P Chart Formula

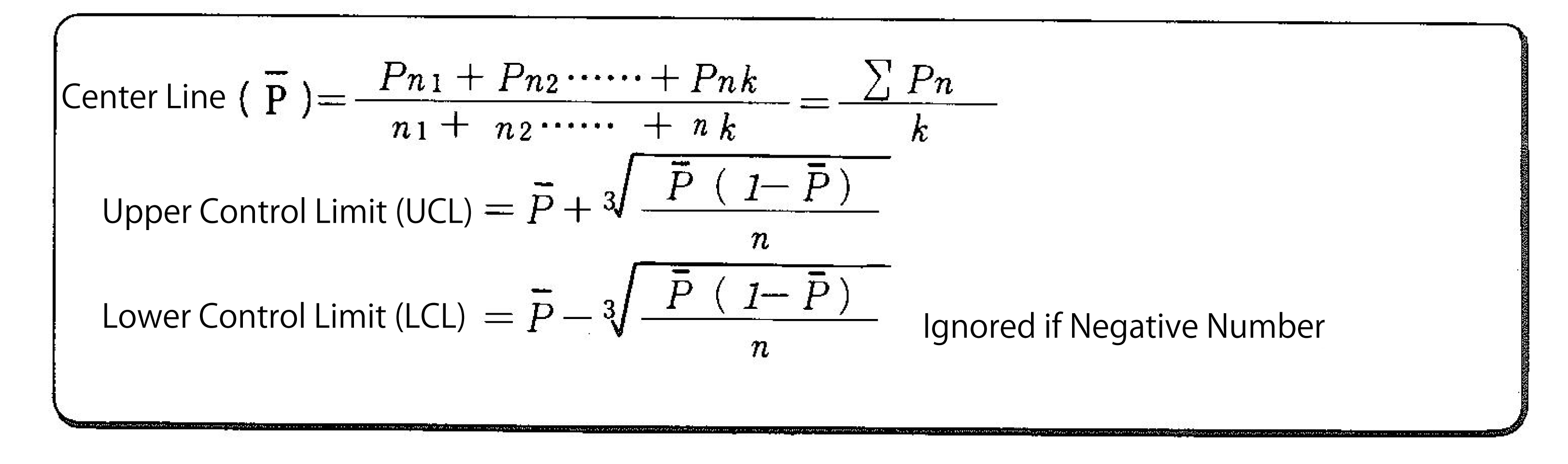

P Chart Formula - There is a difference between a defect and defective, as there is between a nonconformity and. The subgroup size must be large enough for the p chart; Web trying to understand laney p chart formulas? Where np = number of defectives in the sample. This is done by taking the difference between consecutive values. Where is the mean proportion of defectives, calculated as follows: Web the p chart is used when the sample size varies. Web the formula is: Web p charts can be used when the subgroups are not of equal size. Web a p control chart is used to look at variation in yes/no type attributes data. The ratio of observed variation to expected variation is calculated as follows: This is done by taking the difference between consecutive values. Steps in constructing a p chart. Otherwise, control limits may not be accurate when estimated from the data. There is a difference between a defect and defective, as there is between a nonconformity and. Web control limits for p chart. Examples include the number of defective products, meals in a restaurant, incorrect prescriptions, bills, invoices, paychecks, etc. Z is the number of standard deviations. Ps is the proportion defective. Where nj is the sample size (number of units) of group j, and m is the number of groups included in the analysis. Here is the formula used to calculate a p chart. Sample size (n) is 80. The p control chart is used to determine if the fraction of defective items in a. Web p’ chart formula data legend + chart 5. Web for a sample subgroup, the number of defective parts is counted and plotted as either a percentage of the. It is found by dividing the total number of defective units found in all subgroups of the study period by the total number of units inspected in the study period. This is done by taking the difference between consecutive values. Where nj is the sample size (number of units) of group j, and m is the number of groups included. There is a difference between a defect and defective, as there is between a nonconformity and. A less common, although some might argue more powerful, use of control charts is as an analysis tool. This example will just use the first row where the defect is 58 and. P chart is used when you have defectives data with a variable. The p control chart is used with “yes/no” attributes data. Sample size (n) is 80. Web p charts can be used when the subgroups are not of equal size. Use this chart to determine the upper control limit (ucl) and lower control limit (lcl) for a p chart. Web the p chart formula. For plotting the p chart in excel we have to calculate the three important things i.e. How do you create a p chart. Web a p control chart is used to look at variation in yes/no type attributes data. Control charts dealing with the proportion or fraction of defective product are called p charts (for proportion). The ratio of observed. The upper confidence limit for the ratio is calculated as follows: The p control chart is used to determine if the fraction of defective items in a. Web a p control chart is used to look at variation in yes/no type attributes data. Sample size (n) is 80. Data points on a p chart follow the binomial distribution. Control charts dealing with the proportion or fraction of defective product are called p charts (for proportion). Examples include the number of defective products, meals in a restaurant, incorrect prescriptions, bills, invoices, paychecks, etc. The upper confidence limit for the ratio is calculated as follows: Use this chart to determine the upper control limit (ucl) and lower control limit (lcl). Control charts dealing with the proportion or fraction of defective product are called p charts (for proportion). There is a difference between a defect and defective, as there is between a nonconformity and. Web the formula is: Web the p chart formula. Web the p chart is used when the sample size varies. Where nj is the sample size (number of units) of group j. 95% confidence limits for ratio. P = number of nonconforming items / sample size. Σ is the standard deviation of the sample proportion. The most common application is as a tool to monitor process stability and control. Web the p chart formula. Z is the number of standard deviations. Web trying to understand laney p chart formulas? Control charts have two general uses in an improvement project. Each plotted point represents the proportion of defectives for one subgroup, pi: For plotting the p chart in excel we have to calculate the three important things i.e. Conforms with ansi/asqc b1, b2, b3 1996 The first column should represent the sample number or time period, and the second column should represent the number of nonconforming items. Each item on the chart has only two possibilities: The ratio of observed variation to expected variation is calculated as follows: The size, n (i), has to be sufficiently large to have defects present in the subgroup most of the time.

Control Chart for Attributes 1 Control Charts Continuous

P Chart Quality Control MRP glossary of Production scheduler Asprova

P Chart Calculations P Chart Formula Quality America

P Chart Calculations P Chart Formula Quality America

P Chart Formula PDF

P' Chart Formula Quality Improvement East London NHS Foundation

P chart example PresentationEZE

P Chart Calculations P Chart Formula Quality America

Constructing pCharts Lecture YouTube

Control Limits for pchart by hand YouTube

Here Is The Formula Used To Calculate A P Chart.

There Are Only Two Possible Outcomes:

Web Control Limits For P Chart.

Web P Chart Formula:

Related Post: