R Control Chart

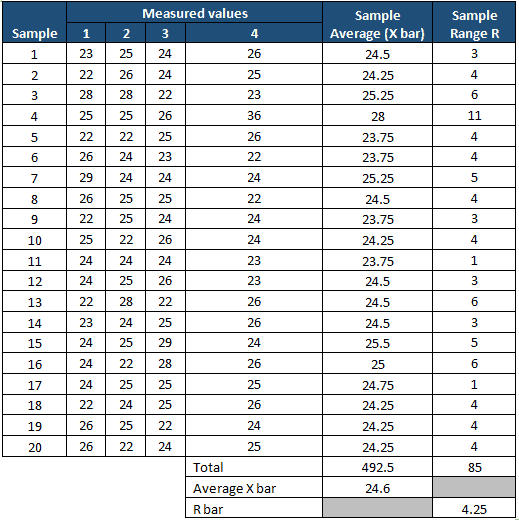

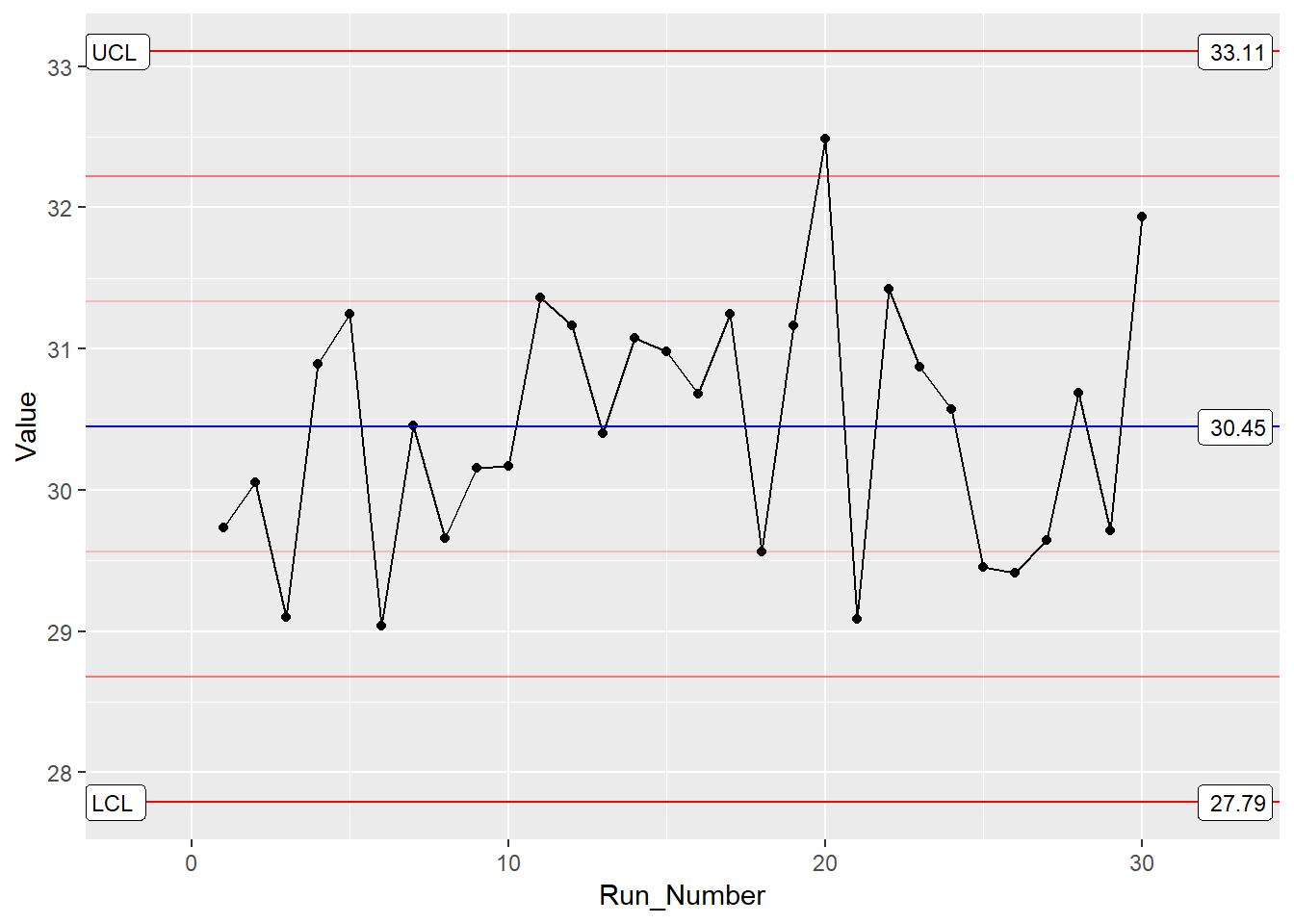

R Control Chart - As a result, a new sound is created. Web cchart.r r control chart description this function builds a r control chart. Data are plotted in time order. Statistical formulas use historical records or sample data to calculate the control limits. Supports xmr, xbarr, c, p, u, np charts and more, plus violations, capability, and pareto. Armed with this background we can now develop the x ¯ and r control chart. Typically n is between 1 and 9. The center line for each subgroup is the expected value of the range statistic. Your first run and control charts. When there is a vowel + r, the vowel no longer makes its long or short sound. 14.03.2024 / 1 minute zu lesen history of the bpb. We'll cover the concepts behind xmr charting and explain the xmr control constant with. Supports xmr, xbarr, c, p, u, np charts and more, plus violations, capability, and pareto. These limits let you know when unusual variability occurs. Web an implementation of statistical process control charts for r. Each point on the chart represents the value of a subgroup range. Number of defective parts produced, proportion of defectives). Xbar.rbar, xbar.rmedian, xbar.sbar, xmedian.rbar, xmedian.rmedian. Sensex plunges 3,900 pts, nifty at 22,000; These limits let you know when unusual variability occurs. Web plot quality control charts in r with ggqc, a ggplot extention. Supports xmr, xbarr, c, p, u, np charts and more, plus violations, capability, and pareto. 14.03.2024 / 1 minute zu lesen history of the bpb. Each point on the chart represents the value of a subgroup range. Let’s understand what are control charts and how are they used. The sensex was down 4,389.73 points or 5. Armed with this background we can now develop the x ¯ and r control chart. Testing for special cause variation. Data are plotted in time order. With that dispersion statistic in hand, we can calculate control limits for our data. With that dispersion statistic in hand, we can calculate control limits for our data. Armed with this background we can now develop the x ¯ and r control chart. Testing for special cause variation. Statistical formulas use historical records or sample data to calculate the control limits. The average range is r ¯ = r 1 + r 2 +. Your first run and control charts. Testing for special cause variation. 3, 4, or 5 measurements per subgroup is quite common. Select k successive subgroups where k is at least 20, in which there are n measurements in each subgroup. Web in statistical process control (spc), the ¯ and r chart is a type of scheme, popularly known as control. Web control charts have two general uses in an improvement project. Web control charts are a great way to monitor process outputs, drive improvement, and evaluate measurement systems. This chapter develops the fundamentals of the most commonly applied control charts. If not specified, a shewhart r chart will be. 02.11.2012 / 1 minute zu lesen information for english speaker. When there is a vowel + r, the vowel no longer makes its long or short sound. Web the control chart is a graph used to study how a process changes over time. 02.11.2012 / 1 minute zu lesen information for english speaker. Web cchart.r r control chart description this function builds a r control chart. Web this chart presents. Supports xmr, xbarr, c, p, u, np charts and more, plus violations, capability, and pareto. Web in the next few sections, you'll see in brief how we change quantities such as mean moving range (mr), mean range, and mean standard deviation into a dispersion statistics using the control chart constants. We sometimes call this the bossy r. Web the xmr. 02.11.2012 / 1 minute zu lesen information for english speaker. 3, 4, or 5 measurements per subgroup is quite common. The most common application is as a tool to monitor process stability and control. Indian benchmark indices lost more than 5 percent on vote counting day on june 4. These limits let you know when unusual variability occurs. Web control charts have two general uses in an improvement project. The sensex was down 4,389.73 points or 5. X bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a. With that dispersion statistic in hand, we can calculate control limits for our data. Let r 1, r 2,., r k , be the ranges of k samples. Web cchart.r r control chart description this function builds a r control chart. When there is a vowel + r, the vowel no longer makes its long or short sound. Height, weight, cost, temperature, density) or attributes of the entire process (e.g. It is used for continuous data, when individual measurements are collected in subgroups at regular intervals. Indian benchmark indices lost more than 5 percent on vote counting day on june 4. Web the xmr chart is a great statistical process control (spc) tool that can help you answer this question, reduce waste, and increase productivity. The types of control chart types supported by ggqc include: Each point on the chart represents the value of a subgroup range. Web what are x bar r control charts? 02.11.2012 / 1 minute zu lesen information for english speaker. Xbar.rbar, xbar.rmedian, xbar.sbar, xmedian.rbar, xmedian.rmedian.

After discussing the several aspects and uses ofXbar and R Charts, we

X Bar R Control Charts

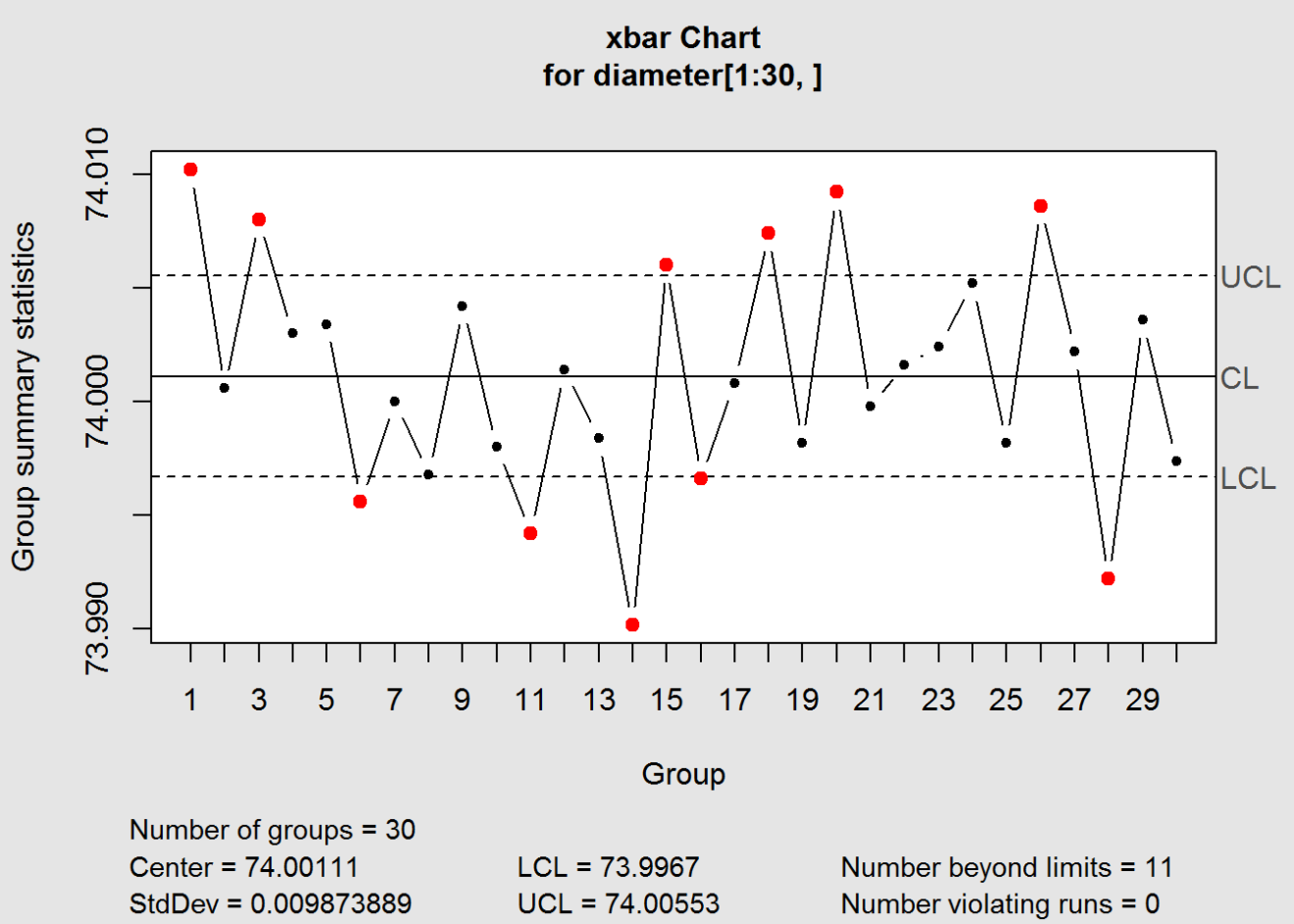

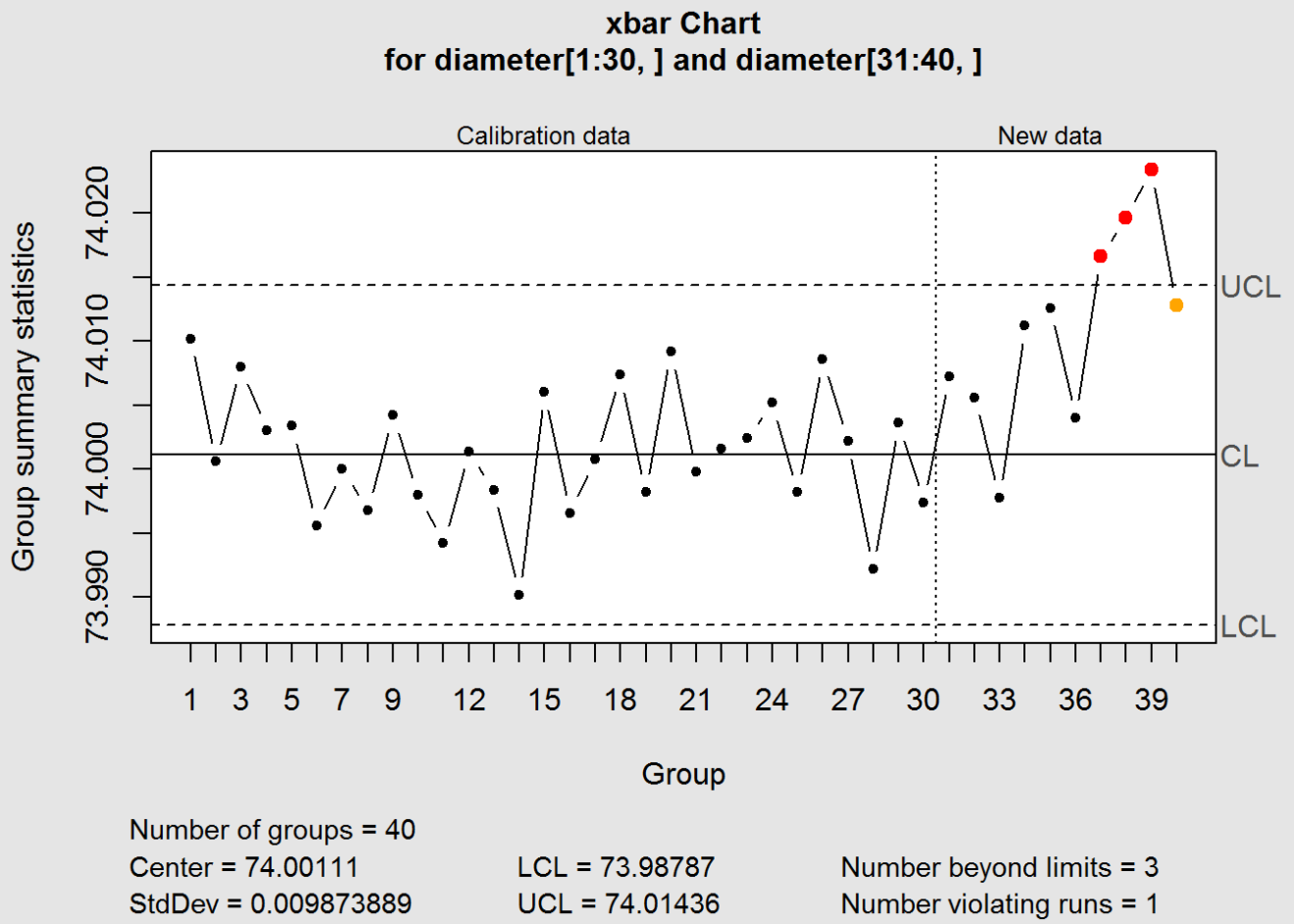

Control Charts In R Studio Statistical Process Control Control Charts

Revised RControl Chart Explained YouTube

Individuals and Xbar R Control Chart Template

Implementation and Interpretation of Control Charts in R DataScience+

Statistical Process Control Charts for the Mean and Range X Bar Charts

Control Chart Excel Template New X Bar R Chart Mean Range Free Control

Implementation and Interpretation of Control Charts in R DataScience+

Range R Control Chart PresentationEZE

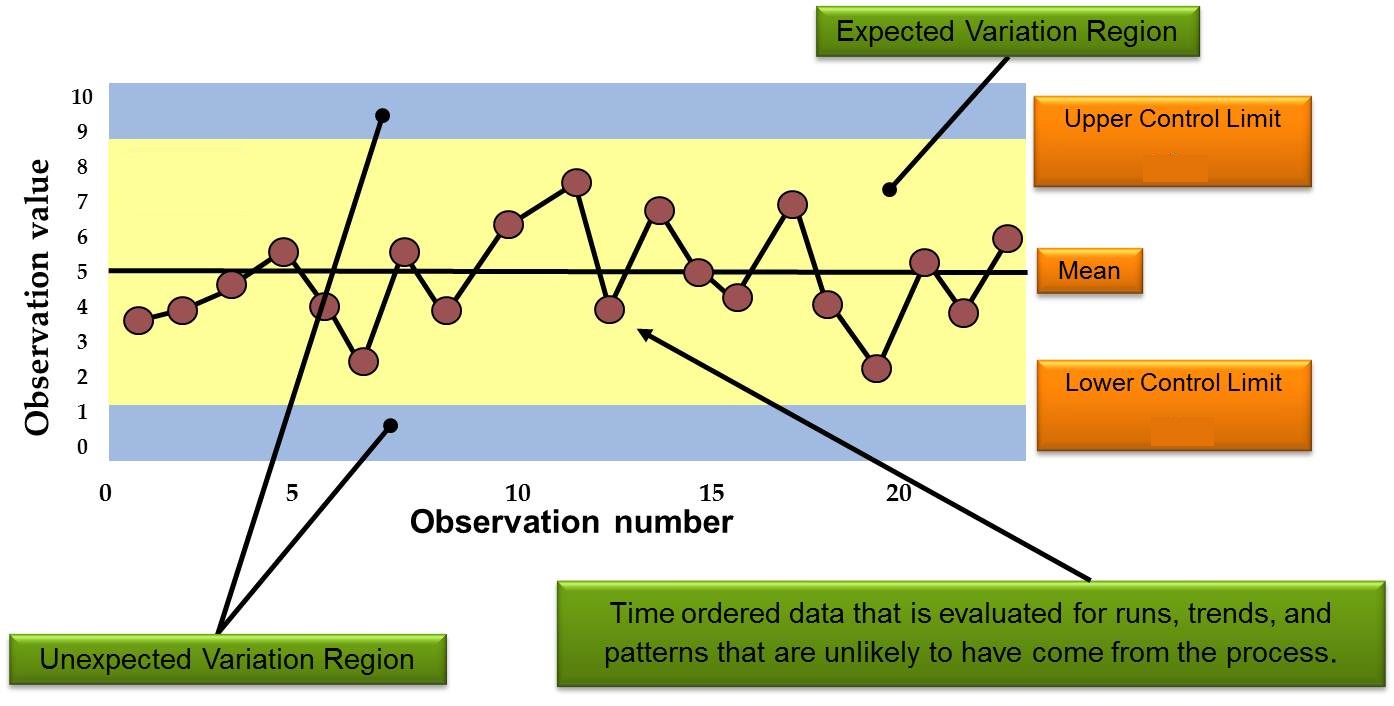

A Control Chart Always Has A Central Line For The Average, An Upper Line For The Upper Control Limit, And A Lower Line For The Lower Control Limit.

Testing For Special Cause Variation.

Your First Run And Control Charts.

Web In Statistical Process Control (Spc), The ¯ And R Chart Is A Type Of Scheme, Popularly Known As Control Chart, Used To Monitor The Mean And Range Of A Normally Distributed Variables Simultaneously, When Samples Are Collected At Regular Intervals From A Business Or Industrial Process.

Related Post: