Perm Rating Chart

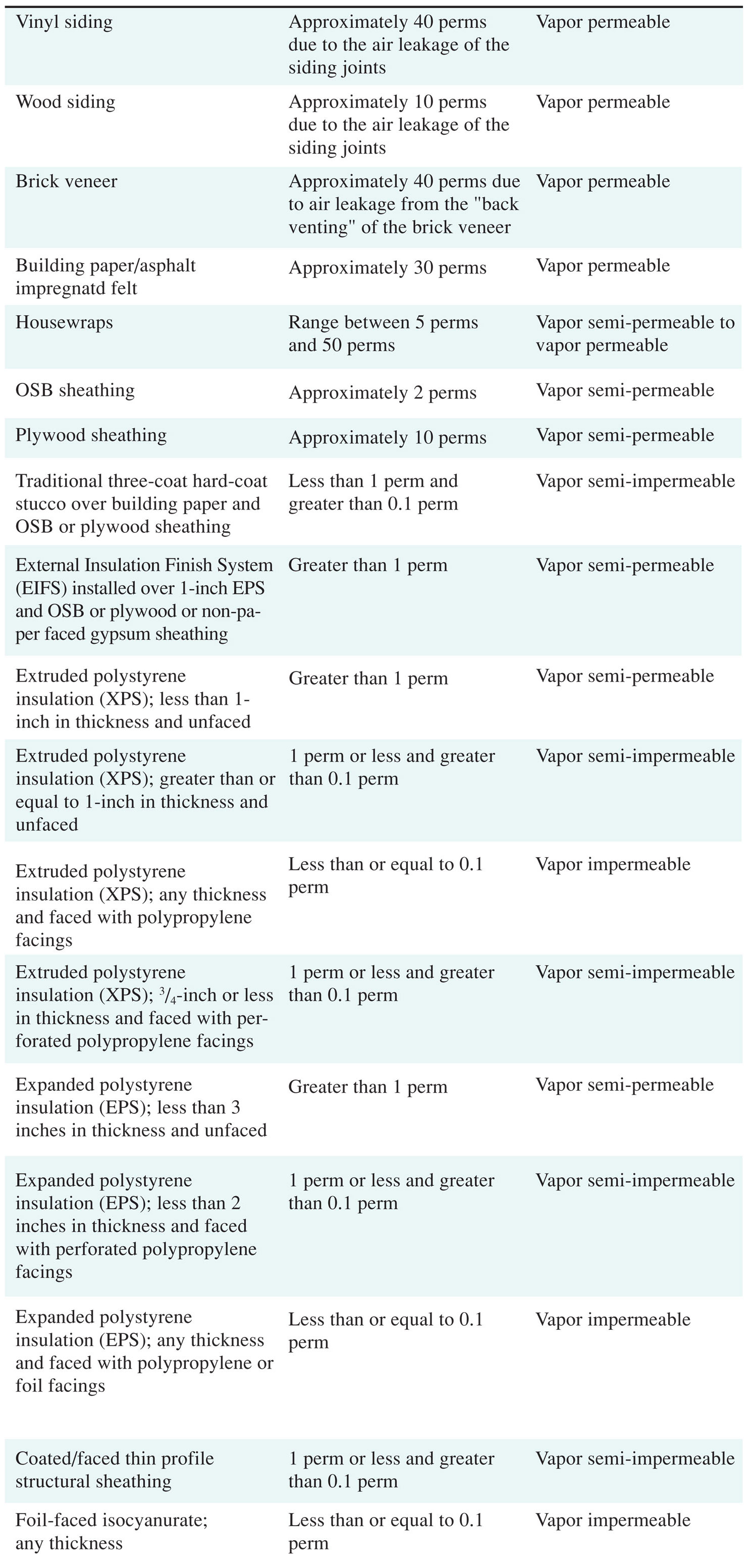

Perm Rating Chart - 35 perms is an equivalent vapor permeance value. The higher the number, the more readily water vapor (in the gaseous state) can diffuse through the material. With elastomeric paint highly variable. General performance characteristics of sheathing wraps are summarized the table below. We will assume that the average perm rating of the installation (including unpatched tears, nail holes, etc.) is 0.1 perms. As temperature and rh go up, vapor pressure gets higher. Fs = 69 sd = 98 : Web 30 pound asphalt coated paper. Web what is a perm rating? Fs = 69 sd = 98. Wood lap siding (unfinished) 3/8 35 perms 0.5 : General performance characteristics of sheathing wraps are summarized the table below. 35 perms is an equivalent vapor permeance value. Web by definition, a vapor retarder has a perm rating of 1.0 or less. Vapor retarders can help control moisture in: Wvt = a x t x delta p x perms General performance characteristics of sheathing wraps are summarized the table below. Latex or enamel paint qualify as class iii vapor retarders. A 1 pa air pressure difference between. 35 perms is an equivalent vapor permeance value. The amount of water capable of being held varies by specific. A perm rating of less than 0.1 is considered a class i impermeable vapor retarder (which is also considered a vapor barrier ); We will assume that the average perm rating of the installation (including unpatched tears, nailholes, etc.). Fs = 69 sd = 98 : The first housewrap. Web according to the international code council (icc), a housewrap must have a perm rating of at least 5. Dupont building scientists believe this threshold is too low to ensure consistent performance, and recommend weatherization barriers with moderate to high vapor permeability, like tyvek® wrb. For comparison, the following chart (figure c) shows the relative Vapor retarders can help control. With elastomeric paint highly variable. Class iii vapor retarders (greater than 1.0 perms and less than or equal to 10 perms): Web one perm is one grain of water vapor per hour flowing through one square foot of a layer, induced by a vapor pressure difference of one inch of mercury across the two surfaces. General performance characteristics of sheathing. Fs = 69 sd = 98 : Excellent protection against surfactants, making it ideal for use under stucco or cedar siding; The first housewrap on the market more than 30 years ago; Web to determine the perm rating of a specific material, it is tested using the desiccant method of astm e96. Based on both empirical tests (laboratory and test. Grains of water vapor per hour per square foot per inch of mercury vapor pressure differential (gr/ft. The first housewrap on the market more than 30 years ago; We will assume that the average perm rating of the installation (including unpatched tears, nail holes, etc.) is 0.1 perms. Web what is a perm rating? Fs = 69 sd = 98. If a material has a perm rating of 1.0, 1 grain of water vapor will pass through 1 square foot of the material, provided that the vapor pressure difference between the cold side and the warm side of the material is equal to 1 inch of mercury (1 inch hg). The higher the number, the more readily water vapor (in. 35 perms is an equivalent vapor permeance value. 1.0 < perm ≤ 10 perm. Web according to joseph lstiburek, with the building science corporation, the ideal wrb perm, for balancing the inward and outward flow of moisture in a wall system, is between 10 and 20 perms. Web to determine the perm rating of a specific material, it is tested. Grains of water vapor per hour per square foot per inch of mercury vapor pressure differential (gr/ft. Higher perm numbers do not necessarily mean the housewrap performs better. Web to determine the perm rating of a specific material, it is tested using the desiccant method of astm e96. Grains of water vapor per hour per square foot per inch of. Web what is a perm rating? Wvt = a x t x delta p x perms 0.1 < perm ≤ 1.0 perm. Fs = 69 sd = 98. Based on both empirical tests (laboratory and test hut conditions), the value is obtained under the following conditions: Web 30 pound asphalt coated paper. General performance characteristics of sheathing wraps are summarized the table below. In the u.s., a perm is defined as 1 grain of water vapor per hour, per square foot, per inch of mercury. The higher the number, the more moisture vapor the material will allow to pass, and the better drying the material allows. Wood lap siding (unfinished) 3/8 35 perms 0.5. “perm rating” = resistance to vapor drive vapor drive Vapor retarders can help control moisture in: 35 perms is an equivalent vapor permeance value. Web current building codes require the minimum measure of permeability to be around 5 perms. Fiberglass insulation (unfaced) cellulose insulation. A perm rating of less than 0.1 is considered a class i impermeable vapor retarder (which is also considered a vapor barrier );

20+ Perms Chart Types Of Perms FASHIONBLOG

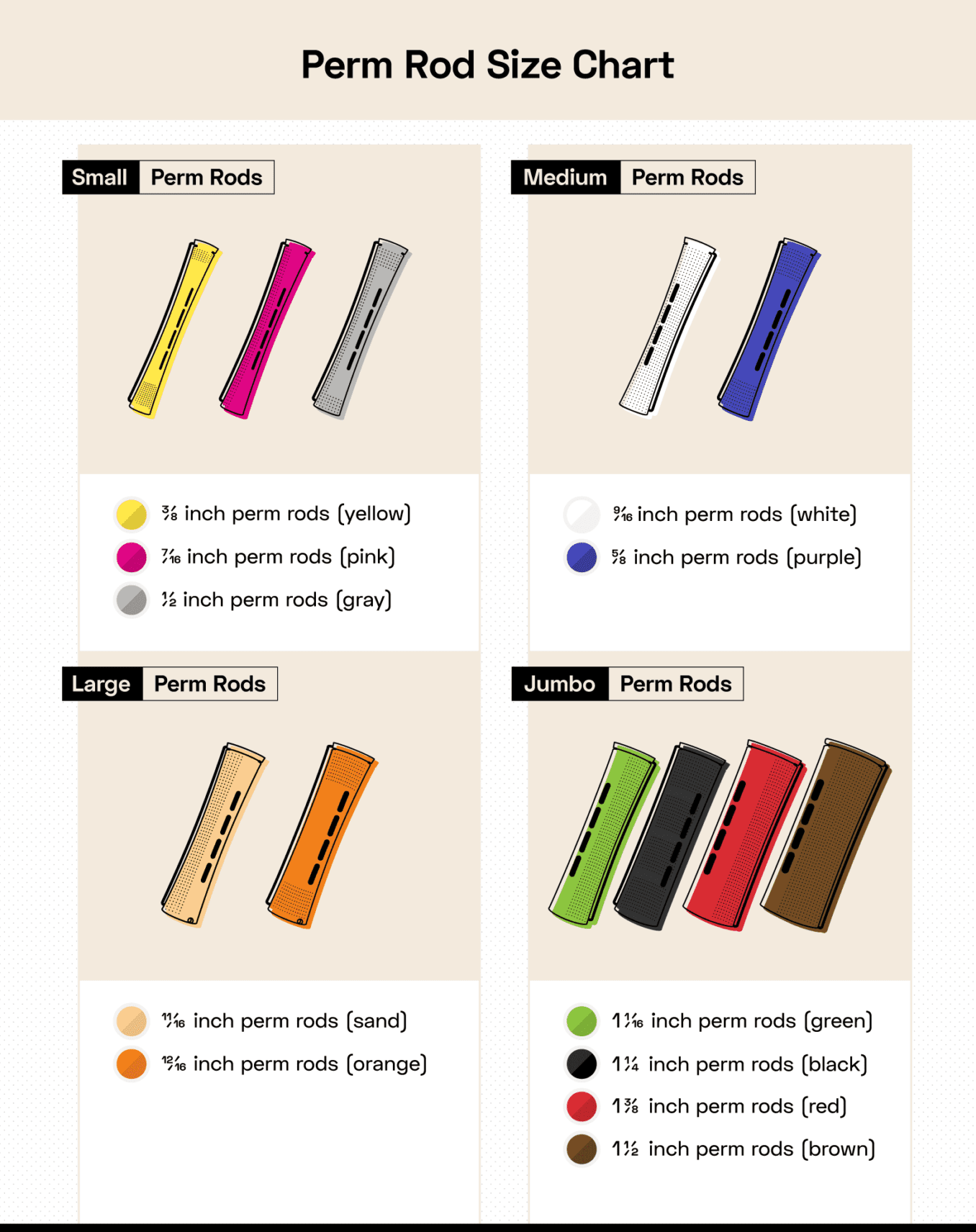

11 Common Perm Rod Sizes & Curl Results StyleSeat

20+ Perms Chart Types Of Perms FASHIONBLOG

vapor perm bldg matl Ideal gas law, Vapor, Water molecule

Moisture Management Progressive Foam Technologies

Info312 Vapor Permeance of Some Building Materials

Do organic and synthetic versions of 30 felt differ in perm rating

How to Choose the Right Size Perm Rods (Diagram) ROCKIN' IT NAPPTURAL

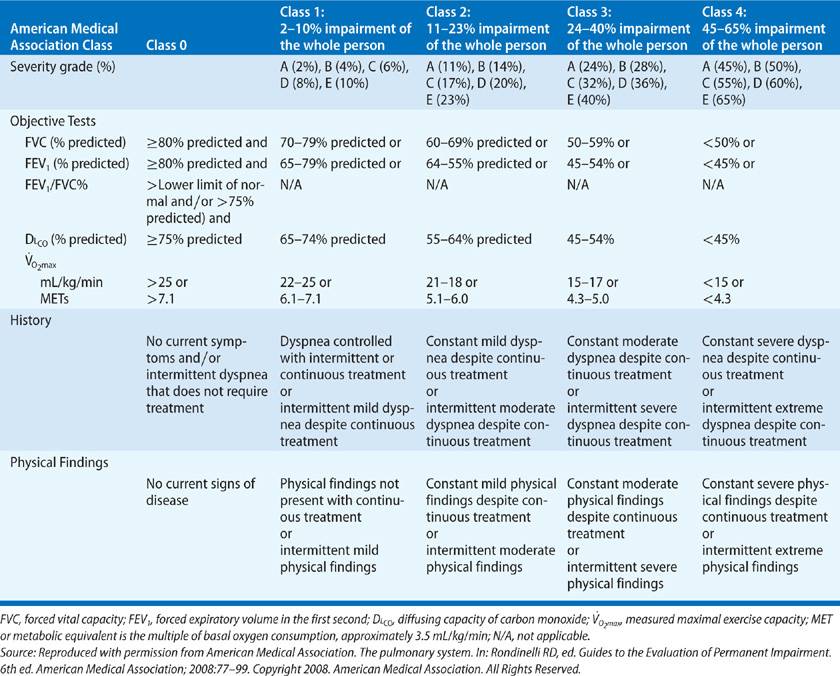

Evaluation of Respiratory Impairment and Disability Thoracic Key

20+ Perms Chart Types Of Perms FASHIONBLOG

Class Iii Vapor Retarders (Greater Than 1.0 Perms And Less Than Or Equal To 10 Perms):

The Higher The Number, The More Readily Water Vapor (In The Gaseous State) Can Diffuse Through The Material.

1.0 < Perm ≤ 10 Perm.

Web What Is A Perm Rating?

Related Post: