Slip Clutch Adjustment Chart

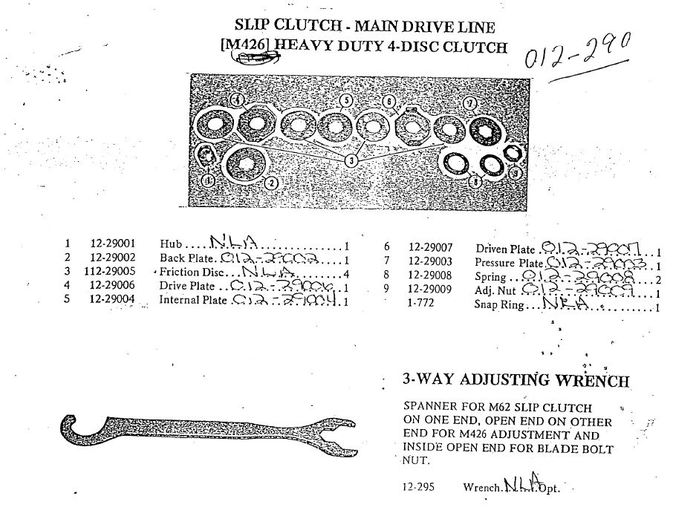

Slip Clutch Adjustment Chart - If it is the type with springs on the bolts then in general you would tighten each bolt/nut until you can't turn the spring by hand then go another 1 1/2 turns. A good way to see if clutch is working properly is to check for heat in the clutch after mowing. Within the realm of pto shafts, the pto shaft with slip clutch holds a special place. #1 · apr 14, 2010. 16k views 3 years ago. 76k views 6 years ago. Here are some pictures from a machine that must not have listened. Web the problem with clutch not slipping at all unless you hit that huge rock or stump, the clutch will end up seizing with rust and it won't protect you driveline at all. Web adjust the nut on the friction clutch to approximately 25% of maximum spring capacity by tightening nut onto spring by hand and then rotating it a half turn. A visual inspection of the slip clutch may show if rust is present. Web can you adjust a slip clutch? Web the problem with clutch not slipping at all unless you hit that huge rock or stump, the clutch will end up seizing with rust and it won't protect you driveline at all. Web a slip clutch, when set properly, will engage and spin between two friction plates, taking the extra load away. 12” (30.5 cm) overall body height: Web the sudden onset of a slipping clutch usually indicates that an oil leak, or something else has contaminated the friction surfaces. Each implement and tractor needs to have the slip clutch tension individually set, as each application puts your tractor and implement under a different workload. If the user finds that the torque. Web a slip clutch, when set properly, will engage and spin between two friction plates, taking the extra load away from the implement and thus protecting it from damage. This unique variant offers added safety, ensuring that your machinery doesn’t suffer from sudden torque overloads. Parts 3 & 5 should move in relation to parts 2, 7 & 9. Web. Each implement and tractor needs to have the slip clutch tension individually set, as each application puts your tractor and implement under a different workload. Web to maintain a slip, it clutch should be inspected and adjusted at the beginning of each new season before you use the implement. Web 5922 posts · joined 2006. 76k views 6 years ago.. Web 5922 posts · joined 2006. How do you know if you've properly adjusted the slip clutch for 48 king kutter ii. Web the problem with clutch not slipping at all unless you hit that huge rock or stump, the clutch will end up seizing with rust and it won't protect you driveline at all. Your weight = 180 pounds.. Web the problem with clutch not slipping at all unless you hit that huge rock or stump, the clutch will end up seizing with rust and it won't protect you driveline at all. If adjustment is required, remove 3 nuts on hand wheel cover then remove cover (fig. This shaft had to be pressed out of the froward/reverse planetary after. A visual inspection of the slip clutch may show if rust is present. Web max compressed spring length = 28.5mm 2 plate clutch = 720 nm, 4 plate clutch = 1300 nm (old series) in many cases the clutch will need to be set to suit the specific application. 76k views 6 years ago. Web to maintain a slip, it. Web can you adjust a slip clutch? Web clutch slipping is a common phenomenon where the clutch disc is not grabbing the flywheel surface as firmly as it should, resulting in slipping between two surfaces and failure to transmit power properly to the drive shaft. A visual inspection of the slip clutch may show if rust is present. When the. Web a slip clutch, when set properly, will engage and spin between two friction plates, taking the extra load away from the implement and thus protecting it from damage. 3/4” (20/27) npt female bottom threaded inlet. Web can you adjust a slip clutch? Web the problem with clutch not slipping at all unless you hit that huge rock or stump,. If the user finds that the torque is low, they can adjust the bolts by tightening them. Web 5922 posts · joined 2006. Each implement and tractor needs to have the slip clutch tension individually set, as each application puts your tractor and implement under a different workload. Do not tighten them too much, as it may reduce the life. This is for reference only. Web slip clutch adjustment will depend on the type of slip clutch. This unique variant offers added safety, ensuring that your machinery doesn’t suffer from sudden torque overloads. 76k views 6 years ago. Parts 3 & 5 should move in relation to parts 2, 7 & 9. This can be done by following the procedure below. Web pull the hand chain slowly in the lifting direction. Using slip clutches in industrial design. Within the realm of pto shafts, the pto shaft with slip clutch holds a special place. Adjust the lock nut to change the setting of the slip clutch (fig. Web adjust the nut on the friction clutch to approximately 25% of maximum spring capacity by tightening nut onto spring by hand and then rotating it a half turn. No matter what the torque from the pto is, the torque of the implement end remains the same. Web to maintain a slip, it clutch should be inspected and adjusted at the beginning of each new season before you use the implement. Clutch does not engage at all. Web a slip clutch, when set properly, will engage and spin between two friction plates, taking the extra load away from the implement and thus protecting it from damage. A good way to see if clutch is working properly is to check for heat in the clutch after mowing.

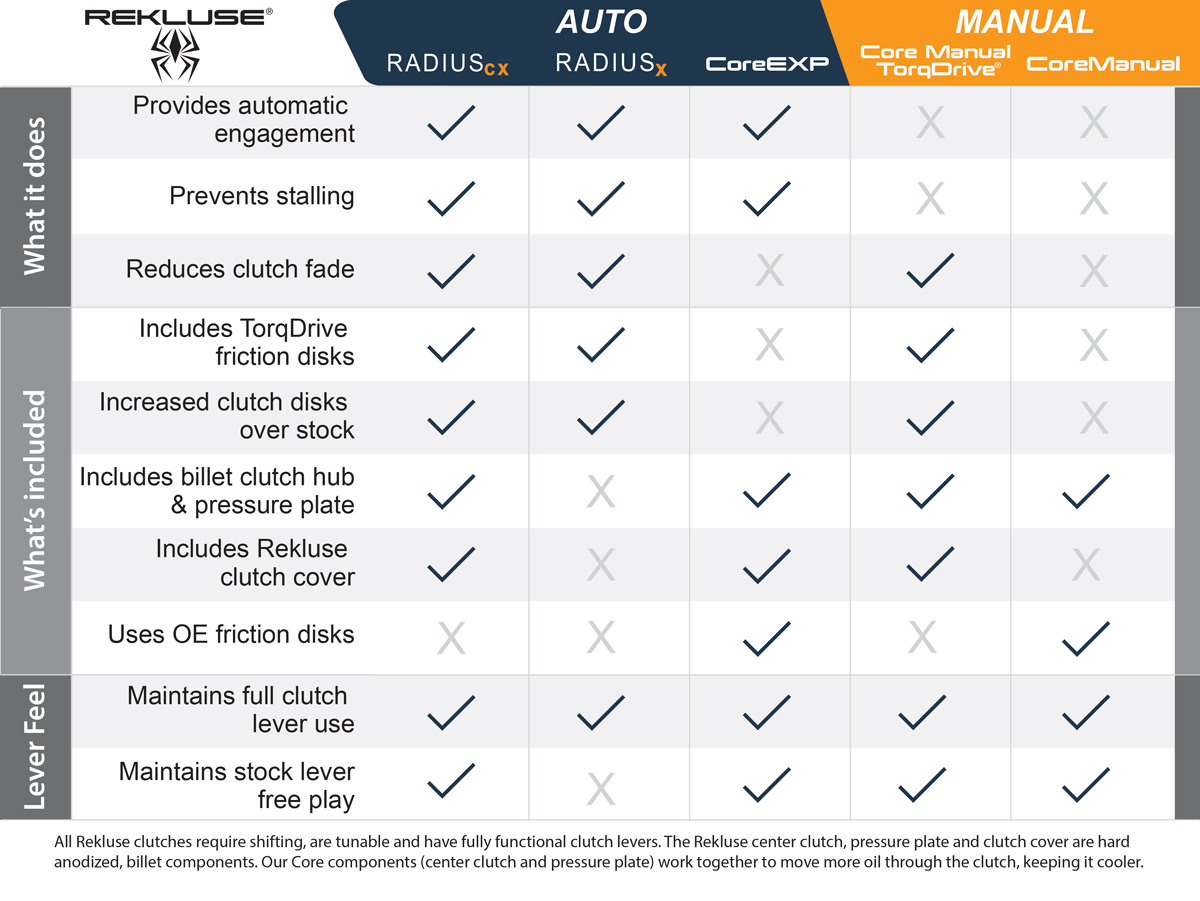

FAQ Rekluse

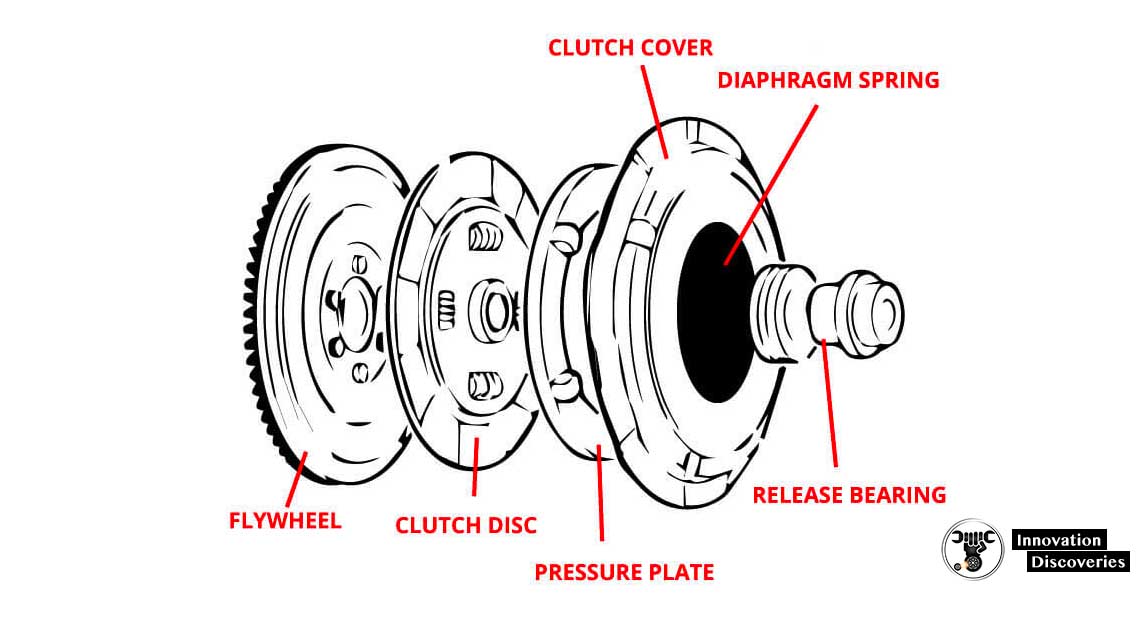

3 Easy Tips to Diagnose a Slipping Clutch

3 Easy Tips to Diagnose a Slipping Clutch

how to adjust clutch pedal properly? IH8MUD Forum

Buy VEVOR Slip Clutch, 1 3/8" PTO Slip Clutch, Smooth Round Ends PTO

Clutch adjustment Antique and Classic Mack Trucks General Discussion

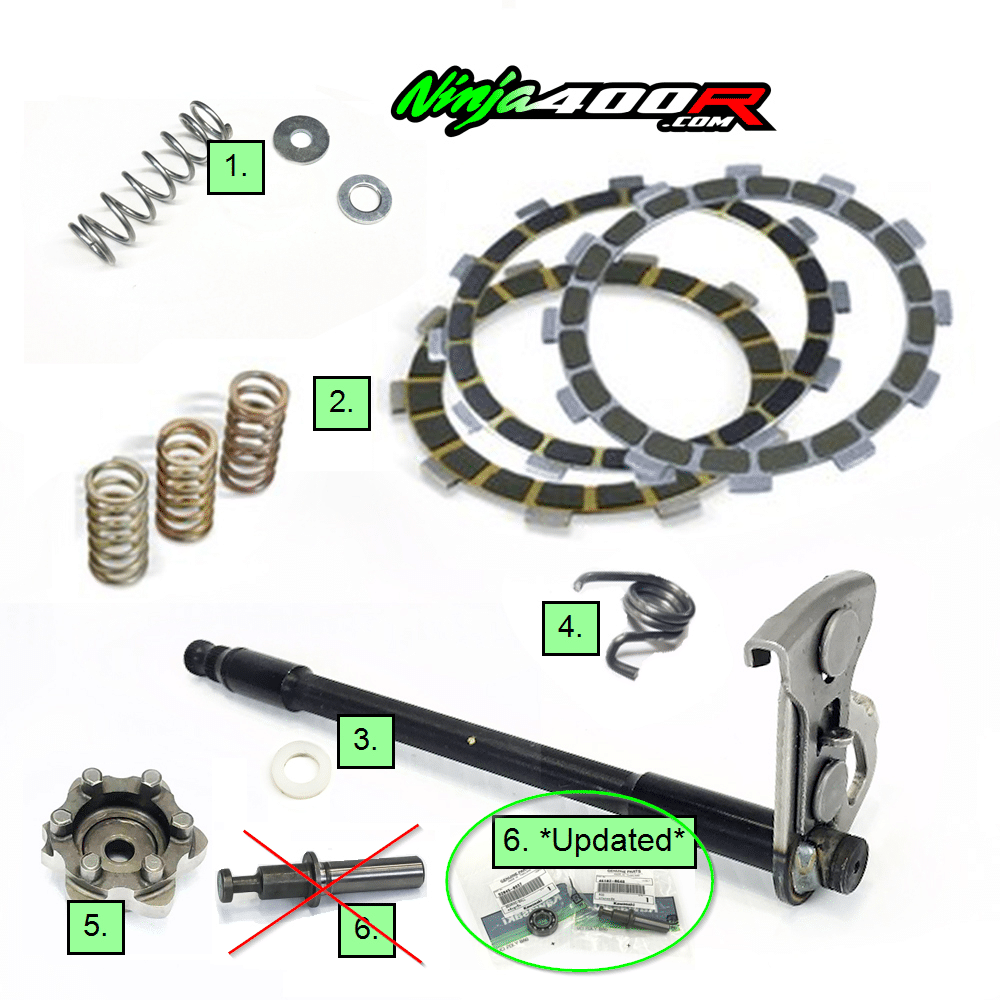

Kawasaki Ninja 400 / Z400 Clutch Slipping, Poor Shifting, False

Slip Clutch Adjustment Chart

How to Properly Adjust & Maintain Your PTO Slip Clutch IronCraft

Slip Clutch adjustment on shredder Yesterday's Tractors

Here Are Some Pictures From A Machine That Must Not Have Listened.

Web Understanding Pto Shaft With Slip Clutch.

Those That Know Me, Have Heard Me Continuously Preach About Keeping The Safety/Slip Clutch On Your Attachments Properly Adjusted.

Run The Machine For A Short Distance (I.e.) 60 Feet Under Work Load And Check To See If The Clutch Slips.

Related Post: