Standard Piping Color Codes Chart

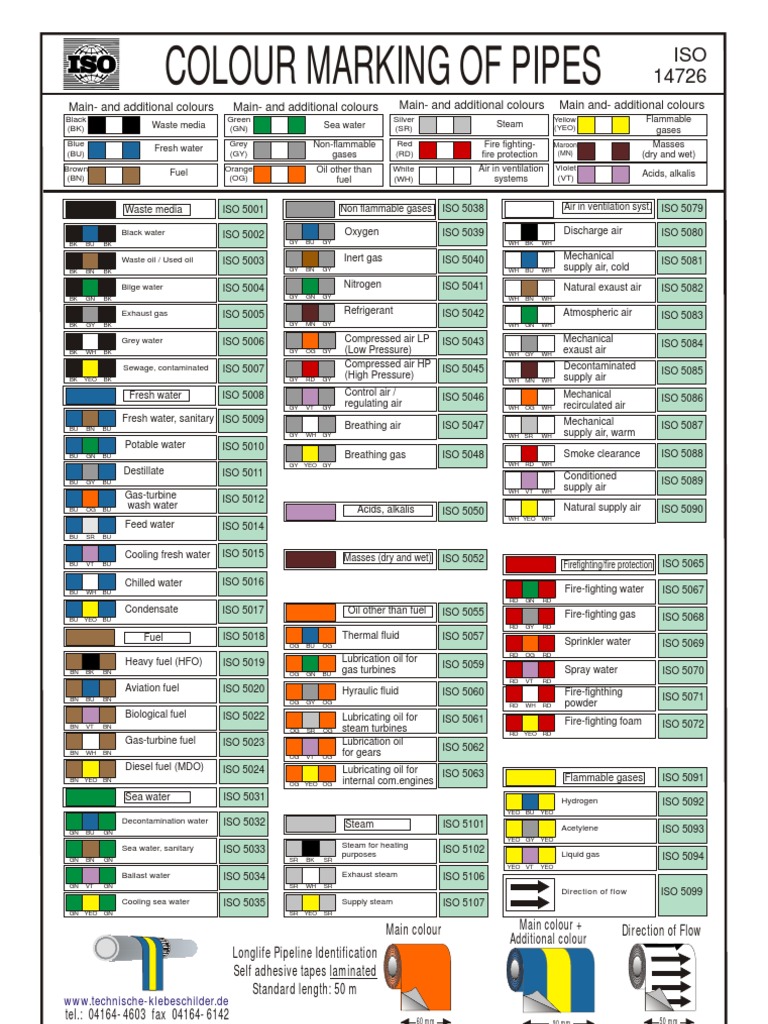

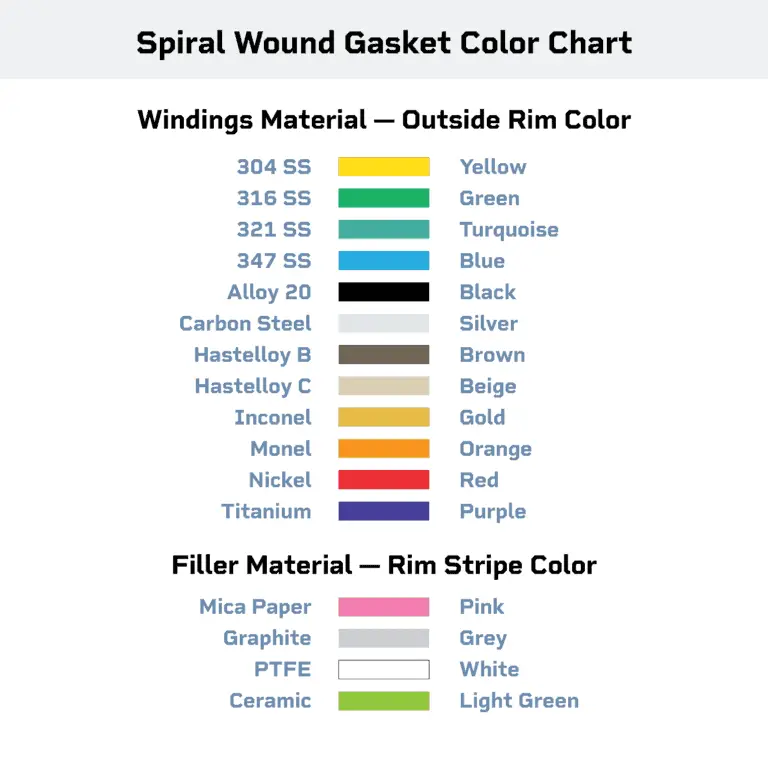

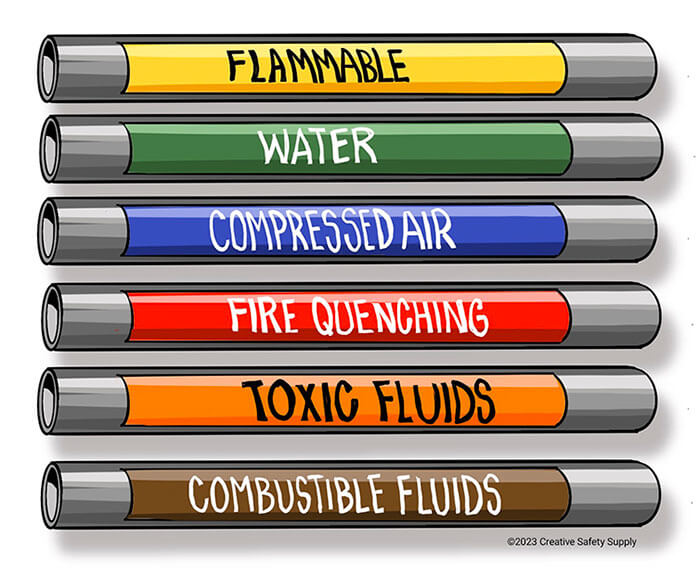

Standard Piping Color Codes Chart - Yellow signifies caution and should be used for any signs warning passersby of tripping and stumbling hazards. By using a pipe color coding chart, workers can quickly and easily identify the contents and function of pipes in a piping system, which can help to prevent accidents and ensure that the system operates. Web this standard explains colors, text, size, and placement of pipe marking labels. This standard explains colors, text, size, and placement of pipe marking labels. Web pipe color coding charts are often based on industry standards, such as ansi/asme a13.1 in the united states or bs 1710 in the united kingdom. Standards may vary by region or municipality. Web a pipe color code chart showing the iiar standards is available. Web according to asme a13.1 for pipe color coding, the color band shall be: Web pipeline color code charts are often based on recognized standards or guidelines, such as the apwa, ansi/asme a13.1, and bs 1710 standards. These charts are also known as pipeline color code standards or reference charts. Colors represented are digital reproductions of actual standards and will vary in appearance due to differences in monitor and video card output. Web pipe marking color code standards. By using a pipe color coding chart, workers can quickly and easily identify the contents and function of pipes in a piping system, which can help to prevent accidents and ensure that. Web businesses should familiarize themselves with the ansi/asme a13.1 pipe color code standard, which is the industry consensus standard for marking pipes. These charts are also known as pipeline color code standards or reference charts. Web pipe marking color code standards. For water and wastewater pipes. There are many standards out there from a variety of sources, but by far. This standard explains colors, text, size, and placement of pipe marking labels. Standards may vary by region or municipality. Red is the standard color for any fire protection tools. For water and wastewater pipes. Web pipe color coding charts are often based on industry standards, such as ansi/asme a13.1 in the united states or bs 1710 in the united kingdom. These charts are also known as pipeline color code standards or reference charts. It also provides guidance on marking location of piping components. Web pipeline color code charts are often based on recognized standards or guidelines, such as the apwa, ansi/asme a13.1, and bs 1710 standards. This standard identifies the color of the labels and what those colors mean. This. Web pipeline color code charts are often based on recognized standards or guidelines, such as the apwa, ansi/asme a13.1, and bs 1710 standards. For water and wastewater pipes. Web according to asme a13.1 for pipe color coding, the color band shall be: Colors represented are digital reproductions of actual standards and will vary in appearance due to differences in monitor. Web this standard explains colors, text, size, and placement of pipe marking labels. Web the use of colour in the identification of pipes can be based on the following colour charts: Red is the standard color for any fire protection tools. It also provides guidance on marking location of piping components. Standards may vary by region or municipality. Web according to asme a13.1 for pipe color coding, the color band shall be: These charts are also known as pipeline color code standards or reference charts. What are the asme (ansi) standard a13.1 color codes? The standards for pipe identification regulate the letter size, marker length, marker color, and location of markers to be installed. Web pipeline color code. The following are the main options for this set of standards: Web pipeline color code charts are often based on recognized standards or guidelines, such as the apwa, ansi/asme a13.1, and bs 1710 standards. In general, the most hazardous feature of the contents should determine the colors used. By using a pipe color coding chart, workers can quickly and easily. By using a pipe color coding chart, workers can quickly and easily identify the contents and function of pipes in a piping system, which can help to prevent accidents and ensure that the system operates. There are many standards out there from a variety of sources, but by far the most popular is the ansi/asme a13.1 standard. Web this standard. 3) the document provides charts showing the standardized color codes for different pipe materials according to the piping fabrication institute standard. These charts are also known as pipeline color code standards or reference charts. This standard covers ideal colors, bands, signage and text that should be used to label pipes in both industrial and municipal treatment areas. The ansi standard. The ansi standard a13.1 on pipe marker visibility and size requirements was updated in 2020, resulting in slight changes from the previous (2015) requirements. Colors represented are digital reproductions of actual standards and will vary in appearance due to differences in monitor and video card output. This standard identifies the color of the labels and what those colors mean. The following are the main options for this set of standards: Colors based on “10 states standards” unless otherwise marked. Osha, ansi and the american society for mechanical engineers (asme) also set color codes for labeling pipes. Web pipeline color code charts are often based on recognized standards or guidelines, such as the apwa, ansi/asme a13.1, and bs 1710 standards. What are the asme (ansi) standard a13.1 color codes? By using a pipe color coding chart, workers can quickly and easily identify the contents and function of pipes in a piping system, which can help to prevent accidents and ensure that the system operates. Web pipe color coding charts are often based on industry standards, such as ansi/asme a13.1 in the united states or bs 1710 in the united kingdom. 3) the document provides charts showing the standardized color codes for different pipe materials according to the piping fabrication institute standard. These colors will be used on almost all pipes to ensure everyone in the facility can immediately recognize the relationship between pipe contents and subsequent hazards. Web this standard explains colors, text, size, and placement of pipe marking labels. Web as noted in the color chart, there are six categories of pipe content, flammable, combustible, toxic/corrosive, fire quenching, other water, and compressed air, that are assigned a specific color combination. Web a pipe color code chart showing the iiar standards is available. Yellow signifies caution and should be used for any signs warning passersby of tripping and stumbling hazards.

Pipe Color Code Standard And Piping Color Codes Chart By Images

Ansi A13.1 Pipe Color Code Chart

ISO14726 (Color Marking on Pipes) Atmosphere Of Earth

Pipe Marking Color Codes Bridge To Safety

Piping Color Code Chart PDF Pipe (Fluid Conveyance) Building

Pipe Color Code Standard and Piping Color Codes Chart by

Iso Standard Piping Color Codes Chart

Pipe Color Code Standard and Piping Color Codes Chart

Pipe Color Code Standard and Piping Color Codes Chart

Pipe Color Codes ANSI/ASME A13.1 Creative Safety Supply

Web 2) Pipes Are Color Coded To Avoid Mixing Of Different Material Grades And To Easily Store, Retrieve, And Identify Pipe Components.

In General, The Most Hazardous Feature Of The Contents Should Determine The Colors Used.

Fire Protection Equipment (E.g., Fire Pumps, Fire Hydrants) Yellow:

This Standard Explains Colors, Text, Size, And Placement Of Pipe Marking Labels.

Related Post: