Spur And Pinion Gear Chart

Spur And Pinion Gear Chart - Web the pinion gear is attached to the motor’s output shaft while the spur gear is attached to an output shaft on the transmission. Enter your car's internal drive ratio to see the final drive ratio (fdr), and see the percentage change in gearing you'll get from a new pinion and spur. > calculation of gear dimensions. B) divide pitches, as shown below. Spur gear ÷ pinion gear = gear ratio. A p = addendum of pinion. To figure out the final drive number, do the math: A few things that have informed these charts. What this number indicates is how much reduction happens as a result of that gear set! Gears are machine elements used to transmit rotary motion between two shafts, normally with a constant ratio. Web what is the difference between a spur gear and a pinion gear? Web you take the number of teeth on the driven (spur) gear and divide it by the number of teeth on the drive (pinion) gear………the numbers are expressed as such: The amount of revolutions that the motor and pinion and spur gear combination will cause the transmission. To a) measure calculate distance rack mod of 10 (module): What this number indicates is how much reduction happens as a result of that gear set! > calculation of gear dimensions. Watch on and find out!pinion gears:h. Gears are machine elements used to transmit rotary motion between two shafts, normally with a constant ratio. Correctly setting up these gears will take your rc car’s performance to another level. What this number indicates is how much reduction happens as a result of that gear set! A few things that have informed these charts. To a) measure calculate distance rack mod of 10 (module): Web as here is a chart that will allow you to run. Web the pinion and spur gears are the gear combination that transfers the power from the motor to the wheels of your rc car. Specifically for tb, ta, ff and trf tc cars. Web spur gear design formula for geometry, pitch, tooth clearance and critical functional data. After installation of the adapter, loosen the set screw and align the edge. A p = addendum of pinion. (inch units applicable for constants) spur gear design calculator. Gear ratio i = z2 (teeth driven gear) Robinson racing offers convenient pinion “6. Web > gear technical reference. Web as here is a chart that will allow you to run the industry standard 64 and 48dp spurs and pinions with the standard tamiya motor mount. (inch units applicable for constants) spur gear design calculator. By nicadraus, october 28, 2019 in general discussions. > calculation of gear dimensions. Gears are machine elements used to transmit rotary motion between two. Web spur gear design formula for geometry, pitch, tooth clearance and critical functional data. The pinion is the smallest gear and the larger gear is called the gear wheel. Changing these gears alters the ‘gear ratio’; Always check your motor temperature frequently on the first run after changing the gearing, motor or increasing battery voltage! A few things that have. To a) measure calculate distance rack mod of 10 (module): Web the pinion and spur gears are the gear combination that transfers the power from the motor to the wheels of your rc car. Web try our gear ratio and rollout calculator to find the right pinion and spur for your car, whether it's team associated, tamiya, traxxas, or any. B) divide pitches, as shown below. How is rc gear ratio calculated? Gear ratio i = z2 (teeth driven gear) You don’t need to spend a lot of money to add gearing options to your pit box. Watch on and find out!pinion gears:h. A g = addendum of gear. The amount of revolutions that the motor and pinion and spur gear combination will cause the transmission to turn in one minute. Web try our gear ratio and rollout calculator to find the right pinion and spur for your car, whether it's team associated, tamiya, traxxas, or any other make. Web always give more. A 72 tooth spur divided by a 20 tooth pinion = 3.60 to 1 or 3.60:1. Web you take the number of teeth on the driven (spur) gear and divide it by the number of teeth on the drive (pinion) gear………the numbers are expressed as such: Robinson racing offers convenient pinion “6. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. Enter your car's internal drive ratio to see the final drive ratio (fdr), and see the percentage change in gearing you'll get from a new pinion and spur. By nicadraus, october 28, 2019 in general discussions. (inch units applicable for constants) spur gear design calculator. Gear ratio i = z2 (teeth driven gear) Web as here is a chart that will allow you to run the industry standard 64 and 48dp spurs and pinions with the standard tamiya motor mount. Always check your motor temperature frequently on the first run after changing the gearing, motor or increasing battery voltage! How is rc gear ratio calculated? To figure out the final drive number, do the math: Here is the big secret. A p = addendum of pinion. Select numbers of teeth in gears and module (pitch). To a) measure calculate distance rack mod of 10 (module):

Rc Pinion Gear Chart

Mod1 Steel Pinion Gear Spur Gears 1039 Teeth 420mm Bore With Screw

Pinion And Spur Gear Chart

RC Pinion and Spur Gear Explained A Beginners Guide

Traxxas Pinion And Spur Gear Chart

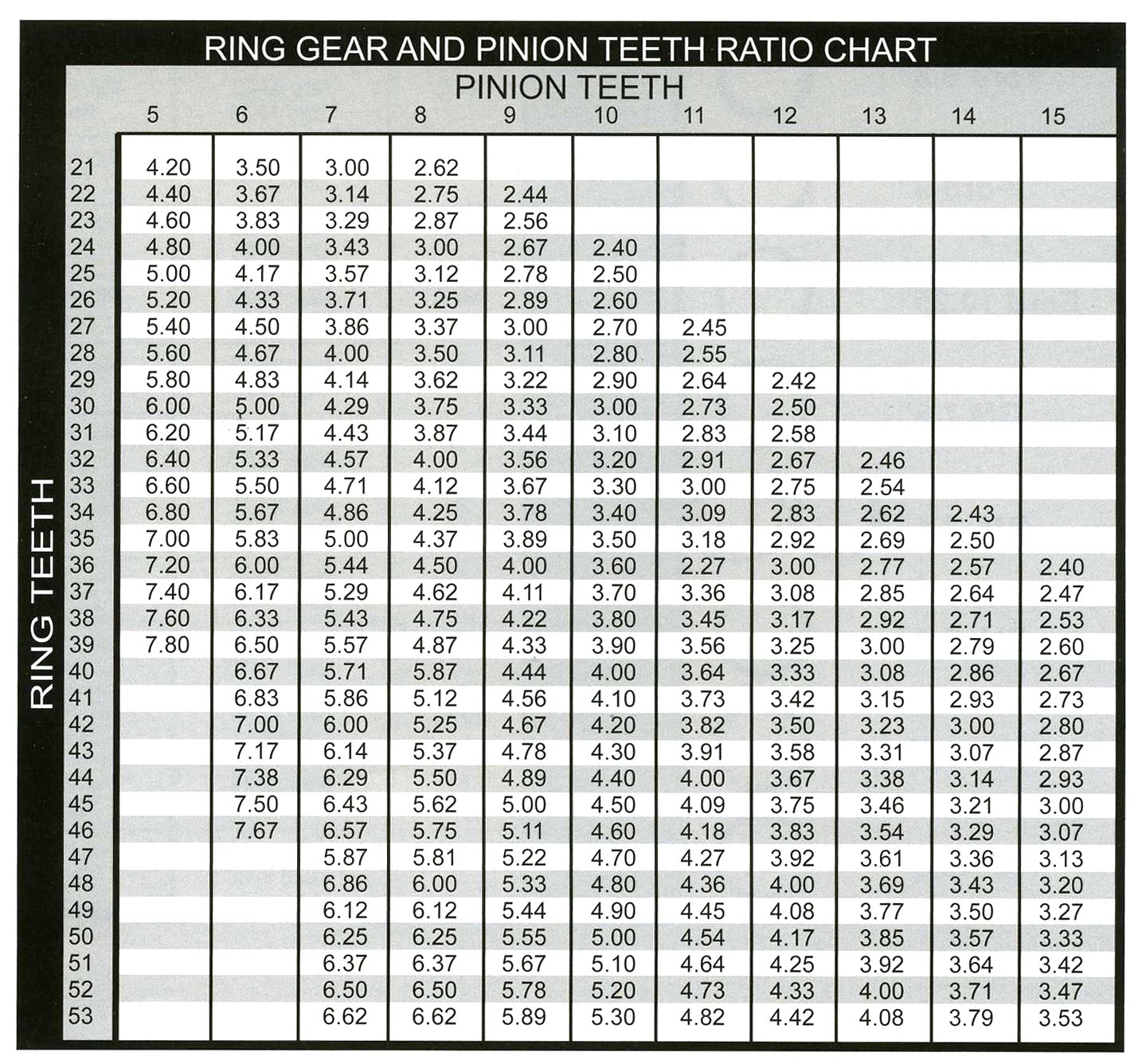

Ring and Pinion Gear Ratio Calculation Chart Quadratec

spur pinion?

Mod 1.5 Steel Pinion Gear Spur Gears 1280 Teeth 425mm Bore With Screw

Metric Spur Gear Size Chart

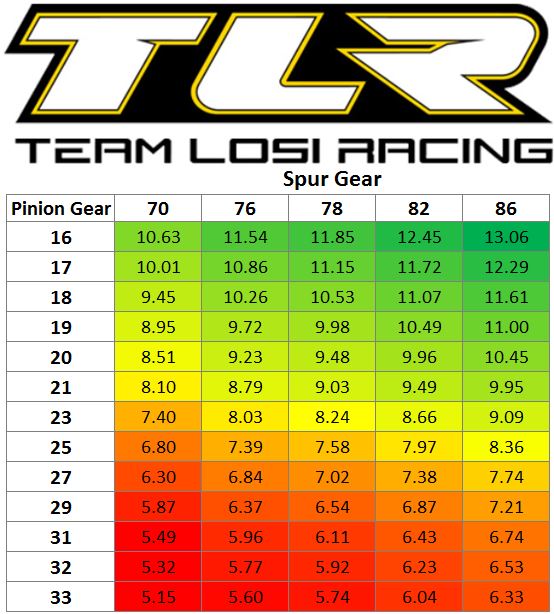

TLR 22SCT Thread (Check First Page for FAQ & INFO) Page 516 R/C

After Installation Of The Adapter, Loosen The Set Screw And Align The Edge Of The Pinion Gear With The Edge Of The Spur Gear As Shown;

The Amount Of Revolutions That The Motor And Pinion And Spur Gear Combination Will Cause The Transmission To Turn In One Minute.

B) Divide Pitches, As Shown Below.

Web The Most Common Gears You Can Change On An R/C Vehicle Are The Pinion Gear, Which Is The Gear Directly Connected To The Motor's Output Shaft, And The Spur Gear, Which Is The Main Drive Gear In A Vehicle, And Usually Interfaces With The Pinion Gear (A Pinion Can Also Be A Gear Associated With A Differential Assembly, So Make Sure To Use Context.

Related Post: