Oxy Acetylene Torch Settings Chart

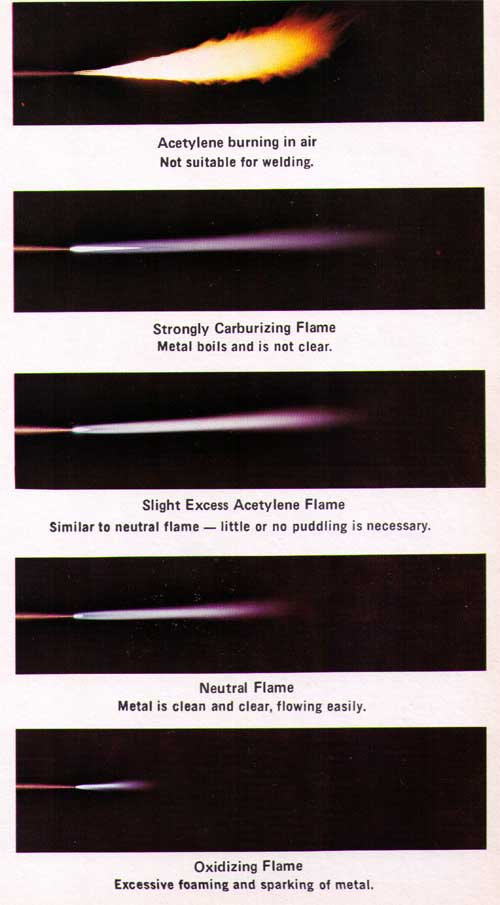

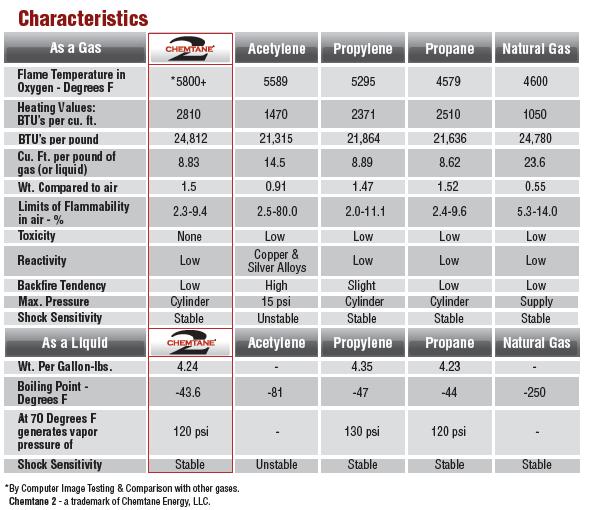

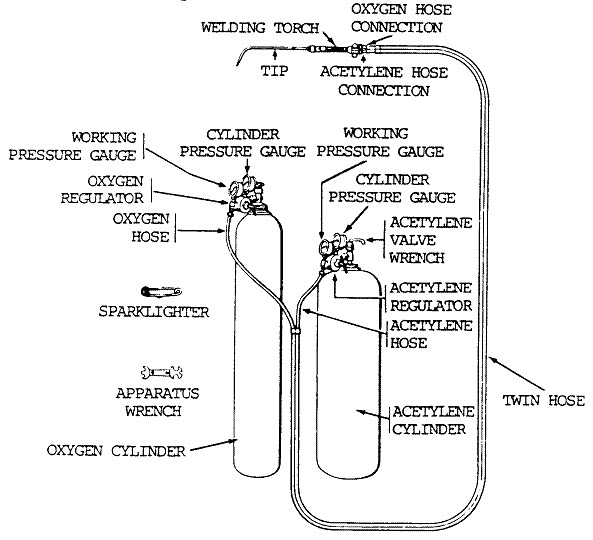

Oxy Acetylene Torch Settings Chart - Web the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. You will see the steps to connect the hoses, regulators, tanks and torch, as well as how to adjust the gas flow and. Retro systems 430 clay valley center, ks 67147. It is an intricate process that requires a great degree of skill, focus and patience, but don’t be discouraged. Web oxypropane burns around 5300 degrees, which is plenty hot, but the rate of burn is smaller. For additonal information refer to www.harrisproductsgroup.com. In addition to these easy to follow instructions, you must always be sure to follow the torch manufacturer's operating procedures. Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. It can be used as a teaching and training tool for the safe operation of an oxyacetylene torch in welding operations. This will be done starting with the cylinders and ending with the torch tip. It combines oxygen and acetylene gases to form a superheated flame that melts and joins two pieces of metal. Web this flame will reach a temperature of 4400°f to 6000°f (2400°c to 3300°c), depending on the fuel gas used as well as the ratio of oxygen to fuel gas. So it takes just a little longer to preheat before a. As a heating tool, the torch can be helpful for bending metal, getting bent parts back to where they belong, or for freeing rusted bolts. Web the first step in setting up your oxy acetylene rosebud torch is to choose the right tip. Web learn how to set up and use an oxy acetylene cutting torch for various metals. Web. Either oxyacetylene or oxypropane works well for torch cutting. This will be done starting with the cylinders and ending with the torch tip. It combines oxygen and acetylene gases to form a superheated flame that melts and joins two pieces of metal. Web harris cutting tip charts. Web learn how to set up and use an oxy acetylene cutting torch. Find out the advantages, disadvantages, and defects of oxy acetylene welding process. It can be used as a teaching and training tool for the safe operation of an oxyacetylene torch in welding operations. For additonal information refer to www.harrisproductsgroup.com. Web harris cutting tip charts. This will depend on the thickness of the metal you are welding, as well as the. It can be used as a teaching and training tool for the safe operation of an oxyacetylene torch in welding operations. Web harris cutting tip charts. Hose for size 4 and larger. As a heating tool, the torch can be helpful for bending metal, getting bent parts back to where they belong, or for freeing rusted bolts. It is an. Tip sizes are often labeled differently depending on the manufacturer, as companies have no industry standards to follow. Of cylinders* cutting oxygen preheat oxygen fuel preheat cutting jet preheat in. Web this flame will reach a temperature of 4400°f to 6000°f (2400°c to 3300°c), depending on the fuel gas used as well as the ratio of oxygen to fuel gas.. Web this recommended practice describes the equipment, applications, and safe practices for oxyacetylene gas welding operations. Of cylinders* cutting oxygen preheat oxygen fuel preheat cutting jet preheat in. This will depend on the thickness of the metal you are welding, as well as the type of joint you are using. In the attachment “injector and equal pressure torches” you will. Web harris cutting tip charts. Tip sizes are often labeled differently depending on the manufacturer, as companies have no industry standards to follow. Find out the advantages, disadvantages, and defects of oxy acetylene welding process. This will be done starting with the cylinders and ending with the torch tip. A chemical reaction occurs when oxygen contacts metal. A chemical reaction occurs when oxygen contacts metal. Hose for size 4 and larger. Find out the advantages, disadvantages, and defects of oxy acetylene welding process. Web the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. Tip sizes are often labeled differently depending on the manufacturer, as companies have no industry. Either oxyacetylene or oxypropane works well for torch cutting. Web learn how to set up and use oxy acetylene welding equipment, including pressure, flame types, rods, and kit. This recommended practice is intended for use by the oxyacetylene welder and/or his or her. Find out the advantages, disadvantages, and defects of oxy acetylene welding process. It can be used as. This will depend on the thickness of the metal you are welding, as well as the type of joint you are using. Web learn how to set up and use an oxy acetylene cutting torch for various metals. Find out the advantages, disadvantages, and defects of oxy acetylene welding process. Web learn how to set up and use oxy acetylene welding equipment, including pressure, flame types, rods, and kit. Selecting the correct welding attachment. Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. It can be used as a teaching and training tool for the safe operation of an oxyacetylene torch in welding operations. ** to provide required flow, use 3/8 i.d. It combines oxygen and acetylene gases to form a superheated flame that melts and joins two pieces of metal. So it takes just a little longer to preheat before a cut. Tip sizes are often labeled differently depending on the manufacturer, as companies have no industry standards to follow. In addition to these easy to follow instructions, you must always be sure to follow the torch manufacturer's operating procedures. A larger tip will generate more heat, while a. Web learn how to set up an oxy acetylene cutting torch in this informative video. Web harris cutting tip charts. As a heating tool, the torch can be helpful for bending metal, getting bent parts back to where they belong, or for freeing rusted bolts.

Oxyacetylene Torch Settings Chart

Oxy Acetylene Settings Chart

oxygen and acetylene pressure settings

Oxyacetylene Torch Settings Chart

oxygen and acetylene pressure settings

Oxyacetylene Torch Settings Chart

Oxy Acetylene Torch Tip Chart

OxyAcetylene Welding Tips Model WJ Compatible with "J" Series Victor

Oxyacetylene Torch Settings Chart

Cutting Torch Guide

You Will See The Steps To Connect The Hoses, Regulators, Tanks And Torch, As Well As How To Adjust The Gas Flow And.

Of Cylinders* Cutting Oxygen Preheat Oxygen Fuel Preheat Cutting Jet Preheat In.

This Recommended Practice Is Intended For Use By The Oxyacetylene Welder And/Or His Or Her.

Use The Right Tip Size For Every Job.

Related Post: