Oxy Acetylene Tip Chart

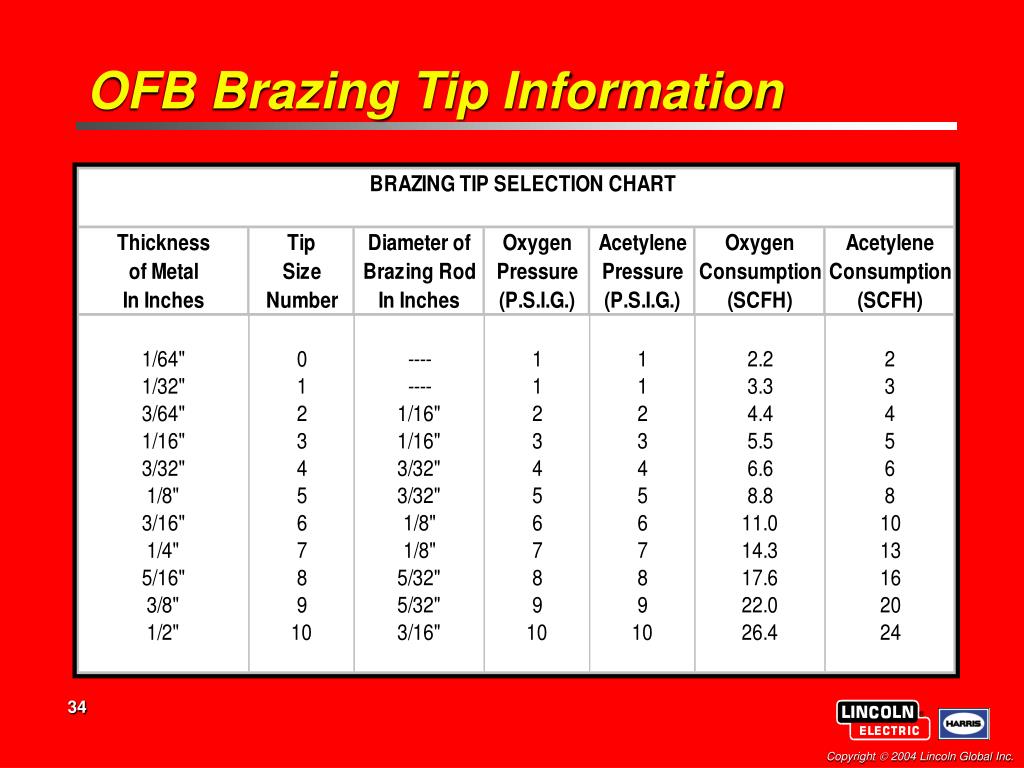

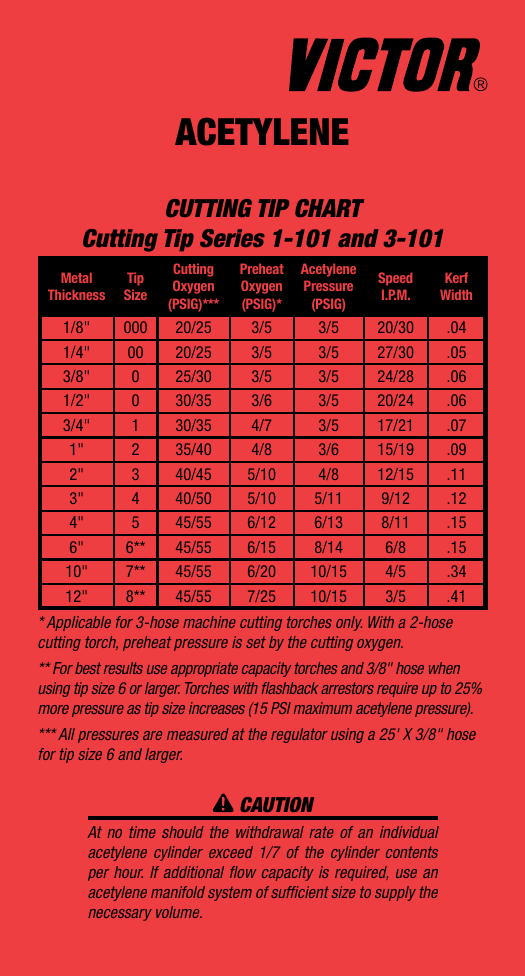

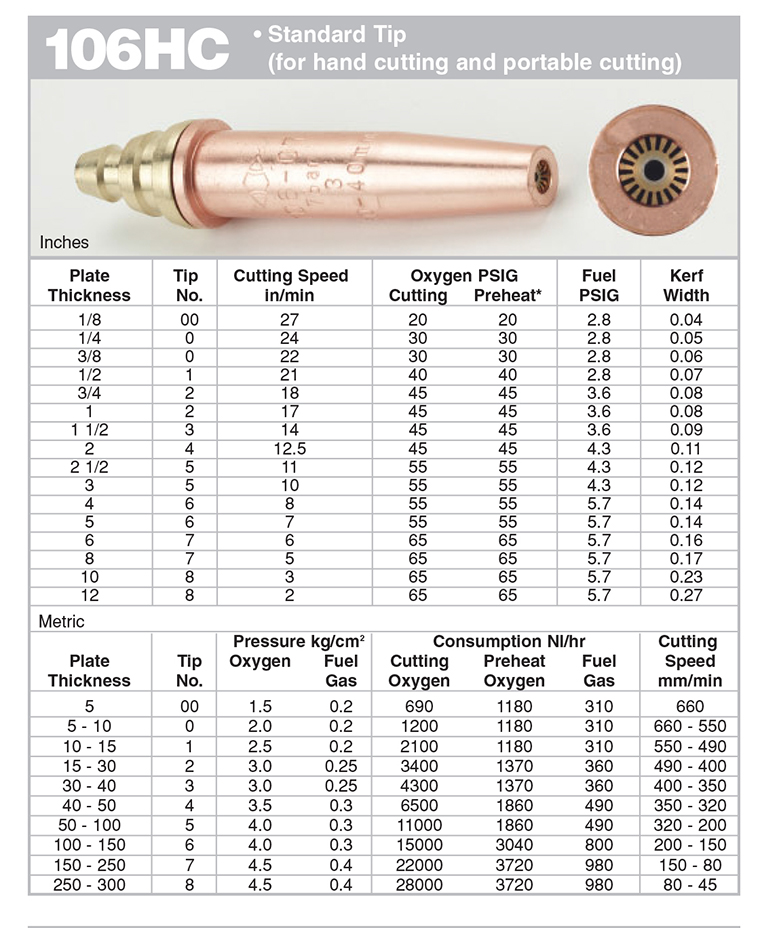

Oxy Acetylene Tip Chart - Cutting tip designs vary based on fuel gas and application. The welding tip chart shows the proper tip sizes and oxygen and acetylene pressures related to the thickness of material to be welded. Web by consulting the victor cutting tip chart that starts on page 63 of this manual, you can consult a victor cutting tip chart to set your pressures and to pick the. The tip size is determined by the orifice for cutting oxygen gas. Web the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. Welding tips usually produce positive pressure (higher than 1 pound per square inch. Web the tip of a welding or cutting torch is where the action is (see figure 1). Web select the tip style for the fuel gas you are using and metal type/condition. 2 connecting gas supplies to the torch. 3 testing connections for leaks. Welding tips usually produce positive pressure (higher than 1 pound per square inch. Web tip size numbers vary among manufacturers, so orifice sizes are shown in number drill sizes. 3 testing connections for leaks. 2 connecting gas supplies to the torch. Cutting tip designs vary based on fuel gas and application. The tip size is determined by the orifice for cutting oxygen gas. The welding tip chart shows the proper tip sizes and oxygen and acetylene pressures related to the thickness of material to be welded. Web tip size numbers vary among manufacturers, so orifice sizes are shown in number drill sizes. Web the tip sizes range from 000 to 8,. 2 connecting gas supplies to the torch. Web select the tip style for the fuel gas you are using and metal type/condition. Cutting tip designs vary based on fuel gas and application. A 1 piece tip is typically used. Welding tips usually produce positive pressure (higher than 1 pound per square inch. Web the tip of a welding or cutting torch is where the action is (see figure 1). Web *** all pressures are measured at the regulator using 25' x 1/4 hose through tip size 5 and 25' x 3/8 hose for tip size 6 and larger. The welding tip chart shows the proper tip sizes and oxygen and acetylene pressures. **** oxygen consumption is 1.1 times the. Web select the tip style for the fuel gas you are using and metal type/condition. Web the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. 3 testing connections for leaks. Web the tip of a welding or cutting torch is where the action is. Web *** all pressures are measured at the regulator using 25' x 1/4 hose through tip size 5 and 25' x 3/8 hose for tip size 6 and larger. *minimum of one 350 cu. Uniweld’s tip selection video was designed to. **** oxygen consumption is 1.1 times the. Web the tip of a welding or cutting torch is where the. Web the tip of a welding or cutting torch is where the action is (see figure 1). Cutting tip designs vary based on fuel gas and application. **** oxygen consumption is 1.1 times the. Web tip size numbers vary among manufacturers, so orifice sizes are shown in number drill sizes. Web the tip sizes range from 000 to 8, coinciding. Welding tips usually produce positive pressure (higher than 1 pound per square inch. Web select the tip style for the fuel gas you are using and metal type/condition. Web by consulting the victor cutting tip chart that starts on page 63 of this manual, you can consult a victor cutting tip chart to set your pressures and to pick the.. The welding tip chart shows the proper tip sizes and oxygen and acetylene pressures related to the thickness of material to be welded. 3 testing connections for leaks. 2 connecting gas supplies to the torch. A 1 piece tip is typically used. Cutting tip designs vary based on fuel gas and application. The tip size is determined by the orifice for cutting oxygen gas. Web uniweld’s matt foster discusses the importance of proper tip selection when using an oxyacetylene torch/outfit. Welding tips usually produce positive pressure (higher than 1 pound per square inch. 2 connecting gas supplies to the torch. Web select the tip style for the fuel gas you are using. Web the tip of a welding or cutting torch is where the action is (see figure 1). 2 connecting gas supplies to the torch. A 1 piece tip is typically used. The tip size is determined by the orifice for cutting oxygen gas. 3 testing connections for leaks. *minimum of one 350 cu. Web by consulting the victor cutting tip chart that starts on page 63 of this manual, you can consult a victor cutting tip chart to set your pressures and to pick the. Web *** all pressures are measured at the regulator using 25' x 1/4 hose through tip size 5 and 25' x 3/8 hose for tip size 6 and larger. Cutting tip designs vary based on fuel gas and application. The welding tip chart shows the proper tip sizes and oxygen and acetylene pressures related to the thickness of material to be welded. Web uniweld’s matt foster discusses the importance of proper tip selection when using an oxyacetylene torch/outfit. **** oxygen consumption is 1.1 times the. Web select the tip style for the fuel gas you are using and metal type/condition.

Oxy Fuel Tip Seat Guide American Torch Tip

OxyAcetylene Welding Tips Model WJ Compatible with "J" Series Victor

SÜA Oxy/Acetylene Cutting Tips Replacement for 6290 Select Qtty and

Oxyacetylene Torch Settings Chart

Oxy Acetylene Tip Chart

acetylene Victor Technologies

Oxy Acetylene Torch Tip Chart

Oxy Acetylene Cutting Pressure Chart

Oxy Acetylene Victor Welding Tip Chart

Oxy Acetylene Torch Tip Chart

Welding Tips Usually Produce Positive Pressure (Higher Than 1 Pound Per Square Inch.

Web The Tip Sizes Range From 000 To 8, Coinciding With A Metal Thickness Of 1/8 To 12 Inches.

Uniweld’s Tip Selection Video Was Designed To.

Web Tip Size Numbers Vary Among Manufacturers, So Orifice Sizes Are Shown In Number Drill Sizes.

Related Post: