Spears Cpvc Cure Time Chart

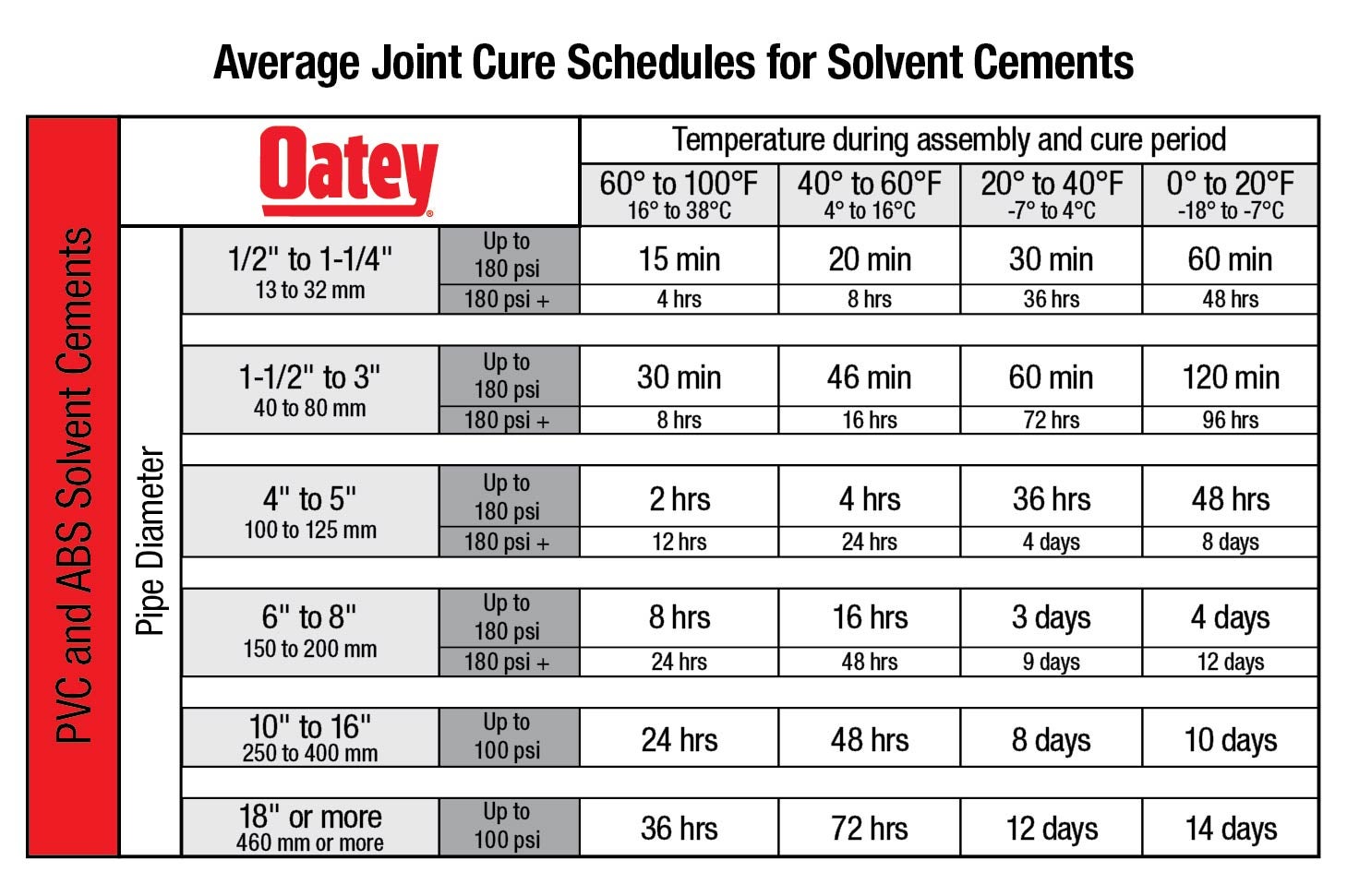

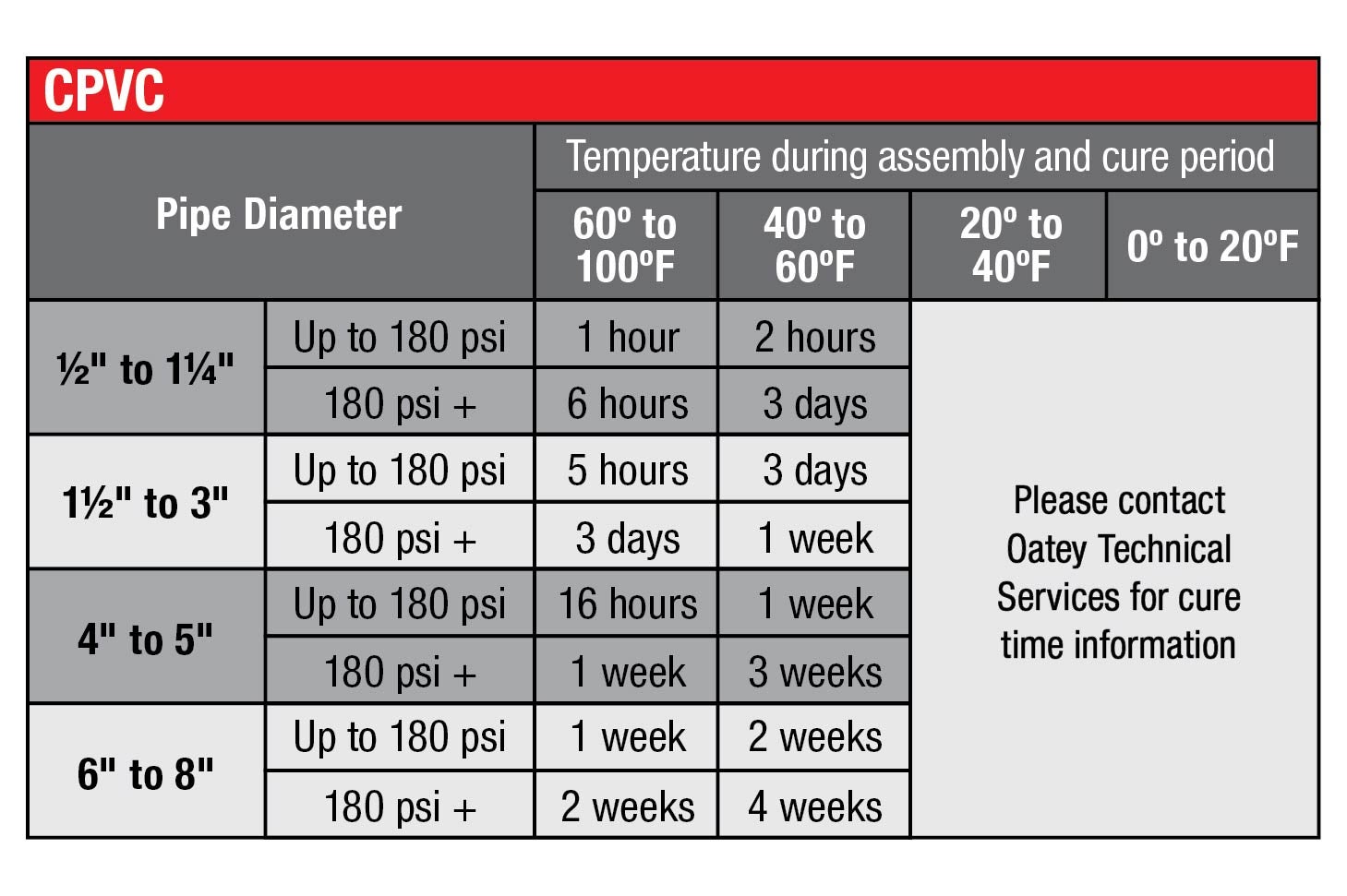

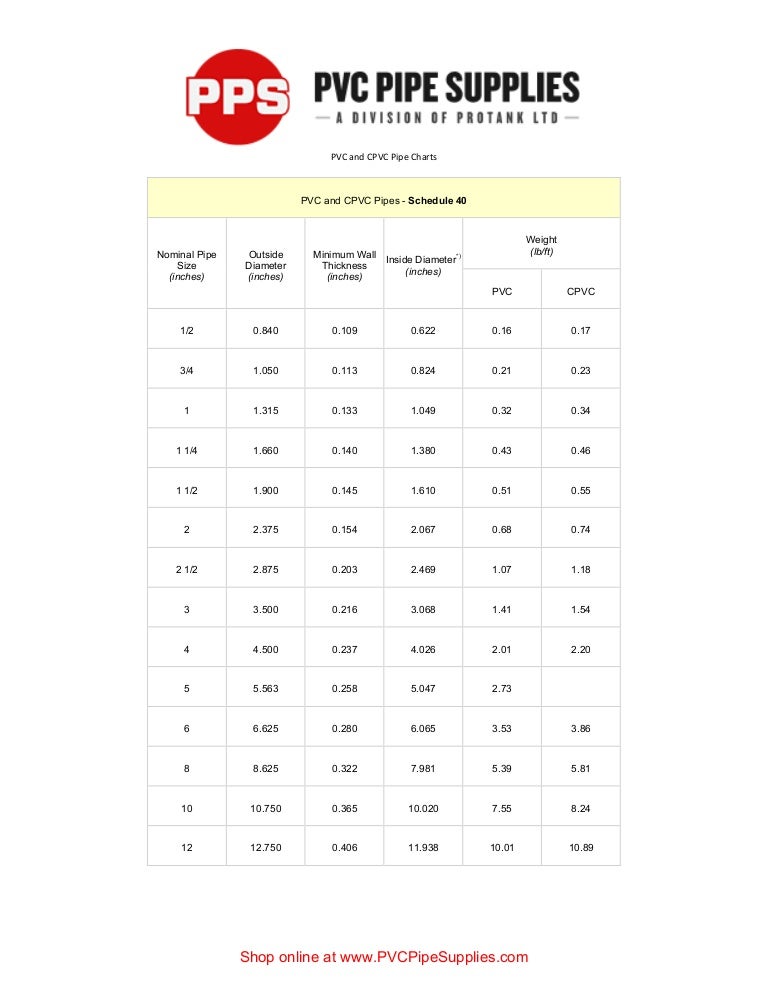

Spears Cpvc Cure Time Chart - Flameguard® cpvc fire sprinkler sample specification. Web in general, pipes in environments that are humid or damp should cure for an extra 50% of the recommended time. Web chloride (cpvc), a specialty thermoplastic material tested and approved by certifying agencies for use in cpvc fire sprinkler systems. Average joint cure schedule for spears® pvc/cpvc solvent cements relative humidity 60% or less cure. Web recommended cpvc cure time? Moisture can slow the cure time, and at this stage of assembly, excessive moisture can reduce joint strength. Be sure to use the correct size applicator. Web average joint cure schedule for spears® pvc/cpvc solvent cements. Web aall cpvc schedule 80 ll cpvc schedule 80 fi ttings shall be produced by spearsttings shall be produced by spears® manufacturing company from cpvc materials, cell. Web cement and primer manufacturers' applications and cure time instructions thoroughly. Minimum cure time prior to testing at 150 psi with cold. Specially recommended for use on schedule 80. Web premium, industrial strength primer essential for proper softening and preparation of pvc and cpvc pipe and fi tting surfaces. Understanding the solvent welding process is crucial for installers using cpvc piping, particularly with products like. Relative humidity 60% or less. Web socket and pipe end. Where t = maximum temperature the system will experience; Web average joint cure schedule for sluyter pvc/cpvc solvent cements. Web in damp or humid weather allow 50% more set time. Average joint cure schedule for spears® pvc/cpvc solvent cements relative humidity 60% or less cure. Web chloride (cpvc), a specialty thermoplastic material tested and approved by certifying agencies for use in cpvc fire sprinkler systems. Web average joint cure schedule for spears® pvc/cpvc solvent cements. Web 52 rows flame guard® cpvc fire sprinkler piping products weights & dimensions: Where t = maximum temperature the system will experience; Understanding the solvent welding process is crucial for. Specially recommended for use on schedule 80. Web in general, pipes in environments that are humid or damp should cure for an extra 50% of the recommended time. Be sure to use the correct size applicator. Cure schedules for new systems. Web cement and primer manufacturers' applications and cure time instructions thoroughly. Web chloride (cpvc), a specialty thermoplastic material tested and approved by certifying agencies for use in cpvc fire sprinkler systems. Web instructions for proper application, set and cure time. Web 52 rows flame guard® cpvc fire sprinkler piping products weights & dimensions: Web average initial set time schedule. Web socket and pipe end. Check the dry fit of the pipe and fitting. Web at 100 psi and temperatures under 40 degrees fahrenheit, a 1 1/4” cpvc pipe can cure in 2 hours. Minimum cure time prior to testing at 150 psi with cold. So, if the manufacturer’s listed cure time is 15 minutes, the pipe. Moisture can slow the cure time, and at. Relative humidity 60% or less. 2 cpvc schedule 80 @ 120°f = 400 psi x 0.65 = 260 psi. Web average joint cure schedule for sluyter pvc/cpvc solvent cements. Web do not test pvc and cpvc piping systems with compressed air or gas. Understanding the solvent welding process is crucial for installers using cpvc piping, particularly with products like. Moisture can slow the cure time, and at this stage of assembly, excessive moisture can reduce joint strength. Web recommended cpvc cure time? Specially recommended for use on schedule 80. Web 52 rows flame guard® cpvc fire sprinkler piping products weights & dimensions: 225 psi (1552 kpa) test pressure (max) ambient temperature during cure period. Cure schedules for new systems. Relative humidity 60% or less. Web socket and pipe end. Web 52 rows flame guard® cpvc fire sprinkler piping products weights & dimensions: Web recommended cpvc cure time? Spears flameguard™ cpvc fire sprinkler products provide unique advantages over traditional metal fire sprinkler. Average joint cure schedule for spears® pvc/cpvc solvent cements relative humidity 60% or less cure. Web recommended cpvc cure time? So, if the manufacturer’s listed cure time is 15 minutes, the pipe. Web average initial set time schedule. Web spears® recommends that only schedule 80 or heavier wall thickness pipe should be threaded. Web in general, pipes in environments that are humid or damp should cure for an extra 50% of the recommended time. Relative humidity 60% or less. Web do not test pvc and cpvc piping systems with compressed air or gas. Web cement and primer manufacturers' applications and cure time instructions thoroughly. 2 cpvc schedule 80 @ 120°f = 400 psi x 0.65 = 260 psi. Be sure to use the correct size applicator. Web socket and pipe end. Web at 100 psi and temperatures under 40 degrees fahrenheit, a 1 1/4” cpvc pipe can cure in 2 hours. Web average joint cure schedule for sluyter pvc/cpvc solvent cements. Pvc pool & spa cements. Web aall cpvc schedule 80 ll cpvc schedule 80 fi ttings shall be produced by spearsttings shall be produced by spears® manufacturing company from cpvc materials, cell. Spears flameguard™ cpvc fire sprinkler products provide unique advantages over traditional metal fire sprinkler. Web average joint cure schedule for spears® pvc/cpvc solvent cements. Web average joint cure schedule for spears® pvc/cpvc solvent cements. Relative humidity 60% or less.

Spears Cpvc Cure Time Chart

The Complete Guide to Solvent Cement & CPVC Fire Protection Systems

Oatey Cpvc Cure Time Chart

CPVC Specification BlazeMaster® CPVC Fire Protection Systems

Manhattan Reefs Time to pvc glue cure?

WO2014014881A1 Fastcuring cpvc solvent cement Google Patents

Five Tips for LargeDiameter Solvent Welding Oatey

Pvc andcpvcpipecharts

CPVC Fittings (For Hot Water) (Copper Tube Size)

Oatey Cpvc Cure Time Chart

Below Is Our Recommended Initial Set Schedule And Joint Cure Schedule For Piping When Using Spears® Pvc And Cpvc Low Voc Cements.

Specially Recommended For Use On Schedule 80.

Web Chloride (Cpvc), A Specialty Thermoplastic Material Tested And Approved By Certifying Agencies For Use In Cpvc Fire Sprinkler Systems.

225 Psi (1552 Kpa) Test Pressure (Max) Ambient Temperature During Cure Period.

Related Post: