Ring And Pinion Gear Pattern Chart

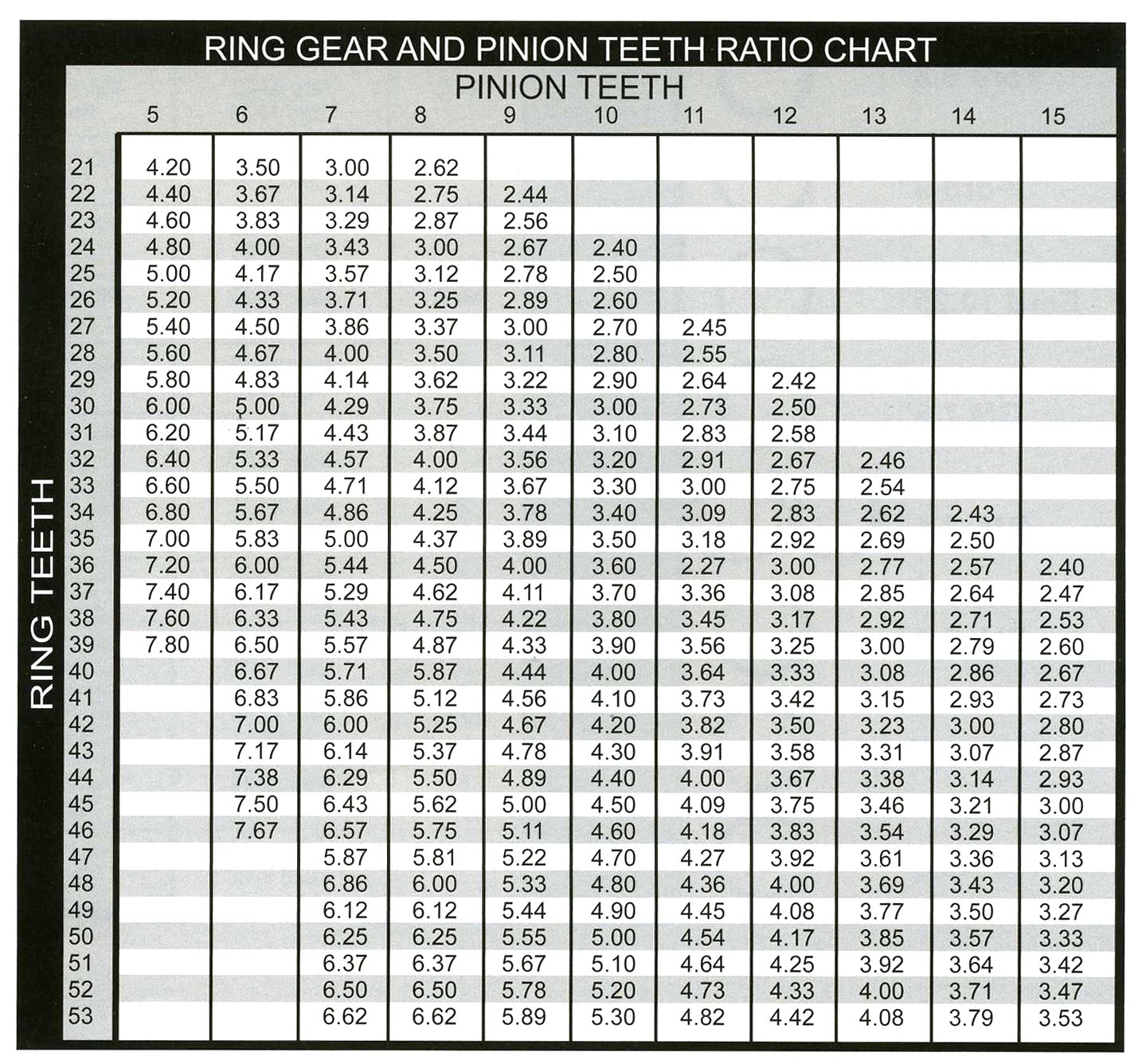

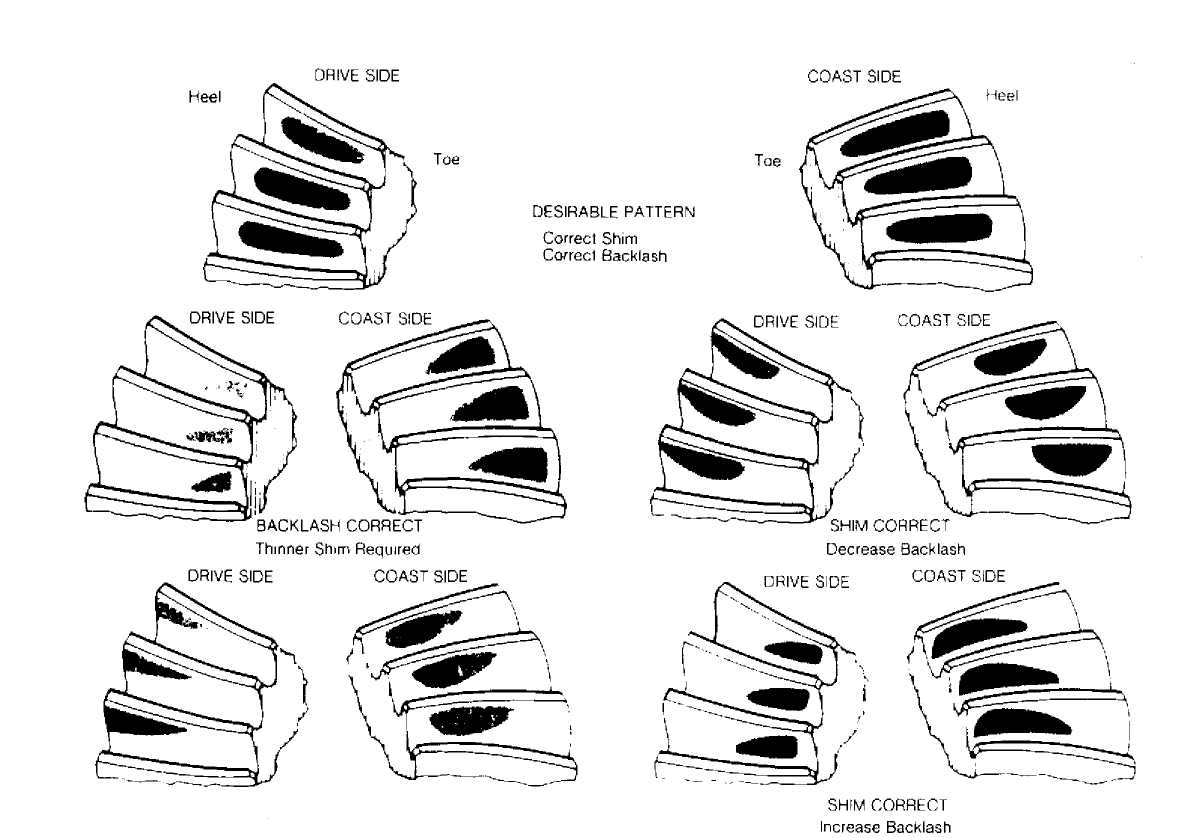

Ring And Pinion Gear Pattern Chart - The prospect of installing and adjusting driveline ring & pinion gears can be intimidating for shops that don’t routinely perform this task. Divide the ring gear tooth count by the pinion tooth count to get your ratio. Use gear marking compound to paint all of the ring gear teeth. The toe of the gear tooth is the portion of the tooth surface at the end towards the center. (1) paint ring gear teeth with a marking compound to both the drive and coast side. Specified in catalog for most applications. Pattern adjustment cause & effect. These symptoms can be signs of a fairly serious problem with your ring and pinion gears, so it’s time to consult with the doctor—the gear doctor. Two cut ring & pinion gears (face hobbed): The order in which adjustments are made during differential assembly and setup are: Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure. The prospect of installing and adjusting driveline ring & pinion gears can be intimidating for shops that don’t routinely perform this task. Gear tooth patterns are. Begin by setting proper pinion. Web we can determine how gears mesh by changing how close the pinion gear is to the ring gear centerline. The toe of the gear tooth is the portion of the tooth surface at the end towards the center. (see figure 2) figure 2: Ring gear and run a full contact pattern check. See manufacturer or the gearset for exact specifications and special instructions before attempting to adjust the ring and pinion. Web is it prematurely worn or chipped teeth? Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic. Two cut ring & pinion gears (face hobbed): Web is it prematurely worn or chipped teeth? The images below illustrate both acceptable and unacceptable ring and pinion gear patterns. Web see how to set up a ring and pinion gear set. Reading contact patterns can be daunting when looking at the average gear installation guide. If the gear was manufactured using the face hobbing method, both a and b will be of equal depth. Web is it prematurely worn or chipped teeth? Web ring and pinion gear tooth pattern. These symptoms can be signs of a fairly serious problem with your ring and pinion gears, so it’s time to consult with the doctor—the gear doctor.. Even if you farm this work out to a specialist, you should understand what’s involved. (see figure 2) figure 2: 1.625 / 29 ring gear bolts: The images below illustrate both acceptable and unacceptable ring and pinion gear patterns. Web ring gear and pinion tooth contact pattern. Web you must first determine the type of gear that you have in order to know which gear pattern chart to use as described in this bulletin. Pulling off a proper differential setup comes down to. Web ring gear and pinion tooth contact pattern. The coast pattern will move deeper toward. Use gear marking compound to paint all of the. Divide the ring gear tooth count by the pinion tooth count to get your ratio. Timeline:0:00 introduction0:22 pinion gear examples 0:40 pinion bearing locations 0:48 oil splash shield and se. These symptoms can be signs of a fairly serious problem with your ring and pinion gears, so it’s time to consult with the doctor—the gear doctor. Web ring and pinion. Two cut ring & pinion gears (face hobbed): Specified in catalog for most applications. This is done using gear marking compound and checking the gear tooth pattern. Web see how to set up a ring and pinion gear set. Pulling off a proper differential setup comes down to. Bearing preload, total turning preload, and ring gear backlash. Every gear has a characteristic pattern. (1) paint ring gear teeth with a marking compound to both the drive and coast side. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed. Web proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation. (10) 3/8x24 or 7/16x20 rh cover bolts: Pulling off a proper differential setup comes down to. The heel of the gear tooth is the portion of the tooth surface at the outer end. The top land of a gear tooth is the surface of the top of the tooth. This is done using gear marking compound and checking the gear tooth pattern. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure. Web how to create & read ring gear patterns. Web here's how to achieve the best ring & pinion contact pattern , every time, in just 3 simple steps! Web this video was created to give people a basic understanding of how to read gear patterns when setting up ring and pinions. Web ring and pinion gear tooth pattern. The prospect of installing and adjusting driveline ring & pinion gears can be intimidating for shops that don’t routinely perform this task. Specified in catalog for most applications. Does richmond make a gear set for my car or truck? Automotive ring and pinion gears must be installed and set up in a very specific way to ensure that they will run smoothly and reliably. Use shims to move the ring gear closer to the pinion to decrease backlash.RING AND PINION TOOTH CONTACT PATTERN...mine with pic MGB & GT Forum

How To Create & Read Ring Gear Patterns

Weber_Ring_Gear_Contact_Pattern_Interpretation.pdf Gear Tooth

Ring & pinion set up, Jantz Engineering advanced masters course

Ring and Pinion Gear Ratio Calculation Chart Quadratec

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube

Ring and Pinion Pattern Help! Ford Bronco Forum

Ring And Pinion Pattern Patterns Gallery

How to Set up Your Rear Gear Correctly RacingJunk News

Figure 83. Proper piniontodifferential ring gear tooth contact pattern.

I Have Included Two Charts Here To Help You Understand And Adjust The Pattern And Backlash.

Or An Ominous Clunking Sound?

Even If You Farm This Work Out To A Specialist, You Should Understand What’s Involved.

(1) Paint Ring Gear Teeth With A Marking Compound To Both The Drive And Coast Side.

Related Post: