Pipe Spacing Chart

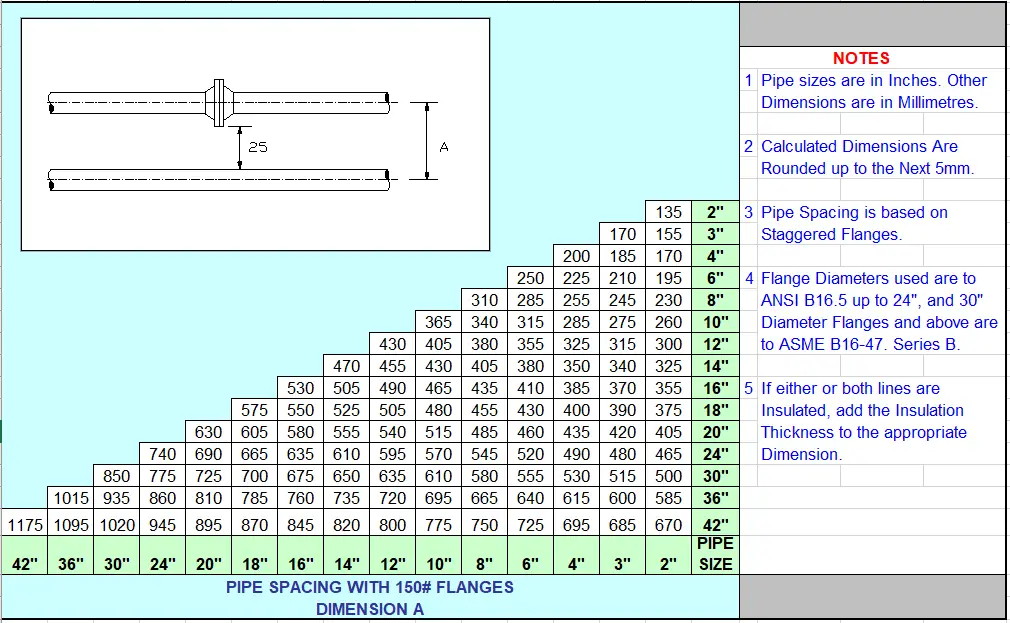

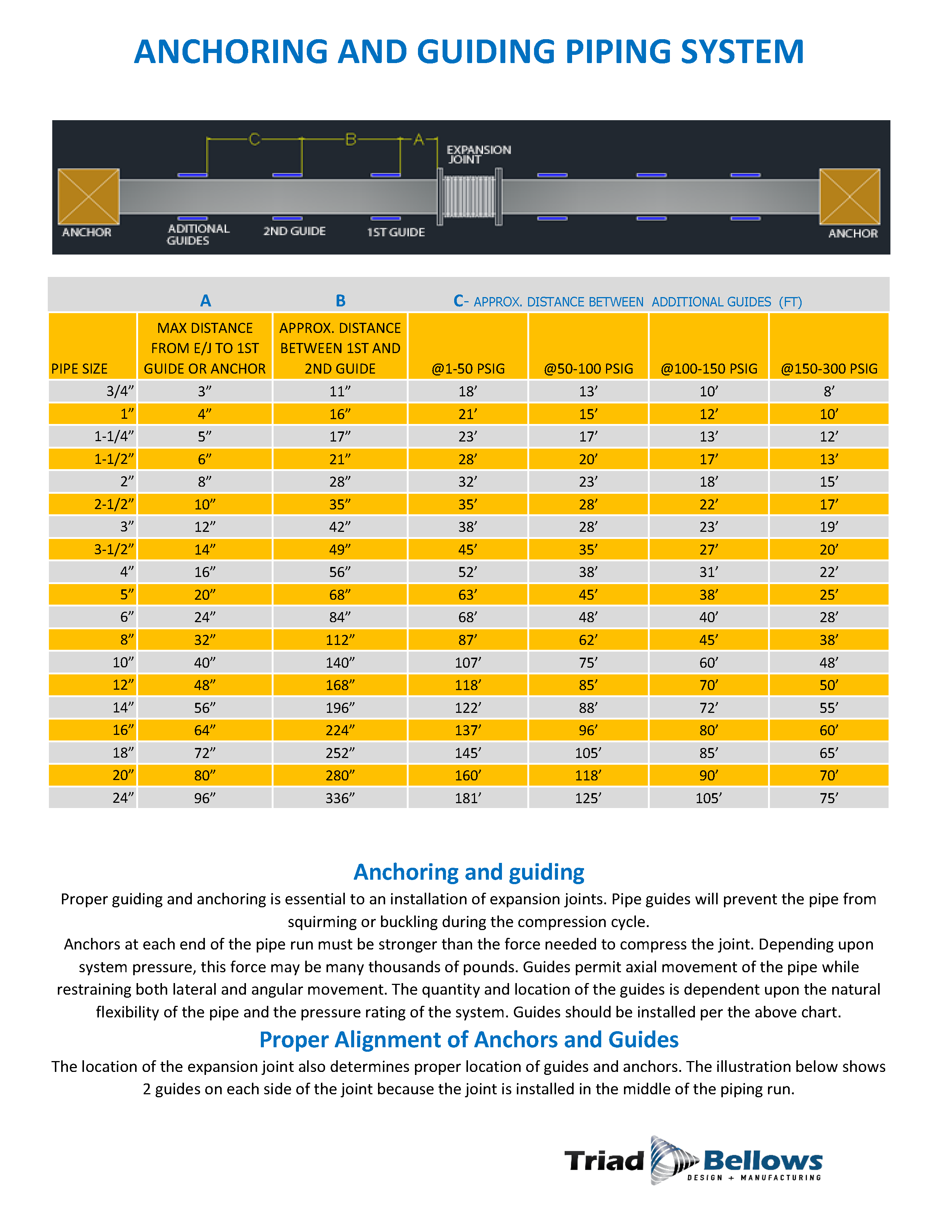

Pipe Spacing Chart - Standardization of wrought steel pipe schedule and pipe. This value is the larger value of: The values does not apply where loads are concentrated with flanges, valves, specialties, etc. Calculations, datasheets, cad blocks and other resources related to science and its subdisciplines. A common rule of thumb is to support loads of this type with hangers on both sides of the load. Web a chart with values for recommended minimum spacing based on pipe diameter, minimum “x” and minimum “s” is shown. Find a pipe support span chart with factors, formulas, and examples. Hangers and supports should not be clamped tightly because the axial movement of the pipe would be restricted. Use the pipe spacing calculator to find the optimal spacing for different piping configurations and npds. Allowable pipe span is the maximum distance between supports or hangers that a pipe can span without excessive deflection or stress. Web use our ansi pipe chart to determine the nominal pipe size, wall thickness, weight and schedule designations. Web posted in pipe layout datasheets. See a table of pipe size and flange rating with corresponding spacing values in millimeters. Web pipe spacing calculator is a convenient tool to calculate the minimum spacing between pipes. A common rule of thumb is. Data given in based on the nps tables given by ansi b36.10m and includes pipe wall thickness, outside diameter, nominal diameter. Web find the standard pipe line spacing dimensions in millimeters for different nominal pipe sizes and insulation thicknesses. See pipe support span charts for different standards and nominal pipe sizes. The charts are based on continuous spans and uninsulated. Pipe spacing is figured for 1 inch between flanges. Use the pipe spacing calculator to find the optimal spacing for different piping configurations and npds. Pipe schedule number is the standard method to define the thickness of the pipes used in process plants. Web additional guides should be located in accordance with the pipe guide spacing chart shown below for. This pipe thickness calculator calculates required pipe thickness for a process pipe based on asme. Web learn how to calculate and use pipe spacing charts for various sizes and flanges of pipes and pipelines. Web additional guides should be located in accordance with the pipe guide spacing chart shown below for standard weight carbon steel pipe or calculated from the. Pipe schedule number is the standard method to define the thickness of the pipes used in process plants. This pipe thickness calculator calculates required pipe thickness for a process pipe based on asme. Web the chart lists recommended spacing for pipe diameters ranging from 1 to 24 in increments of 1/2 for flange ratings of 600#, 300#, and 150#. Web. Web learn how to calculate the minimum spacing between pipes of different sizes and flange ratings in petrochemical and refinery plants. Find standard pipe spacing charts and factors affecting pipe spacing criteria. Select the applicable piping configuration from the four options provided to calculate the pipe center to center spacing. Pipe thickness calculator as per asme b31.3. Dimensions are from. Click to print our line sheet. Web learn how to calculate and select the optimum pipe support span for different piping configurations and materials. Pipe 2 flange od (inches): Pipe spacing is figured for 1 inch between flanges. The chart also shows the minimum spacing between pipes, flanges, valves and other components to avoid clash during construction. Web find the standard pipe line spacing dimensions in millimeters for different nominal pipe sizes and insulation thicknesses. See pipe support span charts for different standards and nominal pipe sizes. Web pvc pipe support spacing (ft.) pipe size (in.) schedule 40 temperature (°f) schedule 80 temperature (°f) schedule 120 temperature (°f) 60: Pipe thickness calculator as per asme b31.3. Spacing. Find a pipe support span chart with factors, formulas, and examples. Web a chart with values for recommended minimum spacing based on pipe diameter, minimum “x” and minimum “s” is shown. Web all pipelines have two basic spacing rules: A 2nd chart for minimum recommended cover based on vehicle loading conditions uses pipe diameter. This pipe thickness calculator calculates required. The charts are based on continuous spans and uninsulated lines carrying liquids. A common rule of thumb is to support loads of this type with hangers on both sides of the load. Web learn how to calculate the minimum spacing between pipes of different sizes and flange ratings in petrochemical and refinery plants. See pipe support span charts for different. Standardization of wrought steel pipe schedule and pipe. Web learn how to calculate the spacing between pipes on a pipe rack based on flange ratings, insulation thickness and project standard clearance. Web pvc pipe support spacing (ft.) pipe size (in.) schedule 40 temperature (°f) schedule 80 temperature (°f) schedule 120 temperature (°f) 60: Pipe 2 flange od (inches): Enter pipe outside diameters, flange ratings, insulation thicknesses and piping configuration options to get the spacing results. Web learn how to calculate pipe support span based on various factors such as weight, material, insulation, temperature, and operating conditions. A common rule of thumb is to support loads of this type with hangers on both sides of the load. A 2nd chart for minimum recommended cover based on vehicle loading conditions uses pipe diameter. Web torsion on open section beams and pipe supports design in the last twenty years, with the increased use of 3d modelling in the o&g industry, most of the epc companies have progressively passed the pipe supports selection and design duties from stress engineers and pipe supports specialists to piping designers, who are directly involved in the 3d. Calculations, datasheets, cad blocks and other resources related to science and its subdisciplines. Web recommended maximum space between hangers for straight horizontal pipes and tubes are indicated in the table below. Pipe schedule number is the standard method to define the thickness of the pipes used in process plants. Calculate spacing between pipes on a pipe rack based on dimensional standard asme b16.5 and. Click to print our line sheet. This pipe thickness calculator calculates required pipe thickness for a process pipe based on asme. The chart also shows the minimum spacing between pipes, flanges, valves and other components to avoid clash during construction.Pipe Spacing Chart PDF PDF

Pipe Line Spacing Chart PDF PDF

Pipe Support Spacing Chart Pdf

Pipe Spacing Chart PDF Matériaux de construction Génie du bâtiment

(PDF) Pipe Spacing Chart Piping Designers .

Pipe Spacing Chart PDF

Pipe Spacing Chart Pipeline Spacing Chart What Is Piping

Pipe Alignment Guides Pipe Guides and Supports

Pipe Spacing Chart A Visual Reference of Charts Chart Master

Pipe Spacing Chart.xls Dimension Pipe (Fluid Conveyance)

The Values Does Not Apply Where Loads Are Concentrated With Flanges, Valves, Specialties, Etc.

It's An Important Parameter In Piping Design And Engineering To Ensure The Structural Integrity And Safety Of A Piping System.

Select The Applicable Piping Configuration From The Four Options Provided To Calculate The Pipe Center To Center Spacing.

Web A Chart With Values For Recommended Minimum Spacing Based On Pipe Diameter, Minimum “X” And Minimum “S” Is Shown.

Related Post: