Oxy Acetylene Victor Welding Tip Chart

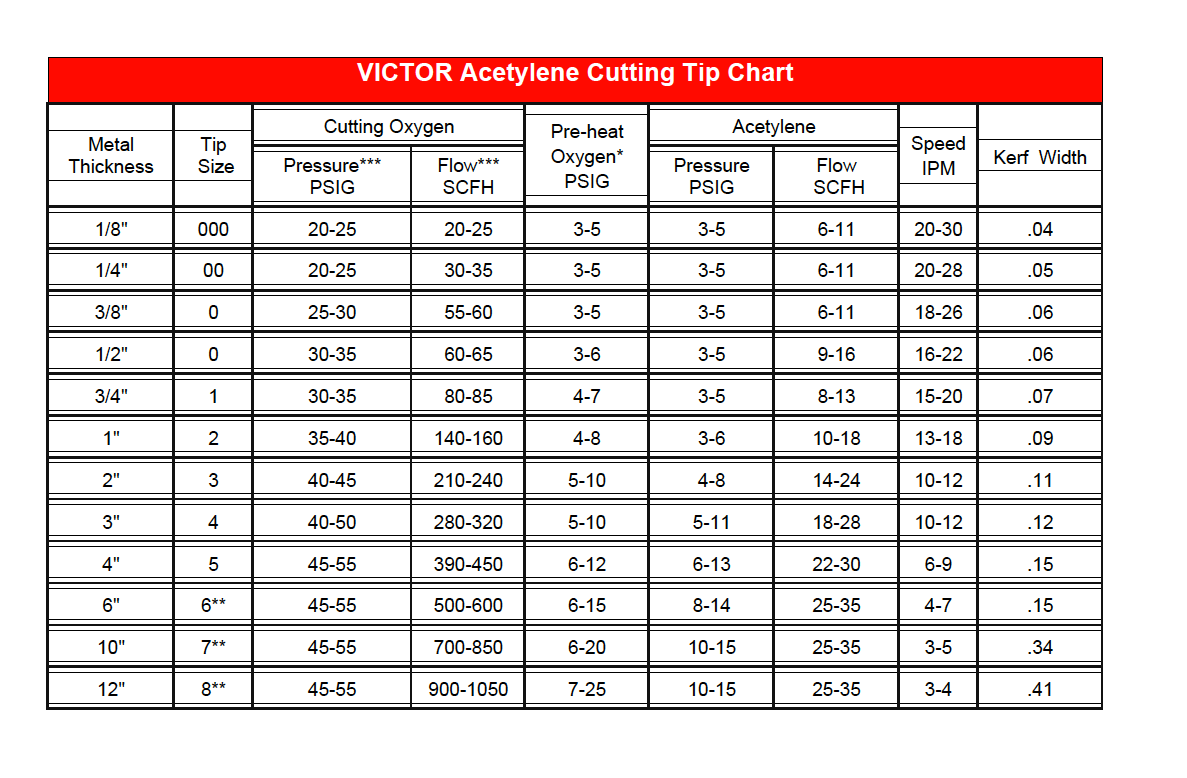

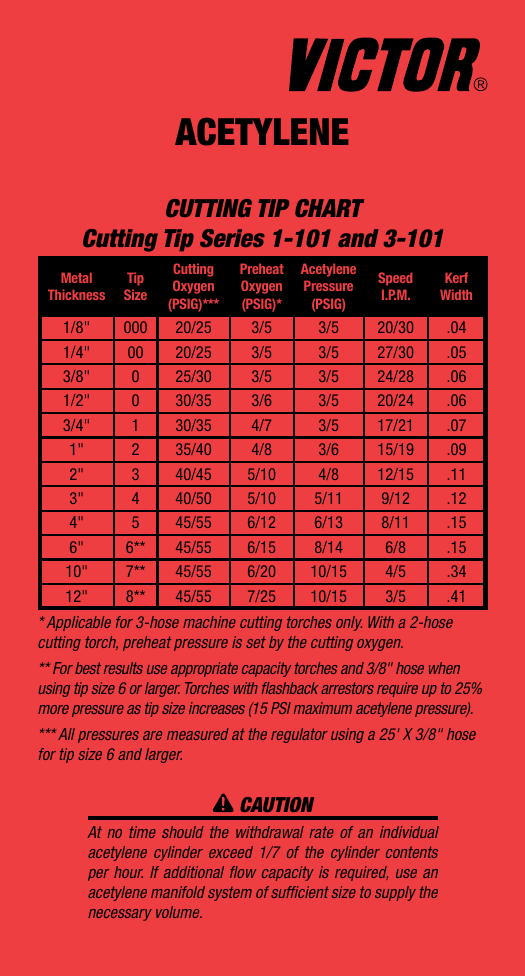

Oxy Acetylene Victor Welding Tip Chart - ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. You must know the manufacturer or model of your torch and/or the part number of the cutting tips you want to replace as this determines the seat type. In stock and ready to ship. Different lenses are recommended for the various processes: If this important step is skipped, damage to the equipment or dangerous flammable gas leakage can result. American torch tip cut charts will help you find very specific specs of our different cut chart models and see which one fits your best needs. In order to be used properly and efficiently. In stock and ready to ship. Shop now and get free shipping within canada on orders more than $149. Use energy “stored” in the supply cylinder. Break down unusable high pressure to a usable lower pressure. Web buy victor series 1 type 101 hd cutting tips (acetylene) online from canada's widest selection of welding supplies. What type of fuel & gas are you using? Use energy “stored” in the supply cylinder. In order to comfortably and safely see the flame when welding or cutting, welding goggles. Shop now and get free shipping within canada on orders more than $149. In order to comfortably and safely see the flame when welding or cutting, welding goggles must be worn. If this important step is skipped, damage to the equipment or dangerous flammable gas leakage can result. Acetylene tips are manufactured with four or six preheat holes and are. If this important step is skipped, damage to the equipment or dangerous flammable gas leakage can result. Precision machined to assure proper gas mix and flame characteristics. Web buy victor series 1 type 101 hd cutting tips (acetylene) online from canada's widest selection of welding supplies. Most of our standard cutting and welding tips are made from tellurium copper with. In stock and ready to ship. Break down unusable high pressure to a usable lower pressure. Acetylene tips are manufactured with four or six preheat holes and are produced to allow light, medium, and heavy preheats for use with clean, dirty, or rusted plate. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6. What type of fuel & gas are you using? Each gas fuel needs the proper torch tip. Novak tip chart, standard meco tip sizes, in wire drill and decimal, victor welding tip sizes, harris torch welding tip operational chart. Fits all victor® 300 series torch handles. Torches have been grouped by function: Web oxy fuel tip brand identification guide. Novak tip chart, standard meco tip sizes, in wire drill and decimal, victor welding tip sizes, harris torch welding tip operational chart. Heavy, medium and light duty, and provide a quick reference allowing you to select the proper torch handle, welding or heating nozzle, tip ends, plus cutting Web victor gpp / mthp. Series 3 tip style, fuel gas usage and victor equipment compatibility shown below. Torches have been grouped by function: Use energy “stored” in the supply cylinder. Break down unusable high pressure to a usable lower pressure. Heavy, medium and light duty, and provide a quick reference allowing you to select the proper torch handle, welding or heating nozzle, tip ends,. In stock and ready to ship. Compensate for supply pressure changes. Fits all victor® 300 series torch handles. Series 3 tip style, fuel gas usage and victor equipment compatibility shown below. Each gas fuel needs the proper torch tip. Web victor gpp / mthp cut chart. Torches have been grouped by function: Break down unusable high pressure to a usable lower pressure. Novak tip chart, standard meco tip sizes, in wire drill and decimal, victor welding tip sizes, harris torch welding tip operational chart. Compensate for supply pressure changes. Web oxy fuel tip brand identification guide. In stock and ready to ship. Web these charts provide an easy selection guide for victor equipment. In order to comfortably and safely see the flame when welding or cutting, welding goggles must be worn. Break down unusable high pressure to a usable lower pressure. Use energy “stored” in the supply cylinder. Each gas fuel needs the proper torch tip. American torch tip cut charts will help you find very specific specs of our different cut chart models and see which one fits your best needs. You must know the manufacturer or model of your torch and/or the part number of the cutting tips you want to replace as this determines the seat type. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. Torches have been grouped by function: Heavy, medium and light duty, and provide a quick reference allowing you to select the proper torch handle, welding or heating nozzle, tip ends, plus cutting Web oxy fuel tip brand identification guide. Most of our standard cutting and welding tips are made from tellurium copper with a. Web victor gpp / mthp cut chart. Precision machined to assure proper gas mix and flame characteristics. Choose from our selection of victor 400 series oxyacetylene welding supplies, including over 60 products in a wide range of styles and sizes. Your payment information is processed securely. What type of fuel & gas are you using? Series 3 tip style, fuel gas usage and victor equipment compatibility shown below. Web these charts provide an easy selection guide for victor equipment.

Welding, Brazing Tip w/ Gas Mixer Style W1 ArcZone

Selecting the Right Cutting Tip RonSon's Torch Repairs & Sales Ltd.

Victor Type HD (300 series) Oxygen/Acetylene Brazing/Welding Torch Tip

Doclib 8051 DocLib 4680 Victor Acetylene Cutting Tip Chart

OxyAcetylene Welding Tips Model W1 Compatible with 100 Series Victor

Oxy Acetylene Welding Rod Chart

acetylene Victor Technologies

Victor Series Type 101 HD Cutting Tips (Acetylene) , 53 OFF

Oxy Acetylene Victor Welding Tip Chart

OxyAcetylene Welding Tips Model WJ Compatible with "J" Series Victor

Compensate For Supply Pressure Changes.

Long Cone Flame For General Welding And Brazing.

In Order To Comfortably And Safely See The Flame When Welding Or Cutting, Welding Goggles Must Be Worn.

Different Lenses Are Recommended For The Various Processes:

Related Post: