Pulse Mig Settings Chart

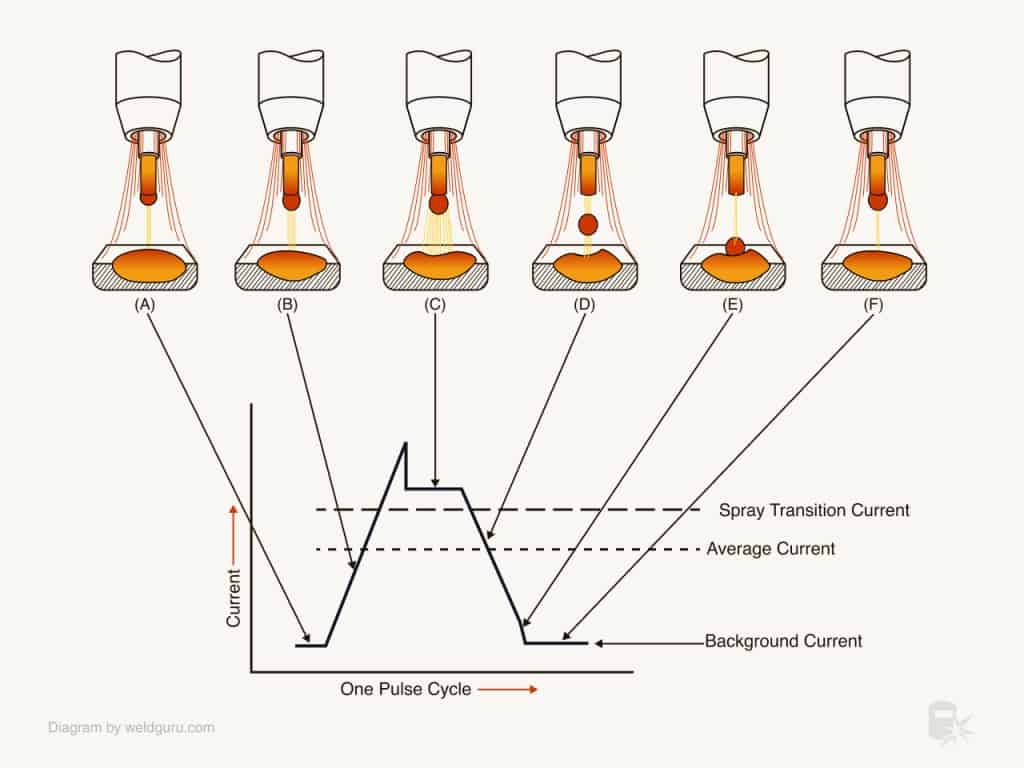

Pulse Mig Settings Chart - Web how thick is the metal you want to weld? 147k views 7 years ago mig welding basics. What is pulse welding for mig and tig; Web pulse mig welding mode ref. Web here are charts showing the wire speed and voltage speed settings required for mig aluminum welding. Use these tips to get the best mig welds. This is best answered by looking at the typical pulse mig 'wave' or. How to selecting welding rod sizes & amperage (chart & guide) But before using these values, we suggest that you have a decent understanding of your preferred metal. The way the pulsed mig welding process works makes it a good choice for reducing rework and minimizing downtime so a welding operation can be. With this in mind, power source manufacturers have built in a voltage adjustment feature. Depress setup speed and adjust left knob (8) to change arc control (7) button to enter arc. Browse suggested weld parameter settings for stick welding, tig. This is best answered by looking at the typical pulse mig 'wave' or. But before using these values, we suggest. Whether you’re new to pulsed tig welding or trying to get the stacked dimes look, selecting the right settings is the key to success. But, regular short circuit mig transfer and even spray mig transfer are limited. Web how thick is the metal you want to weld? These are all things to consider when deciding which type of welder you’ll. Web what’s the difference between mig welding and mag welding? Web settings to use for pulsed mig welding. How to selecting welding rod sizes & amperage (chart & guide) The way the pulsed mig welding process works makes it a good choice for reducing rework and minimizing downtime so a welding operation can be. Once a sales organization brings pulsed. Download the app version of the weld setting calculator for easy reference! The ultimate mig welding guide. Good directional control over the weld puddle, making it easier for new welders Adjust right knob (9) for proper wire feed pulse mig (1, 2) welding mode: Web with the powermig 350mp, you can use the generic gmaw mode where you set voltage. It’s relatively easy to master and can be used in almost all welding applications. The way the pulsed mig welding process works makes it a good choice for reducing rework and minimizing downtime so a welding operation can be. Web consider pulsed mig welding. Web these pulsed mig power sources are capable of adjusting primary and background amps, voltage, and. There are many mig setting charts available from manufacturers that all vary. Browse suggested weld parameter settings for stick welding, tig. Good directional control over the weld puddle, making it easier for new welders The diy guide > mig > tutorial > mig settings calculator. How to selecting welding rod sizes & amperage (chart & guide) Web with the powermig 350mp, you can use the generic gmaw mode where you set voltage and wire speed independently, or you can select synergic gmaw, where wire speed is the main setting and the machine sets voltage for you (but you can adjust voltage if. With this in mind, power source manufacturers have built in a voltage adjustment feature.. But before using these values, we suggest that you have a decent understanding of your preferred metal. But, regular short circuit mig transfer and even spray mig transfer are limited. Once a sales organization brings pulsed to the weld shop floor, the following is what welders, qa personnel and robot technicians and programmers will have to deal with if pulsed. Web weld setting calculator app. Download the app version of the weld setting calculator for easy reference! Whether you’re new to pulsed tig welding or trying to get the stacked dimes look, selecting the right settings is the key to success. Web these pulsed mig power sources are capable of adjusting primary and background amps, voltage, and wire feeding speed,. Web if you're new to pulse mig, one of your questions is likely going to be; Use these tips to get the best mig welds. The ultimate mig welding guide. Web what’s the difference between mig welding and mag welding? What is pulse welding for mig and tig; With this in mind, power source manufacturers have built in a voltage adjustment feature. Web consider pulsed mig welding. Depress setup speed and adjust left knob (8) to change arc control (7) button to enter arc. What are the different parameters and adjustments involved with mig pulse welding? There are many mig setting charts available from manufacturers that all vary. But, regular short circuit mig transfer and even spray mig transfer are limited. 147k views 7 years ago mig welding basics. Web below are charts showing the wire speed and voltage speed settings required for mig stainless steel welding. How to selecting welding rod sizes & amperage (chart & guide) Web how thick is the metal you want to weld? This calculator is intended as a guide to initial power and wire feed settings for people new to welding. Web it covers basic troubleshooting for your weld, the filler wires you’ll need, how to pick a tungsten for tig, how to prepare the tungsten, putting your torch together, plus a full list of recommended settings for tig, stick and mig for every metal type and thickness. Download the app version of the weld setting calculator for easy reference! Web pulse mig welding mode ref. Web setting pulsed mig weld procedures: Whether you’re new to pulsed tig welding or trying to get the stacked dimes look, selecting the right settings is the key to success.

How To MIG Weld Aluminum Beginners Guide (with Chart)

Mig Welding Settings Chart Metric Pdf

Welding Transfer Modes Spray, Global & Short Circuiting

What Is Pulse Welding? And What Do You Use It For? — Jattus

Mig Welding Settings Chart

242 MIG Settings Chart PDF Metalworking Metals

Important MIG Welder Settings You Need to Know (with Chart)

PULSE Aluminum MIG Settings (Pro Pulse 220 MTS Setup Part 13) YouTube

MIG setting chart Diagram Quizlet

MIG Welding Gas Pressure Settings (with Charts)

There Has Been A Quiet Revolution In Tig Welder Design Over The Last 20 Years.

The Way The Pulsed Mig Welding Process Works Makes It A Good Choice For Reducing Rework And Minimizing Downtime So A Welding Operation Can Be.

But Before Using These Values, We Suggest That You Have A Decent Understanding Of Your Preferred Metal.

Browse Suggested Weld Parameter Settings For Stick Welding, Tig.

Related Post: