Oxygen Acetylene Torch Settings Chart

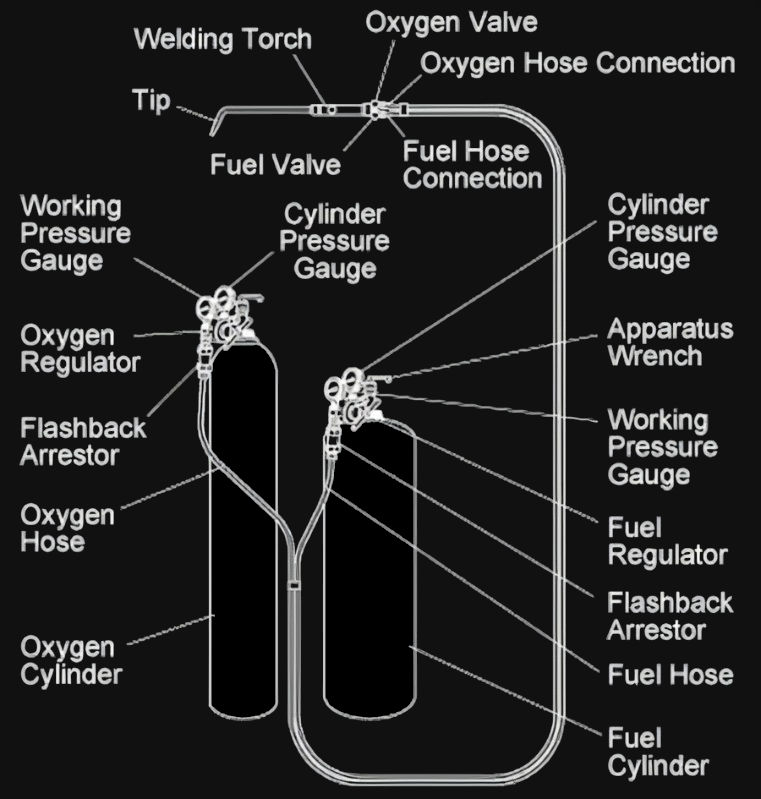

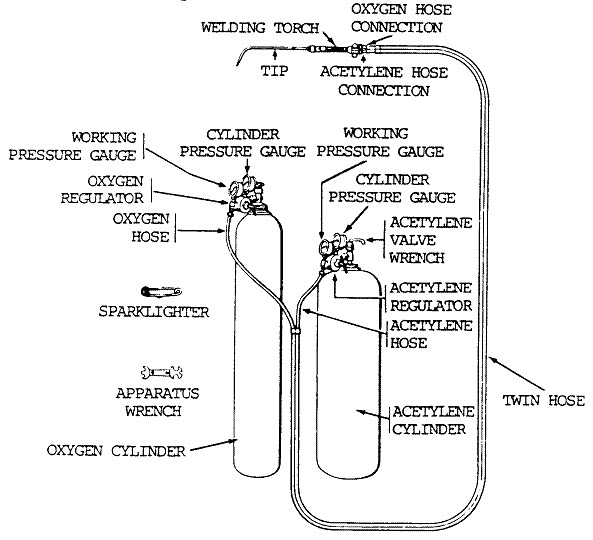

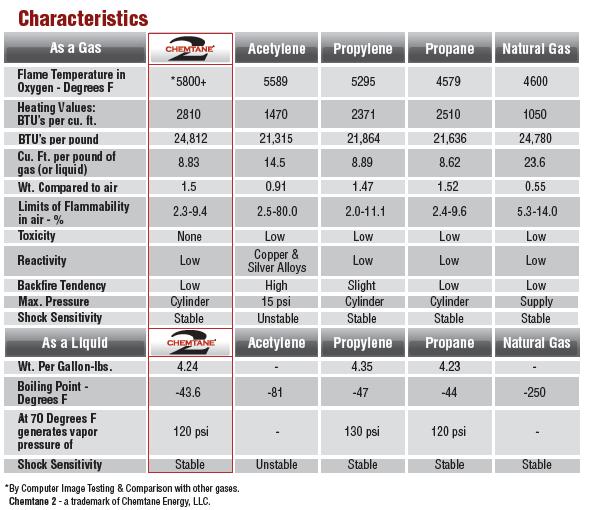

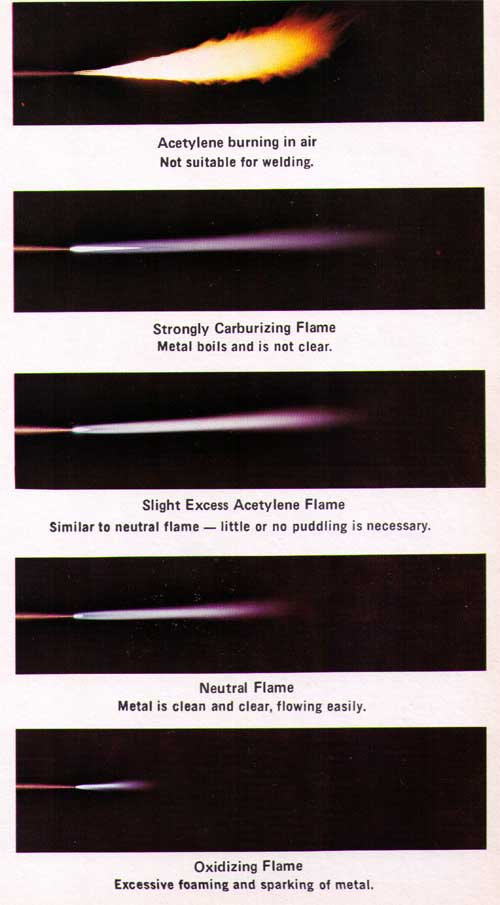

Oxygen Acetylene Torch Settings Chart - Web oxygen/acetylene welding oxygen/acetylene welding orifice (drill size) pressure (psi) application base metal thickness oxygen/acetylene cutting oxygen/acetylene cutting oxygen/acetylene cutting up to 1/8 1/8 to 1/2 1/2 and over up to 1 1 to 6 6 and over oxygen/acetylene welding oxygen & acetylene gas. 60 8.9 shutting off the source and purging the oxygen and acetylene from the system. As with the previous recommendation, this applies to biting less than 1.5 inches thick solid. Web open regulator oxygen and acetylene, set until the pressure matches with what you want or for acetylene 5 to 7 psi and oxygen 7 to 10 psi. Welding and cutting tips the welding tip is mounted on the end of the torch handle and through it the oxygen and fuel gas mixture Now that you understand how your torch functions you can connect it to the rest of your equipment and check for any signs of damage. Web learn how to set up an oxy acetylene cutting torch in this informative video. Web the oxygen pressure typically ranges from 30 to 40 psi (pounds per square inch), while the acetylene pressure should be set between 5 and 15 psi. The first step in setting up your oxy acetylene rosebud torch is. The cutting tip size should correspond to the thickness of the material being cut. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. As with the previous recommendation, this applies to cutting less than 1.5 inches thick steel. Web learn how to set up an oxy acetylene cutting torch in this informative video. Before you start using the cutting torch, it’s crucial to set up. Now that you understand how your torch functions you can connect it to the rest of your equipment and check for any signs of damage. The tip size is determined by the orifice for cutting oxygen gas. 53k views 1 year ago. The cutting tip oxy acetylene pressure will depend on the size. Before you start using the cutting torch,. The manufacturer’s our should ever are followed. Tip sizes are often labeled differently depending on the manufacturer, as companies have no industry standards to follow. The injector type is used when fuel gas pressures are less than 1 psi. The cutting tip oxy acetylenes pressure will depend on the sizes. It’s important to note that these settings may vary based. Before you start using the cutting torch, it’s crucial to set up the equipment properly. Web the oxy acetylene rosebud torch is a versatile tool that can be adjusted to provide different levels of heat, depending on the type and thickness of metal being welded. The cutting tip size should correspond to the thickness of the material being cut. ·. As with the previous recommendation, this applies to cutting less than 1.5 inches thick steel. The welding tip chart shows the proper tip sizes and oxygen and acetylene pressures related to the thickness of material to be welded. The gas and oxygen travels through the handle, mixes at the tip and ignites. Welding and cutting tips the welding tip is. In this type, oxygen at high pressure pulls the fuel gas into the mixing chamber. Web the oxy acetylene rosebud torch is a versatile tool that can be adjusted to provide different levels of heat, depending on the type and thickness of metal being welded. The injector type is used when fuel gas pressures are less than 1 psi. Web. Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. Tip number purpose capacity (width x depth) pressure − psig at regulator consumption − scfh drill size in. Web the torch is made up of a handle, mixing chamber and oxygen and gas valves. The first step in setting up your. Web oxygen and fuel gas enter the torch at almost equal pressures. Tip number purpose capacity (width x depth) pressure − psig at regulator consumption − scfh drill size in. In this type, oxygen at high pressure pulls the fuel gas into the mixing chamber. 60 8.9 shutting off the source and purging the oxygen and acetylene from the system.. Now that you understand how your torch functions you can connect it to the rest of your equipment and check for any signs of damage. 53k views 1 year ago. Web do not use in cutting attachments. 59 8.8 shutting off the torch. Tip number purpose capacity (width x depth) pressure − psig at regulator consumption − scfh drill size. Web the oxy acetylene rosebud torch is a versatile tool that can be adjusted to provide different levels of heat, depending on the type and thickness of metal being welded. Now that you understand how your torch functions you can connect it to the rest of your equipment and check for any signs of damage. 60 8.9 shutting off the. Mm oxygen acetylene oxygen acetylene cutting preheat. Now that you understand how your torch functions you can connect it to the rest of your equipment and check for any signs of damage. The tip size is determined by the orifice for cutting oxygen gas. You will see the steps to connect the hoses, regulators, tanks and torch, as well as how to adjust the gas flow and. The cutting tip oxy acetylenes pressure will depend on the sizes. The third open valve in the torch is the first acetylene after that you can open the oxygen valve. Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. 59 8.8 shutting off the torch. Web learn how to set up an oxy acetylene cutting torch in this informative video. Assemble the torch by attaching the oxygen and acetylene regulators, hoses, and torch handle. Web the torch is made up of a handle, mixing chamber and oxygen and gas valves. Web 8.7 general torch settings. The welding tip chart shows the proper tip sizes and oxygen and acetylene pressures related to the thickness of material to be welded. Web the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. Web open regulator oxygen and acetylene, set until the pressure matches with what you want or for acetylene 5 to 7 psi and oxygen 7 to 10 psi. Sc and mc series special purpose tips for hand torches and cutting assemblies − acetylene.

oxygen and acetylene pressure settings

Oxy Acetylene Torch Tip Chart

Cutting Torch Guide

OxyAcetylene Welding Tips Model WJ Compatible with "J" Series Victor

oxygen and acetylene pressure settings

Oxyacetylene Torch Settings Chart

Oxy Acetylene Settings Chart

Oxy Acetylene Settings Chart

Oxyacetylene Torch Settings Chart

Oxyacetylene Torch Settings Chart

60 8.9 Shutting Off The Source And Purging The Oxygen And Acetylene From The System.

Web Do Not Use In Cutting Attachments.

The Cutting Tip Oxy Acetylene Pressure Will Depend On The Size.

Web Oxygen/Acetylene Welding Oxygen/Acetylene Welding Orifice (Drill Size) Pressure (Psi) Application Base Metal Thickness Oxygen/Acetylene Cutting Oxygen/Acetylene Cutting Oxygen/Acetylene Cutting Up To 1/8 1/8 To 1/2 1/2 And Over Up To 1 1 To 6 6 And Over Oxygen/Acetylene Welding Oxygen & Acetylene Gas.

Related Post: