. Web how to select stick welding rod type, size, and amperage. 2.1 how is welding rod diameter measured? 6010 and 6011 are virtually the same rod. Web stick (smaw) welding rods are available in a variety of diameters, ranging from 3/32 inch up to 1/4 inch. 1.1 how do welding rods differ? Browse suggested weld parameter settings for stick welding. The primary factor when choosing the size of a welding rod is the thickness of the base metal that’s going to be welded. Web how to choose the right welding rod size. Web welding rod sizes sizes & material thickness chart (mild steel) contents. The general trend is that the thicker the. Plus a chart with rod size and amperage per metal thickness in inches and mm. Thin metals (less than 1/8 inch) typically require a rod diameter of 1/16 to 1/8 inch. How to choose a correct welding rod size. The most common diameter for general purpose welding is 3/32, 1/8 inch, and 5/32 inch. Different welding rods sizes, types, and. We’ll get into those below. The primary factor when choosing the size of a welding rod is the thickness of the base metal that’s going to be welded. How much welding you can do in one go will be determined by the 'duty cycle' of the welder. Web i'm still new to stick welding and have been looking around for. The thicker the base metal, the larger the welding rod diameter and amperage. They also determine the strength of the bond holding both metals together. The welding rod should be thinner than the base metal, but not thinner than half of the base metal. Web stick (smaw) welding rods are available in a variety of diameters, ranging from 3/32 inch. Web welding rod sizes sizes & material thickness chart (mild steel) contents. The thickness of the metal being welded is a crucial factor in determining the appropriate rod size. Web s ti ck w el d i n g r o d ch ar t w w w. Web what material are you welding? Different welding rods sizes, types, and. Browse suggested weld parameter settings for stick welding. You can’t use a rod that doesn’t run on your power supply. Web these include corrosion resistance, ductility, high tensile strength, the type of base metal to be welded, the position of the weld (flat, horizontal, vertical, or overhead), and the type of current and polarity required. Web how to choose the. Types of welding rod sizes. Welding rods help in joining metals together. Overhead, horizontal, vertical, and flat. Web how to pick the correct welding rod size. Web home » welders » stick welders. Web anything up to 1/4″ (6.35 mm) thick would be best welded with a 1/8″ (3.2 mm) electrode, and thicker metal would use 5/32″ (4.0 mm). Generally, thicker metal will require a larger rod, while thinner metal will require a smaller rod. We’ll get into those below. E6010 and e6011 size and amperage chart. How to choose a correct welding rod size. It also offers a stable. 3.1 thickness of the metal and electrode size. Web see our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. Hi rocker, you should be fine running 3.2 electrodes on a domestic supply. The welding rod should be thinner than the base metal, but not thinner than half of the base metal. The right welding rod size depends on the metal thickness.

Welding Rod Sizes Chart

Welding Rods for Stick Welding The Definitive Electrode Guide (2019)

Stick Amps Vs Rod size Vs metal thickness Welding rod chart, Welding

Welding Rod Sizes, Amperage & Metal Thickness Chart Kings of Welding

Types Of Welding Rods Chart vlr.eng.br

The ultimate guide to welding rod sizes and classifications, including

Welding rod chart, Welding rods, Welding and fabrication

How Do I Calculate How Much Welding Rod I Need

Welding Rod Amp Chart

Welding Rod Sizes Chart Online Factory, Save 69 jlcatj.gob.mx

The Thickness Of The Metal Being Welded Is A Crucial Factor In Determining The Appropriate Rod Size.

Here’s What You Should Know.

Web These Include Corrosion Resistance, Ductility, High Tensile Strength, The Type Of Base Metal To Be Welded, The Position Of The Weld (Flat, Horizontal, Vertical, Or Overhead), And The Type Of Current And Polarity Required.

Plus A Chart With Rod Size And Amperage Per Metal Thickness In Inches And Mm.

Related Post: