Snap Tie Spacing Chart

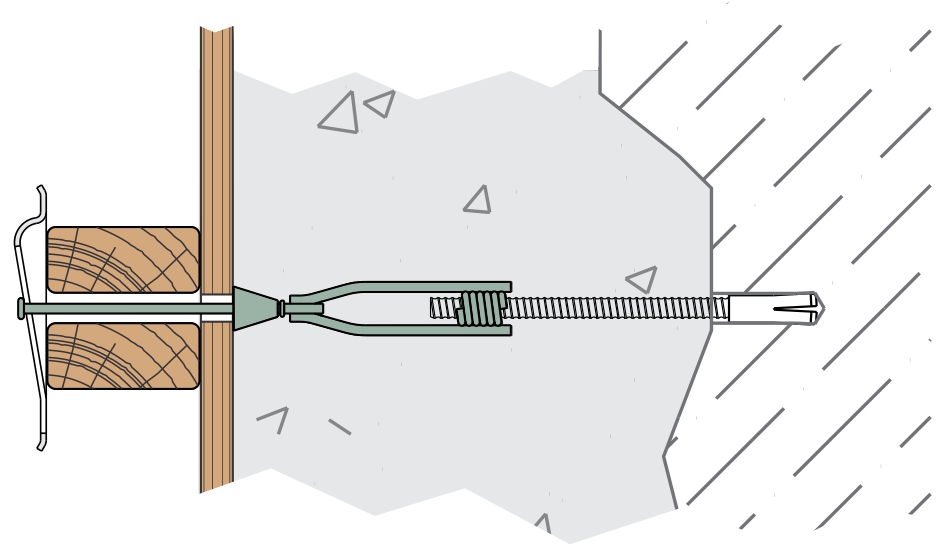

Snap Tie Spacing Chart - S represents the snap tie spacing, which is the distance between individual snap ties along a concrete form. Refer to the back cover for addresses and phone numbers. Web • ties are ordered based on wall thickness • space ties from the top 1’,3’, 5’, 7’ then 1’ o.c. Please call for lead time, pricing, and availability. If you filled the forms to 6ft all at once it would definately blow out. Hex head measures 1/2” across flats. Suitable for commercial and residential applications. 5,050,365 standard breakback is 13/16”. Standard 16” waler spacing with 2x4 lumber. Place the bracket (jahn® a, jahn® c or omni wedge) on the tie 4. 3/4” plywood thickness, face grain perpendicular to walers. Because of high tension stress, 100% breakback is not guaranteed for hex head snap ties with. Hex head measures 1/2” across flats. Place the ends of snap ties through the holes in the plywood 3. Refer to the web site for addresses and phone numbers. These fillers require wall tie connections to Web this diagram is based on: S = (wht) / (l*p) where: Web the formula used in the snap tie spacing calculator is as follows: Web snap tie concrete forms are a simple and effective way for anyone to be able to pour concrete effectively and inexpensive. Web the maximum recommended spacing for wts used with 1x, 2x and 1 1/4 thick forms is outlined in the tables below. Web when using snap ties, correct spacing between double wales is 5/8 to 3/4. These fillers require wall tie connections to Loose washer ties or 1” x 1” cone tie. To the bottom • the american concrete institute. Because of high tension stress, 100% breakback is not guaranteed for hex head snap ties with. Web correct spacing between double wales is 5/8 to 3/4 jahn® a bracket is utilized to hold a single wale and can be installed before or after the wales have been positioned. Place the ends of snap ties through the holes in the plywood. Suitable for commercial and residential applications. Refer to the back cover for addresses and phone numbers. The tables give spacing guidelines for various form heights and types of form boards. Web snaptie spacing and rate placement: Web coating the tie ends with wax will aid in breakback operation. A2 plastic cone selection chart. Normally, a 5/8 drill bit is sufficient. Web correct spacing between double wales is 5/8 to 3/4 jahn® a bracket is utilized to hold a single wale and can be installed before or after the wales have been positioned. Please call for lead time, pricing, and availability. This spacing allows for proper support and reinforcement. Standard 16” waler spacing with 2x4 lumber. The snaptie is available equipped with either plastic spreader cones or loose metal washers. The most common snap tie spacings being used with the jahn forming system are shown below. A 1/2″ breakback is available on special order. Web snap tie concrete forms are a simple and effective way for anyone to be. S represents the snap tie spacing, which is the distance between individual snap ties along a concrete form. The tables give spacing guidelines for various form heights and types of form boards. These fillers require wall tie connections to Place the ends of snap ties through the holes in the plywood 3. Suitable for commercial and residential applications. To the bottom • the american concrete institute requires a 2:1 safety factor on ties for all pour heights tie spacings walls taller than 8' 6,000 lb ultimate tie capacity (walls more than 8’) tie spacing (walls less than 8’) key. Web the formula used in the snap tie spacing calculator is a mixture of algebra and physics: Web the. Web drill holes in plywood 1/8 larger than the snap tie head. In general, for walls up to 4 feet high, spacing can be 6 to 8 inches vertically. Normally, a 5/8 drill bit is sufficient. Pour pressure of 450 psf with l/360 defl ection. Suitable for commercial and residential applications. Drill holes in plywood 1/8 larger than the snap tie head (usually 5/8 diameter drill bit will be required 2. Web the most common snap tie spacings being used with the jahn forming system are shown below. T refers to the tension (load in pounds that each snap tie should hold) l stands for the length between tie ends Web the recommended spacing for these ties typically depends on the dimensions of the vertical and horizontal elements. S = (w * h * t) / (l * p) where: S = (wht) / (l*p) where: Suitable for commercial and residential applications. Because of high tension stress, 100% breakback is not guaranteed for hex head snap ties with. Refer to the back cover for addresses and phone numbers. Web when using snap ties, correct spacing between double wales is 5/8 to 3/4. For different rates of pour and/or other tie spacing, contact a dayton superior technical services department. Web the maximum recommended spacing for wts used with 1x, 2x and 1 1/4 thick forms is outlined in the tables below. 3/4 plywood gives you 50% more strength and 8x3/4 snap ties are sized for this application. Web drill holes in plywood 1/8 larger than the snap tie head. For different rates of pour and/ or other tie spacing, contact a dayton superior technical services department. Hex head measures 1/2” across flats.

Snap Tie Spacing Chart

Scaffolding Federal OSHA Tie Spacing DH Glabe & Associates

Concrete Snap Tie Spacing

Snap Tie Spacing Calculator Online

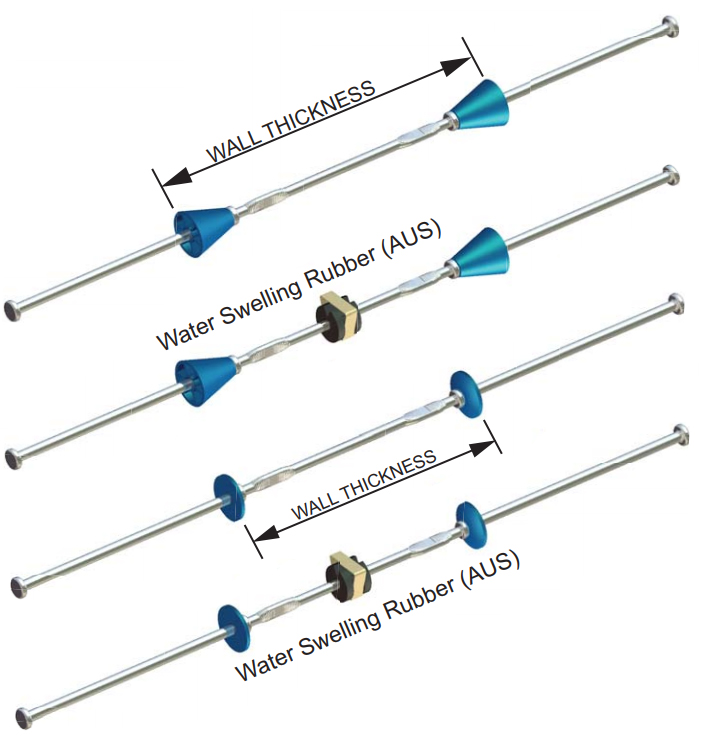

SnapCoil™ Tie — Steel Dog

SC Snap Coil Ties — Steel Dog

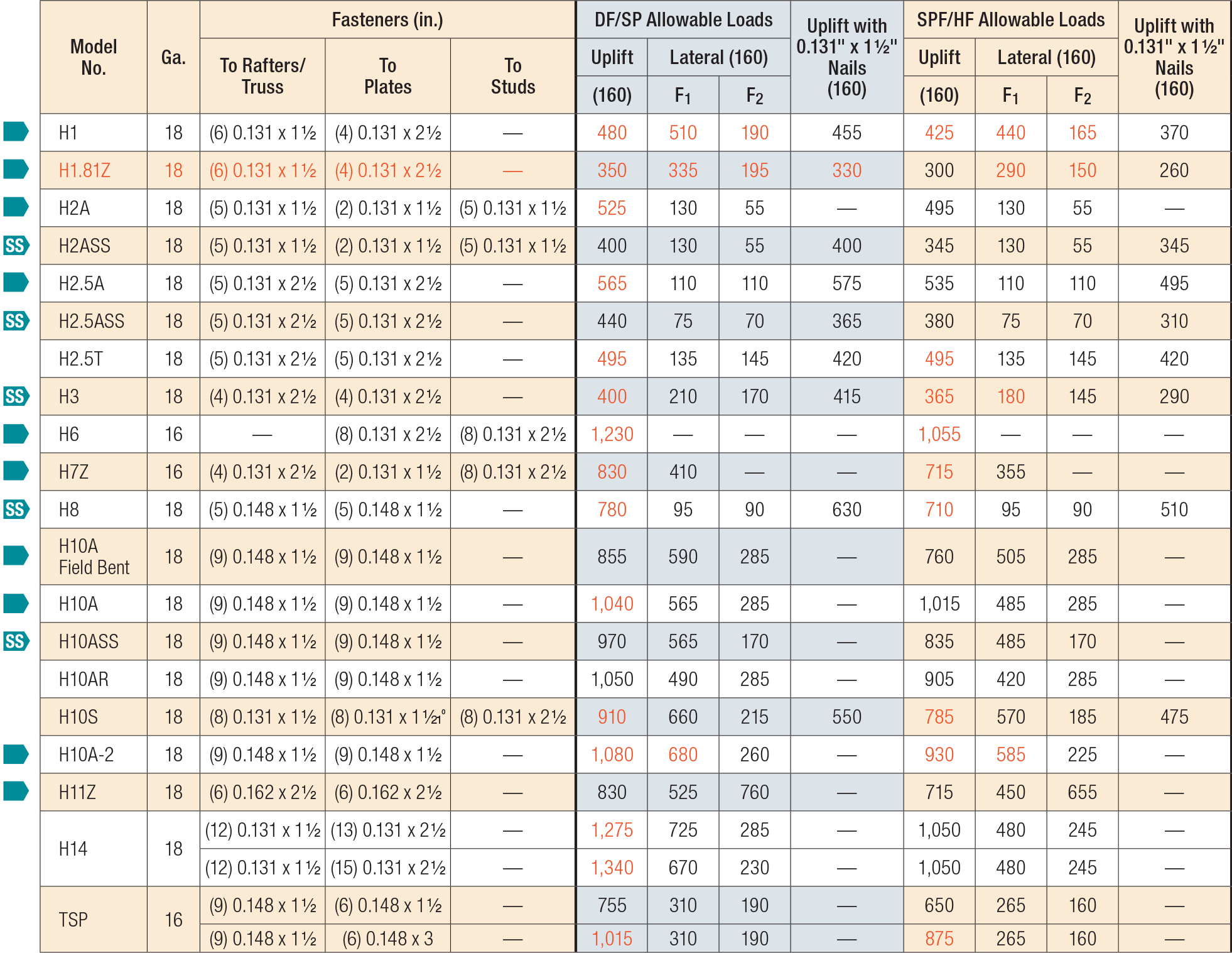

H Hurricane and Seismic Ties Simpson StrongTie

Custom Ties — Steel Dog

Snap Tie Spacing Chart

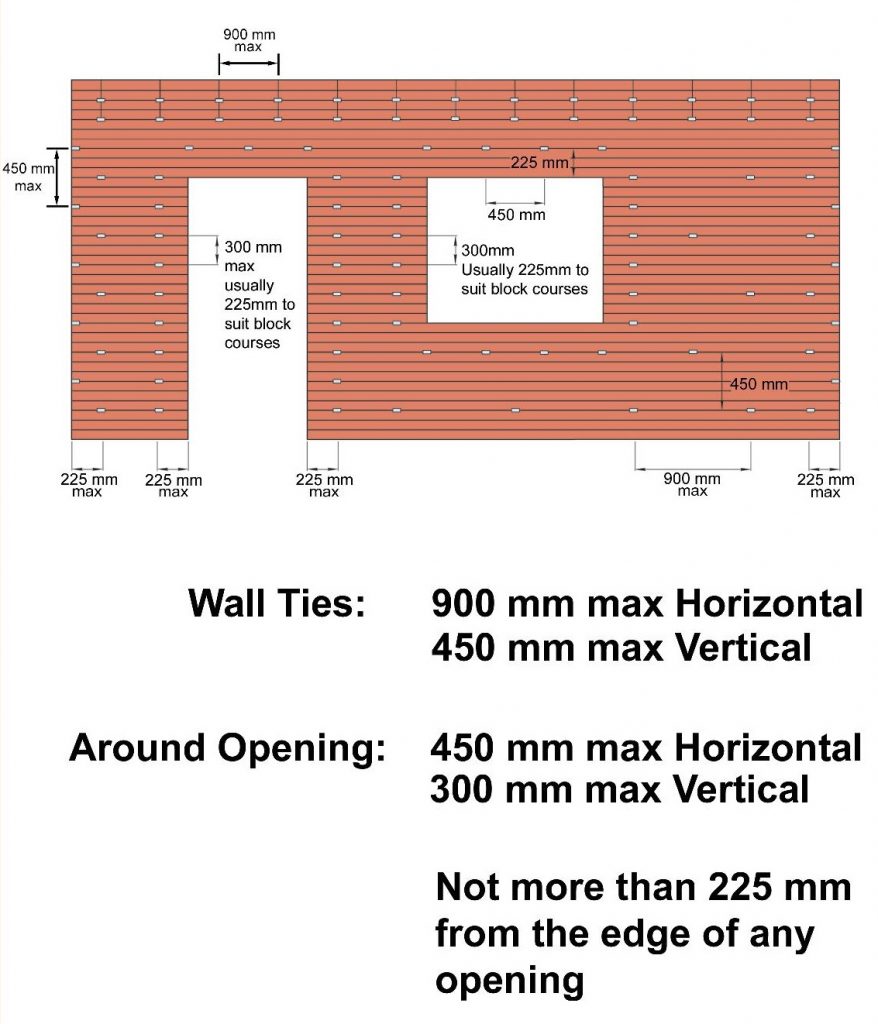

What is standard wall tie spacing? Wonkee Donkee Tools

Too Much Space Allowed Between The Wales May Cause Crushing Of The Wales And/Or The Bending Of The Wedge Allowing The Form To Bulge Outward.

Standard 16” Waler Spacing With 2X4 Lumber.

For Different Rates Or Pour And/Or Other Tie Spacing, Contact Masons Supply.

Normally, A 5/8 Drill Bit Is Sufficient.

Related Post: