Outside Corner Crown Molding Angle Chart

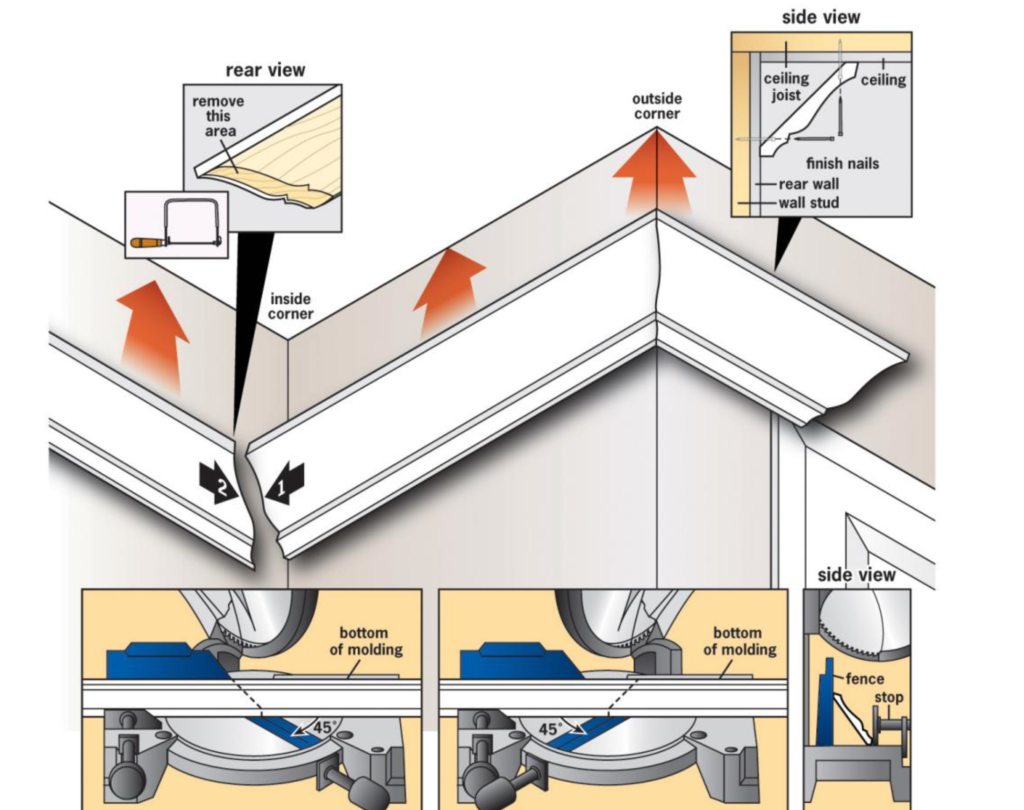

Outside Corner Crown Molding Angle Chart - S = spring angle (the angle from the baseboard to the wall, vertex at the bottom) Web use our angle finder to find the degree for inside and outside corners of walls to make the perfect corner fit. Web joe fusco’s crown molding miter & bevel angle chart. Rotate saw to 45 degrees to the right and cut the second mating molding piece. We subtract 90 from 120, which gives us a 30 degree. Set your calculator to use degrees instead of radians. If using a compound miter saw, set bevel angle to 0° (no bevel) on an inside corner, the top of the molding will be shorter; August 7, 2008 reprinted with permission from joseph fusco. Usually it is a button labled deg. Cut the first length of molding. At least one can hope… to complete this project, you will need all of the materials shown above in addition to a compound miter saw. S = spring angle (the angle from the baseboard to the wall, vertex at the bottom) Web use our angle finder to find the degree for inside and outside corners of walls to make the. A measuring tape will ensure accurate lengths, preventing wastage and unnecessary recuts. Standard crown molding with 52° and 38° angles, and assume that the angle between the wall is 90°. At least one can hope… to complete this project, you will need all of the materials shown above in addition to a compound miter saw. Place the crown lying flat. Miter table is for cutting trim (baseboards, char rails, etc.) with a miter saw or compound miter saw. You can cut it laying flat on your saw with the top always against the fence changing the miter and bevel with each cut. Web there are three common angles for crown molding and about 100 different ways to cut it. Lay. Web set miter angle to half wall angle. See chapter 4 for complete details. Here's a convenient reference for looking up the miter angle and face bevel for cutting and fitting crown moulding. Web a set of crown molding templates give you a visual guide which you can cary around and use to figure out every single corner you have. Web for inside corners, the mud from the drywall install will push the corner out, which will result in the back corners of the moulding touching before the visible ones. It’s simple just put one leg vertical on the wall and then bend the. Let us assume that you measure and angle of 120 degrees. Web set miter angle to. The standard angle of a wall to ceiling is 90 degrees. Set your calculator to use degrees instead of radians. You can measure the degree for vaulted or cathedral ceilings. See chapter 4 for complete details. Web use our angle finder to find the degree for inside and outside corners of walls to make the perfect corner fit. For outside corners, i'll reverse that to 47° or so. Use test blocks or use a bevel gauge to find the angle and measure it against a protractor. For outside corners lay a board against each wall and scribe a line on one board. Web joe fusco’s crown molding miter & bevel angle chart. Web the following two chart shows. Web effortlessly find the perfect crown molding angles with our calculator for flawless installations. Single bevel, double bevel, height of fence and length of cut. S = spring angle (the angle from the baseboard to the wall, vertex at the bottom) You can measure the degree for vaulted or cathedral ceilings. Not many crown charts calculate miter/bevel angles for corners. Usually it is a button labled deg. For outside corners, i'll reverse that to 47° or so. Set the bevel to 33.9 degrees. Web a set of crown molding templates give you a visual guide which you can cary around and use to figure out every single corner you have to cut! Web for inside corners, the mud from the. Web use our angle finder to find the degree for inside and outside corners of walls to make the perfect corner fit. You can measure the degree for vaulted or cathedral ceilings. For outside corners lay a board against each wall and scribe a line on one board. Web crown molding table is for cutting 52°/38° (38° spring angle) and. Take an angle finder and measure the degree from the wall to the ceiling. Standard crown molding with 52° and 38° angles, and assume that the angle between the wall is 90°. Web set miter angle to half wall angle. You can cut it laying flat on your saw with the top always against the fence changing the miter and bevel with each cut. For outside corners, i'll reverse that to 47° or so. It should list the appropriate angle, as well as the bevel and miter angles you’ll need to cut it out. Now there’s no need to precariously hold crown at an angle right next to an incredibly dangerous saw. Get precise measurements every time with our crown molding angle finder. Web crown molding table is for cutting 52°/38° (38° spring angle) and 45°/45° (45° spring angle) crown molding using a compound miter saw. Just remember that now the left side is on the right & the right on the left. Use test blocks or use a bevel gauge to find the angle and measure it against a protractor. Once again, this adjustment will have a special marking on most saws. Web crown moulding miter and bevel angle setting chart. You can measure the degree for vaulted or cathedral ceilings. Place the crown lying flat and face up on your saw. Web effortlessly find the perfect crown molding angles with our calculator for flawless installations.

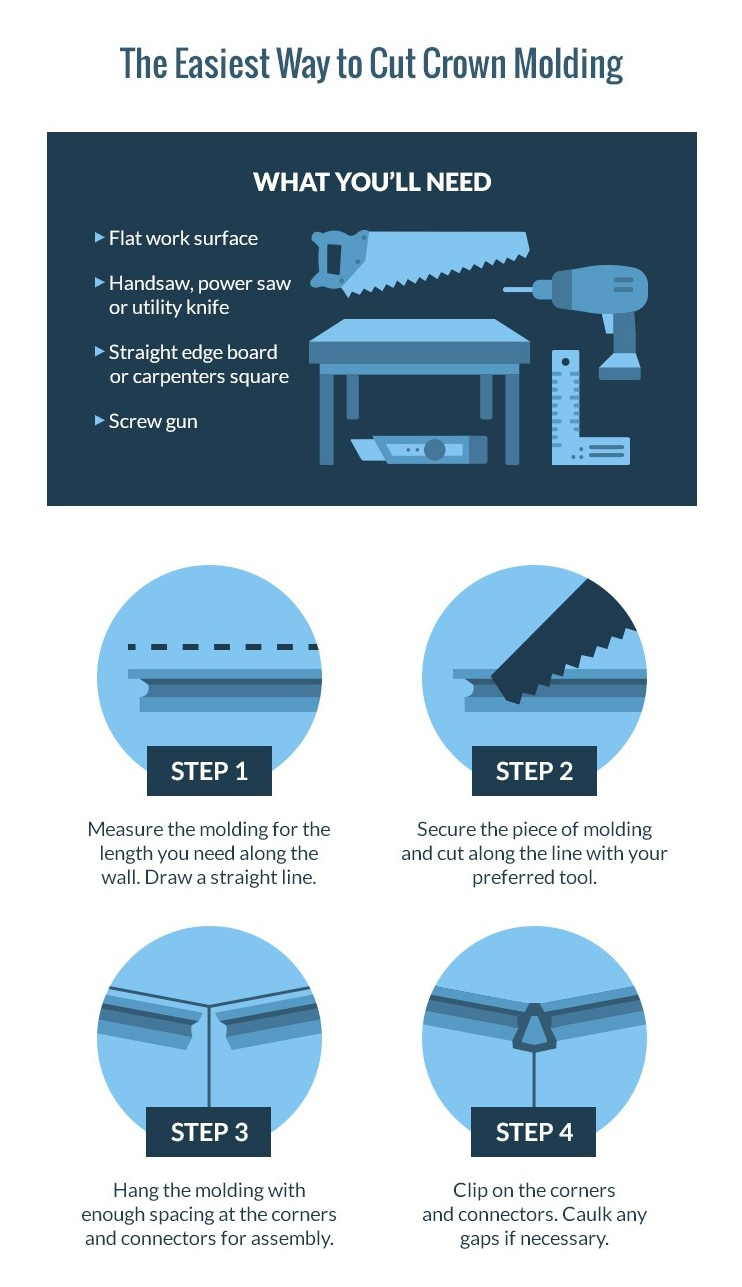

How To Cut Foam Crown Molding Corners & Angles

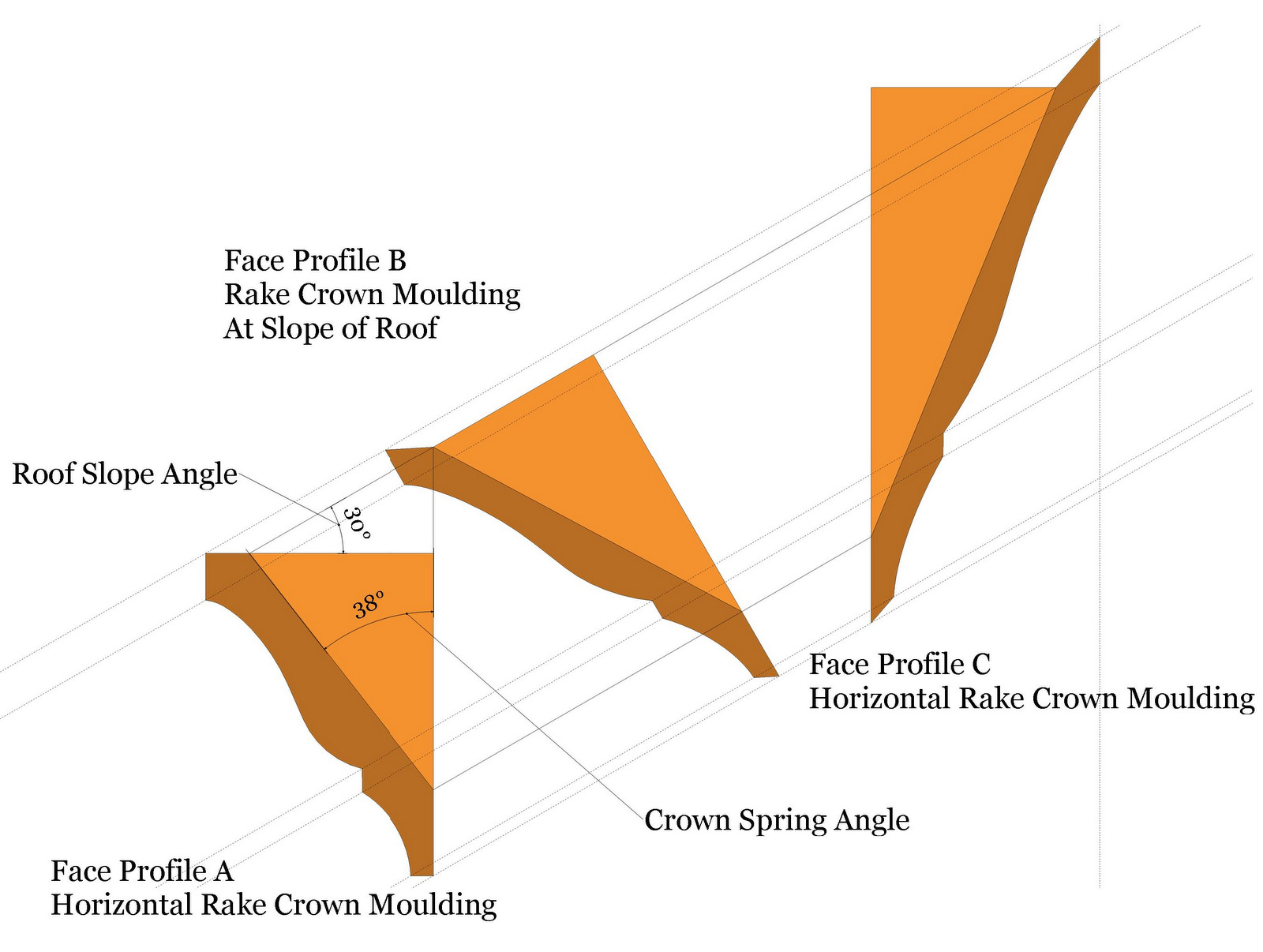

Rake Crown Moulding Miter Angles

Crown Molding Cut Chart

Crown Molding Angles

Crown Molding Angle Chart Outside Corners

How to Install Crown Moulding DIY Home Improvement Blog

How to Cut Crown Moulding The Home Depot

Crown Molding Angle Chart Outside Corners

Angles For Cutting Crown Molding Flat

Angle Chart For Crown Molding

Web The Method I Will Go Into Below Is A Bit More Precise And Detailed And Involves A Combination Of Squared Edges Along With Mitered, Beveled, And Coped Edges And Will Result In A Very Tight Fitting Piece Of Work!

Measure The Crown Moulding Spring Angle.

Measure The Angle From The Wall To The Other Board Edge And Enter That Number And Then Press The Outside Button.

A Measuring Tape Will Ensure Accurate Lengths, Preventing Wastage And Unnecessary Recuts.

Related Post: