Ra Surface Finish Chart

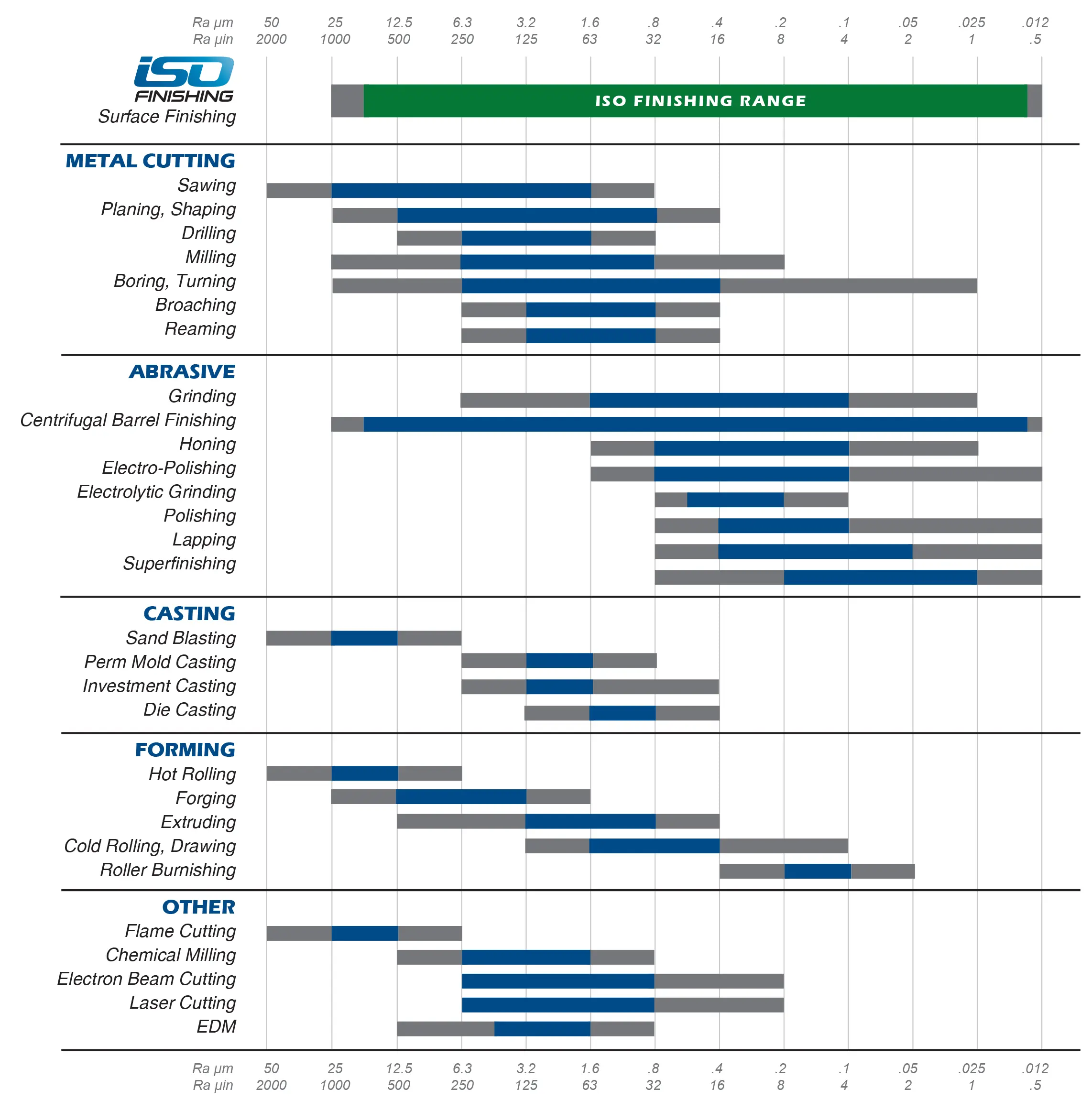

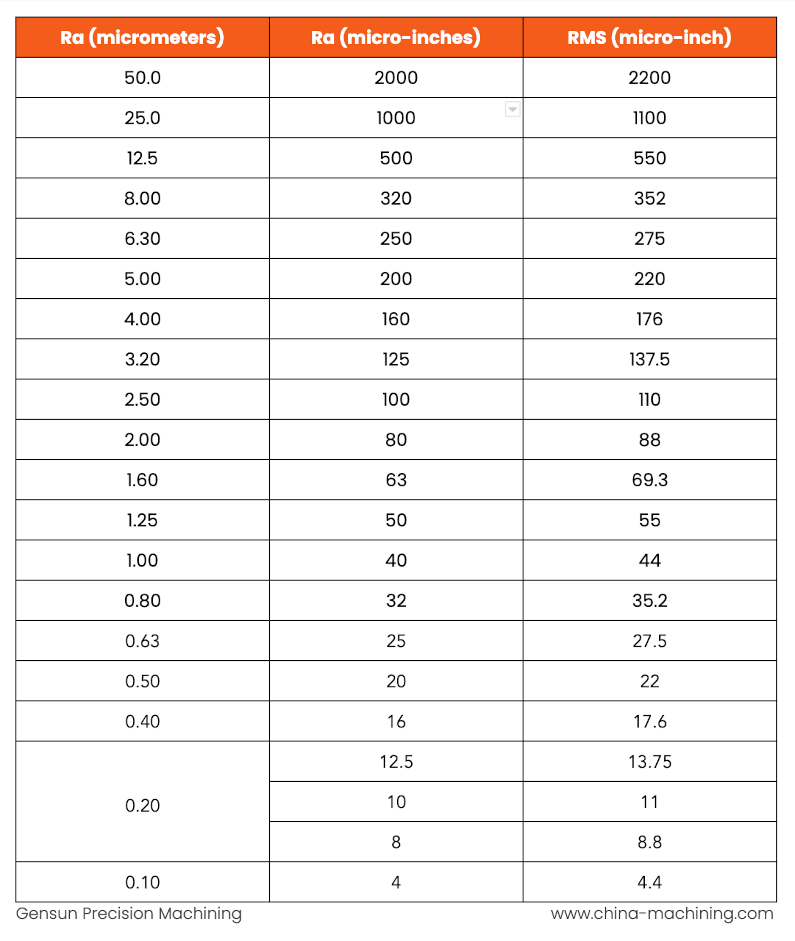

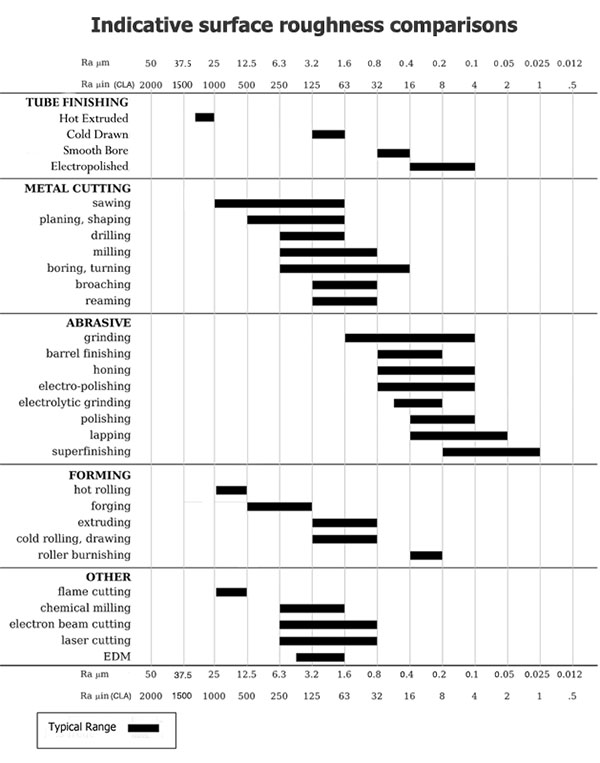

Ra Surface Finish Chart - Web additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. Rt = roughness, total in microns. N = new iso (grade) scale numbers. By understanding and interpreting this chart, manufacturers can make informed decisions regarding machining processes and material selection. The table below converts surface finish or roughness between ra, rz, and rms indicators. On the other hand, rz helps measure the vertical distance between the highest peak and the lowest valley. Cla = center line average microinches. Ra = roughness average micrometers. Rms = root mean square microinches. Ra is a measure of the average length that is between peaks and valleys. Web the ra chart serves as a visual reference to categorize surface finishes based on ra values. Ra is a measure of the average length that is between peaks and valleys. Ra = roughness average micrometers. Iso no = new iso (grade) scale numbers. Cla = center line average microinches. Rt = roughness total microns. The table below converts surface finish or roughness between ra, rz, and rms indicators. Ra is a measure of the average length that is between peaks and valleys. Ra = roughness average micrometers. N = new iso (grade) scale numbers. Got questions about how best to achieve the desired finish? By understanding and interpreting this chart, manufacturers can make informed decisions regarding machining processes and material selection. Ra = roughness average micrometers. The table below converts surface finish or roughness between ra, rz, and rms indicators. Web ra surface finish chart. Ra ranges and corresponding surface finishes. By understanding and interpreting this chart, manufacturers can make informed decisions regarding machining processes and material selection. Iso no = new iso (grade) scale numbers. Web the following charts and tables convert surface finish or roughness between selected industry standard units. Cla = center line average microinches. By understanding and interpreting this chart, manufacturers can make informed decisions regarding machining processes and material selection. Our chart of surface finishes by manufacturing process (see above) gives both. Ra is a measure of the average length that is between peaks and valleys. Ra = roughness average micrometers. Web the following charts and tables convert surface finish or roughness between. Web the following charts and tables convert surface finish or roughness between selected industry standard units. The table below converts surface finish or roughness between ra, rz, and rms indicators. On the other hand, rz helps measure the vertical distance between the highest peak and the lowest valley. Web additionally, manufacturers can use the surface finish conversion chart to compare. Cla = center line average microinches. Web what differentiates ra and rz in surface roughness chart? Ra = roughness average microinches. Rt = roughness total microns. Iso no = new iso (grade) scale numbers. Our chart of surface finishes by manufacturing process (see above) gives both. It also measures the deviation from the mean line on the surface within a sampling length. Rt = roughness, total in microns. Web additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. On the other hand, rz helps measure the. Our chart of surface finishes by manufacturing process (see above) gives both. Ra = roughness average microinches. Rms = root mean square microinches. Iso no = new iso (grade) scale numbers. The table below converts surface finish or roughness between ra, rz, and rms indicators. Web the ra chart serves as a visual reference to categorize surface finishes based on ra values. Rt = roughness, total in microns. Web additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. On the other hand, rz helps measure the vertical distance between the highest peak and the lowest valley. Our. Web what differentiates ra and rz in surface roughness chart? Ra = roughness average micrometers. Got questions about how best to achieve the desired finish? Cla = center line average microinches. Iso no = new iso (grade) scale numbers. Rt = roughness total microns. Web additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. On the other hand, rz helps measure the vertical distance between the highest peak and the lowest valley. It also measures the deviation from the mean line on the surface within a sampling length. Rt = roughness, total in microns. Web the ra chart serves as a visual reference to categorize surface finishes based on ra values. N = new iso (grade) scale numbers. Ra = roughness average microinches. Ra is a measure of the average length that is between peaks and valleys. Our chart of surface finishes by manufacturing process (see above) gives both. Ra ranges and corresponding surface finishes.

Machine Surface Finish Chart

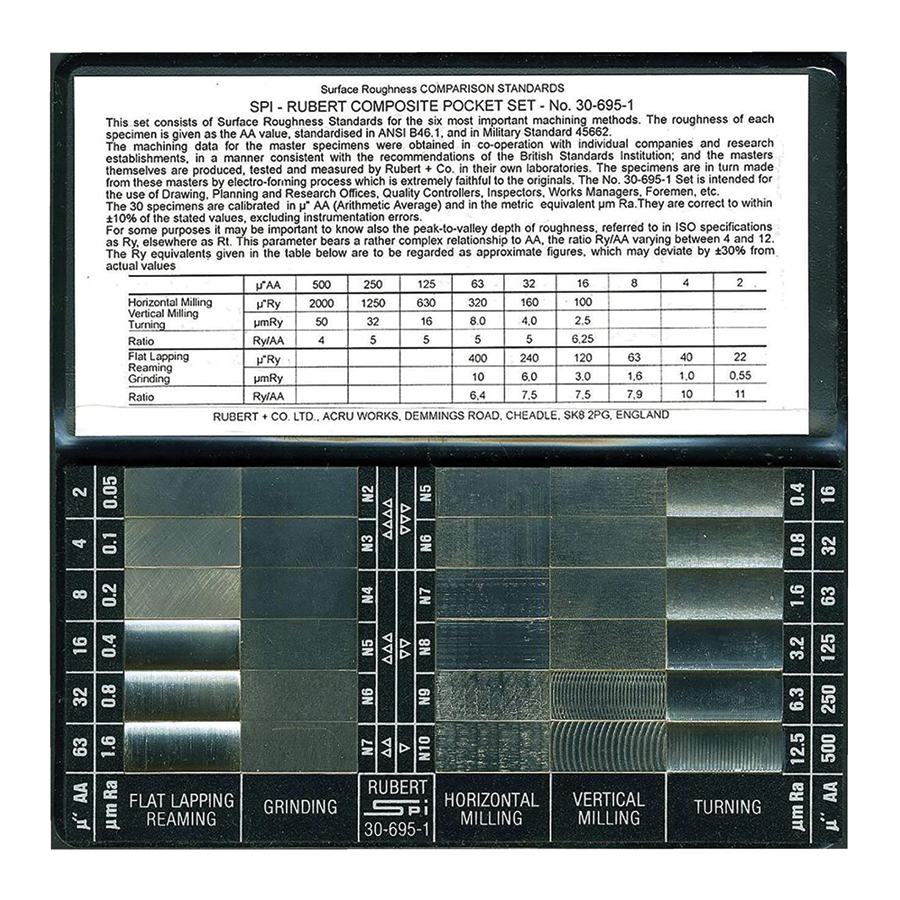

Machining Surface Finish Chart Comparator Method Degr vrogue.co

Surface Roughness Conversion Chart Images

Ra Surface Roughness Chart

Surface Finish Destiny Tool

Rms Surface Roughness Chart

Complete Guide to Surface Finish Charts, RA, RZ, Measurements, Callouts

Surface Finish Ra Chart

Surface Finish Machinng Chart Pdf Surface Roughness Machining IMAGESEE

Ra Surface Roughness Chart

By Understanding And Interpreting This Chart, Manufacturers Can Make Informed Decisions Regarding Machining Processes And Material Selection.

Our Chart Of Surface Finishes By Manufacturing Process (See Above) Gives Both.

Web The Following Charts And Tables Convert Surface Finish Or Roughness Between Selected Industry Standard Units.

Web Ra Surface Finish Chart.

Related Post: