Stainless Steel Tig Welding Settings Chart

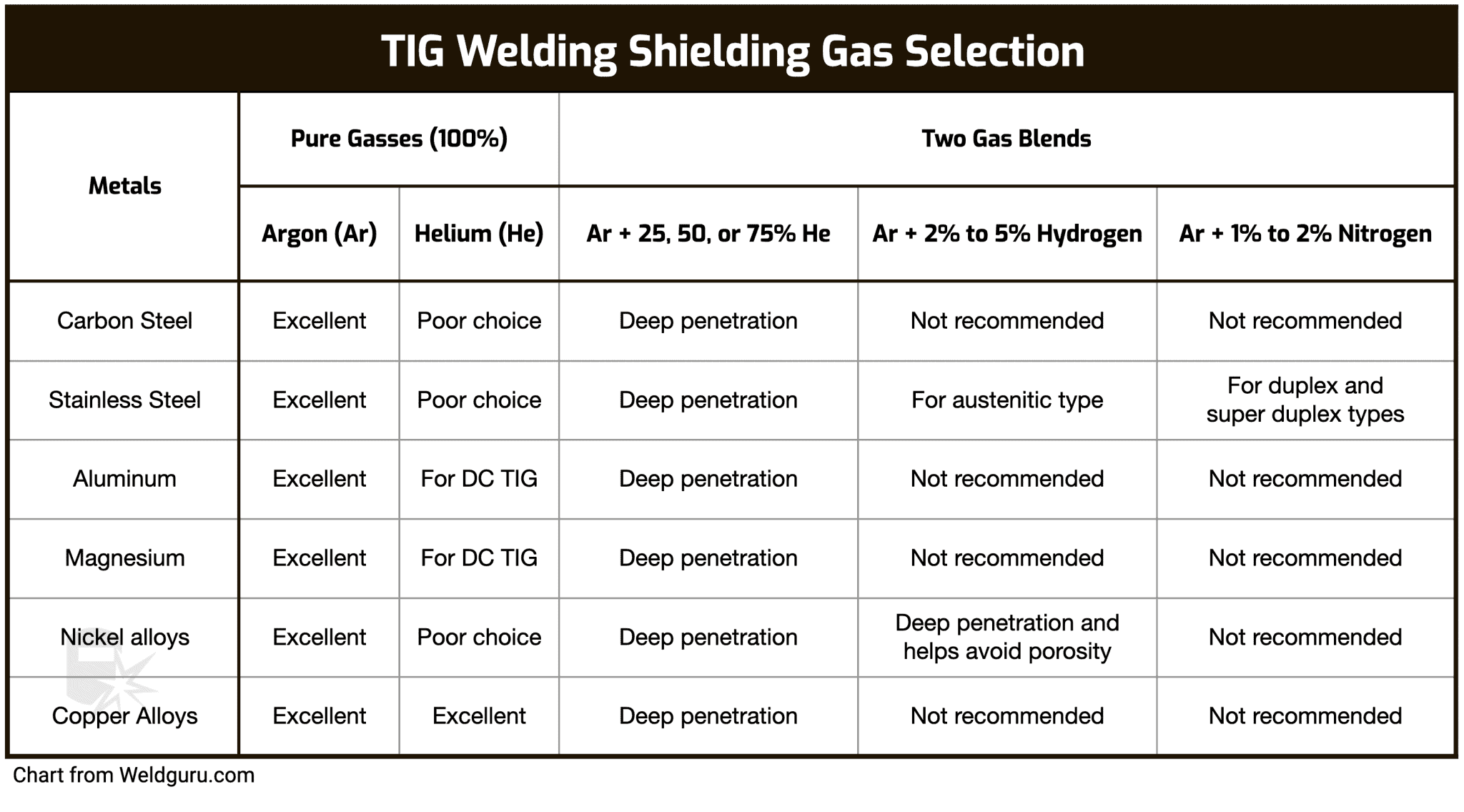

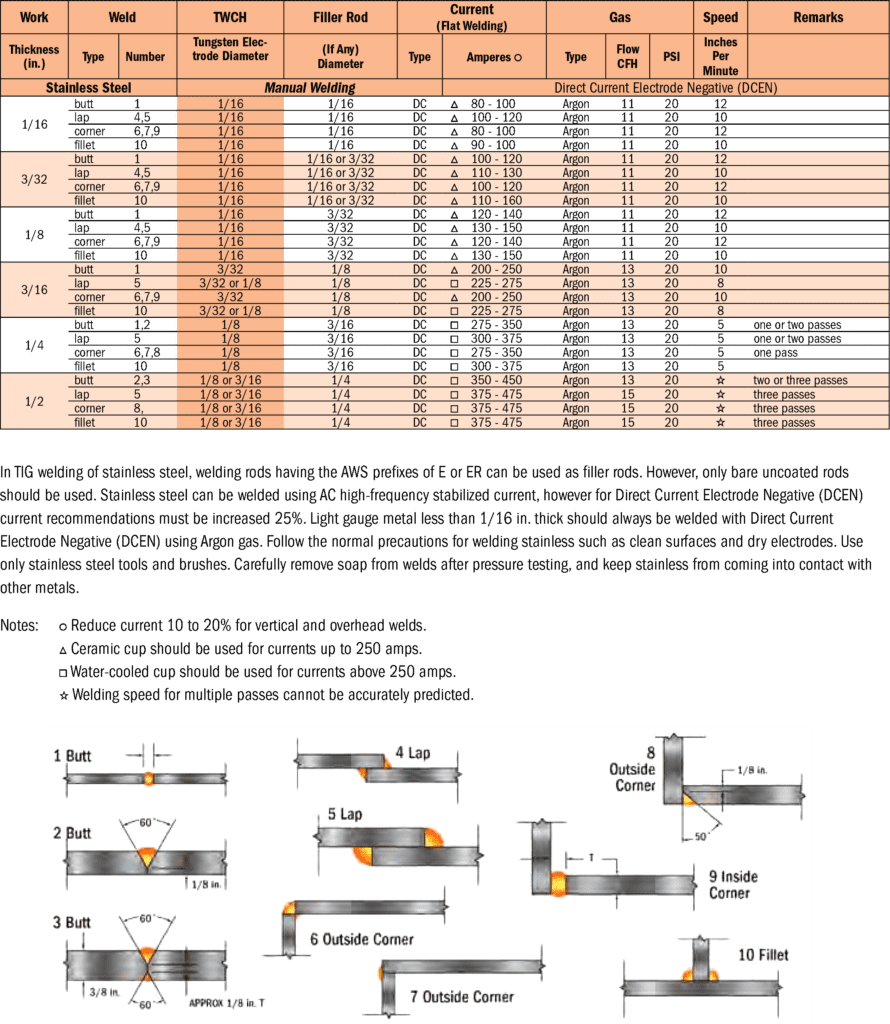

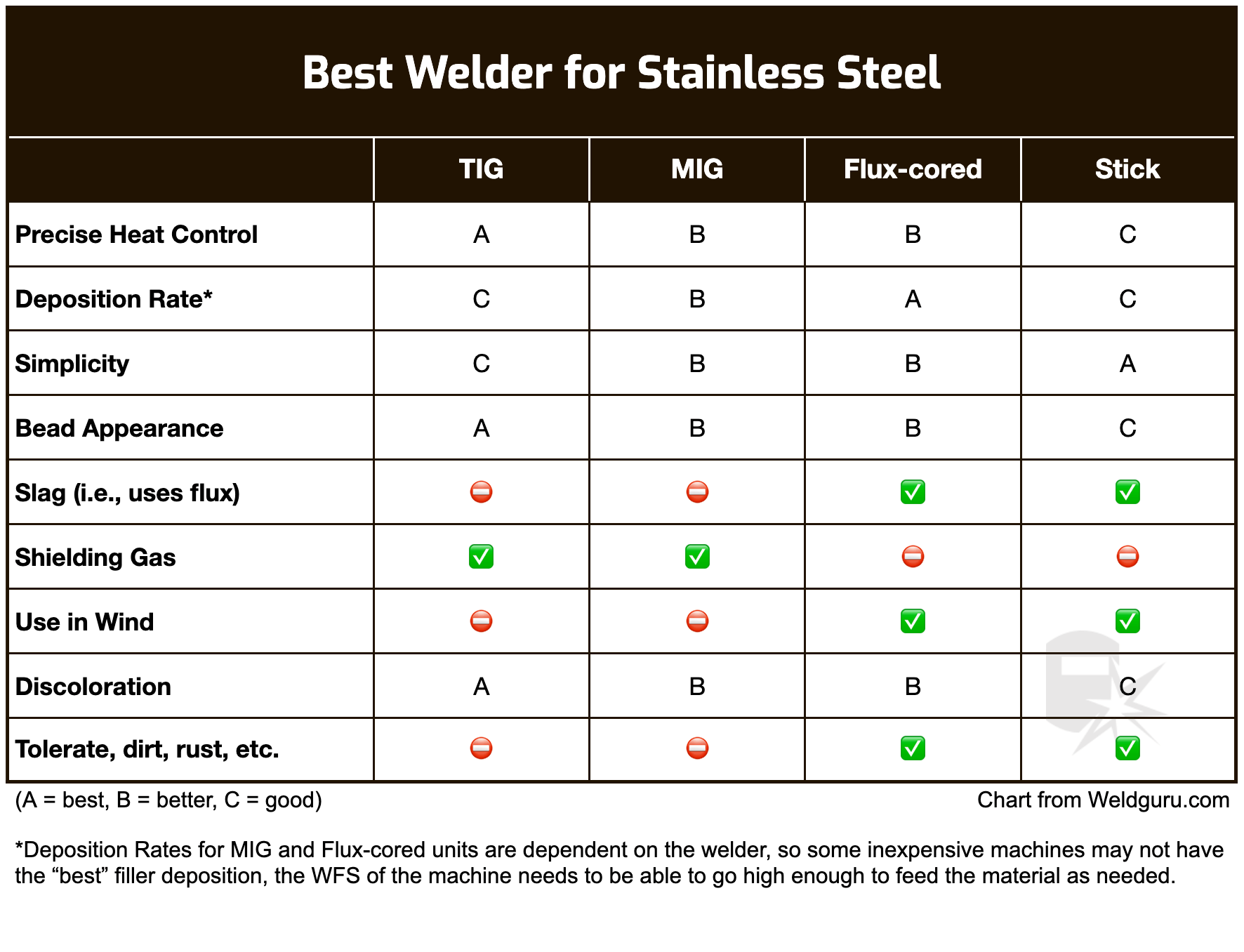

Stainless Steel Tig Welding Settings Chart - Choose a gas or air cooling tig torch. Tungsten diameter and cup size. Use only stainless steel tools and brushes, Tig welding is a precise and intricate welding technique that requires an understanding of the different tig welder settings. Web a good place to start is between 40% and 60%. By using the chart, welders can determine the optimal settings for their welding machine based on the material they are welding and the desired weld size. You will need to set the amperage higher when pulsing, since the nature of the process reduces the overall heat that enters the metal. Even the torch remains cool for 6 hours if you work at 60 to 90 amps. Tig welding, or tungsten inert gas welding, demands precision and control over various settings for optimal results. Web preparing the stainless steel. Web highly useful setting when welding sensitive metals like stainless steel and titanium, which tend to oxidate as the weld cools. See the chart below for current ranges of all sizes. Browse suggested weld parameter settings for tig welding. Web a good place to start is between 40% and 60%. Tap the bottom row buttons. Some of the options need an amperage knob and result display. Tig welding, or tungsten inert gas welding, demands precision and control over various settings for optimal results. Also, similar to other welding styles, tig welding relies on essential variables to determine what settings are appropriate for each application. We need a lot less flow in tig welding. Set the. Web see the chart below for current ranges of all sizes. Dc straight polarity dc reverse polarity ac high frequency selecting correct torch nozzle. Web preparing the stainless steel. Tungsten diameter and cup size. Welcome to our comprehensive guide on achieving perfect welds when tig welding stainless steel. If you’re new to tig welding, the process of selecting the correct settings can be overwhelming. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Web the other four options are what we use to tig weld with. Web this article will teach you the entire process of tig welding stainless steel. Adequate gas. Web a good place to start is between 40% and 60%. Start by thoroughly cleaning the stainless steel. Web the chart usually includes the current range, polarity, filler metal type, shielding gas type, and tungsten electrode size. Dc straight polarity dc reverse polarity ac high frequency selecting correct torch nozzle. An led green light will ensure you the chosen option. Follow the normal precautions for welding stainless such as: It caters to different material types and thicknesses for effective welding. Welcome to our comprehensive guide on achieving perfect welds when tig welding stainless steel. Turn on the machine and the rear panel. This keeps the cord and handles cool for a long time. Web stainless steel technical guide. Start by thoroughly cleaning the stainless steel. Web this article will teach you the entire process of tig welding stainless steel. For stainless steel, it is better to use a gas or air cooling tig torch. Use only stainless steel tools and brushes, Welcome to our comprehensive guide on achieving perfect welds when tig welding stainless steel. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Tig welding is a precise and intricate welding technique that requires an understanding of the different. Follow the normal precautions for welding stainless such as: View technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for your application. Tungsten diameter and cup size. Tap the bottom row buttons. Tig welding is a precise and intricate welding technique that requires an understanding of the different tig welder settings. Web the chart usually includes the current range, polarity, filler metal type, shielding gas type, and tungsten electrode size. Browse suggested weld parameter settings for tig welding. Web the other four options are what we use to tig weld with. An led green light will ensure you the chosen option. Web this article will teach you the entire process of. Web a tig welding settings chart provides essential parameters like amperage, voltage, and gas flow. Web see the chart below for current ranges of all sizes. Tungsten diameter and cup size. Web preparing the stainless steel. Use only stainless steel tools and brushes, This keeps the cord and handles cool for a long time. Web stainless steel can be welded using achf, however, recommendations for dcsp must be increased 25%. Stainless is less thermally conductive than mild steel, so heat does not flow away from the weld quite so quickly. Light gauge metals less then 1/ 16” thick should always be welded with dcsp using argon gas. See the chart below for current ranges of all sizes. A flow of 15 to 25 cfh will cover most applications. Web highly useful setting when welding sensitive metals like stainless steel and titanium, which tend to oxidate as the weld cools. Welcome to our comprehensive guide on achieving perfect welds when tig welding stainless steel. It caters to different material types and thicknesses for effective welding. Later, check the process control and set to tig hf impulse. Web this article will teach you the entire process of tig welding stainless steel.

TIG Welding Charts ILMO Products Company

Stainless Steel Weld Color Chart

Tig Welding Settings Chart

Tig Welding Rods Chart

TIG Welding Parameters Hobart Brothers

Tig parameters chart MIG Welding Forum

Tig Welder Settings Chart

How to Weld Stainless Steel A Complete Guide (2022)

Inspirasi 36+ Stainless Steel TIG Welding Settings

Tig Welding Settings Chart Pdf

View Technical Guides For Guidance On Welding Various Metals And Selecting The Right Hobart Brothers Filler Metal Solution For Your Application.

For Stainless Steel, It Is Better To Use A Gas Or Air Cooling Tig Torch.

Choose A Gas Or Air Cooling Tig Torch.

Browse Suggested Weld Parameter Settings For Tig Welding.

Related Post: