Plasma Cutter Chart

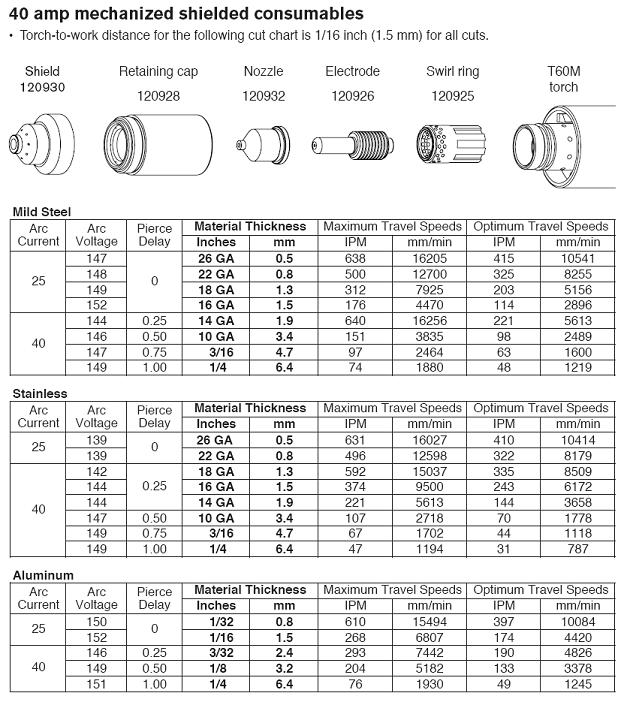

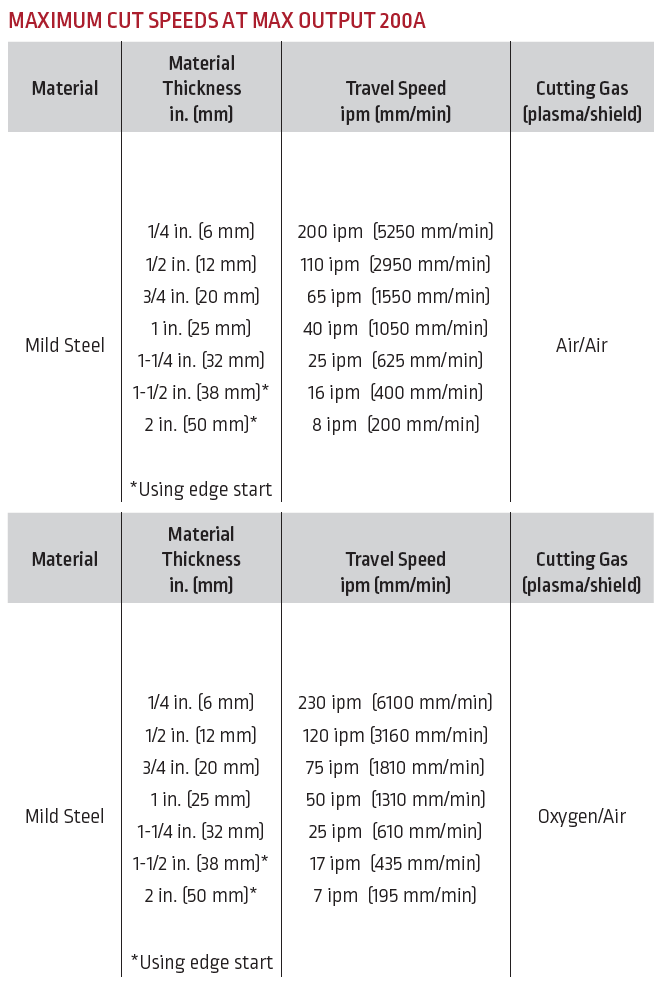

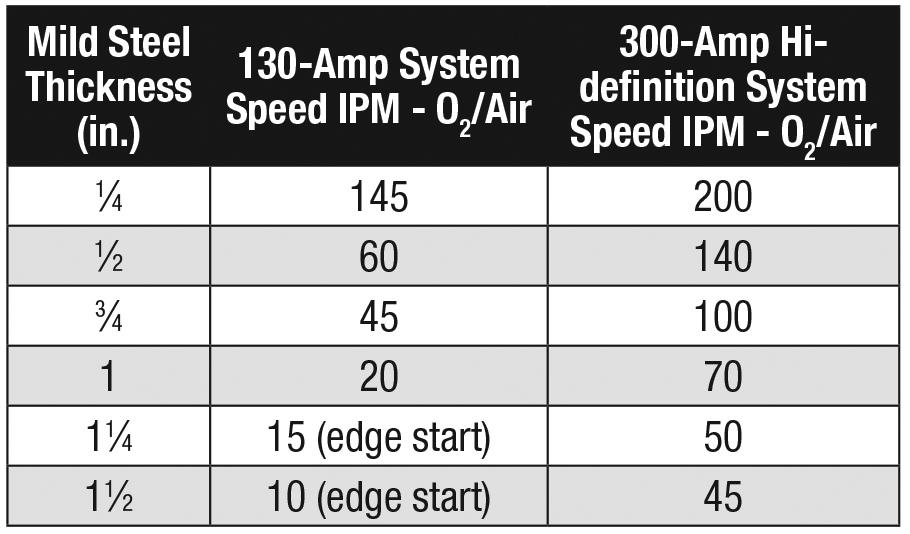

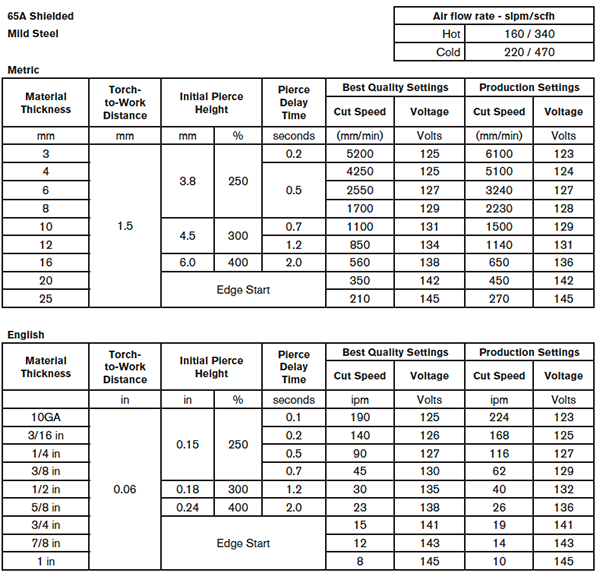

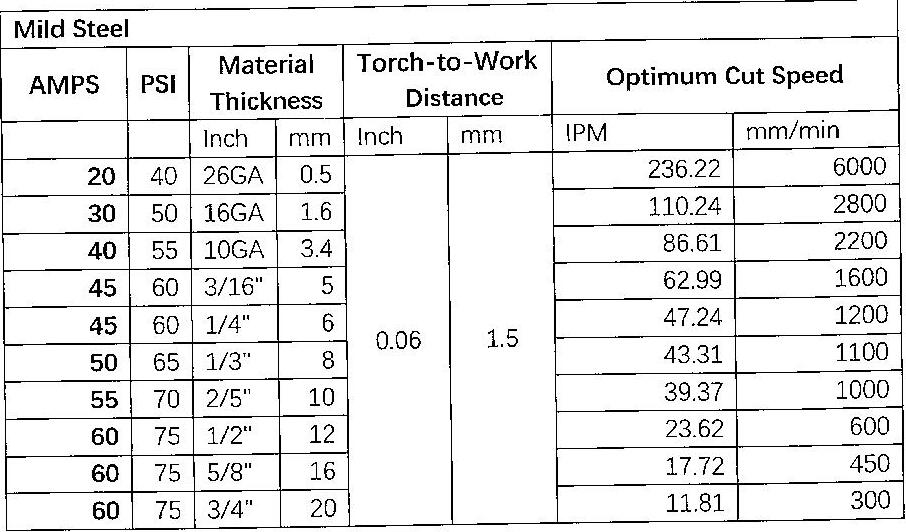

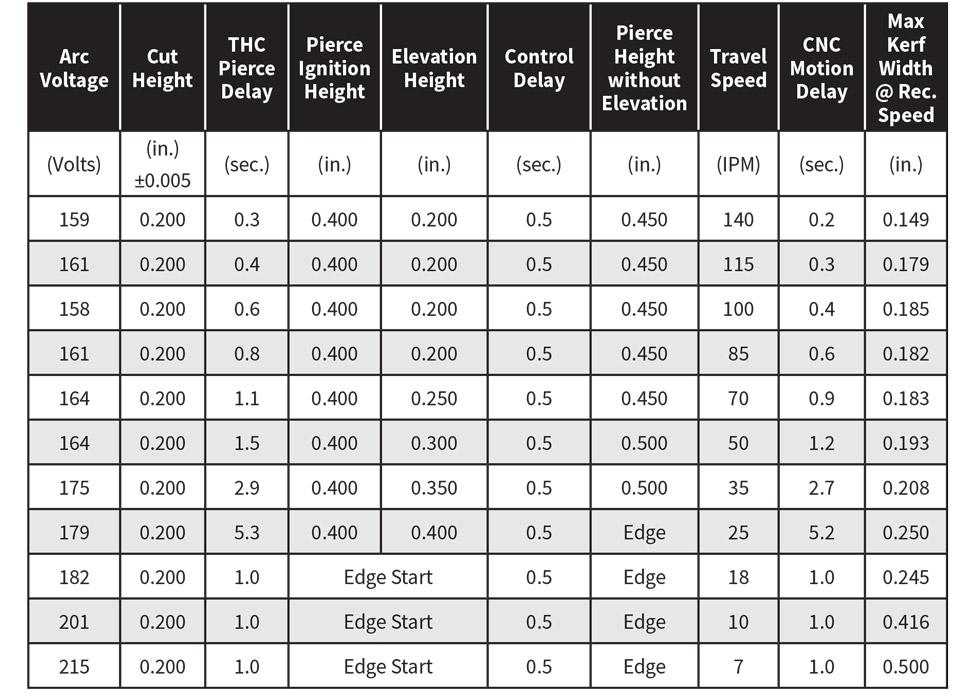

Plasma Cutter Chart - Cutting mild steel, stainless steel, and aluminum at 45 a with air using shielded consumables. The primeweld cut60 110v 220v plasma cutter is excellent for cnc use. Web all of our manuals contain very detailed cut charts, including plasma cut charts for aluminum. Web bad plasma cutting setup ruins productivity and cut quality. Can you plasma cut aluminum with a water table? The cut charts are divided into two areas: Web these plasma systems can cut square edges on steel plate from gauge to 2 (50 mm) thick, create nearly perfect holes, and hold tolerances from.010 to.020 (.25 to.51 mm) depending on material and thickness. Web cut charts are provided for each set of mechanized cutting and marking consumables. Web the charts cover all the material thicknesses that can be cut with that system; Explain which consumable set to use and at what amperage; Web primeweld cut60 cut chart provides the information you need for your best cut. Orifice hole size 1mm =.03937. Cut charts are included for: (2) fast cutting speed, high efficiency, cutting speed can reach 10m/min or above; Explain which consumable set to use and at what amperage; Can you plasma cut aluminum with a water table? We’ll also include handy charts to help you adjust settings based on material type and thickness. It is not a replacement for the detailed information found in the operator’s manual for your plasma system. Web the following cut charts show the consumable parts, cutting speeds and the gas and torch settings. Web all of our manuals contain very detailed cut charts, including plasma cut charts for aluminum. By now, if you've gotten your plasma set up and a dryer installed, you're likely wondering exactly how much air pressure to use, and what amperage to set for each thickness. Select the appropriate plasma cutting setting process for: Most of the time, parts. Every cutting system requires “fine tuning” for each cutting application in order to obtain the desired cut quality. Cutting mild steel, stainless steel, and aluminum at 45 a with air using shielded consumables. (1) wide cutting field, can cut all metal sheets; The cut charts are divided into two areas: Web to determine the optimal amperage and air setting for. (1) wide cutting field, can cut all metal sheets; It is not a replacement for the detailed information found in the operator’s manual for your plasma system. Web these plasma systems can cut square edges on steel plate from gauge to 2 (50 mm) thick, create nearly perfect holes, and hold tolerances from.010 to.020 (.25 to.51 mm) depending on material. Web primeweld cut60 cut chart provides the information you need for your best cut. Web you can develop your own charts and reference those in the future to save yourself time and frustration when different jobs come in the door for your plasma table. (1) wide cutting field, can cut all metal sheets; Small current plasma arc cutting, large current. Web the following cut charts show the consumable parts, cutting speeds and the gas and torch settings required for each process. The primeweld cut60 110v 220v plasma cutter is excellent for cnc use. Web primeweld cut60 cut chart provides the information you need for your best cut. Refer to the plasma cutter's user manual: You can always make slight adjustments. Cutting mild steel and stainless steel with air using finecut consumables. Web these plasma systems can cut square edges on steel plate from gauge to 2 (50 mm) thick, create nearly perfect holes, and hold tolerances from.010 to.020 (.25 to.51 mm) depending on material and thickness. (2) fast cutting speed, high efficiency, cutting speed can reach 10m/min or above; Getting. It does not cover mechanized cutting. Web the following cut charts provide the necessary information in order for the operator using the max200 machine torch system to be successful in plasma arc cutting. Can you plasma cut aluminum with a water table? Select the appropriate plasma cutting setting process for: The primeweld cut60 110v 220v plasma cutter is excellent for. It does not cover mechanized cutting. Web bad plasma cutting setup ruins productivity and cut quality. In fact, the hardest part comes before ever striking an arc — selecting a machine that best matches your application and choosing the right accessories. Web how to plasma cut. Most of the time, parts do not require rework and are ready to use. It is critical that these plasma cutter settings are correct: Web these plasma systems can cut square edges on steel plate from gauge to 2 (50 mm) thick, create nearly perfect holes, and hold tolerances from.010 to.020 (.25 to.51 mm) depending on material and thickness. The user manual should contain a chart or table specifying the suggested amperage and air settings for various metal thicknesses. Web you can develop your own charts and reference those in the future to save yourself time and frustration when different jobs come in the door for your plasma table. Web how to plasma cut. It does not cover mechanized cutting. Web cut charts are intended to provide a good starting point for each different cut assignment. Web bad plasma cutting setup ruins productivity and cut quality. Cut charts are included for: It is not a replacement for the detailed information found in the operator’s manual for your plasma system. We’ll also include handy charts to help you adjust settings based on material type and thickness. You are about to learn how to set up your plasma cutter for maximum results. Refer to the plasma cutter's user manual: Select the appropriate plasma cutting setting process for: Web all of our manuals contain very detailed cut charts, including plasma cut charts for aluminum. Web the charts cover all the material thicknesses that can be cut with that system;

UltraCut HighPrecision plasma cutting systems. 130 amp 800 amp

Plasma Cutter Amps Thickness Chart (PDF Download)

Plasma Cutter Settings Chart Best Guides From Expert

Plasma Cutter Amps Thickness Chart

Plasma Cutter Amps Thickness Chart Online Shopping

Plasma Cutting Thickness Chart

Improve cut quality with these CNC steel and metal cutting tips

Cut charts for everlast plasma 9 by hunterthehobbyist Plasma

CNC Plasma

A check list for a plasma cutting table retrofit The Fabricator

Every Cutting System Requires “Fine Tuning” For Each Cutting Application In Order To Obtain The Desired Cut Quality.

Web Primeweld Cut60 Cut Chart Provides The Information You Need For Your Best Cut.

Web The Following Cut Charts Provide The Necessary Information In Order For The Operator Using The Max200 Machine Torch System To Be Successful In Plasma Arc Cutting.

You Can Always Make Slight Adjustments Later If Needed.

Related Post: