Piston Ring Size Chart

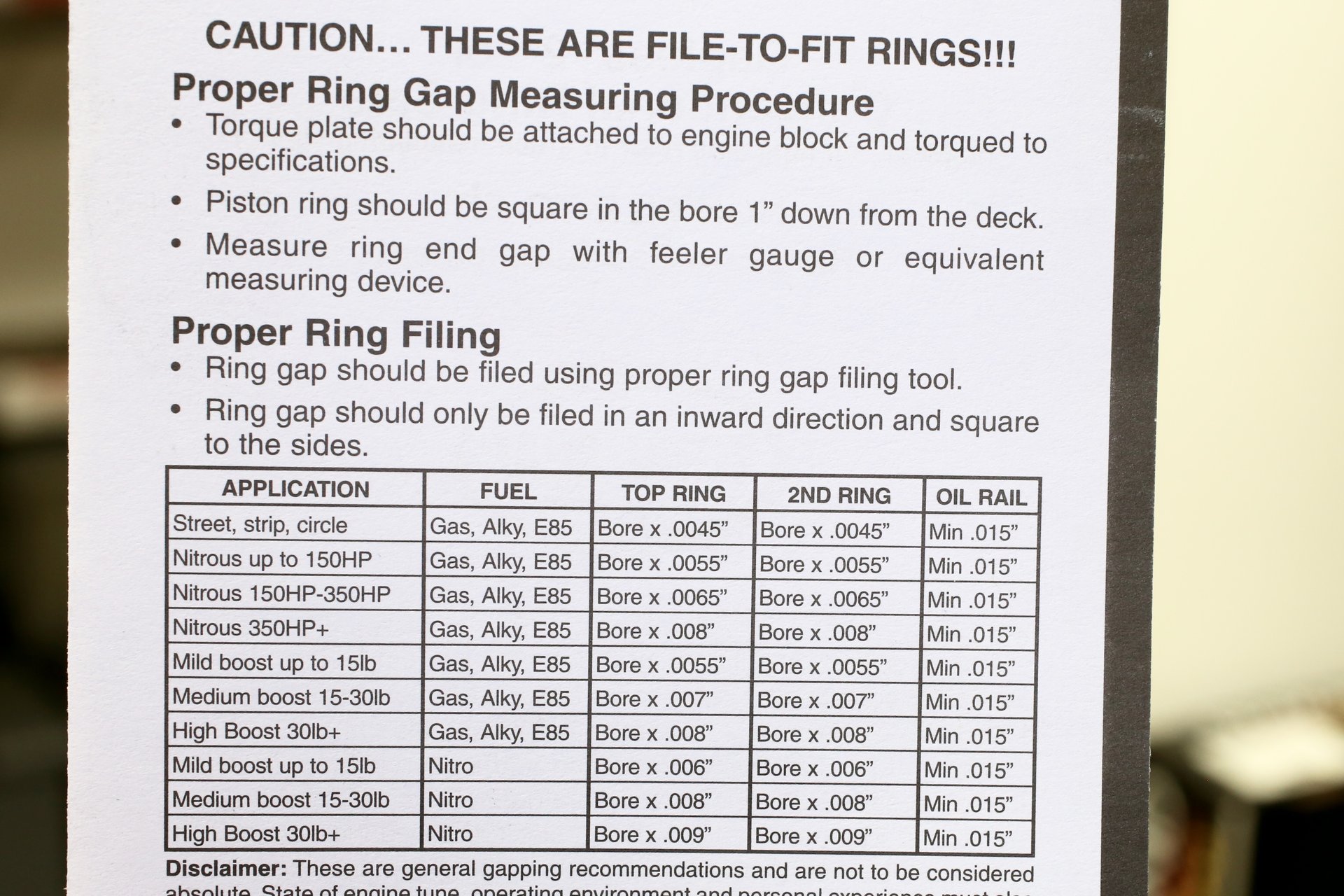

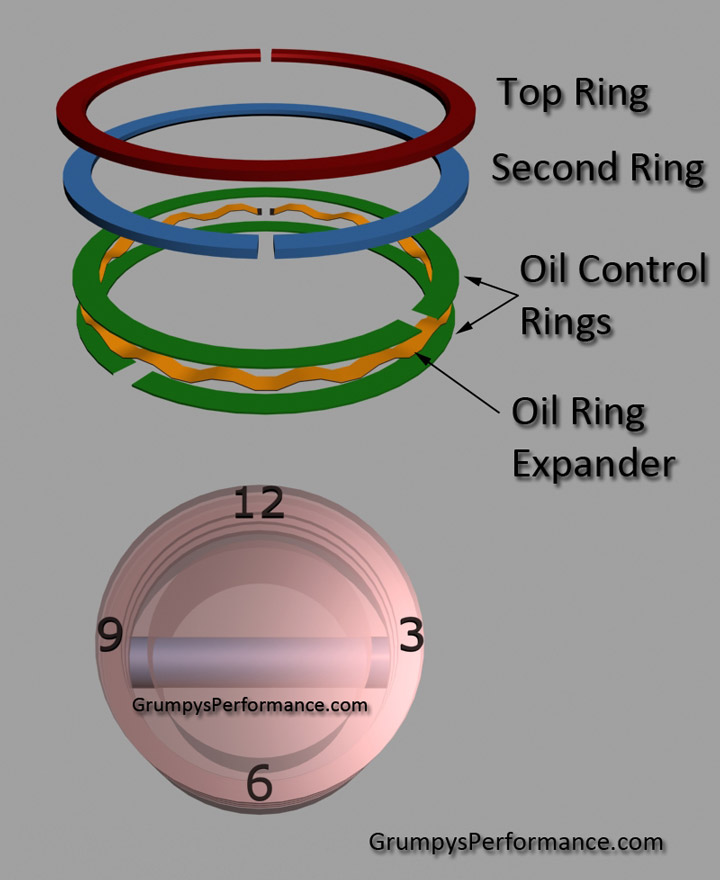

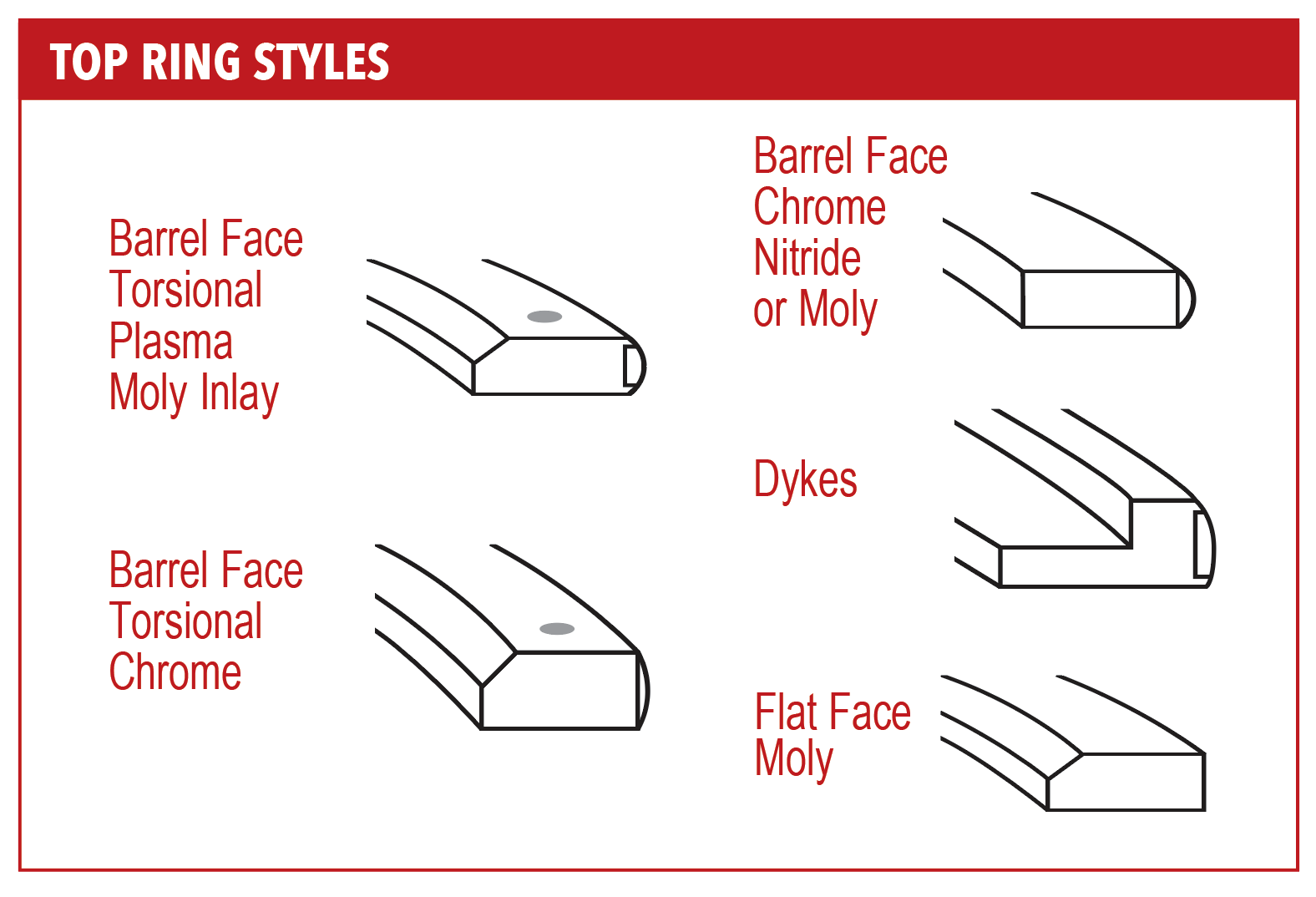

Piston Ring Size Chart - Web piston diameter dictates the final bore diameter. Web the dimension from one side face to the other, or ring thickness, usually expressed in fractional sizes like 1/16 inch, decimal sizes like 0.043 inch, or metric sizes like 1.5 mm. The second groove ring function is to help aid in scraping oil down the cylinder. The second ring end gap would be 4.000 x.0045″ =.018″. Check back, as we update our catalogs periodically. Web typical surface finish for a normal plateau finish would be rpk of 8 to 12 microinches, rk of 25 to 35 microinches, and rvk of 40 to 50 microinches. The primary function of a top compression ring is to seal compression gas and help in heat transfer. For a naturally aspirated street engine using a cast piston with 4.000″ bore, the top ring end gap would be 4.000 x.004″ =.016″. On the first two or three rings, this may take several measurements to get a. Web when using a manual ring filer, start by making six to ten turns of the disc with light pressure on the ring, and then recheck the clearance. If you’re not able to find what you’re looking for, contact us to learn more about our products. Multiply bore size x ring end gap factor. Measuring piston diameter is not determined at the ring area; Web use the chart below to determine the minimum ring end gap. View tech tip » ring groove depths of piston rings. Bill mcknight at mahle aftermarket teaches you how to measure ring face width, ring radial wall thickness and intended bore size. The second groove ring function is to help aid in scraping oil down the cylinder. Measuring piston diameter is not determined at the ring area; End gaps for performance application. Web piston rings may not be the most exciting. Want to know more about ring material and design? Multiply bore size x ring end gap factor. On the first two or three rings, this may take several measurements to get a. End gaps for performance application. Web when using a manual ring filer, start by making six to ten turns of the disc with light pressure on the ring,. It is critical that the piston ring does not protrude past the adjacent piston land or severe engine damage will occur. Rather, the measurement must be taken at the skirt, but only in the specific height location specified by the piston maker. Web when using a manual ring filer, start by making six to ten turns of the disc with. Web everything you need to know about piston rings, thin vs thick, engine break in, and making horsepower. Rather, the measurement must be taken at the skirt, but only in the specific height location specified by the piston maker. Web tough guy tech tips. Web measuring piston rings. View tech tip » ring groove depths of piston rings. A common practice in racing applications is file fitting piston ring end gaps. Want to know more about ring material and design? Web a piston ring’s diameter is directly proportional to the cylinder bore. Rather, the measurement must be taken at the skirt, but only in the specific height location specified by the piston maker. On the first two or. Bill mcknight at mahle aftermarket teaches you how to measure ring face width, ring radial wall thickness and intended bore size. End gaps for performance application. For a naturally aspirated street engine using a cast piston with 4.000″ bore, the top ring end gap would be 4.000 x.004″ =.016″. Web measuring piston rings. If you’re not able to find what. Web piston diameter dictates the final bore diameter. In this article, we’re going to explore how to select, measure, and adjust your ring end gaps to help achieve a reliable ring seal. Web tough guy tech tips. If you’re not able to find what you’re looking for, contact us to learn more about our products. If an overbore of the. A common practice in racing applications is file fitting piston ring end gaps. In a performance application, an optimized plateau finish should have a rpk value of less than 12 microinches, rk of around 20, and rvk of around 40 microinches. Bill mcknight at mahle aftermarket teaches you how to measure ring face width, ring radial wall thickness and intended. Web a piston ring’s diameter is directly proportional to the cylinder bore. Back clearance is the difference between the depth of the piston groove and the radial wall of the ring. For a naturally aspirated street engine using a cast piston with 4.000″ bore, the top ring end gap would be 4.000 x.004″ =.016″. Web the following chart indicates the. If you’re not able to find what you’re looking for, contact us to learn more about our products. Web what makes piston ring selection and ring endgap so important to engine life and power? Web a piston ring is a metal band used to control compression and oil in an engine. Web measuring piston rings. End gaps for performance application. A common practice in racing applications is file fitting piston ring end gaps. In this article, we’re going to explore how to select, measure, and adjust your ring end gaps to help achieve a reliable ring seal. For a naturally aspirated street engine using a cast piston with 4.000″ bore, the top ring end gap would be 4.000 x.004″ =.016″. Web piston rings may not be the most exciting part of an engine build, but knowing how to clock piston rings and how to install rings on a piston is critical to your engine performing properly. Back clearance is the difference between the depth of the piston groove and the radial wall of the ring. Rather, the measurement must be taken at the skirt, but only in the specific height location specified by the piston maker. View tech tip » ring groove depths of piston rings. Web tough guy tech tips. The second ring end gap would be 4.000 x.0045″ =.018″. Web analyze and compare your rings to these charts to help identify which specific style rings your piston (s) came with. Web piston diameter dictates the final bore diameter.

Repair Guides

How to FileFit and Install Piston Rings

ring gapping and basic piston ring info YOULL NEED Grumpys

Repair Guides Specification Charts Specification Charts

Total Seal Chevy 305 Conventional Piston Rings, Style C Free Shipping

Repair Guides Engine Mechanical General Information

![Piston Rings Types And Function Guide] Engineering Learn](https://engineeringlearn.com/wp-content/uploads/2021/04/Piston-Rings-1024x539.jpg)

Piston Rings Types And Function Guide] Engineering Learn

Repair Guides Specifications Charts Specifications Charts

Piston ring gap chart. Greg Clark Flickr

How to Know Which Ring Set You Need for Your Pistons

In A Performance Application, An Optimized Plateau Finish Should Have A Rpk Value Of Less Than 12 Microinches, Rk Of Around 20, And Rvk Of Around 40 Microinches.

Web A Piston Ring’s Diameter Is Directly Proportional To The Cylinder Bore.

Bill Mcknight At Mahle Aftermarket Teaches You How To Measure Ring Face Width, Ring Radial Wall Thickness And Intended Bore Size.

Web Use The Chart Below To Determine The Minimum Ring End Gap.

Related Post: