Polyisocyanurate Insulation Rvalue Chart

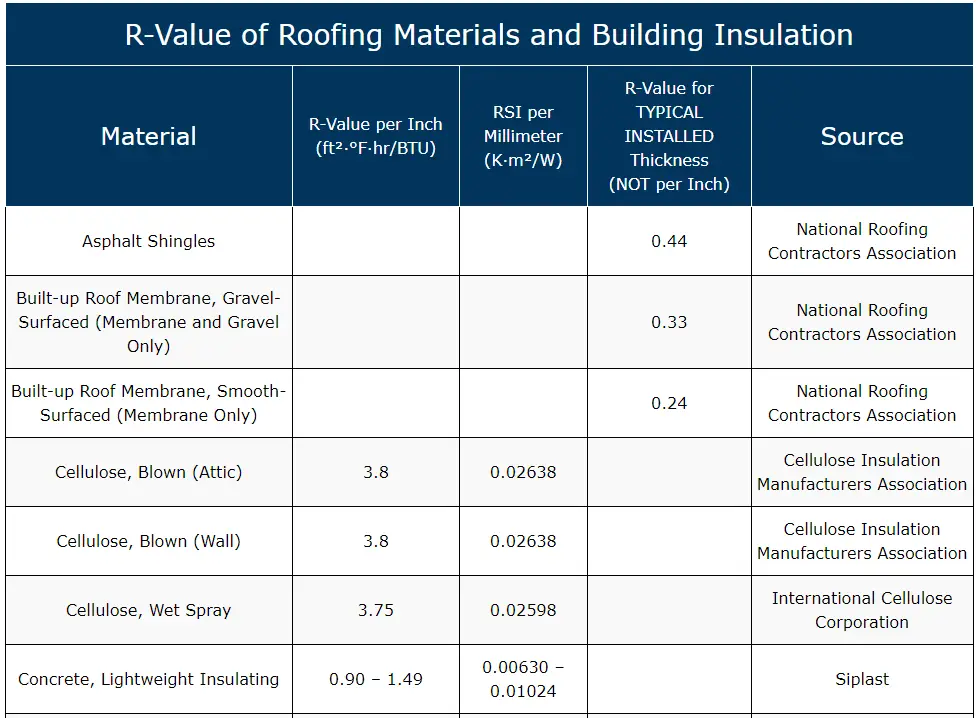

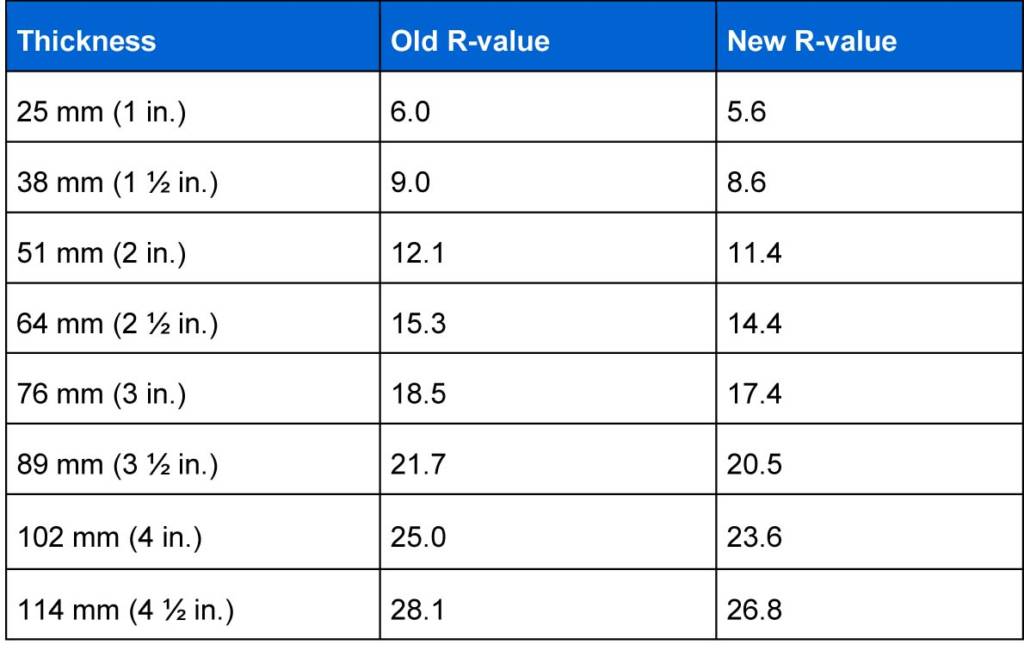

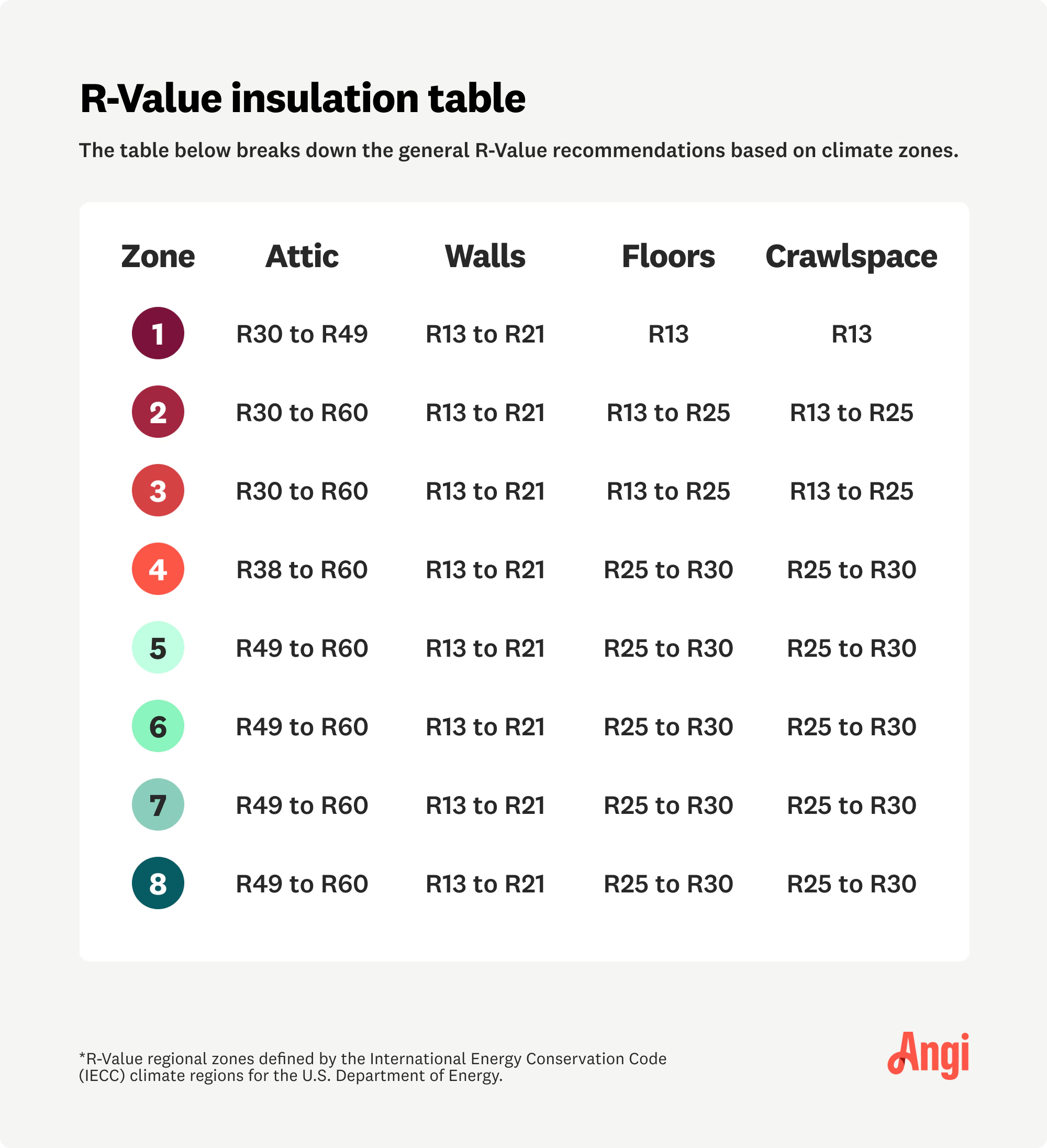

Polyisocyanurate Insulation Rvalue Chart - Energyguard™ polyiso is widely used in commercial construction for new and retrofit applications and is compatible with a large variety of roofing systems. At this thickness, the advantage in thermal performance of polyiso over polystyrene is at least 20%. Web polyiso insulation packaging & weight charts. Easy cutting in the field provides the installer with simplified fabricating on the roof deck. Polyiso insulation packaging & weight charts. For more exact values, please click here to check out our data sheets. Because of its light weight, this material is easy to handle on the jobsite and installs quickly. Compatible with most wall and roof systems. As a result, new lttr values are going to decrease from current values. Namely, we will look into 3 main types of rigid insulation: Polyiso blocks air flow, lowering condensation risks compared to air permeable insulations. Here is the key thing: Thinner walls and roofs with shorter fasteners. Offers various facers and compressive strength options depending on your specification needs. At this thickness, the advantage in thermal performance of polyiso over polystyrene is at least 20%. Web closed cell polyisocyanurate foam core: Because of its light weight, this material is easy to handle on the jobsite and installs quickly. Compatible with most wall and roof systems. At this thickness, the advantage in thermal performance of polyiso over polystyrene is at least 20%. Energyguard™ polyiso is widely used in commercial construction for new and retrofit applications and. Thinner walls and roofs with shorter fasteners. In roof applications, permeable facers are preferred and the average thickness of foam used is 2 inches. Polyiso blocks air flow, lowering condensation risks compared to air permeable insulations. Web polyiso insulation packaging & weight charts. Easy cutting in the field provides the installer with simplified fabricating on the roof deck. At this thickness, the advantage in thermal performance of polyiso over polystyrene is at least 20%. Offers various facers and compressive strength options depending on your specification needs. Web polyiso insulation packaging & weight charts. For more exact values, please click here to check out our data sheets. As a result, new lttr values are going to decrease from current. Namely, we will look into 3 main types of rigid insulation: Because of its light weight, this material is easy to handle on the jobsite and installs quickly. Compatible with most wall and roof systems. Polyiso blocks air flow, lowering condensation risks compared to air permeable insulations. Thinner walls and roofs with shorter fasteners. Polyiso insulation packaging & weight charts. Compatible with most wall and roof systems. Because of its light weight, this material is easy to handle on the jobsite and installs quickly. Thinner walls and roofs with shorter fasteners. As a result, new lttr values are going to decrease from current values. Web polyiso insulation packaging & weight charts. Compatible with most wall and roof systems. In roof applications, permeable facers are preferred and the average thickness of foam used is 2 inches. Here is the key thing: Thinner walls and roofs with shorter fasteners. Polyiso insulation packaging & weight charts. Energyguard™ polyiso is widely used in commercial construction for new and retrofit applications and is compatible with a large variety of roofing systems. For more exact values, please click here to check out our data sheets. Namely, we will look into 3 main types of rigid insulation: In roof applications, permeable facers are preferred. Thinner walls and roofs with shorter fasteners. Compatible with most wall and roof systems. Easy cutting in the field provides the installer with simplified fabricating on the roof deck. Web closed cell polyisocyanurate foam core: Here is the key thing: Thinner walls and roofs with shorter fasteners. Easy cutting in the field provides the installer with simplified fabricating on the roof deck. For more exact values, please click here to check out our data sheets. Namely, we will look into 3 main types of rigid insulation: Here is the key thing: Because of its light weight, this material is easy to handle on the jobsite and installs quickly. In roof applications, permeable facers are preferred and the average thickness of foam used is 2 inches. Easy cutting in the field provides the installer with simplified fabricating on the roof deck. Web polyiso insulation packaging & weight charts. As a result, new lttr values are going to decrease from current values. Here is the key thing: Polyiso blocks air flow, lowering condensation risks compared to air permeable insulations. Energyguard™ polyiso is widely used in commercial construction for new and retrofit applications and is compatible with a large variety of roofing systems. Compatible with most wall and roof systems. Thinner walls and roofs with shorter fasteners. Offers various facers and compressive strength options depending on your specification needs. At this thickness, the advantage in thermal performance of polyiso over polystyrene is at least 20%.

Rvalueofroofinsulation Home Design Ideas

polyiso foam board insulation polyisocyanurate board insulation

Thermax Polyiso Available California Best Insulation Ford Transit

Polyiso R Value Chart

R Value Thickness Chart

Polyiso Insulation R Value Chart

Iso Rvalue Chart

Gaf Polyiso R Value Chart

Polyiso Rigid Insulation R Value Chart

Insulation Thickness Insulation R Value Chart

Polyiso Insulation Packaging & Weight Charts.

For More Exact Values, Please Click Here To Check Out Our Data Sheets.

Web Closed Cell Polyisocyanurate Foam Core:

Namely, We Will Look Into 3 Main Types Of Rigid Insulation:

Related Post: