Peracetic Acid Compatibility Chart

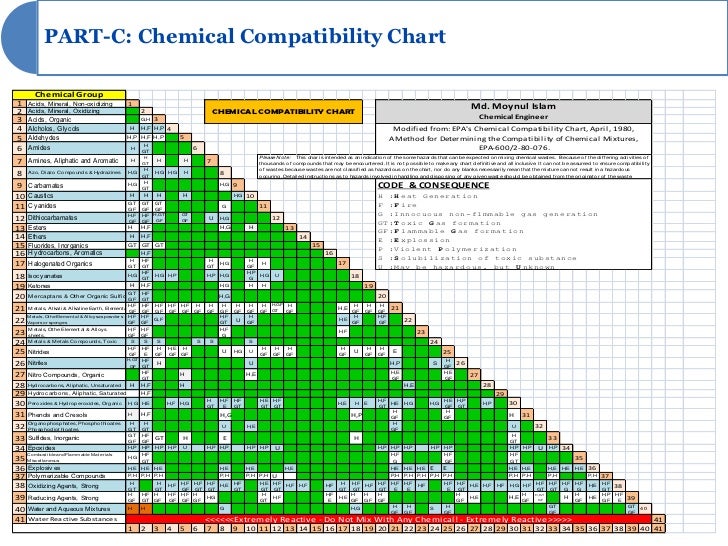

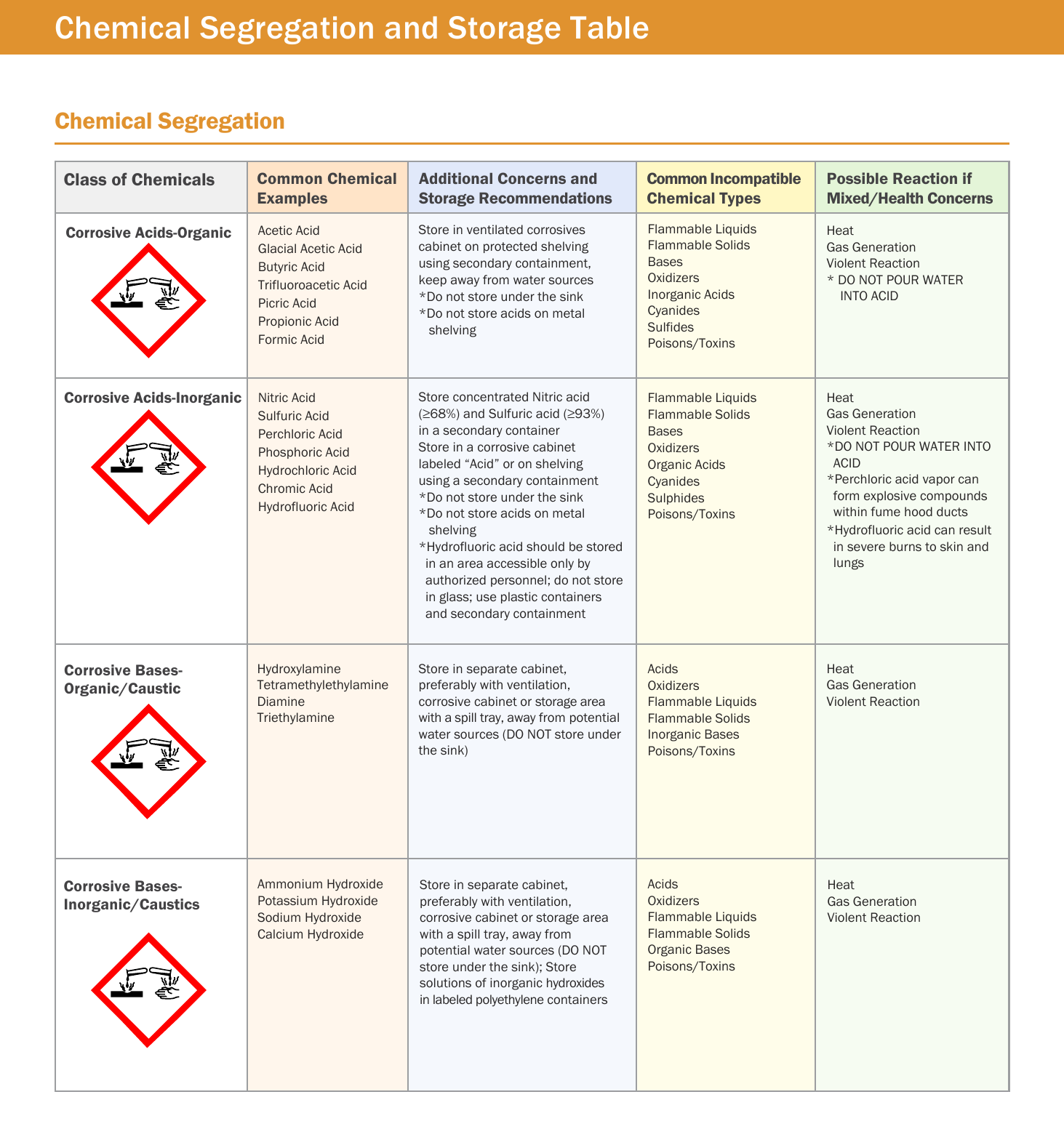

Peracetic Acid Compatibility Chart - Web this chart shows the chemical compatibility and resistance of all popular rubber or elastomer materials. Stenner pump company assumes no responsibility for its accuracy. Assume incompatibility unless otherwise established. However, since the resistance of metals, plastics and elastomers can be affected by concentration, temperature, presence of other chemicals and other factors. Testing under the specific conditions of the application is recommended. Web these recommendations are based upon information from material suppliers and careful examination of available published information and are believed to be accurate. Web the information is provided only as a guide to assist in determining chemical compatibility for wetted components. • ratings are subject to suitable fabrication, pickling and passivation by solvay approved methods. Web compound compatibility rating four different classes of chemical resistance are used in this guide. Little or no damage after 30 days. Web compound compatibility rating four different classes of chemical resistance are used in this guide. For 7 days and 30 days (if applicable) with constant exposure. Web see how acetal, nylon, peek, and other plastics resist different chemicals. Outside factors including but not limited to temperature, pressure, mechanical. Web chemical compatibility chart from ism. Web materials compatibility with peroxyacetic acid solutions up to 17 % general rule: Web compatibility data in the following tables are based on the rankings below: However, since the resistance of metals, plastics and elastomers can be affected by concentration, temperature, presence of other chemicals and other factors. Acetaldehyde acetamide acetate solvents acetic acid acetic acid, 20% acetic acid, 80%. Web compatibility data in the following tables are based on the rankings below: Web see how acetal, nylon, peek, and other plastics resist different chemicals. Ldpe / hdpe at 20°c: The chemical compatibility guide is to be used to help select the most satisfactory combination of materials for a specific chemical, however it is only a guide. Assume incompatibility unless. Testing under the specific conditions of the application is recommended. However, since the resistance of metals, plastics and elastomers can be affected by concentration, temperature, presence of other chemicals and other factors. Web these recommendations are based upon information from material suppliers and careful examination of available published information and are believed to be accurate. Web compound compatibility rating four. Web chemical compatibility chart from ism. Web although the information in this chart was acquired from reputable sources, it should only be used as a guide in selecting a container and closure system. Testing under the specific conditions of the application is recommended. Ldpe / hdpe at 20°c: Outside factors including but not limited to temperature, pressure, mechanical. The chemical compatibility guide is to be used to help select the most satisfactory combination of materials for a specific chemical, however it is only a guide. • ratings are subject to suitable fabrication, pickling and passivation by solvay approved methods. For 7 days and 30 days (if applicable) with constant exposure. Peracetic acid is often referred to as paa.. Web the chemical compatibility of ldpe and hdpe on this chart is tested at 20°c: Web compatibility data in the following tables are based on the rankings below: Web chemicial compatibility guide. Web these recommendations are based upon information from material suppliers and careful examination of available published information and are believed to be accurate. Web chemical compatibility chart from. Service conditions may vary and can affect accuracy of. Acetaldehyde acetamide acetate solvents acetic acid acetic acid, 20% acetic acid, 80% acetic acid, glacial acetic anhydride acetone acetylene acrylonitrile alcohols: Web compatibility data in the following tables are based on the rankings below: • ratings are subject to suitable fabrication, pickling and passivation by solvay approved methods. Web these recommendations. Outside factors including but not limited to temperature, pressure, mechanical. Where material shows no signs of damage such as discoloration or swelling when used with the specific chemical fluid for 24 hours of constant exposure at room temperature. Web chemical compatibility chart. Web see how acetal, nylon, peek, and other plastics resist different chemicals. Web these recommendations are based upon. Outside factors including but not limited to temperature, pressure, mechanical. Web chemical compatibility chart. Little or no damage after 30 days. Shows some effect after 7 days. Web these recommendations are based upon information from material suppliers and careful examination of available published information and are believed to be accurate. Web the information is provided only as a guide to assist in determining chemical compatibility for wetted components. Web this chart shows the chemical compatibility and resistance of all popular rubber or elastomer materials. Materials used in the pump and pumping systems must be chemically compatible. Web these recommendations are based upon information from material suppliers and careful examination of available published information and are believed to be accurate. Web compatibility data in the following tables are based on the rankings below: Web chemicial compatibility guide. The data table below is an application guide, and indicates the resistance of the specific thermoplastics we use in the construction of our products, to common chemicals. Stenner pump company assumes no responsibility for its accuracy. Service conditions may vary and can affect accuracy of. Acetaldehyde acetamide acetate solvents acetic acid acetic acid, 20% acetic acid, 80% acetic acid, glacial acetic anhydride acetone acetylene acrylonitrile alcohols: Web although the information in this chart was acquired from reputable sources, it should only be used as a guide in selecting a container and closure system. Outside factors including but not limited to temperature, pressure, mechanical. Little or no damage after 30 days. Ldpe / hdpe at 20°c: Peracetic acid is often referred to as paa. Shows some effect after 7 days.Chemical Compatibility Table Ammonia Acetic Acid

Chemical Compatibility Table For Metals

peracetic acid chemical resistance chart

O que é gráfico de compatibilidade do material?

Compatibility Chart for Chemicals Acetic Acid Ethanol

Peracetic Acid Dilution Table 250 AMBIC Equipment Ltd UK

Chemical Compatibility Tables

Peracetic Acid Compatibility Chart

Chemical Compatibility Table For Metals

Acid Compatibility Chart

Web Compound Compatibility Rating Four Different Classes Of Chemical Resistance Are Used In This Guide.

Web Chemical Compatibility Chart.

The Information Accuracy Of These Ratings Cannot Be Guaranteed, Nor Is It A Complete List Due To The Extensive Area Of This Field.

Where Material Shows No Signs Of Damage Such As Discoloration Or Swelling When Used With The Specific Chemical Fluid For 24 Hours Of Constant Exposure At Room Temperature.

Related Post: