Plywood Grades Chart

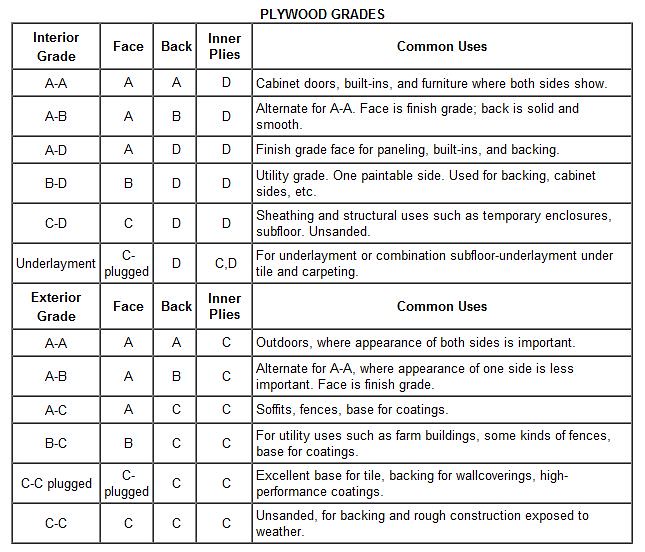

Plywood Grades Chart - Typically, these are graded from a ( the best) to d ( the worst ). Grading tables and other content, including veneer production,. But plywood has many advantages: Web the different gradings of plywood. Veneer sheets are laid on top of each other, with the grain on each layer running perpendicular to each other. Ideal for visible surfaces in cabinetry or furniture.” grade b: Compared to other materials plywood’s many benefits include strength, price and lightness. What do the letters mean? In some wood boards, this grading system also includes numbers 1 to 4 that help determine which types of wood have higher quality. Plywood stands as a versatile cornerstone in woodworking, a material crafted from layers or plies of wood veneer bonded together with adhesives. A, b, c, and d. Web understand plywood grades. Learn more about the different grades of. However, not all plywood is the same, and understanding the different grades is essential for selecting the right type for your project. Web for softwood plywood, each sheet has two grades, one for the ‘face’ veneer and one for the ‘back’ veneer. Compared to other materials plywood’s many benefits include strength, price and lightness. Thinner sheets can also be bent into curved components. There is a variety of plywood available in the market which are specially designed to meet different environments and requirement specification. Slightly lower quality than grade a. Grade b may have minor blemishes but still offers a good, smooth. A and b grade are both very high quality, and so they will cost quite a bit more than lower grades. A grade plywood has the highest quality finish, with no visible defects. Web at forest plywood, we have a large selection of plywood options so you can find the right plywood grade for your next project. Web “a” grade. Web understand plywood grades. The back grades are (best to worst) 1, 2, 3, and 4. Typically, these are graded from a ( the best) to d ( the worst ). Plywood is a versatile and widely used building material with numerous applications in construction, furniture, and woodworking projects. All manufacturers must follow the same grading system to ensure quality. Slightly lower quality than grade a. Web understand plywood grades. Web for softwood plywood, each sheet has two grades, one for the ‘face’ veneer and one for the ‘back’ veneer. The four plywood grades are as follows: But plywood has many advantages: The table above presents the standard thickness of boards that are readily available on the market. Grade b may have minor blemishes but still offers a good, smooth. Thinner sheets can also be bent into curved components. If you’re looking for quality plywood to use on a design feature with a clear finish, a grade timber is your best bet.. However, the most commonly available sizes are 1/4″, 3/8″, 1/2″, 5/8″, and 3/4″. Web plywood manufactured by apa member mills is available in a wide variety of appearance grades, ranging from smooth, natural surfaces suitable for finish work to more economical grades used for sheathing. What do the letters mean? The four plywood grades are as follows: Crossbanded layers and. The four plywood grades are as follows: Plywood is a composition of wood veneers (called plies) and glue (or binder). Structural plywood is suitable for structural applications as a type a bond is used.structural plywood comes in eight standard stress grades and five face veneer qualities. A, b, c, and d. Web hardwood plywood can cost about as much as. Veneer sheets are laid on top of each other, with the grain on each layer running perpendicular to each other. Web plywood’s standard grading system is a, b, c, and d. The four plywood grades are as follows: However, the most commonly available sizes are 1/4″, 3/8″, 1/2″, 5/8″, and 3/4″. Web plywood grades are (best to worst) a, b,. Web “a” grade plywood is the best quality, while “b” grade plywood is the lowest quality. Web at forest plywood, we have a large selection of plywood options so you can find the right plywood grade for your next project. However, not all plywood is the same, and understanding the different grades is essential for selecting the right type for. In some wood boards, this grading system also includes numbers 1 to 4 that help determine which types of wood have higher quality. Plywood is a versatile and widely used building material with numerous applications in construction, furniture, and woodworking projects. We’ll explore the world of plywood grades in this post, with a particular emphasis on trojan plywood and how their grading system could impact your project. Web understand plywood grades. Here’s how to tell them apart based on wood quality. Learn more about the different grades of. Web plywood grades are (best to worst) a, b, c and d for face or front face. Web hardwood plywood can cost about as much as an equal quantity of solid hardwood, depending on grade and appearance. Crossbanded layers and balanced construction mean that hardwood plywood won't shrink, swell, or warp as much as lumber. The back grades are (best to worst) 1, 2, 3, and 4. Compared to other materials plywood’s many benefits include strength, price and lightness. Ideal for visible surfaces in cabinetry or furniture.” grade b: Some plywood comes with “x” added to the end, such as “abx.” the “x” stands for “exposure,” meaning that it can withstand a reasonable moisture level. If you’re looking for quality plywood to use on a design feature with a clear finish, a grade timber is your best bet. Designed to provide you with an understanding of popular hardwood plywood face veneer grades. Structural plywood is suitable for structural applications as a type a bond is used.structural plywood comes in eight standard stress grades and five face veneer qualities.Lumber Grading Chart PDF Wood

Epic Lumber Dimensions Guide and Charts (Softwood, Hardwood, Plywood)

Epic Lumber Dimensions Guide and Charts (Softwood, Hardwood, Plywood

What Are The Different Types And Grades Of Plywood Pl vrogue.co

18 Different Types of Lumber

Understanding Plywood Grades Plywood grades, Plywood and Woodworking

Epic Lumber Dimensions Guide and Charts (Softwood, Hardwood, Plywood

Hardwood Plywood Grades Columbia Forest Products

Epic Lumber Dimensions Guide and Charts (Softwood, Hardwood, Plywood)

Plywood Grades

Although As You’ll See Below, A Few Additional Letters Sneak In From Time To Time.

All Manufacturers Must Follow The Same Grading System To Ensure Quality And Strength.

The Sheets Are Glued Together And Then Pressed To Form A Solid Composite.

The Table Above Presents The Standard Thickness Of Boards That Are Readily Available On The Market.

Related Post: